9 minute read

VBH (GB)

from Fendig Sep 22

Q-smart take up grows

Hardware manufacturer VBH, the company behind the greenteQ brand, has announced that customers who have added the Q-Smart electronic door handle to their door furniture options have seen increased sales recently.

Advertisement

Q-Smart is a stand-alone product that enables the user to gain entry to their home without the need of a traditional key. Instead, they can use their fingerprint, contact card or a phone app to gain entry. Locking is carried out by simply lifting the lever.

Temporary or permanent ‘keys’ can be sent to anyone from anywhere via the smartphone app, which is ideal for granting access to carers, or when family members need to be let in unexpectedly.

Companies who buy Q-Smart have the option of joining the Q-Smart Network, which is a list of companies that end users are directed to if they contact VBH for a Q-Smart quote or installation.

VBH advise that they have invested in direct marketing of Q-Smart to help provide free leads to the network’s members. Activities have included localised advertising and telesales campaigns, advertising in well-known national consumer titles, and even sponsorship in the 2022 British Touring Car Championship.

Gary Gleeson, marketing manager at VBH says: “The vast majority of our products mean absolutely nothing to the general public as they are just components on a window or door. Q-Smart is an exception, though, as it is a stand-alone item, and anyone can easily see what it does and what benefits it brings.

“With that in mind we decided to support our customer base by carrying out some B2C marketing, in a similar way to what we do with our Q-secure consumer security guarantee. We have picked up quite a few sales as a result, which is great for us and great for the members of the Q-Smart Network. Many customers have built on the work that we are doing, and have installed a Q-Smart in their own showroom. They are reporting that Q-Smart really is an attention grabber. We would recommend that installers talk to us about getting a sample in place as soon as possible.”

Companies wishing to join the Q-Smart Network should email VBH at marketing@vbhgb.com or send them a Tweet @vbhgb.

Your cooperation with us –a true partnership

Your cooperation with us –a true partnership

Know-how

Service

Quality

Know-how

We offer you more than 50 years of experience and knowledge in the high-precision extrusion of plastics and in the development of innovative warm edge solutions.

We offer you more than 50 years of experience and knowledge in the high-precision extrusion of plastics and in the development of innovative warm edge solutions.

Customer-specific solutions

We continuously analyze the requirements of our customers and markets to find solutions to current topics and to identify future trends. We can meet your individual requirements and propose solutions within the shortest possible time thanks to our unique production process.

We don’t consider you a customer, but a partner. With a global network of customer support and our three production sites, we are always near you and happy to advise you on all requests relating to the edge bond.

Support and tests

Service

We don’t consider you a customer, but a partner. With a global network of customer support and our three production sites, we are always near you and happy to advise you on all requests relating to the edge bond.

At Technoform, we test and evaluate our products based on applicable standards such as EN 1279, DTA, ASTM E2190 and also on your individual requirements.

Customer-specific solutions

We continuously analyze the requirements of our customers and markets to find solutions to current topics and to identify future trends. We can meet your individual requirements and propose solutions within the shortest possible time thanks to our

Zero-defect performance and standardized processes ensure our consistent quality. We are certified in accordance with DIN EN ISO 9001. Our products also comply with the requirements of applicable standards such as EN 1279, DTA, ASTM E2190 and help to obtain the RAL quality mark for windows, doors, and facades.

Fields of application

Quality

Zero-defect performance and standardized processes ensure our consistent quality. We are certified in accordance with DIN EN ISO 9001. Our products also comply with the requirements of applicable standards such as EN 1279, DTA, ASTM E2190 and help to obtain the RAL quality mark for windows, doors, and facades.

Support and tests

At Technoform, we test and evaluate our products based on applicable standards such as EN 1279, DTA, ASTM E2190 and also on your individual requirements.

Due to the perfect combination of material and form, our products significantly reduce the heat flow via the edge bond and are ideally suited for use in windows, doors, and facades. They are also suited for fire-resistant glass (E, EI, and EW). Our wide range of widths guarantees that our products make a decisive contribution towards sound insulation.

Fields of application

Due to the perfect combination of material and form, our products significantly reduce the heat flow via the edge bond and are ideally suited for use in windows, doors, and facades. They are also suited for fire-resistant glass (E, EI, and EW). Our wide range of widths guarantees that our products

Award nominations, smart products and clever campaigns

Marc Henson, Head of Marketing at Kubu, talks about several award nominations and why you should “Be Smart, Vote for Kubu” We started our journey nearly 3 years ago as a pioneer in the industry for smart sensor technologies in windows and doors and it’s safe to say we’ve achieved a great deal in a relatively short space of time. Kubu is the number one choice for both manufacturing partners and savvy installers as the go to and trusted brand when it comes to smart tech.

Our ‘Be Smart, Work With Kubu’ campaign has been a revelation this year culminating with the FIT Show and recent launch of the window sensor which is already being fitted and activated as standard by a growing number of installers nationwide. We’ve been nominated for Digital Marketing Campaign of the Year and Best Use of Video in 2022 in the National Fenestration Awards and are also a finalist in the G-Awards for Promotional Campaign of the Year – the first time a smart business of this nature has been nominated for multiple trade awards.

So, what is the “Be Smart” campaign?

Cast your mind back to the lead up to the fit show, throughout the show and the immediate aftermath, the general consensus was that we were everywhere. One customer was quoted as saying “What on earth are you doing? I can’t go anywhere without seeing Kubu!”

Developed as a double-entendre, the ‘Be Smart’ campaign was developed to motivate Installers & Fabricators to welcome ‘Smart’ into their business, but also to encourage them to make the right decision on their Smart Partner. Their products and business can “be” smart by working with Kubu, but also they should make the smart decision and work with Kubu! Additionally, it complements the “Works with Kubu®” messaging that is assigned to all products - from hardware to finished windows/doors - that are designed for Kubu smart security.

How did we do it?

With so many, very different product developments and partnerships being announced, it felt like our messaging was in danger of becoming rather disjointed. To create the biggest bang, it was important to create a streamlined campaign to cohesively blend multiple product, benefit and brand partnership messages through one unified, multi-level campaign targeting fabricators, installers and consumers alike.

The culmination of years of hard work in both product development and sales, our “Be Smart, Work with Kubu” campaign introduced industry first products, partnerships and benefits, through high-energy and high-quality videos, posts, party, POS, and PR - all with one crystal clear message, giving our customers even more reasons to “Work with Kubu’.

OK. Blah, blah, blah, just cut to the chase… Did it work? Well, we certainly like to think so!

We had one of (if not the) largest footfalls on our stand at the show (in fact, others even commented that their show was a success because they were next to us); We had insanely good analytics stats (30%+ engagement rates, 28.5% click-throughs, 500%+ increase in page views, you get the picture…); And, we walked away with over 200 qualified leads which we have been consistently converting them ever since!

All because we drove awareness and desire through our digital campaigns and video production. If you liked our content and would like to see more, please head on over to place your final votes.

We’ll buy you a drink if we win. Promise!

Now

Kubu Kubu Smart Security Your Front Door is Unlocked

9:41 1 x door unsecure getkubu.com/trade

Vote for Bereco in the 2022 National Fenestration

Timber window & door supplier, Bereco, announce industry-leading accreditations

Bereco have just announced the successful passing of their annual BlueSky certification audit. The thorough process involves a third-party examination of the products’ weather performance, security, manufacturing, paint application, production processes and material sourcing. These factors, among others, give purchasers a heightened level of confidence in Bereco products’ quality and sustainability.

Bereco also passed their annual Forest Stewardship Council audit, renewing their FSC100% chain of custody certification. This denotes Bereco’s wooden windows and doors are made solely from FSC® 100% certified timber, continuing the company’s ongoing commitment to tackling deforestation.

Nicola Harrison, managing director at Bereco commented, “Sustainability and quality certifications mean so much to us here at Bereco - because we know how much they mean for our customers and the planet. Our BlueSky and FSC accreditations certify our commitment to these causes and are unrivalled in the industry. As regulation evolves, builders, developers and architects must look to suppliers with these accreditations as reputable, reliable and trustworthy partners to avoid unwanted costs and non-compliance.”

Being leaders in the industry, Bereco aims to educate and champion more sustainable practices throughout the supply chain. Their most recent efforts include a series of webinars for industry professionals to give an understanding of 2022’s building regulation update with regard to Approved Documents L, F and O. Praised by attendees for their accessibility, relevance and expertise, the webinar series is free to attend with more sessions throughout the autumn.

To register, visit - www.bereco.co.uk/professional-learning

VOTING IS STILL OPEN!

This year we have been nominated for four National Fenestration Awards! This includes ‘Composite Door Manufacturer of the Year’ and a ‘New Best Product’ nomination for our most recent development the Avantal range, which has huge consumer appeal as homeowners across the UK look to invest in their properties with a next generation, smooth skinned door. In addition to that, our very own Alan Hague, our representative for the south of the UK, has been nominated for ‘Business Development Manager of the Year’.

Please consider voting for us in the following categories, your support would be very much appreciated!

WHAT WE’RE NOMINATED FOR

COMPOSITE DOOR MANUFACTURER OF THE YEAR

BUSINESS DEVELOPMENT MANAGER OF THE YEAR ALAN

VOTE FOR US BY SCANNING HERE

Thermlock® V Polyamide, the difference is clear

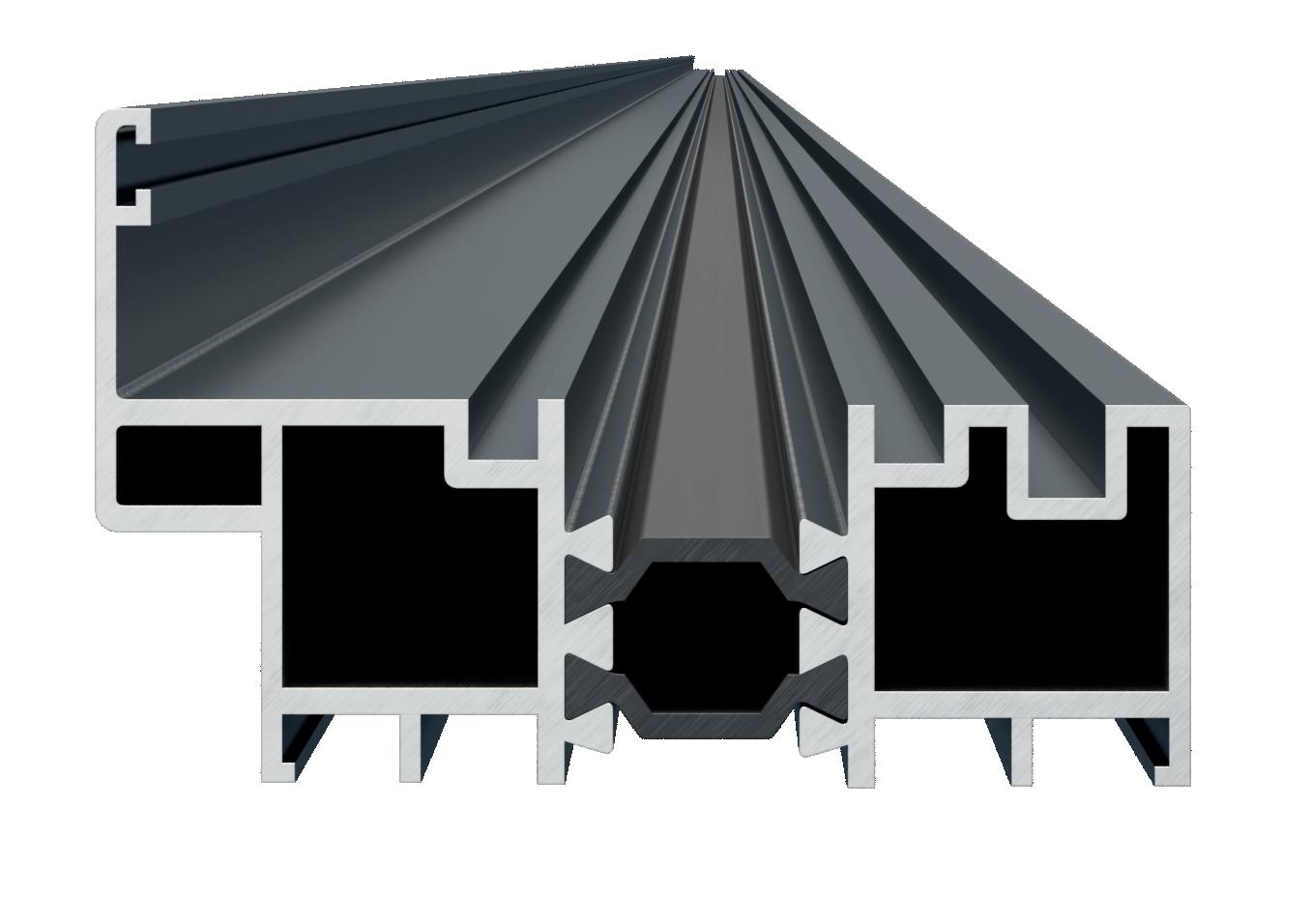

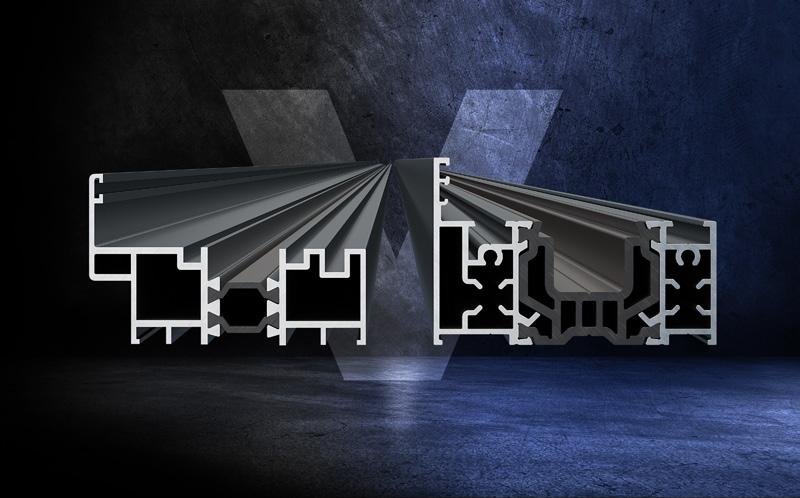

When the foundations for the Sheerline system were laid, one of the weaknesses of existing aluminium systems that needed addressing was the sectors reliance on polyamide thermal breaks.

While polyamide did create a ‘thermal barrier’ that met older thermal efficiency standards, the material struggled to meet the improved standards required by the UK’s carbon reduction commitments. This need to improve the energy efficiency of the nation’s homes has never been clearer than it is right now, with the average household energy bill set to rise to a staggering £3,549 this year, with further increases forecast in 2023.

From the start it was clear that a better solution was required, a thermal break designed for more stringent legislation, that also overcame some of the other inherent limitations of polyamide. It was this need that led to Thermlock®, one of the eureka moments for Roger Hartshorn and his R&D team, when they created the Sheerline system in 2018/2019.

Thermlock® multi-chambered thermal breaks are unique to Sheerline and sit at the heart of every Sheerline product. Made from a special high melting point formulation, which is almost half as thermally conductive as polyamide, Thermlock® allows for wider, integrated one-piece designs that add rigidity to profiles, eliminating the distortion that can occur with separate top and bottom polyamide thermal breaks. This means that every Sheerline product meets the new Part L standards with regular double glazing – helping customers supply high performance products without adding cost. With Sheerline, Part L compliance comes as standard.

While other systems companies are busy trying to shoehorn solutions into their legacy systems, either adding cost via foam inserts or forcing customers to ‘upgrade’ to expensive triple glazing, or much wider systems to meet these new standards, Sheerline customers are left with a competitive advantage and a clear easy to understand, and perfectly matched product offer.

Drawing on their years of experience within the fenestration industry the Sheerline team also knew Thermlock® needed to be as fabricator and installer friendly as possible and its improved screw retention over polyamide helped Sheerline systems pass the most rigorous of tests with ease.

Having already invested over £1million in tooling for its own in-house produced Thermlock® thermal breaks, Sheerline and its customers are already benefiting from the clear advantages this technology brings with better performance and integrated onsite manufacture minimising the risk of third-party supply issues. Coupled to the ability to react quickly to any future tightening of thermal requirements, Sheerline customers can be confident they’ll be ready once again to succeed in an ever-changing marketplace.

To give yourself the Thermlock® advantage and discover more about Sheerline’s innovative aluminium range contact us on 01332 978000 or email info@sheerline.com. Alternatively visit www.sheerline.com for more information.

METICULOUSLY

No1 VS Fabricator in the UK

BY

Graf Weld or Fully Mechanical

PAS 24 and Secured by Design

Energy Rated ‘A’