3 minute read

Providing effective service, repair and upgrade solutions for CNC machine tools

We are delighted in this issue of Industry Update to select Effective CNC Solutions Ltd as our CNC System Design Company of the Month

Effective CNC Solutions was founded in 2017 by Managing Director and experienced CNC Controls Engineer, Gary Pearce. Based in Crewe, Cheshire, the company is firmly positioned in the manufacturing sector for metal and composite machine tools, with a growing global customer reach across aerospace, defence, nuclear, oil & gas and R&D manufacturing.

The industry-leading company provides the following services:• Control system retrofits, upgrades, mechanical refurbishment, and through life servicing for high-value machine tool assets.• Bespoke machinery design and build.• Machine tending solutions – robotics and automation integration.

With a customer-centric approach, Effective CNC Solutions provides high-value solutions at lower costs, as Gary outlines, “We bring a wealth of experience from across the machine tool industry and due to our lower overheads, we pass all savings on to our growing customer base. With a focus on innovation, we have recently developed Evolution 600: an advanced 5 axis metal additive, milling/turning/ grinding hybrid machine capable of producing complex finish machined components from a clear build plate, in a single machine package.

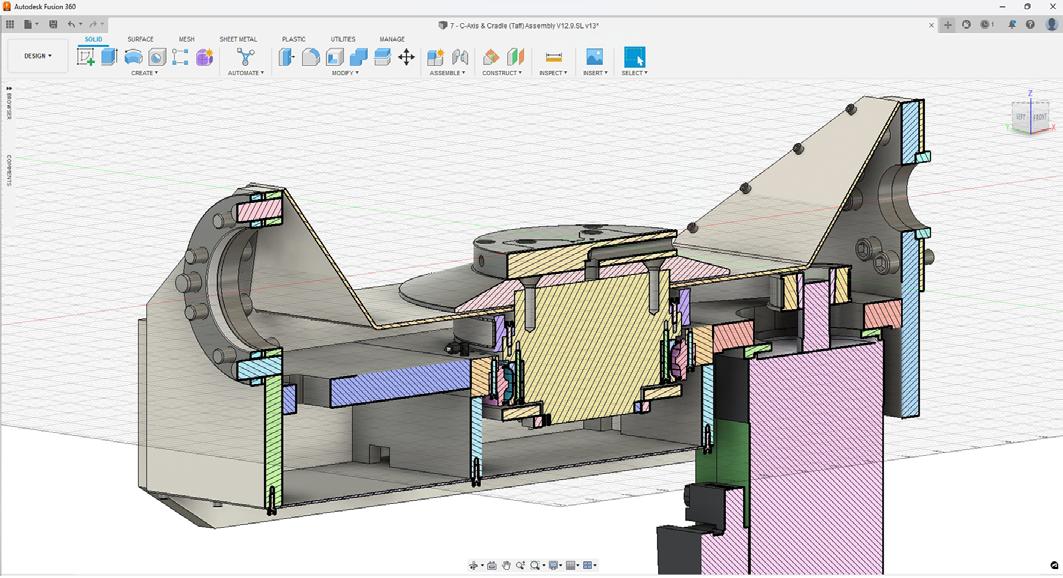

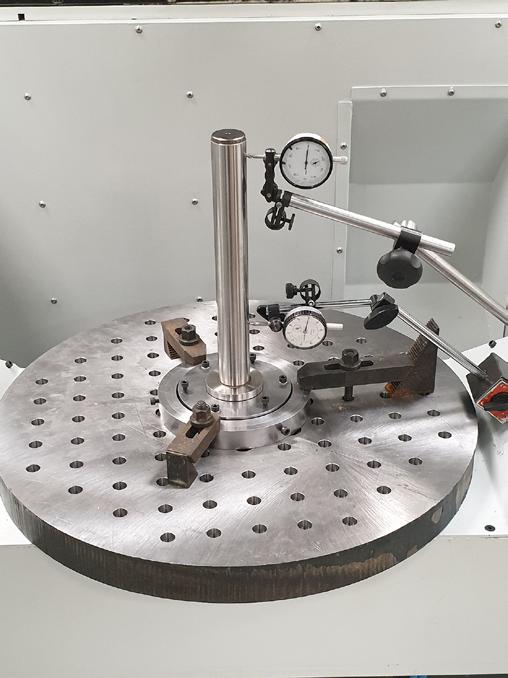

This patented new concept uses a 3-axis bed mill format with a 2-axis trunnion table to manipulate the workpiece in 5-axis around fixed position spindle, turning turret and WAAM additive head stations. Controlled by the powerful Siemens – Sinumerik One – CNC, and a bespoke tool probing system from Renishaw, this cutting-edge machine has unparalleled capability.

“Designed to manufacture components in excess of 800mm diameter or 600mm cube, using inverted workpiece horizontal milling spindle configuration for efficient swarf clearing, the hybrid process allows near net shape metal deposition for minimal material removal and wastage, saving raw material and tooling costs.

“We had the original idea for the design concept back in 2019 and it’s been a real labour of love, supported through Innovate UK grant funding and our partner: GB Engineering (Nantwich) Ltd. Throughout the COVID Lockdown, we focused on building a successful working machine, spearheaded throughout by state-of-the-art CAD machine technology.”

This first-to-market machine brings a bold vision: offering a comprehensive solution for manufacturing complex components in metal from a blank build plate to a finished product on a unique single platform. Concept machine tools have been traditionally demarcated into milling, turning and grinding separately, alongside the latest category of additive manufacturing. Some market designs have seen cross-overs between mill/ turn, mill/grind, turn/mill and mill/ additive but with limited capability. The Evolution 600 bypasses these limitations with its game-changing design, providing high-speed 5 axis milling, with accurate medium and low speed turning, versatile cylindrical grinding and 3D printing/additive manufacturing capabilities in a onestop unit.

“To reiterate, our new machine tool concept synchronises milling, turning and grinding formats into one single platform, seamlessly incorporating additive manufacturing capability – all without having to needlessly switch between different machine types. By extension, the Evolution 600 is perfectly placed for low volume, highvalue workpieces across aerospace, defence, nuclear, oil/gas/petrolchemical, medical and other related application.

“In the future, we are looking to create a training facility for machine tool engineering, to provide the highly specialised skills in the field of machine tool service and repair.”

To find out more about Effective CNC Solutions, see the details below:M +44 (0)7787 553251info@effectivecncsolutions.co.ukhttps://effectivecncsolutions.co.uk