19 minute read

A Custom Foundation

A CUSTOM

FOUNDATION

A profile of contractor Custom Concrete and the project that won them the Concrete Foundation Association’s 2020 Commercial Project of the Year Award.

The commercial and residential contractor, Custom Concrete is a family-owned and operated company going on 50 years young. They celebrated their quinquagenarian anniversary in April 2019. For three generations the company focused primarily on residential foundations. To further diversify work offerings, about eight years ago they added a commercial division.

Six years later, it turned to be an advantageous decision and became its own standalone company within the Custom Concrete umbrella. Including the subcontractors, the company is comprised of roughly 250 employees, about 50-55 are in the commercial division.

One of the largest challenges for Custom Concrete has been personnel. They’ve found a short-term solution with subcontracting more, but then discovered that’s a double-edged sword: even the subcontractors are challenged with personnel.

On top of that, COVID. While the business was able to qualify as essential, they discovered like many other concrete contractors around the country, that a number of clients did not. While they experienced some stalled projects or some projects not move forward at all, others ramped up and were able to pivot their strategy to take advantage of those opportunities when they came by. One tactic was to bid more aggressively—or more robustly. They pursued where they could in the opportunities within the commercial market like warehouses for Amazon and Walmart. The pandemic also brought an opportunity in the construction of a laboratory for diagnostic equipment for COVID testing.

It is this Commercial Division that earned the company its recognition from the Concrete Foundations Association (CFA). Its commercial project for

The purpose of the foundation was to be home of a heavy stamping machine for an automotive manufacturing plant. Precise accuracy was key to sucess.

Photos courtesy of Custom Concrete

FOUNDATION

Lafayette, Ind., won the CFA’s 2020 Project of the Year Award for Commercial Structure. Where they are typically known for foundations—this project brought them placing a foundation of a different kind.

As described at CFAwalls.org:

“Projects of the Year is a program that delivers recognition of the combination of innovation, craftsmanship and creativity of the concrete contractor as well as the vision and creativity of the design professional. Projects submitted annually to this program represent the leading work across the breadth of castin-place concrete solutions produced by association members. They demonstrate the technical challenges overcome by the professional craftsmen found throughout North America and continue to set a new standard for quality and technological achievement for the castin-place industry.”

Project submittals for 2021 are now open with a deadline of April 30. Additional recognition programs from the CFA include: • The Top Safety

Awards: Recognizing those committed to a safe working jobsite; • The Professional

Achievement

Awards: Recognizing the professional achievement and commitment from individuals, honorees are nominated by peers; • The Legacy Awards (The Robert

D. Sawyer Award and the Lifetime

Achievement Award): A special recognition to individuals who made significant contributions to the industry; • The Contractor of the Year:

Acknowledging a contractor’s unselfish commitment to peers, service, technology, and knowledge; • Associate of the Year: Honoring a single National Associate member

for their commitment to the CFA; • Innovative

Contractor of the

Year: Recognizing an individual’s or company’s innovative ideas within the construction, management, marketing, etc.;

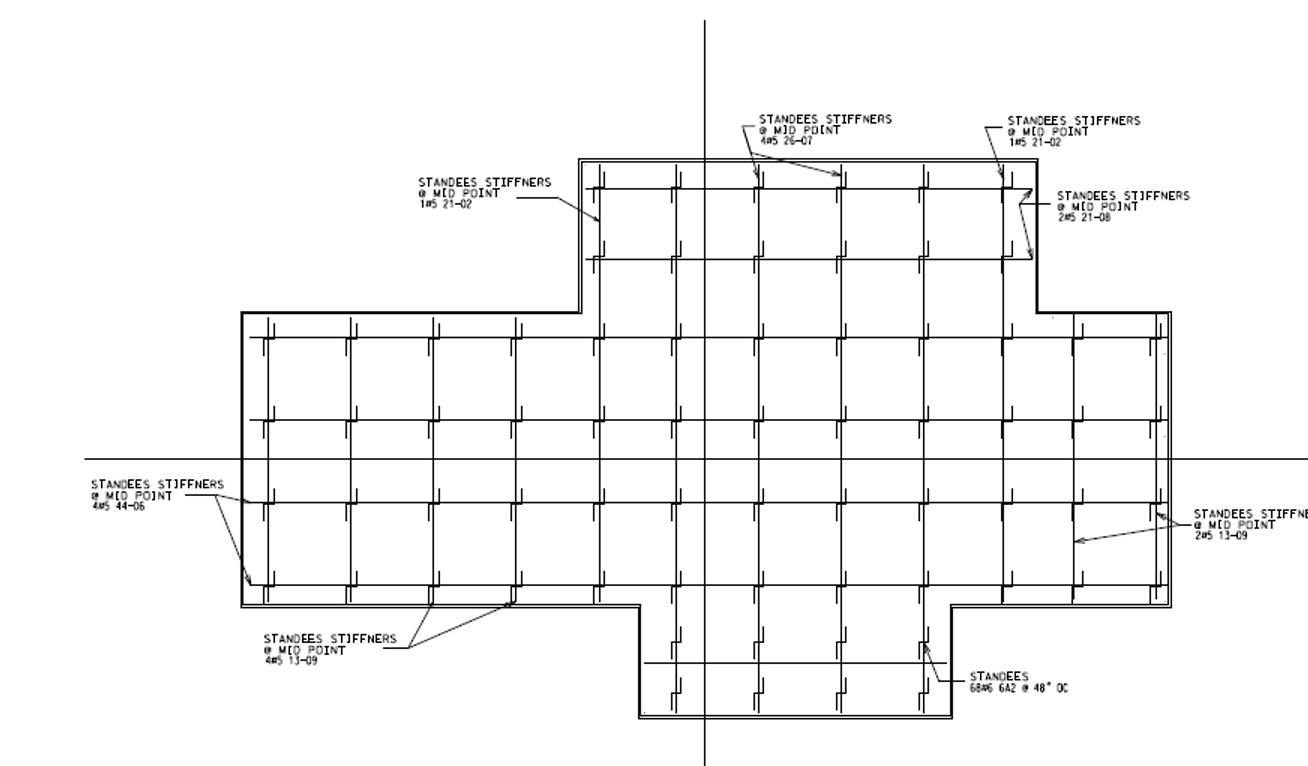

The project included multiple construction joints which also required PVC waterstop. All footings had a double mat of rebar.

• Kick-start Member of the Year: Given only to members within their first three years with the CFA; and • Most Valuable Player: Recognizing one’s hard work in the research, pioneering spirit in poured concrete foundations.

COMMERCIAL PROJECT OF THE YEAR

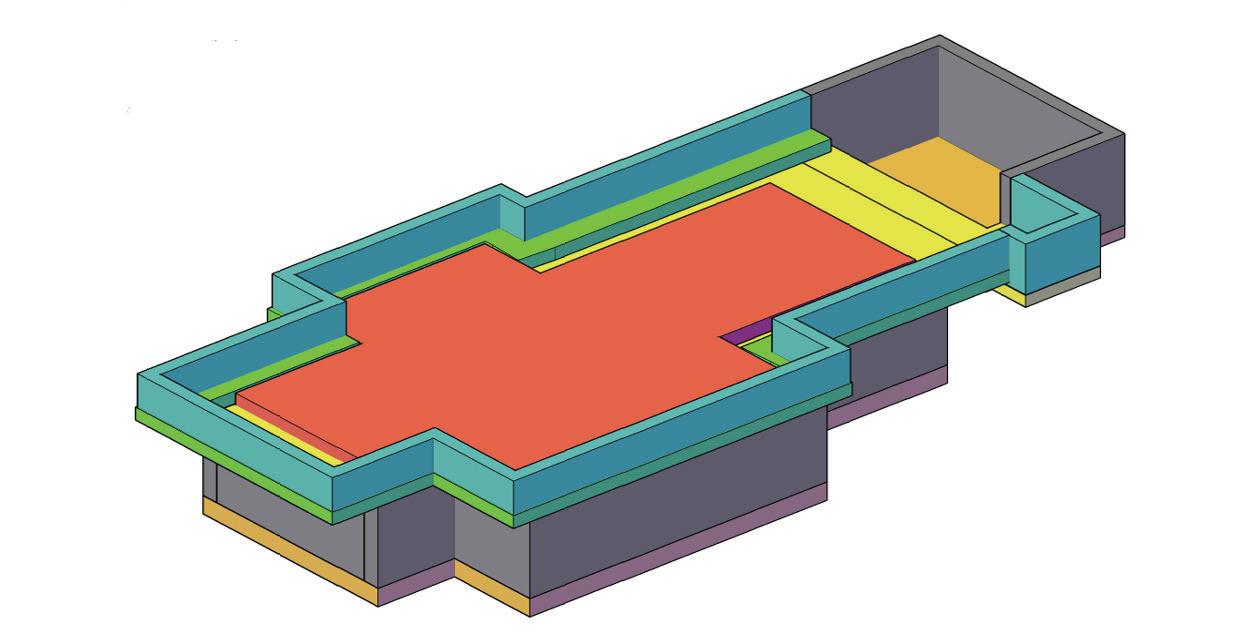

Custom Concrete’s 2020 CFA Commercial Project of the Year ended up being an isolation base for stamping press for a major automobile manufacturing plant. Picture a stamp coming down onto a raw piece of plate steel to cut out a part, because it takes so much volume and pressure, the foundation needed to be isolated to not shake the surrounding foundation every time.

It is here that Custom Concrete had to overcome their first challenge: all work had to be done indoors and while work was ongoing all around them with active employees and processes. High safety standards had to be met without disrupting production which was a logistic challenge all around to balance productivity and safety. On top of the limited indoor space, material and equipment were bottlenecked. Everything needed to travel in and out through a single point of access to the location inside: one overhead door. A 100- by 50-ft. area was made available to them to collaborate, but even then this area wasn’t always available. They installed a dust curtain with an air scrubber around the project itself (also roughly 100 by 50 ft.) to contain airborne particulates and emissions.

In essence, picture a swimming pool with a base featuring a joint around the perimeter with foam insulation as a buffer. Contractors dug a 12-ft. hole in the middle of the existing building next

to existing foundations and placed 300 cubic yards of 5,000-mix concrete.

The majority of the concrete needed to be poured at once, but because of its 9-ft. thickness (roughly), it was important to keep the temperature consistent throughout so it cured correctly. The team utilized three battery-operated sensor/thermometers in the concrete to track the temperatures to ensure it cured as needed. The device connected to a phone and synched via wi-fi providing readings and the necessary data. They placed one at the bottom elevation, one mid-elevation and one at the upper to track the curing through the entire slab.

Plans had to be thought of from the pit bottom and up. Each step carefully planned out. The base was poured then the foam to isolate the block from the rest of the facility. Using 2x4s at the top, the dowels required a specific spacing to support the weight of the concrete—else the plywood would break. Screws from the 2x4s held the dowels in place. Once the seams were taped and a Visqueen barrier was used to keep the concrete from adhering to the plywood—concrete was then ready to be placed.

One of the special specifications in the job included a vibration isolition foam called Regufoam, which they acquired from Unisorb, which required itself a 1.5-in. air gap. Quick on their feet, they discovered a quite clever solution to overcome this challenge – through the thickness of the form itself.

QUICK SPECS

• 1,146 sq ft. footprint • 157.75 linear ft. of wall, 8 ft. wall height with 12 in. and 16-in. thicknesses • 602.75 cubic yards of concrete • 35 tons of steel reinforcement • 6 tons of #8 and #10 rebar • 286 inertia blocks

Custom Concrete installed 3/4-in. plywood with 3/4-in. slick dowels. Once cured and the dowels and plywood removed, they had their needed gap space. The experience was a learning curve, but representatives for the Regufoam product were available for any questions regarding the installation.

PRECISION

The placement has to be precise. Heavy machinery was planned to be placed at the location and it needed to be level to the rest of the work floor. Custom Concrete needed to accommodate for the pressure of the weight and the absorption in the Regufoam. This required exactly 5/8-in. of concrete to be placed higher than the finished floor.

Besides that, Custom Concrete needed to think on their feet to get the heavy equipment down the 12-ft. deep project area (and then out again) as well as removing the slick dowels themselves. The manufacturing client, allowed them to utilize an overhead crane.

They ended up utilizing a subcontractor for the pump truck and poured during the week of Christmas. At first, they set up a pump inside, but later foot traffic inside the building limited this efficiency. A pump truck with a z-boom was set up outside and connected through the overhead door to the next pump—piggybacking or daisy-chaining pumps together to get material into place. The z-boom design allowed Custom Concrete to use a 30-meter pump accommodating the low clearance.

Unique challenges aside, they actually ran ahead of schedule. In fact, they poured the actual base two weeks prior to the original plans. The deadline was at the end of January and wanted to give the block a full 27-day cure.

Since the client was going to place heavy stamping manufacturing equipment on top, no polishing was done. The only finishing that was applied was a slick finish and drilling to set equipment anchors.

Aside from needing to install a footing for a specialized piece of equipment, aside from needing to hit exact specifications to ensure safety and a level floor, the best part: the entire project went without injury.

The job required a high level of accuracy and pours were done in phases. The lowest pad was 24-in. thick. For more from the Concrete Foundations Association, visit ForConstructionPros.

com/10072513.

Concrete Tips for Safer Sawing & Drilling

Expert advice on how you can optimize safety during cutting and drilling operations.

As with other applications, it’s important to conduct an assessment of the application and jobsite prior to cutting or drilling into concrete, asphalt or other surfaces. This will enable you to plan out the project, identify the necessary equipment for the task, as well as assess any potential risks.

A jobsite assessment is very important as it will allow the workers to plan their work more efficiently, say product experts at Hilti. In addition, it increases the worker’s awareness of potential hazards and how best to mitigate them, therefore helping ensure the proper measures to increase health and safety on the jobsite are implemented.

Tony Calcopietro, national account/ export sales manager, EDCO, agrees, noting, “Construction sites are always full of potential hazards. Before saw cutting or drilling, it is extremely important to inspect the work area. Check to ensure a safe and secure workspace for things like proper lighting, ventilation, auto or pedestrian traffic, noise, etc.

“Address all hazards accordingly before you begin operating the equipment to ensure safety for both the operator and those surrounding the jobsite,” he adds.

USE THE PROPER TOOLS

Having the right tools is one of the basics required to complete cutting or drilling operations in a safer manner. An inappropriately sized tool can do more than slow production or potentially lead to equipment downtime.

“Inadequately powered equipment can also expose an operator to physical injury should they try to push an underpowered saw or drill beyond its capability,” Calcopietro points out. “Diamond blades or bits may jump out of the cut or get pinched in the cut, creating additional expenses and exposing operators to preventable, unnecessary steps.

“Know how deep you are cutting or the size of the hole you will be drilling,” he advises. “Knowing depths of cuts or drilling diameters will help you choose the right horsepower saw or drill based on manufacturer guidelines.”

Conducting a jobsite assessment can help to ensure operators have the proper tools and accessories. It will also help you to identify the power source available or needed to run the saw or drill.

Gas-powered equipment is recommended for outdoor use, while electric-powered saws and drills are primarily used indoors. “For electrical saws and drills, identify and utilize an electrical outlet that is secured by a GFI and ground,” says Calcopietro. “Inspect

When wet cutting with diamond blades, make sure you have ample water on the blade for dust suppression to prevent hazardous silica dust from becoming airborne.

Photo Credit: EDCO

extension cables and any electrical junction boxes to be sure they are safely run to the workplace from a generator or outlet.”

Make sure cables are intact and not frayed. “Frayed cables that expose internal wiring can expose personnel to electrocution,” says Calcopietro. “Also, choosing the correct cable size (length and gauge) will prevent downtime caused by tripping circuit breakers or damaging electric motors on the equipment.”

Larger industrial facilities are where you typically find propane-powered saws. For these applications, proper ventilation is required. “Improper ventilation can result in the operator or nearby workers passing out from the propane engine exhaust fumes,” says Calcopietro.

PREPARE FOR OPERATION

Prior to use, conduct a thorough inspection of the saw, drill, blade or bit. “Be sure the machine is operating at 100%, and make sure all machine hardware is tight,” says Calcopietro. “Loose machine hardware can cause the equipment to vibrate excessively, causing blade or bit damage, which can be harmful to the operator or nearby workers.”

Inspect the blade or bit for defects or cracks and check that it is installed properly with a tightened locking collar and nut. “Failure to ensure all hardware and accessories are tight can cause the diamond blade or bit segments to fracture and chip, resulting in projectiles on the site causing injury or death to operators or nearby workers,” Calcopietro cautions.

At minimum, follow the manufacturer’s routine maintenance schedule in the user’s manual, Hilti product experts advise. Checking air filters, tightening the blade arbor before use and checking for any damage can reduce downtime and improve safety.

Certain applications may require additional accessories to maximize safety. For example, most manufacturers recommend using a drill stand when core drilling with core bits over 3 in. in diameter. “This helps the operator gain better control of the equipment. A core drill stand prevents the operator from losing their grip on the drill, thus twisting out of his/her hands, resulting in injury,” says Calcopietro.

“Also, be sure the surface you are standing on is firm and secured,” he continues. “Proper stands, a firm grip and proper footing of hand-held core drills is important to prevent physical injury.”

KNOW WHAT YOU’RE GETTING INTO

Prior to cutting or drilling, make sure you know what’s behind the wall, in the floor or below the surface.

Knowing depths of cuts or drilling diameters will help you choose the appropriate power required based on manufacturer guidelines.

Photo Credit: EDCO

“Assessing the jobsite is very important—this will let you know where you can and cannot cut or drill,” says Andrew Mayer, business development manager - light equipment, Chicago Pneumatic Power Technique.

Prior to starting the job, walk the site to look for potential hazards such as rebar sticking out of the surface or debris along the cut line. Mark off these areas so they are clearly visible to the operator.

Be sure to identify the location of gas lines, electrical cables, water lines, etc. Hilti recommends scanning surfaces to help identify areas where rebar, live lines, post-tension cables or pipelines could be present. Don’t always rely on the drawings of a surface to tell the full story of what’s behind or underneath it, the company’s product experts advise.

“Be aware of and avoid cutting into live electrical conduits, any pipes, any rebar or areas that are important for the integrity of the building or structure. Cutting through live power cables, water/sewer pipes or structurally required supports will result in unforeseen project cost overruns and possible operator injury,” says Calcopietro.

“This is why it would be a great idea to get in touch with the utility companies before any cutting or drilling is started,” Mayer comments. “This way, they can identify those areas for you and accidents can be prevented, saving a lot of time by not having to do this yourself.”

In addition, take special precautions when cutting or drilling into floors on multi-level structures. “Once the cut or drilling is complete on a multi-level structure, the floor slab or core could fall from the ceiling into an active workspace, creating the potential for striking a worker, resulting in injury or possible death,” says Calcopietro. “To avoid this, be sure the work area below is clear of personnel and properly secure the cut-out material, preventing it from dropping below.”

Another necessary precaution for this and other types of cutting or drilling may include using barricades around the work area to protect workers and/or prevent unauthorized access.

During the cutting process, let the tool and blade do the work, Hilti product experts advise. Don’t apply unnecessary pressure to the tool, which can cause extra wear and tear on both tool and blade. In addition, keep the tool in line with the cut. Twisting in the cut can cause wear on the tool, risks breaking the blade or, worse, increases the chance of kickback.

CONTROL THE RISKS

Of course, proper personal protective equipment (PPE) is essential when cutting and drilling. Make sure operators follow OSHA requirements for PPE, as well as those required and suggested in the tool or equipment operating instructions.

According to Hilti, required PPE may include safety glasses, safety toe boots, hard hats, ear protection and potentially gloves, depending on the task. In some situations, such as flying sparks, face shields may be advised.

Be especially wary of the risk of eye and ear damage and whether both eye and hearing protection are required. “Users must be vigilant when it comes to these two parts of the body,” says Mayer. Injuries to feet are also common. “Proper foot protection should always be worn.”

But when it comes to hazards, perhaps the most commonly identified— and frequently cited—is dust. “In my opinion, the largest and most dangerous risk is the exposure to silica dust,” says Mayer. “While running this type of equipment, there tends to be a lot of dust created.”

“Breathing in harmful silica dust particles can lead to silicosis and cancer,” says Calcopietro. Dust control was once largely ignored. “Some users were wearing no protection at all,” Mayer points out.

It is now closely regulated by OSHA, with strict standards for silica dust exposure. OSHA regulations require some form of dust suppression for most cutting and drilling applications to ensure exposure levels fall below prescribed limits. The type of dust mitigation required varies depending on the equipment and application.

DOWEL PIN DRILLING SAFETY TIPS

One of the more specialized types of drilling applications is dowel pin drilling. These drill units are typically used for larger-scale outdoor drilling such as road or airport construction or repair.

While many of the risks associated with hand-held drills are eliminated, certain precautions are still required with these drill rigs. For example, a dowel drill uses percussion-style drilling, meaning the drill steel used to chip through the concrete applies a hammer-type action. “This causes vibration in the drilling unit itself,” says Rob Minnich, president/chief marketing officer, Minnich Manufacturing. “Injuries can easily be prevented by maintaining and tightening bolts and brackets on the drilling unit daily.”

Dowel pin drills also contain moving parts with pinch points that should be avoided. E-Z Drill advises staying clear of the carriage assembly to avoid being caught between the carriage and frame, and using the carriage lock when moving the drill to prevent the assembly sliding onto fingers and hands. The drill’s lifting handles, and proper lift techniques, should also be used if manually moving the drill around the jobsite. For greater distances, E-Z Drill advises using a weight-rated chain or strap attached to the drill’s lifting bale and locking the carriage.

Because many patchwork jobs require dowel pin drilling to be performed in high-traffic areas, Rob Minnich advises utilizing an airpowered, self-propelled drilling unit. Not only do these drills pull the air compressor while moving to the next drilling type, they are typically a remote-controlled system. Such machines can reduce operator fatigue by eliminating the need to manually move the machine.

Remote operation further enhances safety by keeping operators away from active traffic. “Using a remote-controlled unit offers operators maximum drilling efficiency and uptime while enhancing overall safety and productivity on the jobsite,” says Minnich. “Wireless remote-control technology also allows operators to drill faster and more accurately while avoiding dust, debris and obstacles.”

Further enhancing safety is technology designed to mitigate dust. “Silica dust inhalation is a long-term concrete drilling hazard,” Minnich acknowledges. “OSHA and manufacturers have addressed this issue by providing dust collection equipment to accompany drilling units.”

Optional dust collection systems or dust suppression kits not only minimize the risk of inhalation, they help to eliminate the “dust storms” that can obscure drivers’ visibility as they pass through the work area, further enhancing safety for workers as well as for motorists.

Conducting a jobsite assessment can help to ensure operators have the proper tools and accessories available. It will also help you to identify the power source available or needed to run the saw or drill.

Photo Credit: Chicago Pneumatic

OSHA MOVES FORWARD WITH REVISIONS TO SILICA DUST

RULE

Diamond blades and core bits can be operated wet or dry. “For wet blades/ bits, be sure you have ample water on your blade/bit for dust suppression to eliminate hazardous silica dust from becoming airborne,” says Calcopietro. “The water is also used to properly cool diamond segments to prevent them from chipping and becoming projectiles causing injuries. Have a proper slurry management system in place to be OSHA compliant.”

For dry blades/bits, use proper manufacturer-specified dust collection shrouds and vacuums.

“The use of some type of dust suppression equipment, either dry, such as a vacuum system, or wet— using either a water hose or a fixed water-emitting system attached to the equipment—would help mitigate risk,” says Mayer.

But dust suppression doesn’t replace the need to wear the prescribed PPE throughout the cutting or drilling process. “Make sure you are wearing the proper PPE equipment—shoes, hard hat, gloves, eye protection and dust mask,” Mayer emphasizes. “This would also apply to all personnel working in the same area.”

For more information on saws, visit ForConstructionPros.