5 minute read

HOW DRONES HELPED BUILD THE PERFECT LIFE SAFETY SYSTEM FOR A WATER TOWER

HELEN GOLDBLATT, E.C. FENCE & IRON WORKS, INC. | KATHRYN NEWELL, IDS DRONES INC.

A Tower, A Ladder, and A Big Challenge

Water towers may seem like simple structures from the ground but maintaining them is anything but. Reaching the top of these structures requires a carefully designed access system that follows the tower’s curve and provides workers with safe, secure footing. That’s exactly what EC Fence & Iron Works set out to do when tasked with replacing the life safety equipment on a massive water tower.

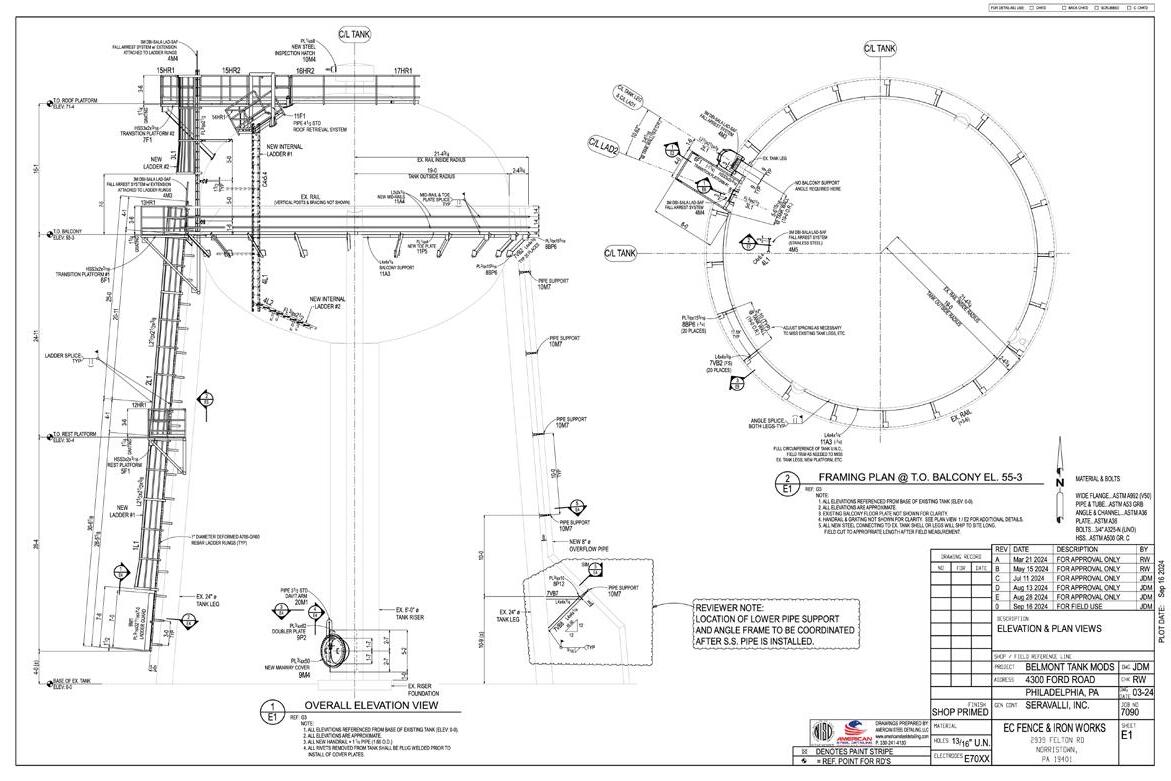

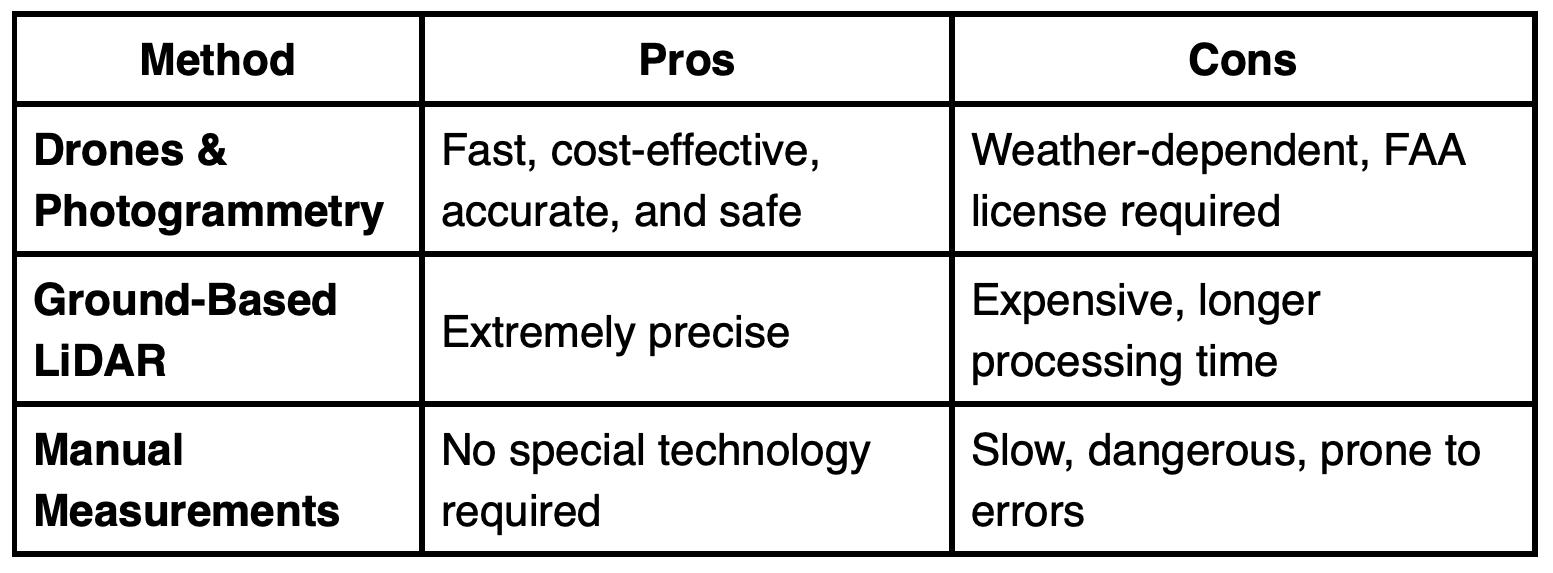

But there was a catch. The new ladder and safety system had to fit perfectly with no gaps, no guesswork, and no “we’ll fix it in the field” adjustments. Traditionally, this would mean climbing the tower with measuring tools, a process that is time-consuming, physically demanding, and prone to inaccuracies.

To ensure absolute precision while keeping workers safe, EC Fence & Iron Works partnered with IDS Drones and Digital E Consulting. Using advanced drone technology and photogrammetry, they gathered precise measurements in a fraction of the time — and without a single person needing to climb the tower.

Step One: Capturing the Data

Rather than relying on manual measurements, IDS Drones and Digital E Consulting deployed a drone equipped with a highresolution camera. Before launching, the team conducted a thorough site inspection, identifying potential obstacles like power lines and ensuring weather conditions were ideal. The drone flew a programmed path around the tower, capturing a series of overlapping images from multiple angles. Additional shots from above documented the top of the tank, ensuring a complete visual record.

To supplement the aerial data, EC Fence & Iron Works used a FARO M70 Scanner, a ground-based LiDAR system, to take scans of the tower’s base and the surrounding structures. Merging

these scans with the drone imagery created a comprehensive 3D model. The accuracy between the two technologies confirmed that the data collection was a success.

Step Two: Transforming Images into a 3D Model

Once the drone landed, the collected images were processed through photogrammetry software, stitching them together into a detailed 3D digital model of the water tower. This model provided engineers with precise measurements, eliminating the risk of miscalculations. With the exact specifications in hand, they designed the new ladder and safety equipment to fit seamlessly. The digital model also streamlined fabrication and installation, removing the need for costly field adjustments.

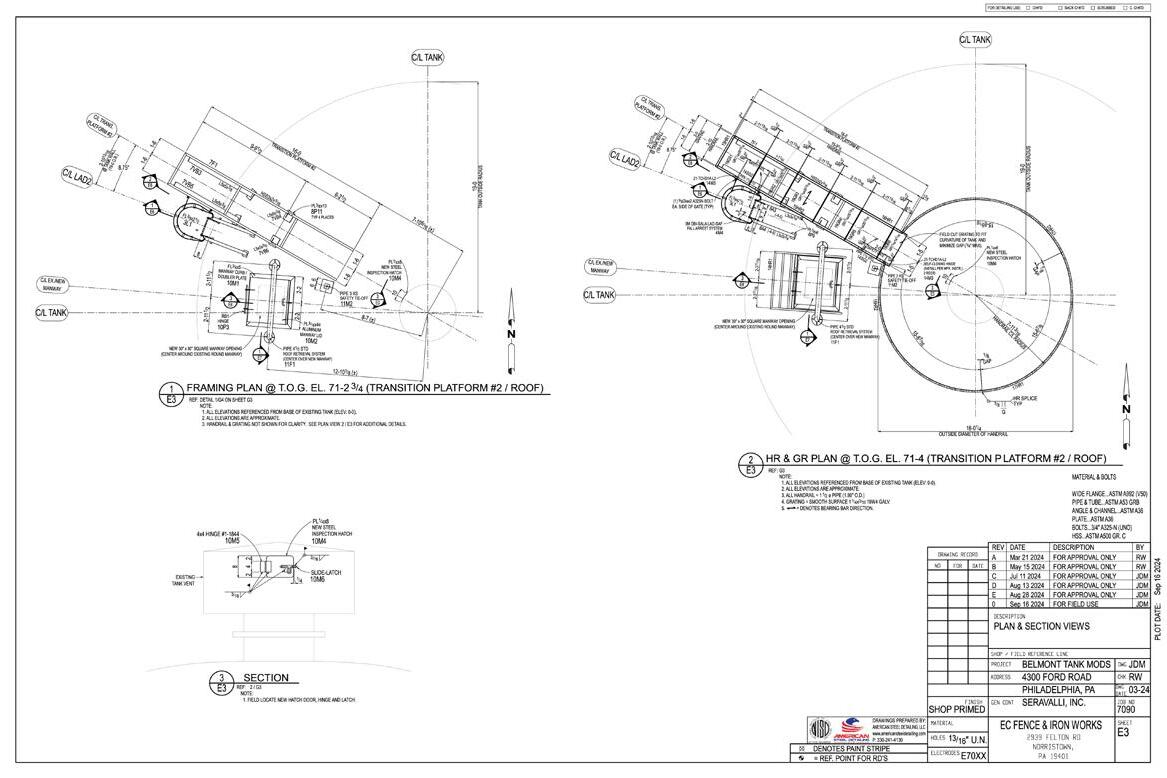

Step Three: Comparing Measurement Methods

The use of drones and photogrammetry was not just a hightech solution, but also the most practical option. Traditional measurement techniques were considered, but they fell short in key areas.

While LiDAR scanning offers the highest level of precision, its higher cost and extended processing time made photogrammetry the more efficient choice for this project. Compared to manual measurements, drones improved both safety and accuracy while drastically reducing the time required to capture data.

The Final Payoff: A Perfect Fit

With a flawless 3D model guiding the way, EC Fence & Iron Works fabricated and installed:

• Custom steel ladders designed to match the exact curvature of the tower.

• Bracing and railings engineered for maximum stability and worker safety.

• Grating platforms ensuring secure access for maintenance crews.

Since everything was manufactured to precise specifications, installation was completed quickly without the need for lastminute modifications. This approach saved time and labor costs while improving safety by incorporating modern fall protection features.

Lessons Learned and Overcoming Challenges

Even with advanced technology, every project comes with challenges. A few key lessons emerged:

• FAA Compliance: Commercial drone operations require licensing and regulatory approval.

• Reflective Surfaces: The tower’s metal exterior caused some imaging distortions, which were corrected through additional processing.

• Weather Conditions: Drones cannot fly in high winds or rain, making precise scheduling essential.

Despite these obstacles, the efficiency and accuracy of drones and photogrammetry far outweighed the challenges.

A Model for the Future

This project demonstrated that drones and photogrammetry are not just cutting-edge tools but practical solutions for improving construction and infrastructure work. The key takeaways from this approach include:

• Safer Worksites: By eliminating the need for dangerous climbs, drones keep workers out of harm’s way.

• Safer Worksites: By eliminating the need for dangerous climbs, drones keep workers out of harm’s way.

• Faster Project Timelines: Data collection is completed in hours rather than days.

• Cost Savings: Reducing errors, streamlining fabrication, and minimizing rework lowers overall expenses.

As the construction industry continues to embrace these technologies, projects like this will become the new standard. What once required physical labor and risk can now be accomplished with precision and efficiency, proving that innovation is not just about new ideas but about smarter, safer, and more effective solutions.