6 minute read

Recycling Crushing Products

IROCK Tracked & Wheeled Conveyors

IROCK Crushers offers wheeled conveyors that are road portable and can be hauled to different locations or relocated on site with the help of a truck; tracked units make maneuvering around a jobsite easy as they can move under their own power and can be folded and loaded onto trailers for relocation from site to site. • For sand and gravel, crushed stone, recycling applications and more

ForConstructionPros. com/12144900

Kleemann Mobicone MCO 9i EVO and MCO 9i S EVO

Kleemann’s Mobicone MCO 9i EVO and MCO 9i S EVO mobile cone crushers offer aggregate producers secondary or tertiary crushing in a fuel-efficient, Tier 4 Final emissions-compliant machine. • Cone crusher diameter permits a raw feed capacity of 287 tph, with a feed size maximum of 8.25 in. • Diesel-electrical drive provides low fuel consumption in a compact design • Power plant generates 332 hp at 1,500 rpm • S-version provides a discharge conveyor-mounted final classifying screen with oversized aggregate return conveyor

ForConstructionPros. com/12228931

Ammann RSS 120-M Shredder, Iron Separator & Screener

The Ammann three-in-one RSS 120-M prepares recycled asphalt for use in an asphalt plant. The RSS 120-M functions as a shredder, iron spearator and screener and can recycle asphalt ranging in size from milling to larger pieces/slaps. • Protective processing maintains desired grain sizes • Track mounted • Shredder utilizes two low-speed, electrically driven shredder-rotating shafts • Process up to 198 tons of recycling materials per hour • Dust reduction system

ForConstructionPros.com/20973199

KPI-JCI Astec Mobile Screens Fast Pack Aggregate Processing System

The Fast Pack system is an innovative, patented combination of crushing, screening and stockpiling equipment. • Self-erecting with the ability to turn moving days into production days with moving times as low as 12 hours • Can operate as a complete system or operate units separately • Drastically reduces downtime and offers 400- to 600-tph capacities • Provides users a savings of at least 20% • Offers self-contained or electric processing

ForConstructionPros. com/12314890

Haver & Boecker Niagara Primary Crushing Plants

Haver & Boecker Niagara offers rugged primary crushing plants in a wide variety of configurations for pre-crushing, secondary and tertiary crushing in the mining and aggregates industries. • Haver &

Boecker

Niagara provides crushing plant systems with a variety of components, including impact, jaw, cone or roller crushers, Haver screens or rolling screens, push feeders, apron conveyors and Haver vibrating feeders

ForConstructionPros. com/21065589

Evoquip 230 Impact Crusher

The Cobra 230 features a rapid setup time and intuitive control system with push-button operation that enable it to be crushing within minutes. • Crusher setting can be easily adjusted via user-friendly hydraulic assist • 3.4-cu.-yd. hopper includes an integrated pre-screen for fines removal, and the feeder speed auto regulates based on load • Impact crusher has a 34” x 24” crusher inlet and 33-in.-wide by 34-in. rotor diameter • Includes a 275-hp Volvo Tier 4 Final engine and fuel-efficient, high-performance direct drive system • Potential output up to 275 tph

Engineered Innovation.

From innovative designs to Caterpillar dealer service and support, Weiler is paving the way to success for contractors across North America. Weiler’s material transfer vehicles, commercial pavers, road wideners, windrow elevators, static split-drum compactors, soil stabilizers, rock drills, tack distributors and front mount screeds are engineered with innovative features to increase productivity while reducing operating costs. Weiler equipment is sold and serviced exclusively at Caterpillar dealers throughout North America.

Astec Mobile Screens Ranger Compact Track Line

Astec Mobile Screens Ranger line of compact track equipment includes a variety of jaw crushers, impact crushers, cone crushers, incline screens and trommels. • These compact units will serve a variety of new markets including building and construction, landscaping, quarry operations and plant and tool hire • The ease-of-use, ease-of-transport, versatility and flexibility of compact, track-mounted units make them ideal for smaller operations

ForConstructionPros. com/21105604 Keestrack R3 Screening and Crushing Plant

Keestrack’s R3 plant is available as dieselhydraulic or fully hybrid “e”-version. • Production rates up to 250 tph • Flexible processing of a large variety of raw and recycling materials • Pre-screening • High-performance impact crusher 48 ICR 10000 with 770 x 960 mm inlet opening • Heavy-duty 920 mm rotor (44-in. diameter) • Optional 9-ft. x 4-ft. single-deck with reciruclation conveyor after screening unit

ForConstructionPros.com/21107274

Rotochopper FP-66 Horizontal Grinder

The FP-66 horizontal grinder from Rotochopper has been updated to increase the capacity of materials that can be processed by the remarkably reliable midsized grinder. • The larger 30-in. feed opening and increased powerfeed lift height allow larger materials into the grinding chamber – increasing productivity and efficiency • Now available with a more aggressive powerfeed and either a 630 or 755 horsepower diesel engine

ForConstructionPros.com/21120420

RUGGEDLY BUILT TO OUTPERFORM AND OUTLAST ITS COMPETITORS.

The RC Series Industrial Crusher reduces reclaimed asphalt pavement to any desired output size in a single pass. Contact us today to find out more!

ALLU Demolition and Quarry Crushers

The crusher series initially includes three crusher models for excavators in the 10- to 33-ton range. • Reversible crushing reduces potential for jamming, blockages or obstruction with rebar while delivering greater levels of production • Feed plate design built into jaw ensures the feeding function in a fully loaded chamber delivers high rates of production with minimal risk of bridging • Simple mechanical pin adjustment for output size regulation with quick adjustment for various output specifications • Clam-like crusher opening allows for easy, quick replacement of wear parts

ForConstructionPros.com/21121513

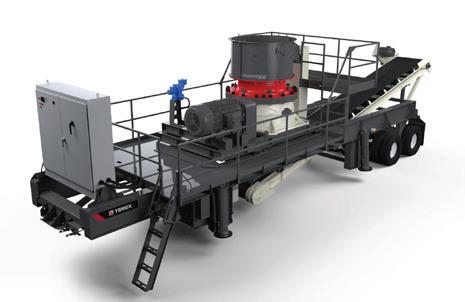

Cedarapids CRC320 Cone Crusher Plant

The CRC320 features the TG320 bushing cone crusher that can be easily set up to deliver peak cost per ton by selecting the optimum crushing cavity and eccentric throw to suit the application requirements. • 300-hp, 1,800-rpm motor and crusher are mounted on a rubberisolated frame • Plant combines the cone crusher and a 15-hp, 42-in.-wide discharge conveyor on a portable all-electric chassis • Crusher is fitted with an overflow chute and removable overflow panel so the overflow can buffer feed surges in a closed-circuit application

ForConstructionPros.com/21135418

Superior Industries P500 Patriot Cone Crusher

The P500 Patriot Cone Crusher is engineered to operate most effectively at 500-hp with a head diameter of 59-in. maximum feed opening of 13.5-in. and closed side settings from 3/8 - 2-in. • Inverted or reverse design of tramp relief cylinders ensure the hydraulic seals are not exposed to contamination during operation • Tramp relief system designed with fewer accumulators for less maintenance. An automatic pressure relief valve means additional protection • Universal crushing chamber design requires no major, timeconsuming change outs when transitioning from secondary to tertiary applications • If loss of clamping pressure, counterclockwise countershaft rotation causes crusher to open rather than turn down, which can cause significant damage • Superior manufactures its full line of Patriot Cone Crushers in 200, 300, 400, 500 and 600 horsepower models

ForConstructionPros.com/21111775

Eagle Crusher 1200-25 CC Crushing Plant

The Eagle Crusher 1200-CC with Pre-Feeder Screen is designed for larger-sized jobs with high volumes of material at- or near-spec. • Two-deck screen-feed system greatly increases total production as the millings and fines go through the screen to stop wear and tear on the impactor and dramatically increase tonnage • Available in tri- or quad-axle versions, the two-deck inclined screen produces two cubical spec products