2 minute read

BPMA productwinners demonstratesustainability

The most recent BPMA product awards turned thefocus on sustainabilityintwo categories. Sustainable Product of the Year Platinum winner was CHX’s rHIPS.b range of plastic promotional items which aremade from aspecially developed material that is tested to ISO 15985and ASTM B5511certification. Made from recycled plastics, thematerial is fully biodegradable, and unlike other popular bioplastics it does not requireextremely particular conditions to biodegrade. rHIPS.b polymer is brokendownbyover 600naturally occurring microbes in home compost, marine, and landfill.

Gold awardwent to Trading’s Cyclo+ Awar Tote Bag whichispart closed-loop production system that upcycles pre-consumer textile wasteand grants consumers the abilitytotrack theentirejourney of their product with Awaretracer technolo

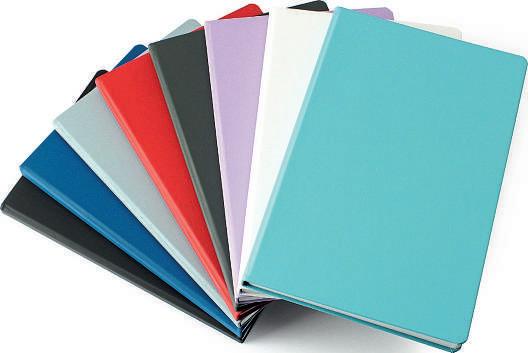

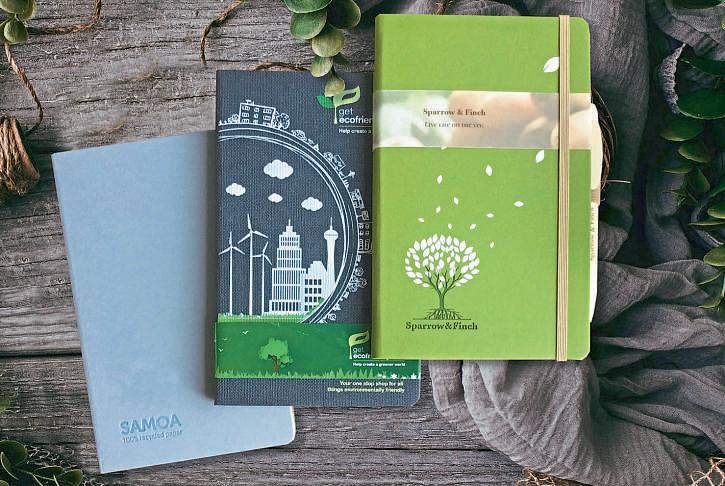

Textile wasteisused durable, coloured yarn of themost environment alternativesusedtomakethe bags. Silver went to Juniper Trading’s Recyco notebooks whichare UK made from recycled materials and availableasstandardlined books, wellness journals, business planners, and withtrim options.

Therewas also an awardfor theSustainable Innovation of theYear whichwent to XD Connects’Impact AwareRPETlightweight rolltop backpack

This year’s Gold winner wasDesktop Ideas’MrBIO Smart (NFC) charge cable.

Productfocus –sustainable tech

BabyUSB is taking abig step forwardin its quest forsustainable tech,withanew range of poweroptions made from a unique blendoforganic hemp,cotton and RPETrecycledplastic bottles.

The SustainX range includes power banks, awireless charger and acharging cable. The 10,000mAh powerbank is made from four recycledbottles, its smaller 5,000mAh brotherfromtwo and theQiwireless chargerfromone and a half bottles.

To addtoboththeirvisual and eco appeal, theproducts arefinished with organic hemp and cotton fabric.The same materials also featureinBabyUSB’s tablet and laptop pouches.

Kashif Siddiquei, BabyUSB’s managing director,said: “There’s never been abettertimeto‘keep it local’. Our dedicated warehousing and branding facility, based in theUK, means we can offer our best sellers withaquick turnaround, even forsmaller quantities.”

FSC paper is standardfor all bound Castelli diaries, notebooks, and used in theproduction of all sales literature. It has apaperless order processing system to ensurepaper usage is kept to aminimum.

Castelli promotes wastereduction throughout thecompanyand has completed apackaging audit.

It is also started theprocess to be become bothBCorpand EcoVardis certified.

The ethical approach hasproved advantageous when advertising fornew employees, who aremotivated, driven and passionateabout theenvironment.

By making an ethical and positive supplier selection Castelli is now involved in theCarbon Capturescheme and, to date, has planted 424,638 trees and helped raise over £1.57m forthe Woodland Trust, capturing over96,000 tons of CO2through positive purchases of paper

From farm to bag

Acotton bagfeaturing full transparencyfromfarmtofinal product is thelatest innovation from Jutebag, in aquest to produce a bagproviding an unrivalled level of accountability.

The cotton is grownonthe Kenyan island of Lamu, procured from smallscale farmersat apremium.Farmers aregiven thecotton seeds forfree and only natural fertilisers areused.

The rawcotton is sent to aginnery and then to ThikaClothingMills, whichproduces thefinal fabric This is then sent to thecoastal city of Mombasa, wherethe bags are stitched beforebeing transported by sea to theUK.

Jutebag director Parit Shah was bornand brought up in Kenyaand personally visited thefarms and all theproduction facilities while planning this initiative

Eachbag comes witha unique QR code that can be scanned to access detailed information about the journey of thecotton from thefarm to thefinal product.

Half of profits from thesales of thebag will help fund achildren’s education project in thecotton growing area.

Parit said: “The brands buying this bagcan feel confident that they are making asustainable and ethical choice and profits going back to the cotton growing villages will makea positive impact to thefarmers and their communities.”