6 minute read

World of Concrete 2022 Wrap-Up

WORLD OF CONCRETE Wraps Up for 2022

• The show took over 632,000 NSF of the expansive and newly expanded LVCC • Hosted over 1,100 industry-leading suppliers • Over 150 first-time exhibitors

The 47th World of Concrete convened close to 37,000 registered professionals, the consistent foot traffic in the expo halls and engagement with the comprehensive educational offerings underscores the industry’s critical need for in-person connection.

More than 1,100 industry-leading suppliers, with just over 150 of which were first-time exhibitors, offered attendees a wide range of brands to explore from the most sought-after global enterprises to niche SMBs spanning a variety of applications.

Registered participants had the opportunity to engage with education made available at the event. World of Concrete’s educational programs serve as an incubator for knowledge sharing and technical know-how, helping the industry overcome challenges and tap into new opportunities for growth. With more than 11,000 expert-led sessions, this year’s education explored a balance of technical and forward-looking topics, ranging from 3D printing in concrete construction, women in construction, waterproofing: the next generation of solutions, and much more.

Not only does the industry gather at World of Concrete’s annual event for deal-making and education, but to see and demo the most new products available on the market and see the latest industry developments that lay the groundwork for the coming year.

Trends from the event:

• Greater job site productivity, with new battery systems that deliver

Diablo shows how its proprietary blends can save 50% of your time with less heat and less wheel changing— while remaining less than $100 retail.

Mason Cole Stamper, along with his mason tender, Jeff Becker, took home top honors at 2022 SPEC MIX BRICKLAYER 500 at World of Concrete 2022.

more power to the hand tools used to perform demanding concrete tasks, such as drilling, cutting, and demolition; • Introduction of equipment that is automating concrete construction activities, including 3D printing, rebar tying, and drilling overhead holes; • Entrance of new materials that increase contractor productivity while still ensuring durable repairs; • Streamlined management data management systems that enable contractors to tighten a project’s critical path; • And product and equipment updates that reduce a project’s carbon footprint and increase contractor productivity.

A RECORD FUND-RAISING

The Concrete Industry Management (CIM) program held its silent and live auctions, generating an all-time record of more than $1.74 million. Donations

MB America had demos of its skid loader crushing bucket attachments. At right, Doosan’s DX50Z-7 Mini Excavator features a Zero-Tail Swing design for confined spaces or landscaping projects.

Aquajet’s Aqua Cutter 750V features Infinity oscillation that moves the water jet in a figure 8, pattern, removing more concrete in a single pass while reducing shadowing, eliminating the risk of pipe holes and providing an ideal bonding surface.

originated from the live auction and online contributions, marking a historic moment in the program’s rich history at World of Concrete that is designed to give students entering the concrete workforce industry experience early in their careers. World of Concrete is proud to partner with the CIM program, a business program developed specifically for the concrete industry to provide students with a four-year Bachelor of Science degree in Concrete Industry Management.

WORLD’S BEST BRICKLAYER

The 2022 edition of the SPEC MIX BRICKLAYER 500 World Championship crowned Mason Cole Stamper as the “World’s Best Bricklayer,” along with his mason tender, Jeff Becker. The two took home top honors and bragging rights, in addition to a new Ford F250 4x4 truck and more than $10,000 in cash and prizes. Scott Tuttle and mason tender Brian Tuttle locked in the second most-coveted award at the event, the SPEC MIX TOP CRAFTSMAN, laying 730 brick in one hour. Their effort won the Tuttles a new Kubota RTV-X1140, plus more than $10,000 in cash and prizes.

SUSTAINABILITY

New this year and central to World of

NOT ALL TRENCH DRAINS ARE CREATED EQUALLY PRO-PLUS®PLUS TRENCH DRAINS

Innovative and Labor-Saving SMC/GRP Drainage Channels made from glass-fiber reinforced composite.

Lightweight Extremely Strong Shatterproof Easy to handle and install Requires less manpower

When comparing PRO-PLUS® to polymer concrete its strength, weight, and thermal expansion is unmatched.

PRO-PLUS® Strength 1.5 times Stronger 35% greater Compressive Strength 80% greater Flexural Strength 78% greater Tensile Strength

PRO-PLUS® Weight 70% Lighter

PRO-PLUS® Thermal Expansion 1.7 times less

800.36.JOSAM | www.josam.com

Concrete’s core values, the exhibition organizers formalized the event’s commitment to sustainability in collaboration with renewable energy partner/ sponsor HILTI. The program was intentionally executed with three objectives: inspiring sustainable development, environmental responsibility and social responsibility – each pledge supporting the event’s commitment to shaping the concrete industry for a sustainable future. Thanks to HILTI’s Renewable Electricity sponsorship, World of Concrete’s electricity use is powered by sustainable and renewable energy sources, saving an estimated 204 tons of CO2e.

POWERING CONCRETE

Unveiled first at the 2021 show, the Honda eGX advanced batterypowered motor was featured in various equipment. Noteably in an Allen Engineering walk-behind trowel and Compressed Air Systems air compressor.

Powered by a lithium ion battery, the eGX’s quiet motor lets the operator work for extended periods, and at night or near residential areas. Charged and discharged batteries can be interchanged rapidly, and the Honda quick charger (<1 hour/80 percent charge) provides maximum operating time and productivity. Because the Honda eGX can sustain a wide range of temperature conditions, it can be used in virtually all seasons.

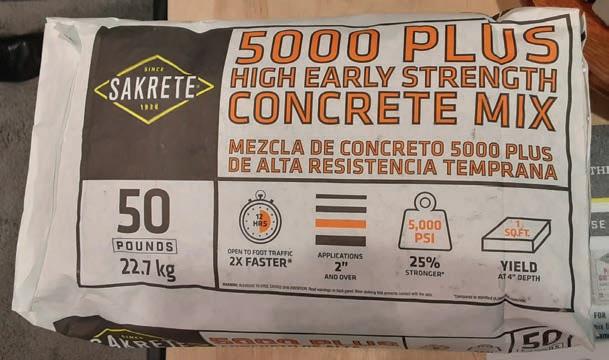

Sakrete is updating its bag design to provide contractors important information.

FOR OVER 80 YEARS

MAX developed the World’s First battery powered rebar tying tool in 1993 and has a history of manufacturing durable and reliable industrial tools for 80 years. has a history of manufacturing durable and reliable industrial tools for 80 years. Since then, MAX rebar tying tools have revolutionized rebar tying work in a variety of other jobsites all around the world. All MAX products are engineered to perform on professional contractors jobsites and with MAX’s 200 R&D engineers we have continued to jobsites and with MAX’s 200 R&D engineers we have continued to improve upon MAX proprietary technology, which led to the invention of the TWINTIER® rebar tying tools. TWINTIER® technology allows the tools to tie 4,000 ties per charge while delivering just the right amount of to tie 4,000 ties per charge while delivering just the right amount of wire for greater productivity and cost savings. These unique innovative features make the TWINTIER® the most efficient rebar tiers in the industry. Today, MAX manufactures a full line of rebar tying tools that can tie between mesh up to #9 x #10 rebar.

MAX USA Corp. • 205 Express St. Plainview, NY 11803 • U.S.A. - Phone: (800) 223-4293 • FAX: (516) 741-3272 • www.maxusacorp.com