3 minute read

From sand to post

Summit Steel & Wire’s fencing products are world renowned for their durability and marketleading quality.

Made in Christchurch, using only the highest quality raw materials in their state-of-the-art production facility, Summit has tried and proven its XFence, Pro Fence and Summit product ranges in the harshest conditions and most testing applications across the globe.

Advertisement

But what is it that separates their products from the rest?

Summit Steel & Wire’s primary wire supplier, InfraBuild Wire, has a long and proud year history in wire production – over 100 years– and has been manufacturing high quality fencing products for the Australian and international markets.

InfraBuild is a fully integrated steel manufacturer with control of its upstream raw material inputs thereby maintaining strict control over the quality of the steel rod that is its key input to wire manufacturing.

Steel is sourced from the Whyalla Steelworks in South Australia’s Middleback Ranges, 400km North-West of Adelaide where 1.2 million tonnes of iron-ore is produced every year and turned into commercial grade billet feed.

The billet is then sent to a processing plant, in the New South Wales beach town of Newcastle where the billet is turned into the class leading wire used in Summit’s products. LEADING THE WAY

InfraBuild Wire are also a leader in galvanised wire production technology operating a number of galvanising lines with a significant portion of their capacity reserved for production of the corrosion resistant Zinc/Aluminium coated wires. This is the zinc/aluminium wire that Summit uses in its Xtralife™ fencing products. In the Newcastle processing plant, the billet is rolled into its final wire form. Then it is sent through for its two gas wipe layer coatings of zinc/aluminium. The gas wipe coating differs from other ways of manufacturing, as it allows the wire an even spread of the zinc/aluminium layer. Other methods can leave an uneven coating which promotes patchy wear and the potential for rust to appear sooner.

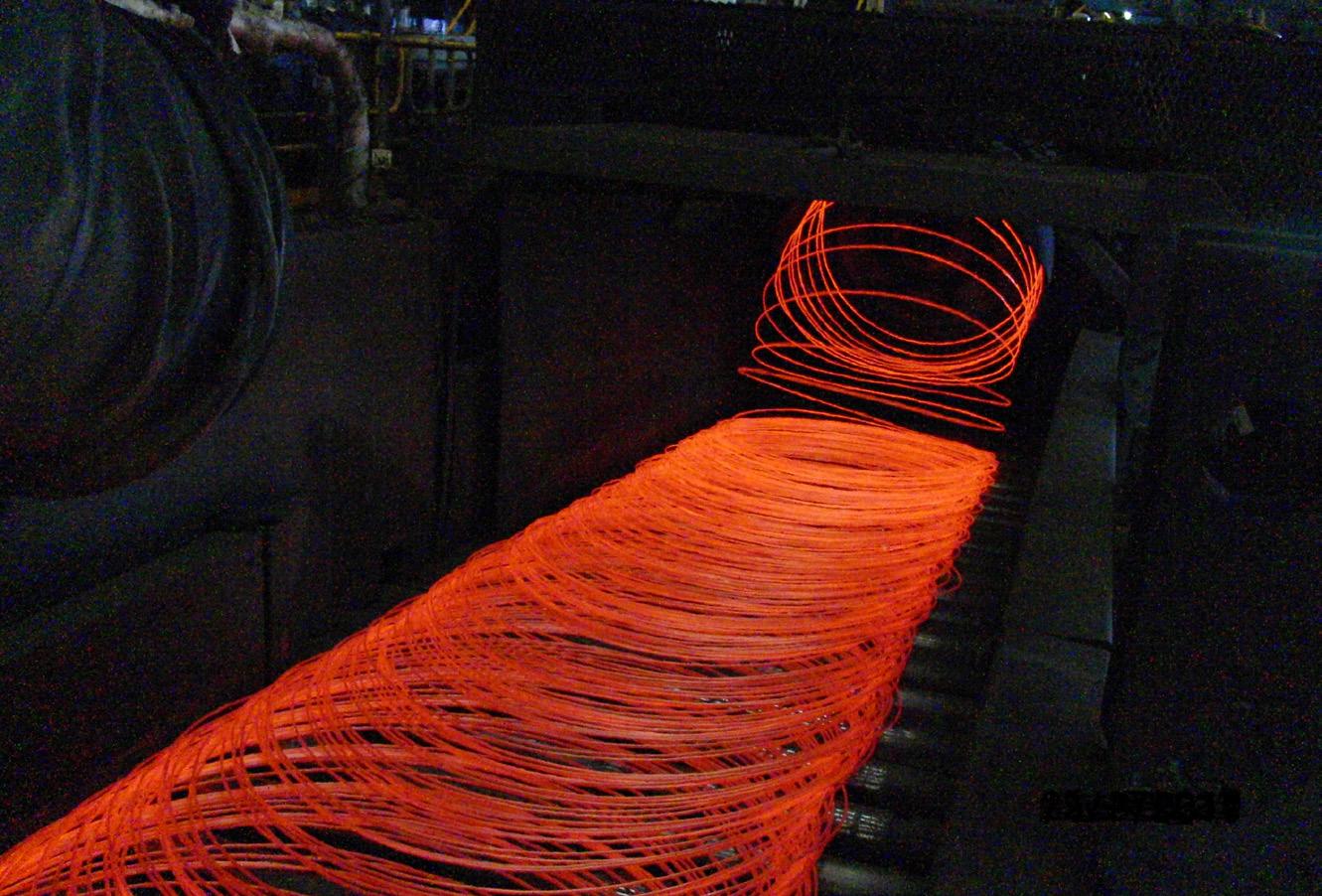

Red hot billet on the production line

Close up view of production site

Raw materials sourced from the Whyalla Steelworks in South Australia's Middleback Ranges

Summit Steel & Wire coils in production

Between the two even coatings an intermetallic barrier layer forms around the wire, this can lead to up to three times the lifespan from equivalent zinc coating on wire. The separate coatings provide both galvanic and barrier protection by creating an oxidising electrolytic cell, with the steel wire protecting it from any harsh environment. More common processes only use a zinc alloy coating for the wire which doesn’t provide as much protection, as well as being less ductile and more prone to cracking, all of which reduces the overall lifespan of the wire.

CERTIFICATION

InfraBuild Wire has held ISO9001 Quality Management Systems certification for many years and closely monitors the quality of its wire products via its NATA accredited testing laboratories. Each parcel of wire destined for use by Summit Steel & Wire is tested for tensile strength, diameter, coating adherence and coating weights.

The wire is shipped to Summit Steel & Wire’s manufacturing plant in Christchurch. This plant is home to many state-of-the-art fencing machines that operate 24 hours a day manufacturing thousands of tonnes a year of coiled wire, fabricated netting, fencing staples, and barbed wire for the domestic and international markets. Strict traceability processes are achieved from the procurement of raw feed and right through its manufacturing processes assisting Summit to provide world-class levels of quality assurance and control.

All the above ensure’s that both Summit Steel & Wire and its customers can have the utmost confidence in the quality of the fencing products they are working with.

If you would like to learn more about our products and services get in touch with your local Summit territory manager to help you with your next project.