16 minute read

BUILDING A BUSINESS

BY JASMINE YE HAN

Optometrist Jeffery B. Yunker thought he didn’t have enough money to build his own vision center, until he found out about a specialized loan program with a lower down payment and interest rate than other options he had explored.

Through the Small Business Administration’s 504 program, Yunker built Lifetime Vision Center in Grand Forks with only 10 percent of the total cost and opened in October 2003. “Without the program, I would not have been able to get the loan and build the practice I’ve always wanted,” Yunker says.

Eric Giltner, senior area manager of the Grand Forks SBA, says Yunker’s story is not unique, and specialized loan programs often are used to help business owners tackle construction projects more affordably. It’s one of two main programs used for new business construction in the region, along with the Participating in Assisting Community Expansion program through Bank of North Dakota in Bismarck.

Sba 504

SBA 504 is designed to assist in building new business locations, Giltner says. It allows the borrower to invest as little as 10 percent of the total cost of a project, while the lender provides a loan for 50 percent of the cost and the SBA provides the remaining 40 percent through an SBA-approved development company.

The 10 percent down payment, which is low compared with investments for conventional financing, “allows the business to preserve capital for operations and growth,” says Steve Dusek, president and CEO of Dakota Certified Development Corp., one of three SBA-approved development companies in North Dakota.

Other advantages of the 504 loan program include a lower interest rate for the portion of the loan through the SBA, and a fixed interest rate that makes it easier for the borrower to predict overall cost, Dusek adds.

“The majority of our loans done on buildings — which includes construction and purchase of existing buildings — are through 504," says Chuck Hughes, deputy district director of the SBA South Dakota District Office in Sioux Falls.

The 20-year term, however, is not flexible so it can be difficult to refinance, Giltner says. “When businesses go into a 504 loan, they need to understand that the 40 percent (through SBA) is going to be non-negotiable as far as refinancing,” he says. “They can also pay it off, but it’s difficult to pull back and say, ‘I’d like lower interest and longer term.’”

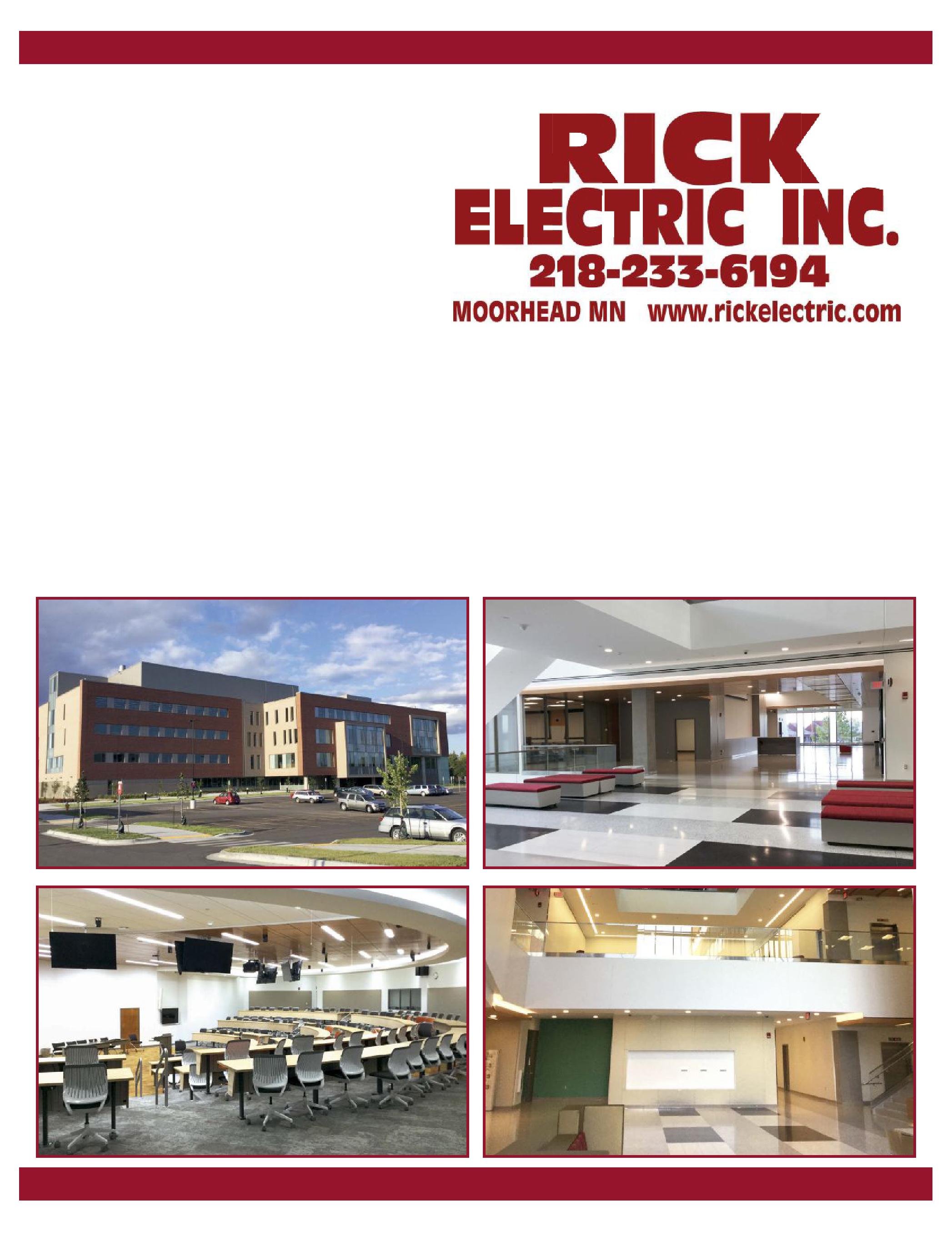

Professional Electrical Service for the Upper Midwest

At Rick Electric, Inc., we’ve proudly been providing electrical services to the the Red River Valley since 1964. Whether you are a home owner, business owner or government contracting officer, our specialists can provide a range of services from new wiring to electrical maintenance and troubleshooting.

Rick Electric, Inc., was proud to be involved with the University of North Dakota for the Electrical Construction on this $124,000,000 project for the state of North Dakota. This State of the Art , 325,000 square foot building is one of the largest construction projects in North Dakota. Rick Electric, Inc. has been doing projects at UND since the 1960’s including Upson Hall, Chester Fritz Library, Hyslop Sports Center, Clifford Hall , Rural Technology Center, North Dakota School of the Blind remodeling and the new Collaborative Energy Complex, Phase 1. Rick Electric, Inc. has the experience, manpower and technical knowledge do handle any project . We have been satisfying customers for over 52 years in the Red River Valley!

Rick Electric Inc. was proud to work on UND’s School of Medicine and Health Science

Pace

PACE is a community-oriented program designed to help create jobs. It has two elements: community-based loans through Bank of North Dakota and a local lender; and a reduction of a borrower’s interest rate through the PACE fund and the local community. The interest rate buydown option can help lower a business’s loan interest rate by 5 percent, or to the floor of 1 percent, says Todd Steinwand, chief business development officer at Bank of North Dakota.

Through the interest rate buydown element, PACE offers up to $300,000, with the requirement of a matching amount from the local community as a loan or grant, Steinwand says. The funding from the community could be from a local development corporation, contributions, community funds or other community sources. “The local community helps drive this, they are the one to approve whether they wanted to do the buydown or not,” Steinwand says. While the loan and interest rate buydown are approved all at once, the buydown does not kick in until construction is complete and the loan is in the permanent financing phase.

“The PACE program is for job creation, so it mainly targets primary sector companies and is not designed for retailing," Steinwand says. But he adds it’s not limited to the primary sector. It also applies to companies that the community thinks will help bring in jobs. As a criteria, the borrower must demonstrate that one job will be created and retained for every $100,000 of total loan proceeds.

Ask a Banker

Apart from PACE and SBA 504, many other local, state and federal programs can help make construction projects more affordable. Businesses usually don’t need to directly deal with the state or federal agencies that devised the loan programs, according to Giltner, Dusek and Chris Wolf, northern valley market president at Alerus in Grand Forks. “More often, the bank looks at the business plan to see if there is any specialized program that fits the project. The bank is the lead and is responsible for bringing in the other parties,” Wolf says.

Dan Jacobson, chief lending officer at Alerus, suggests businesses involve lenders early in the process. “Early dialogue with the bank will help the planning process, so the bank can anticipate the loan request and act,” he says.

Jasmine

QHow do construction companies recruit employees for all levels and positions successfully?

AThe four principal avenues of recruitment in the order of productive results are:

• Contacting employees who have previously worked for the company and may have had a short seasonal layoff. Clearly the company has a history and knowledge of the skillsets and abilities these employees bring to the table.

• The second most productive process is having existing employees recruit or nominate prospects from their social networks. This may or may not involve paying an incentive for those successfully recruited. The implication that an existing employee is “vouching” or recommending a peer does carry some weight with employers.

• The third modality of recruitment is via print and electronic media advertising and/or organizations such as Job Service. The last five to seven years, with the oil play activities, has not yielded the results traditionally associated with this recruitment process. The oil patch simply was able to pay a much higher premium for talent.

• The final method which some companies have undertaken involves recruitment via industry training programs or trade schools. This is especially evident in skilled trades, heavy equipment and commercial driver licenses.

PRESIDENT JOHN KRUEGER VICE PRESIDENT GREAT PLAINS BENEFITS GROUP INC. BISMARCK, N.D

QWhat types of off-season jobs do laborers take, and do they generally come back to the same company when construction season starts up again?

AInterestingly enough, more and more companies are seeking to reduce the seasonal layoffs traditionally associated with the road and building construction industries in the upper Midwest. Two reasons seem to surface most frequently:

• What used to be an eight- or nine-month construction season is now much closer to a 10-month season or even year-round activities. This is particularly true in building construction where project management can create greater opportunities for employees to work inside or at least in more heated enclosures as opposed to suffering through the elements. In the road construction realm, crews are also working routinely for 10 months and many companies supplement their traditional “layoff” time with ancillary businesses such as snow removal, allowing a greater number of legacy employees to winter over still employed.

• The advent of the Affordable Care Act has created a new population of employees who previously did not cost the employer insurance premiums. Generally speaking, currently, any employee who has worked in excess of 1,000 hours in the previous 12 months must now have access to employer-sponsored health insurance and retirement benefits. Starting and stopping these benefits can end up being a cost burden to employers, so many choose to make use of the skills and abilities as mentioned above. Additionally, many of those road construction companies are using the “layoff” time for extensive equipment maintenance and employee training.

QWho is applying for construction jobs, and are companies seeing an influx of applicants coming from the oilfields?

AThe applicants for the construction jobs are pretty much the same as the pre-oil boom, skilled workers and laborers for whom construction is a career. Additionally, there is still a noticeable population of college-age students choosing the summer construction jobs as a way to fund some of their higher education expenses. The influx of former oilfield worker applicants is mostly dried up. The transient nature of these workers means they are off to new oil plays in other locations.

QDo applicants come from construction training programs or are they skilled laborers looking to transfer their skills?

AThere was a time when construction companies would and could recruit workers from trade schools or training programs, especially heavy equipment or specialized equipment operators. We have several of those community college programs in the Dakotas and Minnesota, which are very highly rated. Unfortunately, that high esteem has produced an extraordinarily large corporate recruiting program with which most construction companies cannot effectively compete. In some instances, we are seeing students committing to corporations during their first or second year of training and receiving a full tuition reimbursement and/or a substantial monetary signing bonus.

QWhich positions are hardest to fill and why?

AProbably those middle management positions usually titled foremen, supervisors or project managers. When the economy was rolling with ag and oil business, these positions, typically salaried, found fewer takers. Salaried managers were working long or longer hours than those they were responsible for managing, who were receiving premium wages which would be impacted by a multiplier of 1.5 for every hour worked in excess of 40 hours in a seven-day work week. It was not uncommon for the foreman or supervisor to net less than their subordinates.

QWhat do you think are the most important skills a construction worker in your sector of the industry needs to possess?

ACarpentry skills are one of the most important skills needed. All trades and subcontractors on a project are doing some type of carpentry work from framing building walls to electricians setting conduit piping. All trades perform some sort of carpentry tasks. Along with carpentry skills, construction workers need to have current knowledge on how to safely operate tools. As trades persons continue to move forward, they need to understand computer systems, total station systems, Building Information Modeling as well as iPad operation and applications.

QWhat is your favorite part of being a construction worker?

AMost would think the end of a project is my favorite part, but I enjoy seeing all the pieces of a project being put together after foundations have been poured. I enjoy seeing the daily changes of work being done, overcoming daily challenges and working through tasks that need to be done. There is a lot of work involved in building any type of construction project. A lot of people ask why the process takes so long. When I start showing them how many intricate pieces there are in completing a quality project, not to mention completing a project safely and on time, they start to understand the complexities and the durations that are required. Seeing the excitement and happiness of owners when they walk through their projects is very rewarding and I enjoy answering their “How do you build this?” questions.

ROGER KLEBE PROJECT SUPERINTENDENT

SIOUX FALLS CONSTRUCTION, JOURNEY GROUP CO. SIOUX FALLS, S.D.

QHow would you describe the dynamics of a construction team out on a job site?

AHaving a positive attitude from every member of the project team is very important. The general contractor must lead efforts with a positive attitude as the project moves forward. Every project will have unforeseen conditions arise. Over the years, project schedules have become more compressed, in turn making small schedule delays more critical in the overall project schedule. The project team must work together to solve issues while maintaining schedule and quality expectations.

QWhat type of training did your job entail and what is your job title and description now?

AMy current position is superintendent and my main focus is overseeing operations on a jobsite including subcontractors, suppliers and employees. No. 1 priority on my jobsites is safety. I conduct project-specific orientations for everyone working on site, and the entire project team holds each other accountable for safety. I maintain daily logs of progress and issues, create and monitor daily schedules and coordinate subcontractor team members. As a carpenter, I’m able to complete some of the tasks on the site.

Not knowing exactly what career path I wanted to take, I started as a construction laborer in 1990. Over the first several years, I worked alongside and learned from older, more seasoned employees and picked up trade skills from them. I attended a fouryear Associated General Contractor carpenter apprentice program and continued to pick up skills by working alongside older carpenters. I continued to work my way up the ladder and went through multiple classes and training for “stepping up to supervisor.” I’m currently going on my 26th year with Journey Group.

QWhat are your career goals?

AMy goal is to keep working with Journey Group. Even though I have been here many years, I’m still learning new ways to construct/build projects. Construction changes every day and I’m learning the tech side of construction, including different programs that help the building process such as BIM. Electronic sharing of information including shop drawings, details, changes and requests for information helps us communicate on a jobsite and keep everyone informed.

I hope to keep being a supervisor of construction projects in future years, but am always looking for opportunities to train for higher positions within the company. As I look back in history to when I started in construction, I used to envision what it would take to earn my current position as superintendent. It took a lot of hard work, but it is rewarding when you can look at your projects and know you built it from start to finish.

PHIL SIEK (LEFT) SENIOR DIRECTOR OF PLANNING AND CONSTRUCTION

JEFF HOSS EXECUTIVE DIRECTOR OF DEVELOPMENT SANFORD FARGO

QWhat would you recommend companies building their first large project be aware of before they get started?

A

JH: It’s important for companies to be realistic about the project and understand all aspects that will be involved. It can be a major undertaking, but with the right team, proper planning and goal setting, it can be a very rewarding experience.

PS: I would emphasize the importance of planning. Identifying and gaining buy-in from key stakeholders on scope, schedule and budget is paramount to the success of the entire project process. Not all aspects of a project can be known up front, but the scope, schedule and budget should be. Ensuring these are established and agreed upon initially can greatly reduce the chance for potential issues that could come up through other phases of the project.

QWhat is the biggest, most important lesson learned after seeing through a huge project like this?

AJH: Planning, planning and more planning. Align your strategy, tactics and timeline. Frequently reevaluate progress against barriers and timeline. Keep your project team aligned and leadership up to date on progress.

PS: Due to the long duration of the project, which will be over five years from initial planning to opening, maintaining a clear vision and buy-in on scope, schedule and budget is of utmost importance to the success of a project.

QHow can a proper budget be built before the project that accommodates for any changes in plans or designs that take place during construction?

AJH: Plan, design, detail, contingency funding, risk realization and finally, stick to the plan.

PS: What it really comes down to is how you analyze risk. Identifying any potential future risks is a good start, then trying to quantify contingency amounts to cover them if needed. Of course there could still be unforeseeable situations, so having a contingency for unexpected risk is critical as well — typically historical data of like projects can help set this amount. Owner-driven changes are always a risk on projects as well. It’s human nature to rethink things as the project progresses, so you need to be prepared to address these requests with questions: Is it really needed? Are there safety or regulatory impacts if changes are not implemented? Is it a “nice to have” or “need to have?” Those are the important questions to ask in determining whether the owner-driven change is warranted or not.

QWhat types of planning team members are crucial for this kind of construction project?

APS and JH: A multidisciplinary team that fosters an environment of collaboration and teamwork is ideal. We brought in all partners internally; including administration, direct patient care and support departments, which allowed us a 360-degree view of how design decisions affected all areas of operations. This was further enhanced with the involvement of the design consultants and construction manager, along with major equipment/technology vendors, community members and also the patient advisory council.

QWere there hiccups along the way Sanford was not prepared for and how were they handled?

AJH: With every project there are bound to be some setbacks. To manage these, first set clear expectations of the planning team and understand scenario planning. It’s so important to develop contingency plans. Also, make sure to confront rumors aggressively and establish a good communication process.

PS: Change management is always important in construction projects, especially one of this size. There will always be changes along the way, but it’s how you proactively manage them that limits the disruption to the project. With a multi-year project like this one, things change such as leadership, regulatory/codes, industry/economic effects, work flow of end-users and technology so there are many variables that must be addressed.

QWhat major trends are you seeing in the construction industry?

AOne of the major trends in our region is how our homeowners are truly customizing their homes to their own styles and needs. Our homeowners are coming to the initial meeting with their ideabook folders from Houzz.com or Pinterest, showing us the end results they are looking at for their space.

We are finding the style of today’s homeowners to be more of a transitional style with a modern flavor to it. Homes still feature a great room area with the kitchen, dining and family area open. But the homeowners are leaning more toward a minimal style and are finding that less is more.

They like more clean lines in their home design and accessorizing. Most new homes feature a walk-in tile shower in the master suite. Also, free-standing tubs are very popular in the master bathroom area as well.

For lighting, LED recessed lighting is being used throughout the home. The decorative lighting fixture is being used as the jewelry of the home. Homeowners are using these light fixtures to personalize each room to the needs and style of the room.

The interior of homes are using finishes that are lighter, with wall colors in the lighter gray and beige color palette. White finishes on interior woodwork and doors continue to be the trend as well, with some stained woods as an accent.

For flooring, there is less carpet going into homes and more of the hard surfaces such as wood and tile. The Laminate and luxury vinyl tile floors are gaining in popularity with the “wood look” that you can get from these products. For the exterior of homes, we are still keeping with the prefinished materials for the siding and using more vertical siding and stone for the accents. Homeowners are looking to keep the entire home as low-maintenance as possible.

(continued on page 36)

(continued from page 34)

QWhich of these trends have the largest impacts on the industry and why?

AThe internet and Home and Garden Television (HGTV) have had a major impact in our industry. Our customers are coming to their first meetings having done their homework. They are able to check out styles and designs on websites such as www.houzz. com and www.pinterest.com. These sites will allow the customer to set up idea books where they can organize their pictures by room, finishes, interior looks, exterior looks, landscaping, etc. So whether they are building a new home or doing a remodeling project, they are able to narrow down many of the finishes before the project even starts.

QWho benefits most from these evolutions in construction?

AEveryone involved in the project really benefits from these evolutions in the building industry. With so much being discovered online and from the HGTV shows, we find that our customers are not waiting for the new trends to come to our area like it used to be. Now we see these new trends at the same time as the rest of the country does and our customers are able to take advantage of that instantaneous information that is out there.

And the customizing of these spaces is also a benefit for us as contractors and suppliers, as we are able to use our creativity to design and build these great spaces for our customers. It is always fun using new ideas and materials in a project.

QWhat further changes do you think we’ll see in the coming year?

AThe building industry remains steady in our area. With interest rates continuing to stay low, homeowners are still looking at doing home improvement projects or upgrading to a new home.

We have noticed that more homeowners are looking at simplifying their spaces and designing areas that are more cost effective — getting the most out of every space in their homes. Every project is unique, which makes this such a fun business to be involved in.

QWhat changes have come about in funding for building projects, if any?

AOne thing that we notice about funding our building projects is that the rules in the banking industry are constantly changing. With these constant updates in the rules and procedures in the lending industry, we find that the funding programs that banks are offering to contractors and homeowners are also constantly evolving.

In our area, the majority of the custom new homes are being funded by a construction loan. These construction loans can either be taken out by the homeowner or the builder. We always tell the homeowners to check with their banks on the home construction and home improvement loans that they offer and find the one that fits their situation the best.

Your energy starts here.

Be the light.

The world we share provides abundant vitality –time with those we love and beautiful landscapes to explore. It’s why we use our natural resources to create electricity in the cleanest, safest manner possible. To us, it’s more than delivering light, it’s being a light for our members and our communities by ensuring our environment remains vibrant for all future generations.

basinelectric.com/bethelight