5 minute read

Energy solutions and Power-to-X: Lufthansa Group's commitment to sustainable aviation fuel for CO2 neutral goal

Tu Pham

As the aviation industry faces increasing pressure to reduce carbon emissions, sustainable energy solutions have become a top priority. One of the most promising innovations in this sector is Sustainable Aviation Fuel (SAF). As a leader in aviation, the Lufthansa Group is committed to advancing SAF adoption as a crucial component of its sustainability strategy. Currently, Lufthansa Group is the biggest SAF buyer in Europe.

THE IMPORTANCE OF SAF TO THE FUTURE OF AVIATION

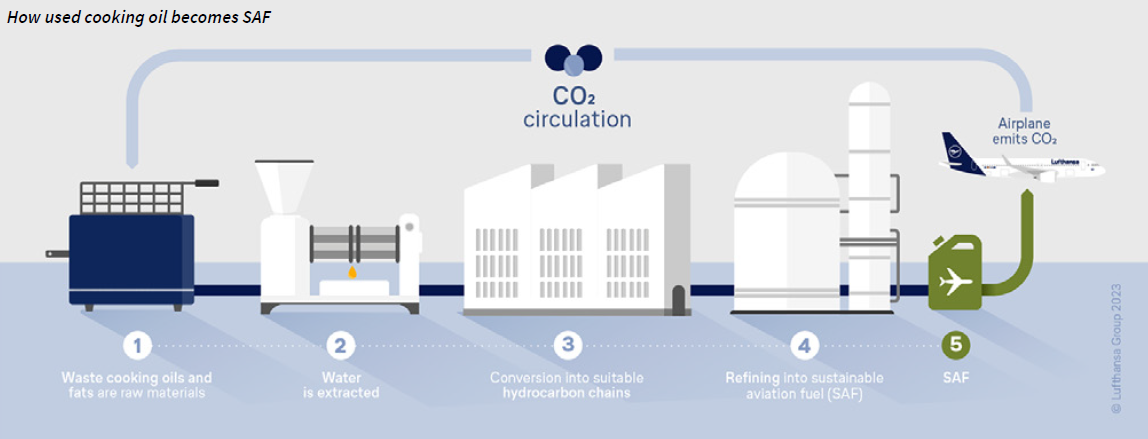

SAF is essential in the fight against climate change and for ensuring the long-term sustainability of air travel. Unlike traditional jet fuel, SAF is derived from renewable sources such as biomass, waste oils, and even synthetic processes powered by renewable electricity. It has the potential to reduce carbon emissions by up to 80% over its lifecycle compared to fossil-based aviation fuel.

For the Lufthansa Group, SAF represents a key pillar in achieving its ambitious decarbonisation targets. With the aviation industry facing increasing regulatory pressures and consumer demand for greener travel options, the development and large-scale adoption of SAF are vital for maintaining competitiveness while reducing environmental impact.

THE INNOVATION BEHIND SAF

The science behind SAF production is a testament to human ingenuity. Unlike conventional fuels, SAF can be produced through various innovative pathways, including:

Hydroprocessed Esters and Fatty Acids (HEFA): Derived from waste oils and fats, HEFA is the most widely used SAF today.

Fischer-Tropsch (FT) process: Converts biomass or municipal solid waste into synthetic fuel.

Power-to-Liquid (PtL) technology: Uses renewable electricity to produce hydrogen, which is then synthesised with CO2 to create liquid fuel.

These cutting-edge technologies make SAF a viable, drop-in alternative to conventional jet fuel, enabling airlines to integrate it seamlessly into existing supply chains without requiring modifications to aircraft engines.

KEY MILESTONES IN SAF DEVELOPMENT

The journey toward SAF adoption has been marked by significant milestones:

2008: The first SAF test flight is conducted.

2011: Lufthansa becomes the first airline to operate commercial flights powered by a SAF blend on a regular basis as part of the “BurnFAIR” project.

2016: The industry sets an ambitious goal to achieve carbon-neutral growth from 2020 onward.

2021: Lufthansa Group commits to using SAF as a central part of its sustainability strategy, investing heavily in research an procurement.

2022-2023: Lufthansa partners with multiple SAF producers to secure long-term fuel supply agreements, expanding its efforts globally.

SAF is essential in the fight against climate change and for ensuring the long-term sustainability of air travel.

COLLABORATION TO PROMOTE SAF PRODUCTION IN THAILAND

Recognising the need for a collaborative approach, Lufthansa Group actively participates in the SAF Working Group, a collaborative initiative that brings together stakeholders from the aviation industry, energy sector, and government to accelerate SAF development.

By joining policymakers, energy companies, research institutions, and stakeholders in travel industry, Lufthansa Group aims to contribute our experience and perspectives in developing further the awareness of the Thai market and boosting motivation to have local production of SAF happening in Thailand. Specific initiatives include:

Educating trade partners and communities through exclusive workshops and seminars.

Collaborating with industry partners on knowledge-sharing initiatives.

Advocating for SAF adoption with local authorities.

Within Thailand, Lufthansa Group has successfully onboarded major travel agency partners and corporate customers to purchase SAF certificates, offsetting their travel emissions.

CURRENT SAF ADOPTION AND CHALLENGES IN THAILAND

While SAF adoption is gaining momentum globally, its deployment in Thailand faces several challenges:

• Limited local production: while big local energy companies have started investing in the production of SAF, the large-scale supply is still missing until mid-term time frame, making imports necessary.

• High production costs: SAF remains more expensive than conventional jet fuel, requiring government incentives and economies of scale to drive down costs.

• Regulatory uncertainty: While there is growing interest in SAF, clear regulatory frameworks and policies are needed to support its development and boost the confidence of local producers on the viability of such a big investment into the production line.

Despite these obstacles, Lufthansa Group remains committed to incorporating SAF into its operations. By integrating SAF into its fuel supply, Lufthansa is not only reducing its carbon footprint but also demonstrating leadership in driving sustainable aviation in Thailand and beyond.

FUTURE OUTLOOK FOR SAF IN THAILAND

Thailand has made significant strides in renewable energy, driven by national strategies to promote sustainability. The National Renewable Energies Development Plan (REDP) 2009 encouraged investment in biofuels, biomass, and alternative energy R&D. This was followed by the Alternative Energy Development Plan (AEDP) 2015-2036, targeting 30% renewable energy consumption by 2036 across electricity, heat, and biofuels.

A major development in SAF production is the National Oil Plan Drafting 2024, led by Thailand’s Department of Energy. This plan aims to support domestic SAF production through investment incentives, reinforcing the country’s commitment to sustainable aviation.

One of the most promising steps toward SAF production in Thailand is the SAF plant development by Bangchak Group. As Thailand’s largest oil refiner, Bangchak Group commenced construction of an SAF facility in 2024, marking a significant milestone for the country’s aviation sustainability goals. Although Thailand currently does not produce SAF at scale, the government aims to integrate SAF into the aviation fuel mix, targeting a 3% SAF blend by 2030 and an ambitious expansion to 60% by 2050.

With strong government backing and collaboration between airlines, fuel producers, and policymakers, Thailand has the potential to lead regional SAF production.

References:

• Sustainable Aviation Fuel - Lufthansa Group

• Flying with sustainable aviation fuel

• Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA)

• 20220913_PM_MoU_OMV_LHG_SAF_EN.pdf

• แผนพัฒนาพลังงานทดแทนและพลังงานทางเลือก (AEDP) - Enconfund

Contact details:

Tu Pham

Sustainability Anchor for Thailand, Vietnam, Philippines and Mekong Region

Lufthansa Group