5 minute read

John MacKinnon achieves professional registration with the Engineering Council

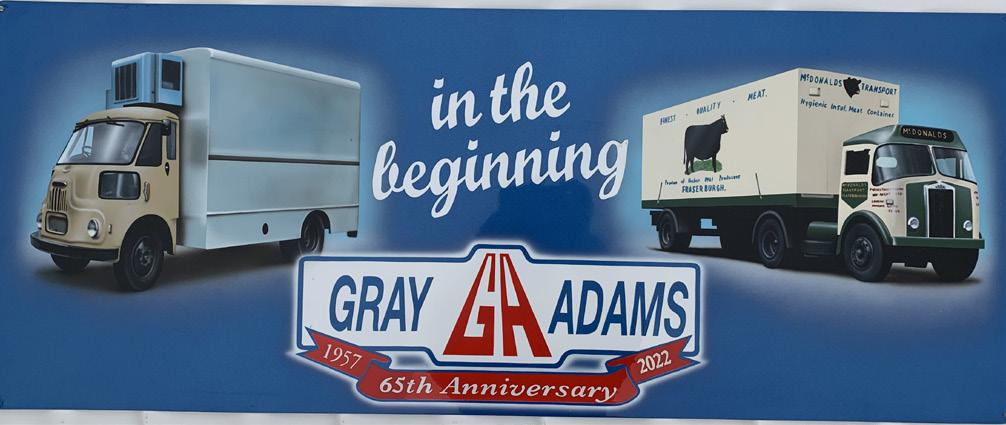

I’m often asked about the history of Gray and Adams, how it all started and became what it is today. Jim Gray and his partner Jim Adams commenced business as Gray and Adams, in 1957 in premises at the rear of Jim Gray’s home in School Street, in Fraserburgh.

Advertisement

Both men had recently completed their National Service – Jim Gray in the REME and Jim Adams in the RAF. Their premises had originally been a dairy and therefore had to be completely renovated and adapted for the purpose of carrying out car repairs by family and friends. (The site today is used as storage facilities for Fraserburgh Kitchen and Bathroom Centre, though the original buildings have been demolished.)

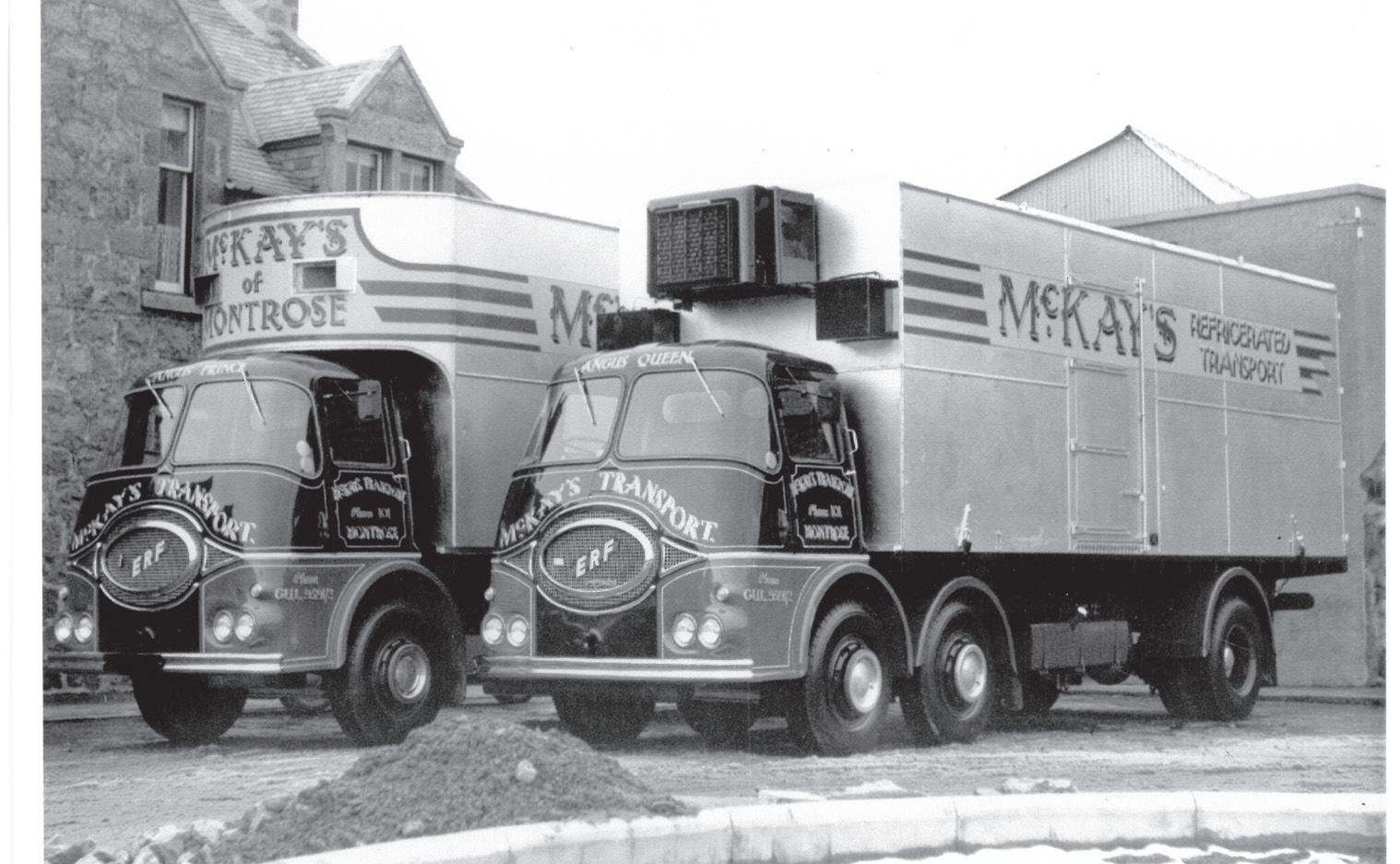

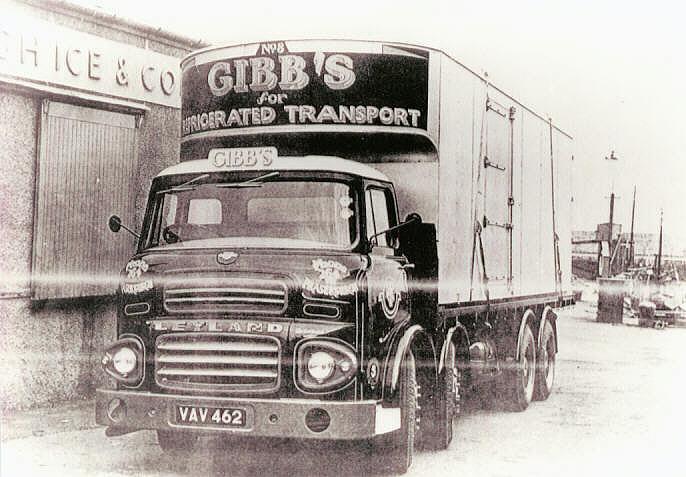

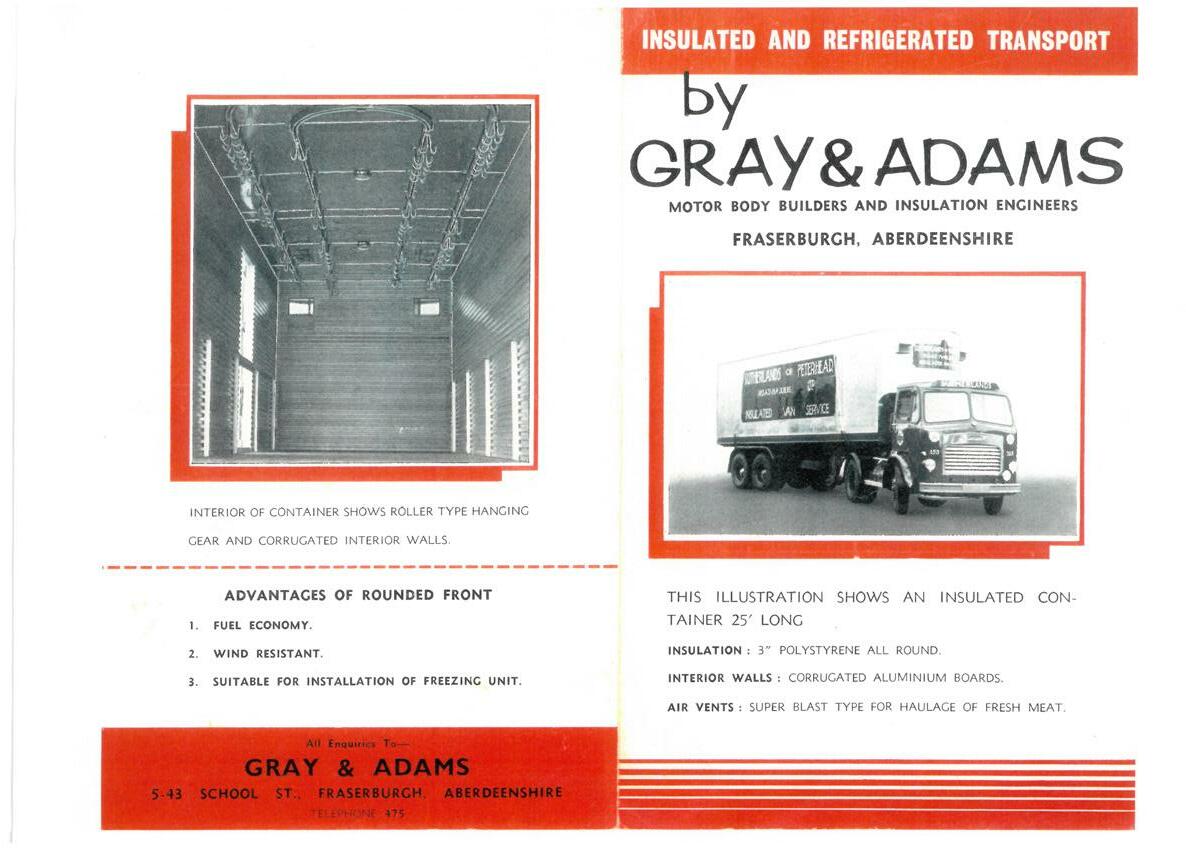

The car repair business flourished in those early days, and it was not long before the two Jim’s extended their operations to commercial bodywork repairs, furniture vans, mobile shops etc. By this time the company had purchased additional premises further up School Street, which were converted to carry out both the building of insulated bodies, and also accident repairs to cars and commercial vehicles. (This site is now occupied by Dingbro Motor Factors.) Of course, in the mid 50’s, nearly all transport was in the form of flat-bed platforms and Fraserburgh, being a major fishing port, was shipping tons of fresh fish south on these flats. The only concession to temperature control, was the crushed ice, which was packed around the boxes before they were roped and secured to the platform. With no motorway network then existing, the time taken to deliver these products meant that their freshness was spelt with a very small “f” indeed, and in 1959, a local fish merchant asked Jim Gray if he could build him an insulated box to clamp on to one of his platform rigids to carry fresh fish and meat products. Jim accepted the challenge, and the very first Gray and Adams insulated body was built. As soon as these insulated bodies went on the road, enquiries started to come in from other operators, and orders soon followed. At this time, both Jim Gray and Jim Adams were working in the workshop along with the coachbuilders and a few joiners and apprentices. As the business increased, they had to increase the small workforce and Jim Gray took to the road, to sell the container concept to other road hauliers, further south. It was not unusual for him to leave Fraserburgh at 3 o’clock in the morning in order to be in Carlisle for an appointment at 9 o’clock. Then return to Fraserburgh the same day and go back into the workshop to help finish off a body which was due for completion the next day. This type of commitment was the key to the strength of the company. Jim Adams was also actively involved in the day to day running of the workshops, including the car repairs and even helped out with Argon/arc welding the aluminium tread plate floors when other operators were unavailable. In the early years, insulated bodies did little more than delay the warming process but, using dry ice and two strategically placed vents on the front panel, the cooling effect could be extended further with air from outside being passed through these vents and over the dry ice. The design of the front panel, rather than being flat and square was radiused in order to gain maximum efficiency. In 1962, Gray & Adams were appointed the sole Petters agent for Scotland. Petter, at that time, were building fridge units under licence from Thermo King America. As interest in the concept of refrigeration grew, Jim Adams became more involved with this part of the enterprise, both with the installation of the new units and the servicing & repairs, which often involved him putting his tool box and the spare parts into the back of his Mini Cooper S and travelling across the country day or night. In 1963, the demand for refrigerated bodies had increased to such an extent, that the company had to add an extension to their premises, to relocate the car repair and paint shop. They had also added mobile travelling shops to the list of manufacture, the moving of the car repairs allowed for more room to accommodate commercial trucks and bodies. In 1965, when the regulations were changed to increase the maximum permitted length of trailer to 33ft, it became clear that the existing premises in School Street were too small for the size of the operation. Then in 1966 the company moved to purpose built premises located in South Road, Fraserburgh, where we remain to this day. We still provide accident repairs to cars and light vans and this remains an important part of the business to this day. In 1967, shortly after moving to the new premises, the Construction & Use Regulations changed yet again, increasing maximum weights to 32 tons Gross Vehicle Weight (GVW) and also allowing a maximum body length of 40ft, which lead to the introduction of large front mounted diesel/electric fridge units. In 1968, Jim Gray became involved with the whisky distillers the result of which, was the design and construction of a special dual-purpose trailer, which had a crown lock body for carriage of whisky kegs from distillery to bonded warehouse. This body also had roof hatches and hopers in the floor, so that it could first arrive at the distillery with barley for malting, then when the body was empty and all Exploring the options between ice and the new technology of the refrigeration unit

hatches secured and custom sealed, could be loaded with whisky kegs. Part of the portfolio at that time also included building tipper bodies, rigids and trailers. In 1970, a decision was taken to offer a one-stop deal. Instead of building boxes to clamp to customer’s own platforms, they were offered a complete vehicle with Gray & Adams reefer body constructed on to a skeletal two member chassis which was purchased from various chassis manufacturers. It was with this design that the company took its first major order for 50 trailers of this new concept – big stuff indeed for a small manufacturer. More to follow