3 minute read

Startup brings UAVs to wind industry

Company creates application to monitor turbines remotely

BY KAYLA PRASEK

Wind energy is still a fairly young industry, but father-son duo Jeff and Greg Thorsteinson are poised to help the industry grow with their startup EdgeData, a Grand Forks, N.D.-based big data company which will help those in the wind energy industry analyze turbines safely. The Thorsteinsons say their company is the next step for the wind energy industry.

“There was a rush to get wind turbines in the ground, but the industry hasn’t matured to take care of those turbines,” co-founder Jeff Thorsteinson says. “About 2 to 3 percent of the cost of a wind farm should go to maintenance, but owners are losing 11 to 15 percent because of a loss of efficiency. By maintaining your wind turbines, you’re going to keep your costs lower.”

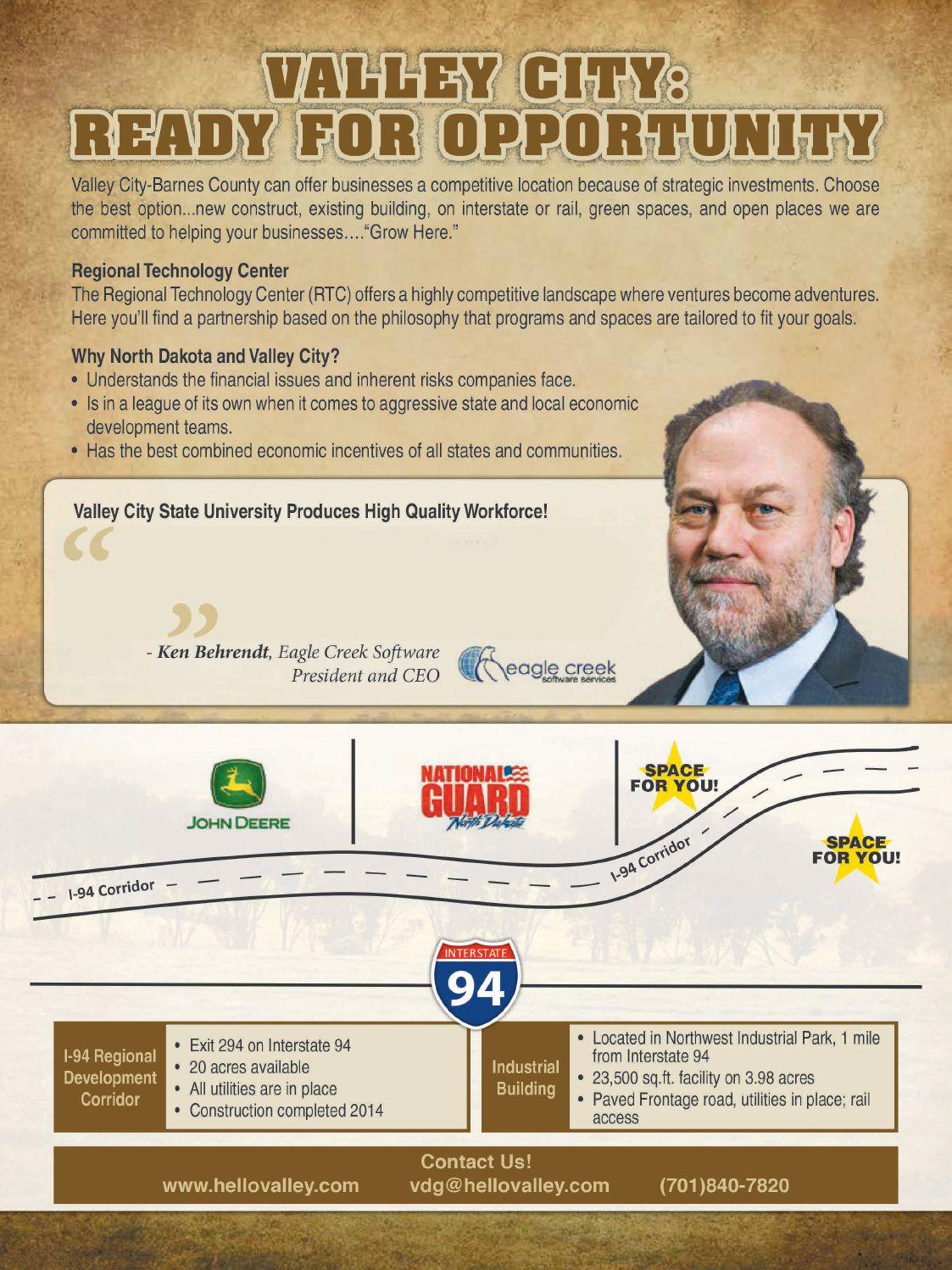

Grand Forks, N.D.-based EdgeData plans to utilize unmanned aerial vehicles to monitor commercial turbines. Additional applications could include utility lines and agricultural applications. PHOTO: EDGEDATA

And that’s where EdgeData’s product BladeEdge comes in. BladeEdge is an automatic condition assessment of wind turbine blades that is built into the workflow of the blade manufacturers. Thorsteinson says blades need periodic checks to make sure they’re in optimal condition, and the only way to do those checks right now is by climbing the turbines, which is highly dangerous.

BladeEdge utilizes unmanned aerial vehicles (UAVs) with a number of sensors on board to gather data as they fly around each turbine. Thorsteinson says the UAVs can get within 10 feet of a turbine, which is necessary for a thorough inspection. The UAVs take high-resolution photos and videos, which are then processed so manufacturers and wind farm owners can see any damage to the turbines and ultimately get the damage fixed.

The decision to use UAVs to gather the data was an ideal choice because “we want to get up close, but it’s not comfortable for a person to be right up there,” Thorsteinson says. “The area around a wind farm is already restricted airspace, and we believe UAVs should be used for dark, dirty and dangerous jobs. Using UAVs to inspect wind turbines replaces that dangerous job. The cost of human life is inestimable.”

Thorsteinson says EdgeData is one of the first companies doing this type of work, and is the only one doing an automatic assessment of turbines and their condition. Because the wind industry is still growing, “we have to keep the fleets viable so owners can see returns on their investments,” Thorsteinson says.

Thorsteinson believes there are three prospective users of BladeEdge: Owners of wind farms who need to decide whether to repair damaged blades, companies that manufacture turbine blades and want to evaluate their condition in the field and companies that build wind farms and want to see how their farms are performing overall. “Once we’ve fully developed our product and broken into the market, it could be that other people may want the information that’s provided,” Thorsteinson says.

Thorsteinson, a 1982 graduate of the University of North Dakota, has spent his career working at Involta, a data center, while his son, Greg, has a background in aviation and crop insurance. They both became interested in UAVs and realized, with the help of Kevin Rusk, director of UND’s Tech Accelerator, that wind energy was an untapped industry. “Kevin had experience with LM Wind Power, which we ultimately partnered with in October,” Thorsteinson says.

Rusk also encouraged the Thorsteinsons to apply, through the UND Tech Accelerator, for a $450,000 matching Research ND grant. The grant, which they received this spring, will allow them to have lab space in the Tech Accelerator and be able to collaborate with LM

Wind Power and SmartC2. “It will also provide us with project management and business development,” Thorsteinson says.

In mid-May, EdgeData expected to begin flying its UAVs in June. “It’s not hard to fly the UAVs and take photos; it’s getting it to go into the workflow that we’re working on right now,” Thorsteinson says. The company is capable of delivering its prototype, which is essentially in the beta testing phase, to interested parties and offers customers the option of contracting with EdgeData to provide the service or purchasing the application to run on their own. Thorsteinson says the decision to purchase BladeEdge as either a service or an application would depend on a company’s security and privacy needs. Within BladeEdge, a company could choose to only have photos or videos or both, along with other types of services.

“We want to drive the cost down so it makes sense to an owner to do an inspection,” he says. “We don’t want the cost to deter someone from having that inspection done. We think it’s all about the data, and the opportunity provided by Research ND means there are North Dakotans out there who can benefit from this.” PB

Kayla Prasek Staff Writer Prairie Business magazine 701-780-1187, kprasek@prairiebizmag.com

New-well gas production per rig

Monthly

July-2014

FordHaynesvilleMarcellusNiobraraPermianUtica

July-2014

July-2014 July-2015

Indicated monthly change in oil production (Jul vs. Jun)

July-2014 July-2015

BakkenEagle FordHaynesvilleMarcellusNiobraraPermianUtica

Indicated

July-2014

July-2014

Indicated monthly change in gas production (Jul vs. Jun)

July-2014 July-2015

July-2014

U. S. Energy Information Administration | Drilling Productivity Report

Interest Rates

Employment

Gas Captured/Sold

Data provided by David Flynn, chair of the University of North Dakota Department of Economics. Reach him at david.flynn@business.und.edu.