35 minute read

Livestock

Optimising suckler her d per for mance with strategic supplementation in final stages of pr egnancy

The final six weeks of pregnancy are key to supporting short and longterm performance of suckler herds, says Dr Alison Bond, nutritionist for Rumenco. “At this point in time, cows should be maintaining a body condition score of 2.5-3 with the nutritional focus shifting towards supplementation for colostrum development and prevention of metabolic issues that can lead to complications such as difficult calvings and milk fever,” explains Dr Bond. Meeting these critical nutritional requirements can be done with a multipurpose product like LIFELINE PreCalver, balanced with vitamins, minerals, trace elements and specialist nutrients in the form of mannan-oligosaccharides and beta-glucans. Importance of Colostrum Colostrum is the sole source of antibodies for disease resistance in newborn calves, with quality and quantity of colostrum being essential for priming the immune system to prevent youngstock illness such as scour and respiratory disease. “Colostrum quality should be at least 50g/l of IgG or a 22% BRIX reading and can be influenced as it starts to develop in the final five to six weeks of pregnancy – with the final two weeks having the greatest impact,” says Dr Bond. In a farm study validated by Harper Adams University College, a high performing spring calving herd in Shropshire was found to have a 9.46% increase in colostrum immunoglobulin over the control group when fed LIFELINE Pre-Calver. Colostrum management is equally critical, says Dr Bond, with a calf’s ability to absorb IgG antibody molecules reducing from 40% at birth to less than 5% after 20 hours. “To ensure the passive transfer of antibodies, calves require three litres of colostrum (or 10 percent of body weight) in the first two hours of life, followed by similar size feed within 12 hours. For a suckling calf, this requires around 20 minutes of continuous suckling, which can be difficult to achieve” says Dr Bond. “Emphasising colostrum quality and management will have a significant impact on the long-term health and performance of the herd.” Mobilising calcium and preparing for labour Another essential nutritional focus in the final stages of pregnancy is to increase magnesium levels while simultaneously decreasing calcium. “Milk fever (hypocalcaemia) is a common issue in suckler cows at calving. As soon as a cow calves down and starts milking, her body is going to have massive calcium requirements. While she should have plenty of calcium available in store, she won’t be able to access it quickly enough if it is tied up in bone, which can often lead to milk fever,” says Dr Bond. By reducing calcium supply in the diet in the weeks leading up to calving while increasing magnesium, a cow’s calcium reserves will become mobilised so she can access it more quickly at calving time. Research from SRUC has also indicated that magnesium is critical to aiding uterine contractions to help shorten the birthing process. “The combination of supplementing with magnesium while pulling back calcium has proven to be an effective way of switching on the system to start pulling available calcium from the bone to be made more available to the cow postpartum while simultaneously supporting the birthing process,” explains Dr Bond. The vital role of trace elements In many suckler systems, poor quality silage is reserved for the herd’s winter ration, making it essential to give them a lift in nutrition in the final stages of pregnancy. According to Dr Bond, trace elements are an essential part of this equation, directly impacting the calf’s immune response and vigour, along with the cow’s future productivity. “Vitamin E supplementation is essential during this time to maintain the cow’s health in the run-up to calving and both her and the calf’s immune system postpartum. It also has a huge influence on colostrum quality,” says Dr Bond. “Selenium is another essential trace element ahead of calving to develop brown fat in the calf, which supports vigour at birth.” To support the cow’s future fertility, she recommends producers ensure copper requirements are being met with multiple copper sources to avoid nutrient lock-up and to trigger the luteinising hormone which plays a key role in fertility post calving. “In these last weeks running up to calving and shortly after, a cow is going to have a lot of stress put on her system as her nutrient stores are utilised to support the final stages of foetal development while starting the production of colostrum,” says Dr Bond. “A multi-purpose supplement like LIFELINE Pre-Calver helps fill all of those final nutrient requirements to prepare her to give birth to a healthy and thriving calf.”

Beef producers can finally plan ahead with confidence, following the launch of the world’s first smart, datadriven beef contract which sets a secure price 24 months ahead. In a development which is set to transform the British beef industry, Breedr has launched the UK’s first ever long-term minimum-priced contract based on lifetime animal data. With price certainty giving producers confidence to invest, and the data used to improve efficiencies throughout the supply chain, this will not only reduce the industry’s environmental footprint but also improve the consistency and quality of the end product. In addition, the team has launched a new risk-free way to buy and sell livestock, based on lifetime animal data and weights. The Breedr live trading platform means producers can buy and sell through the free app with certainty, with a price guarantee in case of any differential in the weight of weaned calves and stores between farms. Sellers are also ensured payment within 72 hours of collection, and trades will be commission free until later this year. “As beef producers ourselves, we know how tricky it is to plan ahead with confidence – one batch of bad calves can ruin a farm, as can a downturn in the beef market,” says Ian Wheal, founder of Breedr. “But by making better use of data we can buy and sell with transparency, predict growth rates, and know that we’re supplying the processor with what they want – ensuring a secure end market and price.” The contract is worth more than £130m to British beef producers over the next seven years, offering a 24-month minimum price for any cattle with lifetime data, with producers also receiving a proportion of any uplift in price above that. Rearers can opt to be paid on a per kg growth basis, eliminating the need for capital outlay on youngstock, while advanced payments are available to smooth cash flow.

“With Brexit, the whole food industry is facing an uncertain time – but British agriculture is innovating to meet UK and global needs,” says Mr Wheal. “Being able to plan ahead with certainty finally gives farmers the peace of mind they need to invest and build profitable businesses.” Farmers using the free app are finishing animals five months earlier than the industry average, with 24% more carcasses reaching the target specification. They are saving 1.8t/head in feed and reducing their carbon footprint by 20%, he adds. Adam Quinney, chair of beef and lamb at AHDB, says: "At AHDB we are very supportive of technology that is helping bring certainty, and collaboration between farmer groups in the supply chain. The benefit of these supply chains encourages improvements to genetics, farm productivity and therefore environmental impact in the long term.

Breedr is a good example British innovation utilising technology to develop supply chains for farmers and processors alike."

The network now has over 2,000 members and 120,000 registered animals across the UK, many of whom are joining forces to create integrated supply chains to further improve efficiencies. By collating data on genetics, growth rates, health, and carcass grades, producers can identify the most productive breeding lines and management methods, optimising productivity throughout the supply chain. “We run regular webinars for our members, bringing in expert speakers to help farmers improve efficiencies every step of the way,” says Mr Wheal. “This is a true community of forward-thinking farmers, who are sharing their own top tips and forming robust business partnerships. Together, farmers have the power to drive this positive change.” For more information visit www.breedr.co

British beef suckler farmers will be able to share realtime cattle data with their vet while in the field thanks to a new mobile app. Created by the Veterinary Services team at Scotland’s Rural College (SRUC), the Herd Health Planning app enables farmers to collect and record data as events occur – and immediately share this with their vet. Vets can then analyse the information and help farmers set priorities, and improve efficiency and animal health, through the health planning process. The app - which is free for Scottish farmers registered to the Animal Health Planning System (SAHPS) and available to others for a small subscription includes an e-medicine book which complies with farm assurances and other statutory requirements. It is also connected to the British Cattle Movement Service’s tracing system (BCMS), meaning cattle records such as births, deaths and movements, can be updated instantly. No internet is required to record events, with all data stored locally on the app and sent to both BCMS and SAHPS systems as soon as Wi-Fi and/or mobile data become available. The Scottish Government-funded app, which is now downloadable for Android and Apple devices, allows farmers to: • Provide early communication of herd health to their vet • Download all cattle currently on the holding through BCMS • Record bulls in/out dates • Record movements, births, deaths and upload to BCMS • Record disease incidents and production data • Record animal treatments, creating the e-medicine book • Record and save data off-line • Enter information once and use it multiple times Health Planning Development Manager Dr Foteini Manolaraki said: “We recognise that time is a precious commodity for today’s farmers. Rather than taking notes while out in the field or in the shed and then copying them into the computer, this new app allows them to share their cattle data with their vet while on the move. This information is then shared multiple times via BCMS and SAHPS software, which could allow earlier vet intervention if necessary.” For more information or to sign up to the app, visit: www.sahps.co.uk or email: enquiries@sahps.co.uk

Galebr eaker launch new tube ventilation system to help r educe livestock heat str ess

G

alebreaker have launched a brand new tube ventilation system for farmers looking to combat the negative effects of heat stress on livestock. The VentTube Cool – the latest addition to the successful VentTube range –provides a chill effect and replenishes barns and sheds with clean, fresh, equally dispersed air at animal level. Fully retractable and more cost efficient than traditional fans, it addresses and solves the damaging impact of high ambient temperatures and damp environments on milk yield, fertilisation rates and animal comfort. "The VentTube Cool has a unique design which allows it to distribute clean fresh air and provide a stable environment for livestock," says William Johnson, Sales Manager at Galebreaker. "With strategic air holes running down its length, the VentTube Cool quickly and easily optimises air circulation and removes the problems associated with traditional fans. The result is significantly improved animal productivity and far less instances of respiratory disease." The VentTube Cool is a perforated retractable tube inflated by a specified fan. The fan, mounted to an outside wall, draws fresh clean air into the building which passes through a horizontally mounted tube. By providing outside air, internal bacteria and polluted inside air is pushed out of the building by the positive pressure principle. Strategically sized and positioned openings then direct the air giving a consistent airflow. The innovative Retraction System, unique to the VentTube Cool, reduces the surface area of the tube and minimises the risk of damage from crosswinds.

One customer said:

"We have been running the VentTube Cool constantly since it was fitted and the results have been noticeable. This winter we had less instances of pneumonia, which we believe was due to better ventilation and movement of air in the building. During the autumn and winter months when the air outside is cold and still, we found that the VentTube Cool helped to push the stale, warm air out and bring in fresh, clean air." To find out more about the VentTube Cool, contact the Galebreaker Sales Team at marketsupport@galebreaker.com NEW MILK VENDING MACHINES AT CONNAGE HIGHL AND DAIRY

Connage Highland Dairy, based at Ardersier near Inverness, have this week opened their brand new 'Connage Express' vending machine operation. Selling their own organic milk, both prebottled and also for self-service customer refills, is relatively new for the dairy which is better known for its range of multi-award-winning organic cheeses. Open from 7 am until 7 pm, 7 days a week, and accepting cash as well as cards, the express machines not only sell Connage produced milk and cheeses but also products from other local businesses such as eggs and bacon as well as chutneys, biscuits, honey, coffee and more. Milk customers can buy a pre-filled bottle of milk or purchase a 1-litre bottle to refill themselves each time they return. Connage bottled milk is also now available to customers of Ardersier based Macleod Organics as part of their box delivery scheme. Connage Highland Dairy Owner, Jill Clark, said: "Whilst many customers still come into The Cheese Room where we stock a vast range of cheeses and other items, and many of our customers from further afield shop online, many people just want to come to a vending machine and take something away quickly. The fact that the Connage Express is open for longer hours than the shop also fits around people's busy lives. "During our first few days of opening we have seen a fantastic flow of cars coming along and customers seemed to be really enjoying the experience. The range of items is large enough that everybody can find something that they will enjoy and I think that people enjoy getting local, quality products in an easy and efficient way." Visit www.connage.co.uk to find directions to the farm or for more information about Connage Highland Dairy.

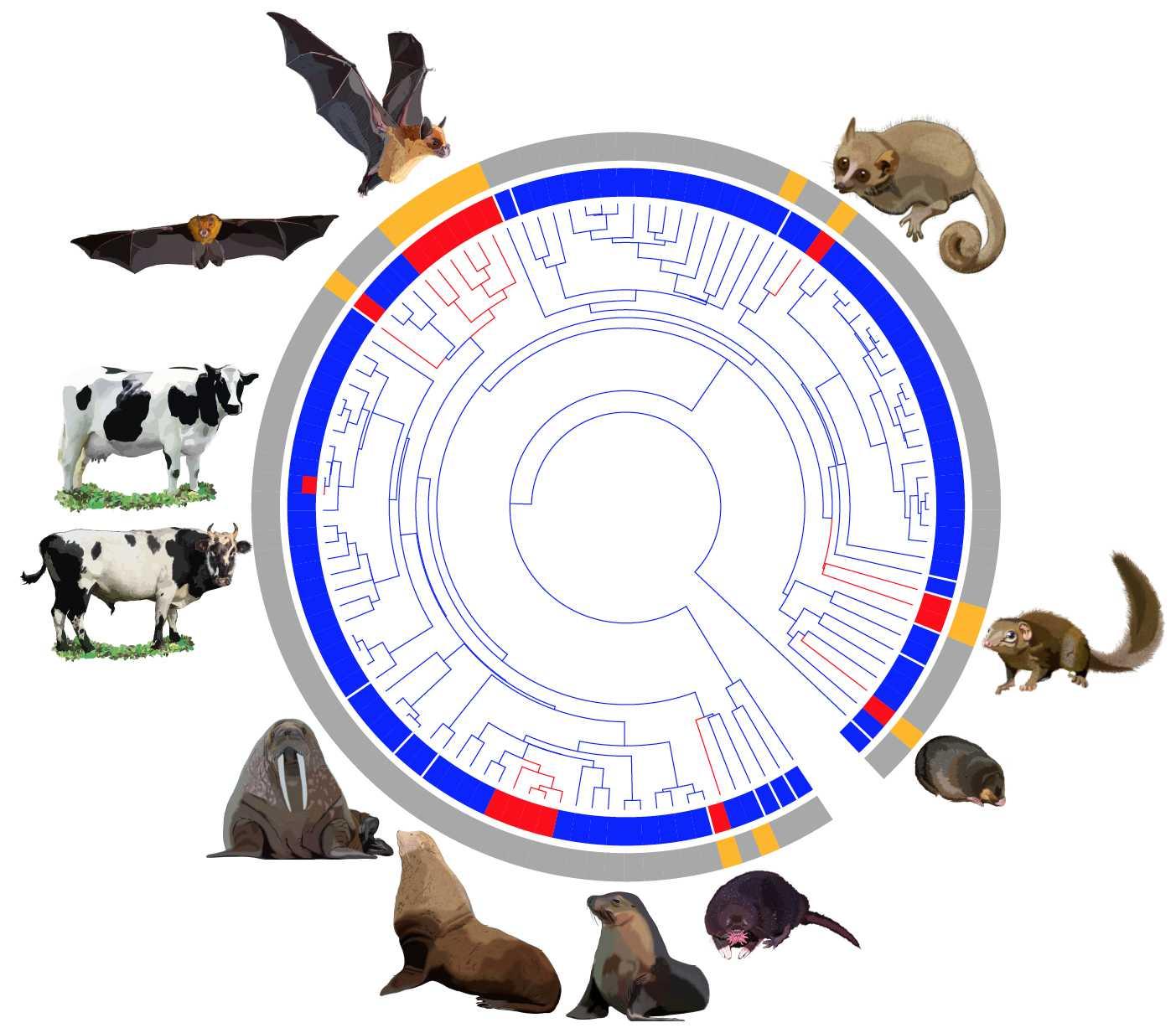

| Livestock New r esear ch fr om the RVC explor es the genetic adaptions and evolution of livestock and wild animals in r esponse to extr eme climates

New research from the Royal Veterinary College (RVC) and the Institute of Cytology and Genetics in Novosibirsk, Russia has identified the genetics of extreme climate adaptation which help the world’s most northern Yakut cattle population in Siberia survive their extreme cold environment. This work, published in Molecular Biology and Evolution, paves the way for a greater understanding of how livestock and wildlife are coevolving to adapt to climate change.

While the origins of Yakut cattle are unknown, this population, which can be found up to 200km above the Polar Circle and survive temperatures as low as -70 degrees Celsius, has had little interbreeding with other cattle populations, or closely related species such as yak, bison and guar. With their last common ancestor traced to European cattle breeds from approximately 5,000 years ago, researchers have surmised that the adaptations to extreme cold climates found in Yakut cattle are mostly derived from their own genetics. It was also found that Yakut cattle share many genetic variants which are similar to those found in Asian and African cattle breeds, but not those found in Europe. The research, led by Dr Denis Larkin, Reader in Comparative Genomics at the RVC, also found that these genetic variants likely represent the ancestral alleles, or variant form of genes, that have been lost in European cattle due to human selection and breeding for milk and meat production. However, retaining these variants has enabled Yakut cattle to adapt to changing environment conditions and extreme cold. The findings also suggest that the same genetic variants could help cattle breeds in Asia and Africa to adapt to their own challenging climates. While sharing some traits with Asian and African counterparts, one finding did differentiate Yakut cattle – the presence of one specific high-frequency coding nucleotide variant, which changes protein features. This particular variant was not found in any of the more than 100 other sequenced cattle breeds, nor the ancient DNA samples from closely related species from Siberia, excluding possibility of introgression. This mutation affects a highly evolutionary conserved position in the nebulin-related-anchoring protein (NRAP), which links actin filaments in muscles, including heart muscle. Interestingly, from the more than 100 mammals studied, only 16 species displayed the same change, likely enabling them to hibernate, enter torpor, deep dive or adapt to the cold. Convergent evolution at the same nucleotides is rare and, before this study, were reported for different species only. For example, in bats and dolphins the same mutation is present in a gene involved in echolocation, while multiple fish species have a mutation in the protein called rhodopsin, to adapt to different marine and freshwater light conditions. This research suggests however, that a convergent evolutionary change has occurred at the same nucleotide of the NRAP gene in many cold-adapted species and a single northernmost cattle breed. It has therefore discovered that convergent evolutionary changes can form quickly in breeds of domesticated species, likely providing them with features absent from the rest of the species. There are multiple studies showing that NRAP is involved in climate adaptations in mammals, reptiles, and even fish. However, this research has now discovered that it is involved in adaptation to cold climates in the Yakut cattle as well. Interestingly, work on humans and mice shows that mutations in NRAP cause cardiomyopathy, a disorder when pumping ability of the heart is altered. Dr Larkin and Dr Laura Buggiotti, Bloomsbury SET Innovation fellow at the RVC, hypothesise that a similar mechanism could help the heart in cold adapted and deep diving species, pumping blood more efficiently when it is cold. Given the growing body of research highlighting the link between climate change and extreme weather, the research could mark an important step in mitigating the worst effects of extreme cold in the context of livestock farming. Dr Denis Larkin, Reader in Comparative Genomics at the RVC and who led this research, said: “This study is a breakthrough because it shows for the first time that convergent evolution acts not only at the species level but on the human-made breeds as well. It is amazing to see that exactly the same amino acid change has formed and become nearly fixed in a single breed of cattle adapted to extreme environment and 16 species of mammals.” Dr Laura Buggiotti, Bloomsbury SET Innovation fellow at the RVC and first author on the paper, said: “The Yakut cattle still holds a lot of mysteries but now we know it is very close to the ancestral cattle population and contain genetics which made them adaptable to extremely cold temperatures. This is something we need to pass to other breeds to be able to survive climate changes”.

Supplementing to suppor t fer tility and milk pr oduction on grass

Strategic use of rumenprotected fat supplements help meet energy requirements and support milk quality As grass growth takes off in the early part of the grazing season, nutrition focus tends to be on completing the transition from the winter TMR to a grass-based diet without succumbing to post-turnout milk fat depression. While this remains important, fertility also needs to be made a priority, says Dr

Richard

Kirkland, ruminant nutritionist for Volac Wilmar Feed Ingredients. “For spring calvers, there’s a short window to support a cow’s body condition to help secure her getting back in calf. During early lactation, cows cannot eat enough to meet the high energy demands of milk production and enter a state of ‘negative energy balance’, using energy from body fat stores to support the genetic drive for milk production, and lose condition. Research indicates a fall-off in conception rate of around 10% for each 0.5-unit loss in condition through this period,” explains Dr Kirkland. Early spring grass can support reasonably high levels of production though intakes can vary considerably depending on weather conditions, putting pressure on energy intakes. “Perfect grazing conditions may support 25+ litres of milk per day, but dry matter and energy intakes can be significantly reduced in wet, overcast conditions. We can see similar effects in the peak of summer where grass availability and heat stress will reduce intakes,” says Dr Kirkland. Milk fat is also a challenge to maintain in this period as the low fibre, high sugar, high unsaturated oil levels disrupt rumen activity and lead to conditions where milk fat production is not favoured. “While early grass growth may be akin to rocket fuel, it is more rapidly fermentable which will cause disruptions in rumen pH and pass more quickly through the digestive system. These conditions lead to an increased risk of acidosis and along with the high oil loads a significant milk fat depression,” says Dr Kirkland. Strategic use of rumen-protected fat supplementation in buffer rations According to Dr Kirkland, using a combination of digestible fibre sources and rumen-protected fat supplements in buffer rations will help protect milk production and support fertility in early lactation. “Rumen-protected fat supplements have around 2.5-times the energy content of cereals, making them ideal to help maintain energy supply through variable springtime grazing conditions while reducing undesirable rumen effects through the transition from the winter diet to the spring grazing scenario,” he says. To support both fertility and milk production during this time, Dr Kirkland advises feeding a rumen-protected fat supplement with a research-proven ratio of C16:0 (palmitic acid) and C18:1 (oleic acid) to strategically influence the partitioning of nutrients between milk and body condition. “Fatty acids, the building blocks of fat supplements, influence the partitioning of nutrients to specific areas of cow performance, enabling producers to choose supplements according to milk contract requirements at particular stages in the lactation cycle,” explains Dr Kirkland. During the early lactation period C18:1 (oleic acid) is a key fatty acid, increasing partitioning of energy and nutrients to improve body condition as well as improved development of fertilised eggs. However, given the challenges of early spring grass, products containing higher levels of C16:0 (palmitic acid) can be considered as effective ingredients to increase milk fat production. “Careful choice of supplements is essential at grazing to provide those vital megajoules of energy in a form that stimulates the rumen and milk fat production,” Dr Kirkland concludes. “Selecting a rumen-protected fat supplement such as Mega-Max, farmers can support both fertility and milk production performance while helping ensure energy demands are being met.”

Chicken donations cr eate 55,000 meals

Donations of chicken equating to 55,000 meals have been shared with some of the country’s most needy charity groups. More than 23 tonnes of poultry, from Scotland’s Rural College (SRUC) and poultry breeding company Aviagen, have been donated to the food redistribution charity FareShare. The donations of chicken breasts and legs, from the SRUC/Aviagen poultry processing plant in Edinburgh, started in April 2020 and have continued throughout the coronavirus pandemic to alleviate stock pressures caused by the closure of hospitality and food services during lockdown. FareShare has then redistributed the chicken to charities across Scotland. Colin MacEwan, Director of Commercialisation and Innovation at SRUC, said: “These donations quite simply go to the people who need it most - particularly during this difficult time. “Currently we are alleviating our own problems in part with these donations, but we hope to continue supporting FareShare in some form in the future.” Magnus Swalander, General Manager, Aviagen Limited, said: “Aviagen is committed to helping our local communities, especially in this time of urgent need. We’re in the business of putting food on every table and feel fortunate to be able to donate a nutritious source of protein to such a worthwhile charity.” Teresa McGoldrick, Food Sourcing Officer for FareShare in Scotland, said: “Our relationship with SRUC and Aviagen has really blossomed since early 2020 when they began providing us with chicken. “Thousands of families and community groups affected by food poverty across Scotland have benefitted from this nutritious and delicious food and we are very grateful for their continued support.” Grace Muir, from the Fidra Court Community Kitchen in Edinburgh, said: “The chicken we get from FareShare is fantastic. The chicken breast portions are huge and go down a treat with our service users. We are very thankful and would love to see them keep coming in.” Since the very first donation in April 2020, SRUC and Aviagen have donated 23.1 tonnes of chicken. Using the WRAP calculation of an average balanced meal weighing .42kg, this equates to 55,001 meals. For more information, contact: rosie.free@sruc.ac.uk; 0131 535 4219.

Gr eat British Beef Week is 'going gr een' as its 11th year focuses on sustainability

British beef farmers are to receive industry-wide recognition at the end of April, with their support for sustainable production practices being the focal point of Great British Beef Week 2021. The campaign is to take place between 23-30 April 2021, with organisers Ladies in Beef (LiB) once again supported by AHDB, as well as Red Tractor, National Farmers Union, The Royal Agricultural Benevolent Institution and Hybu Cig Cymru. Great British Beef Week (GBBW) 2021 will proudly showcase the strides being taken by British farmers in the sphere of sustainability, with Britain continuing to maintain its position as among the most sustainable in the world. The campaign is to be run predominantly via digital channels, with regional media and in store activity also being used to highlight innovative and sustainable farming methods from producers across Britain. Jilly Greed, who co-founded Ladies in Beef with NFU president Minette Batters, said: “Great British Beef Week enables us to shine a light on all aspects of the beef production process. Our farmers are passionate about the beef they produce and are committed to delivering high quality red meat for consumers to continue to enjoy. “Managing land in a sustainable way is a fundamental responsibility of the modern-day farmer. This includes farming regeneratively, improving grasslands and paddock grazing, planting trees, maintaining wildflowers for the bee population, harvesting and giving cattle rainwater to drink. British beef production boasts a carbon footprint of just less than half the global average, and reflects the hugely important and positive work our farmers are putting in day-by-day. It’s vital that we keep bringing attention to the ways our producers are respecting the land, whilst also producing the foods we enjoy eating.” Industry representatives and other stakeholders who are keen to support Great British Beef Week 2021 can do so by visiting www.ladiesinbeef.org.uk. Extra information on the campaign, as well as some useful downloadable content, is also available. Further campaign-related news will be released in the weeks leading up to Great British Beef Week 2021. Look out for #GBBW21 to join the conversation.

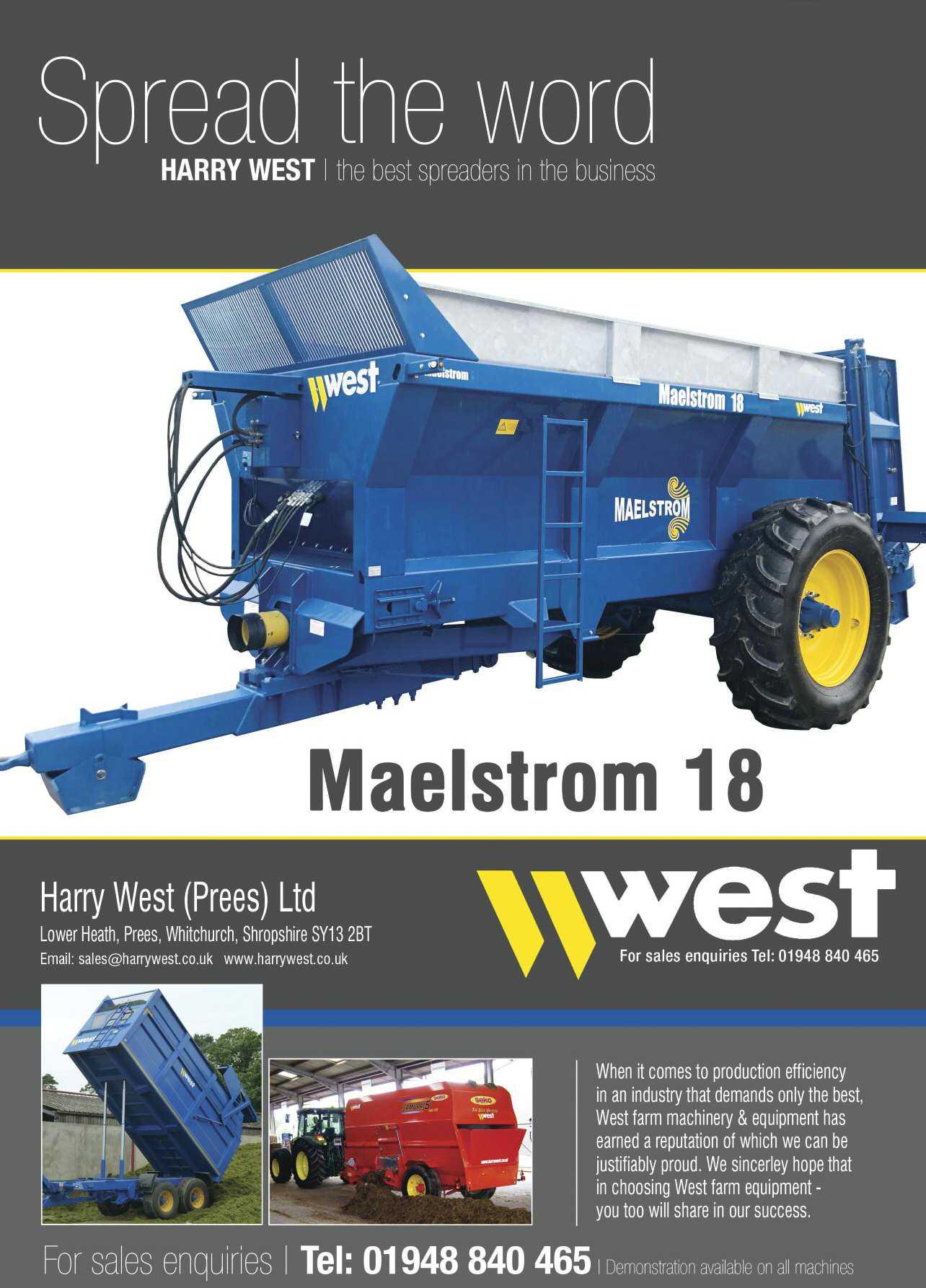

| Muck & Slurry INDUSTRY-FIRST FEATURES FOR NEW JCB TELESCOPIC WHEELED LOADERS

Anew range of telescopic wheeled loaders that set new performance standards has been launched by JCB with an industry-first 50kph eight-speed powershift transmission and the most powerful engine in a machine of this type. Together with a new cab that gives the operator outstanding visibility, these developments feature in the 173hp TM420S, a new flagship model for JCB’s ‘Stage V’ telescopic wheeled loader lineup. JCB Agriculture Managing Director John Smith said: “This new range underscores JCB’s leading position in agricultural materials handling. As tough, durable and highly manoeuvrable machines, the ‘TM’ telescopic loaders have always been at the top of the popularity charts with farmers and agricultural contractors.” There are four models in the range with new variants and performance upgrades throughout. Lift capacities and lift heights continue at 3.2 tonnes and 5.20 metres for the TM320 and TM320S, and 4.1 tonnes and 5.45 metres for the TM420 and new TM420S.

They all feature the new cab with a onepiece windscreen extending into the roof for much-improved upwards visibility, an increase in total glass area and a rear view camera, plus illuminated steps and a courtesy delay when the lights are switched off in the dark.

The TM320 gets more power at 130hp while outputs for the TM320S and TM420 rise to 150hp, and all models have the new fuel-saving Autostop feature for JCB 448 DieselMAX engine that avoids wasteful prolonged periods at idle speed. As standard, the range-topping TM420S with its 173hp engine comes with a 50kph version of JCB’s new eight-speed auto Powershift transmission, with Torquelock direct drive in every gear. The TM320S can have this transmission as an option but otherwise is equipped with the 40kph version also used in the TM320 and TM420 that has Torquelock in forward gears five to eight. In auto mode, the transmission responds to light use of the accelerator pedal by shifting up and down at a relatively steady engine speed for optimum fuel economy, but more aggressive pedal use results in delayed up-shifts to exploit the full power and torque available at higher revs for maximum acceleration and productivity. Forwards visibility from the new Command Plus cab is effectively increased by 13% while the overhead glazed area is 52% larger than before thanks to the one-piece windscreen that sweeps up and over the operator’s head, where an optional roof wiper keeps the maximum area of glass clean. Inside the cab, the new ‘memory’ steering column can be pushed away to leave and enter the cab more easily, the cab steps are illuminated, and having parked the machine in the dark, the programmable 360-degree lighting can remain switched on for a while before turning off automatically. An assignable ‘hot key’ button on the hydraulics control joystick is a new feature that can be used for switching between transmission auto and manual modes, torque lock-up engage/ disengage and auxiliary hydraulic valve control.

Alternatively, it can be given the task of muting the radio, answering or hanging up calls on a Bluetooth-connected mobile phone, or acting as a master switch for the work lights.

Syr eN: stabilizing liquid manur e for optimal nutrient utilization

Fully utilize nutrients with SyreN To optimally utilize the because liquid manure contains a high quantity of nitrogen that is dissolved in the liquid manure fluid and appears in the form of ammonia nutrients in the liquid and ammonium. Both forms of manure and make them more nitrogen are chemically balanced in available to the plant, Vogelsang the liquid manure medium. When the cooperated with Danish company pH value of the liquid manure is BioCover to expand its product lowered, this balance changes. A portfolio with SyreN. The partnership greater share of the gaseous applies in Germany, Austria, ammonia is then converted into Switzerland, the Benelux states, ammonium (salt), which does not France, Poland, Czech Republic and evaporate from the liquid manure. A Slovakia. The chemical process pH value of 6.0 triggers this stabilizes the liquid manure by chemical reaction and is considered adding sulphuric acid and reduces the target value for SyreN. nitrogen losses by up to 70 percent. The SyreN system uses a sensor to automatically measure the pH value of the liquid manure and adds the necessary quantity of sulphuric acid to lower it and stabilize the liquid manure at the target value. This is

Lower nitrogen losses and emissions

The concentrated sulphuric acid is kept in a front tank and is fed into the liquid manure stream in a mixing chamber directly upstream of the linkage. The mixture of sulphuric acid and liquid manure splits into ammonium and sulphate of sulphur. Both compounds are optimally suited as plant nutrients because the plants can directly absorb them as nitrogen and sulphur fertilizers. Harald Vogelsang says, “SyreN is a closed, reliable system with which farmers and contractors can retrofit their existing technologies, such as dribble bar and trailing shoe systems, and thereby achieve low emissions comparable to those achieved with the slitting technology. At the same time, they benefit from the power and high area coverage of this spreading technique.”

For more information, visit: vogelsang.info or take a look into our virtual showroom and discover SyreN: vogelsang.info/int/ agricultural-showroom

Agri machiner y and innovation by Mastek

Mastek Ltd was established in 2000 by Paul Quinn and is based in Cootehill, Co. Cavan, Ireland. Since 2009 Mastek has become a world market leader in slurry handling and umbilical equipment. Mastek manufacturers a full range of umbilical and tanker dribble bars, trailing shoe applicators, reelers and associated equipment. In 2016, Mastek officially opened a new state-of-the-art 924m2 factory unit, specifically for agricultural machinery. This has helped to increase production and grow their export business with machines now heading as far as Finland, Denmark, Sweden, Russia and New Zealand. The UK is a key market for Mastek’s slurry equipment with Mark Roberts based near Shrewsbury and Ben Willcox based in Somerset. Mastek have two key partners in relation to their slurry systems, firstly Snap-tite lay flat slurry hose is a key part of the business. The second key partner is Bauer who supply Mastek with their full range of separation and pumping equipment. The company continues to have great success with their Professional Universal Dribble Bar (PUDB) with sales of over 2,000 units to date. The unique system is achieved by mounting the dribble bar directly onto a custom-built replacement door, with the fill point and splash plate moved to the rear of the dribble bar. This allows the dribble bar to be fitted “on farm” within a matter of hours. The dribble bar requires two double acting hydraulic services, one set for the folding mechanism and the macerator operated by a changeover switch in the cab and the other service to open and close the dribble bar gate valve. Mastek fit their own award winning “SuperCut” macerator to the dribble bar which was designed specifically to handle long fibre and debris by using 6 unique V-shaped cutting discs to shear long fibre and plastic. Each hose outlet has a one-way air valve, this gives an even flow and helps to prevent blockages. The full specification “professional” universal dribble bar is fully galvanised with sprung loaded arm protection and weighs in at only 450kg, ensuring not to off balance the weight distribution of the slurry tanker. Mastek have recently launched a brandnew 7.5m Micro Trailing Shoe. This tanker-mounted trailing shoe is designed to provide the ultimate value to the farmer, with a simpler design that is easier to operate compared to their Eco Trailing Shoe and other trailing shoes on the market. Like the Eco Trailing Shoe, each spring is capable of putting up to 8kg of pressure on the coulter to ensure the slurry is placed under the grass cover and to

prevent grass contamination. The machine is light, yet it is a very strong and robust machine. This machine has a specially designed hydraulic system where it lifts and tilts for headland turning and continues to fold the booms for transport with one single hydraulic service. On this machine, Mastek have launched their new SuperCut Micro Macerator. After the renowned success of their awardwinning SuperCut Macerator, the SuperCut Micro Macerator is a variant designed for smaller applicators. Speaking to Mastek’s Managing Director Paul Quinn, he explains that “the SuperCut macerator was designed for our 12m booms which have 48 outlets. When we were using our SuperCut macerator on 7.5m applicators, only 28 of these outlets were required. Our new SuperCut Micro Macerator is specifically designed for smaller applicators, where it is much more efficient and 35% lighter.” Just like its big brother, it is capable of macerating high fibre slurry, plastic and other foreign objects. It is also capable of distributing slurry evenly on uneven ground. The Mastek

Micro Trailing Shoe can be fitted

to existing tankers that are equipped with brackets, or on all new tankers. The other new product to Mastek’s range is the larger Linkage Mounted 10 & 12m dribble bars. These machines follow on from the companies umbilical dribble bars which can be supplied without a umbilical arm to reduce weight and with the addition of brackets to suit any linkage or fixed bolt holes which are available on the rear of the tanker. These larger dribble bars are suited to larger tandem axle tankers and have the benefit of reducing the number of wheel markings across the field. The 12m dribble bars are also being used in conjunction with 24m tramlines. These linkage mounted dribble bars feature a unique hydraulic accumulator arm protection system meaning if the arm comes into contact with a hedge or post it will allow the arm to pass the obstacle then hydraulically return to its working position. Mastek pride themselves on the build quality and reliability of their products and are keen to provide solutions for small slurry tankers on family dairy farms all the way up to complete systems for large scale farming operations and agricultural contractors.

NORTH OF EN MARK RO

| Muck & Slurry Hi-Spec muck and slur r y spr eaders

W

hen it comes to comes to the handling of muck and slurry, HiSpec Engineering have the ideal solution in their comprehensive range of machinery.

Vacuum tankers

The Hi-Spec tanker range includes a wide range of models with capacities from 800 gallons (3,600 litres) up to 5,000 gallons (22,700 litres), all available with numerous filling and other options, allowing you to tailor tankers to your specific needs. All Hi-Spec vacuum tankers are

manufactured using high quality British steel and incorporate internal implosion rings and a collared dished end as standard to ensure the strongest possible construction. All tanks are fully supported by the complete chassis frame and models are available with both standard or stepped recessed axles. The recessed axle lowers the centre of gravity, which not only improves stability both on the road and on undulating ground. Options include a wide range of filling options, including high capacity pumps and a cab operate filling arm. The intake system can also incorporate a Vogelsang Rotacut 5000 chopping unit to avoid any potential blockage to the injectors caused by straw or silage in the slurry. A wide range of spreading attachments are available, including the Hi-Spec Trailing Shoe, available in working widths of 6.0, 7.5 and 9.0 metres. This features a robust chassis mounted mast which ensures that the tanker and shoe are perfectly balanced and that the shoe is properly supported to the tanker. It are also designed so that both the fill points and splash plate can be used without any modifications. The Hi-Spec trailing shoe can also be used as a dribble bar if needed without any contact with the ground.

Rear and side discharge muck spreaders

The range of spreaders from Hi-Spec Engineering

| Muck & Slurry include the unique rear discharge XCEL 1250 spreader. The Hi-Spec XCEL 1250 is unique in that it uses a rotary chain and flail system to achieve a good break up of material, which is then spread using a pair of spinning discs. The shredding rotor carries 22 heavy duty chains, which in turn carry 12mm Hardox flail heads, mounted under a 4mm Hardox hood, that shred all the material to an even consistency and ensure no lumps are deposited onto the spreading rotors. An adjustment plate on the shredding rotor hood, evenly places the manure onto the spreading discs to ensure an even spread. The Xcel 1250 has a capacity of 12 tonnes and can evenly spread material up to 24m. The material to be spread is moved rearward by a single slat marine grade floor chain, drivenby a hydraulic motor with overload protection and variable speed adjustment. Options include various tyre sizes, a weigh cell and the ISOBUS compatible RDS iSOCAN Apollo spreader control system or the straightforward Digi-Star GT400 weighing system.