2 minute read

TECHNOFORM USING THERMAL EDGE BOND SOLUTIONS cooperation with us –partnership

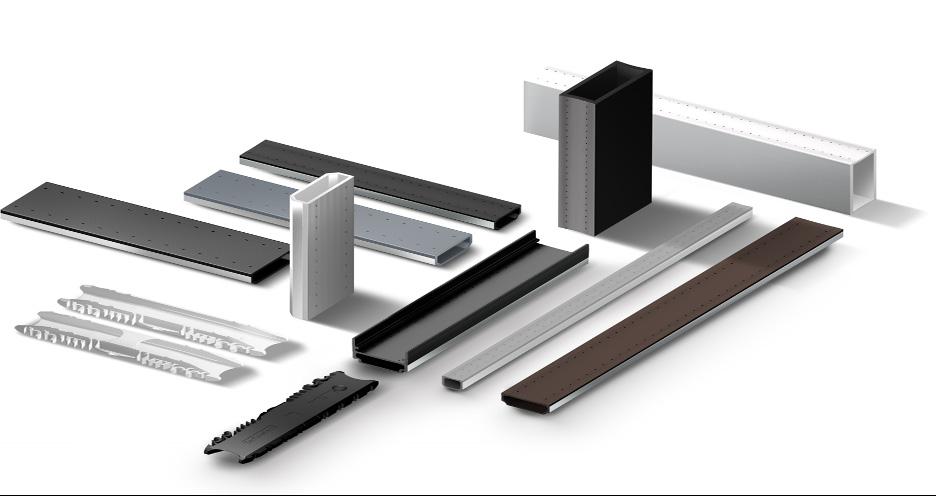

Technoform have perfected the manufacture of hybrid warm edge spacers from a combination pf precision engineered polypropylene and ultra-thin stainless steel, which wraps around the side and back elevation. A fully durable product, easy to process with zero moisture vapour and gas transmission. Technoform have developed this solution, fully certified to EN1279 with the ability to be processed through conventional cold bending equipment. The presence of specially engineered polypropylene bridging significantly reduces thermal conductivity. As a result, our range of hybrid spacers achieves the warm edge performance of a non-metal spacer, whilst maintaining the benchmark durability of stainless-steel box spacers.

High energy efficiency, long service life and indoor comfort are key factors to sustainable building design. High performance fenestration is a key component of delivering a comfortable and energy efficient built environment. To achieve this, a durable thermally and acoustically optimised edge bond for insulating glass is required.

Advertisement

than 50 and knowhigh-precision and in innovative solutions.

Warm edge spacers work by separating the panes of glass in double and triple glazing and made from low conductivity materials. The cavity created by the spacer reduces heat transfer across the centre of the glass, and the use of a Technoform warm edge reduces thermal conduction across the opaque area of the edge of the glass. By reducing the heat transfer at the edge bond, use of Technoform range of warm edge spacer translates into energy savings for buildings. The precision engineered hybrid spacer from Technoform delivers ultimate performance and lifelong gas retention.

Service

Technoform warm edge solutions set new standards in surface quality and match the most stringent building regulations and building owners requirements. Our hybrid warm edge spacers achieve excellent thermal and acoustic performance without sacrificing design, and most importantly, durability.

Technoform run a unique extrusion process which allows us to customise our spacer designs to your needs, whether you are commencing your transition into warm edge technology or require the highest thermal performance insulating glass. Designers also love the aesthetics of our warm edge spacers because of the attractive surface finish and full range of colours available. Our range of warm edge spacers are ideal across a full range of fabrication processes such as bending and cut & corner alongside our range of innovative connectors & corner keys. The flexibility of the Technoform spacer also makes it a go-to for radius shaped IGU’s such as arch tops and circular shapes.

Quality

Product Portfolio

We don’t consider you a customer, but a partner. With a global network of customer support and our three production sites, we are always near you and happy to advise you on all requests relating to the edge bond.

Our standard range of thermal edge spacers will soon be extended to include exciting new innovative solutions focussed on climate stress, PIB squeeze out, increased thermal performance and ranging from 6.2mm to 32mm in width. The current range of Technoform spacers includes a broad range of colours and spacer widths from 6.2mm to 32mm. Our West Midlands based warehouse is perfectly located to service all areas of the UK and we offer 1-3 day delivery as standard, as well offering a collection service if required.

Zero-defect performance and

Thinking future. Together. Contact us today: richard.john@technoform.com Tel: 07802 72 42 75 consistent quality. We are certified in accordance with DIN EN ISO 9001. Our products also comply with the requirements of applicable standards such as EN 1279, DTA, ASTM E2190 and help to obtain the RAL quality mark for windows, doors, and facades.

Bright Light into Living

Now

Kubu Kubu Smart Security Your Front Door is Unlocked

9:41 1 x door unsecure getkubu.com/trade