2 minute read

Packaging Facilities

The major fresh commodities exported were coconut dry (10213 Mt), pumpkin (146 Mt), mango (163 Mt), watermelon (116 Mt) and eddo (89 Mt) while the major processed commodities exported were copra (755 Mt), heart of palm (386 Mt), coconut crude oil (289 Mt), coconut water (94 Mt) and copra meal (61 Mt).

A total of forty (40) fresh products and twenty (20) types of processed products were exported for 2013.

PACKAGING FACILITIES

The Packaging Facilities were established to ensure traceability and the correct monitoring of fruit and vegetables being exported from Guyana. The Central Packaging Facility and Parika Agro-Packaging Facility are the only two approved Packaging Facilities for fruits and vegetables in Guyana. The packaging houses facilitate the processing of fresh fruits and vegetables to Barbados, Antigua, Trinidad and St. Lucia; as stipulated by the protocols that all produce from Guyana to these countries must be processed at the approved Packaging Facilities

Figure 25: Central Packaging Facility located in the National Exhibition Complex, Sophia Figure 26: Parika Agro Packaging Facility located in Parika (behind the NDC)

Operation

The two packaging facilities have equipment used for washing, drying and sanitizing and cooling (cold storage and refrigerated trucks). Furthermore, the facilities are opened daily on a daily basis. Priority for the use of the facilities is given to exporters who would like to export to the four countries that have protocol arrangements with Guyana. Additionally, the Parika Agro Packaging Facility has a wharf that is readily available to farmers. This wharf is also called “the farmers walkway”.

Services Offered at the Packaging Facilities

The services available to exporters are as follows:

Refrigerated Containers (both Packaging facility is equipped with two 40ft containers)

Refrigerated Trucking Service

Rental of Plastic Crates to farmers and exporters

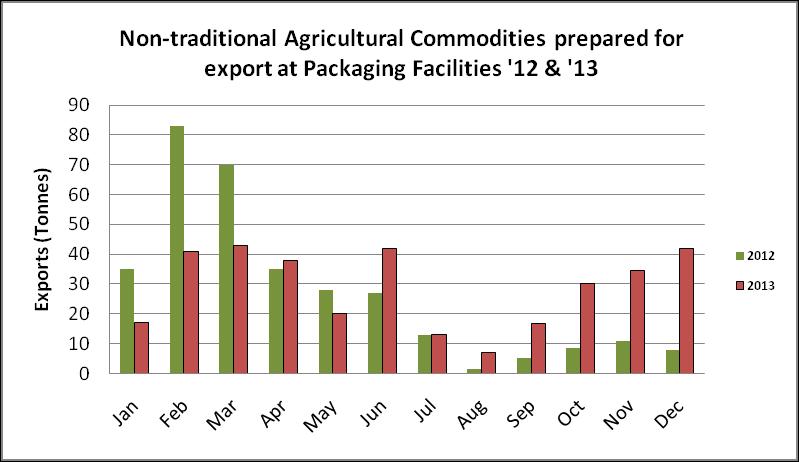

Performance of the Facilities for 2013

Central Packaging Facility

For the year 2013, the Central Packaging Facility processed a total of 270,271 kgs of produce, which was shipped to USA, Barbados, Canada, Antigua, St Maarten and Suriname. The Packhouse recorded a total of one hundred and three shipments (103) –ninety-two (92) by air and eleven (11) by sea.

Parika Agro Packaging Facility

Parika Agro Packaging Facility processed a total of 72,793kgs of produce, which was shipped to Barbados. The Packhouse recorded a total of fourteen (14) shipments, ten (10) by air and four (4) by sea.

Refrigerated Containers

In 2013, the cold- storage containers have been used eight (8) times.

Figure 27

Figure 28: Refrigerated Container

Refrigerated Trucking Service

To maintain the cold chain (keep the produce as cool as possible) for fruits and vegetables especially when it is being transported is the use of Refrigerated Trucks. Guyana Marketing Corporation has six (6) refrigerated trucks that are available for use in the maintenance of the cold chain. In 2013 these trucks were used 39 times.