3 minute read

REDUCING RISK

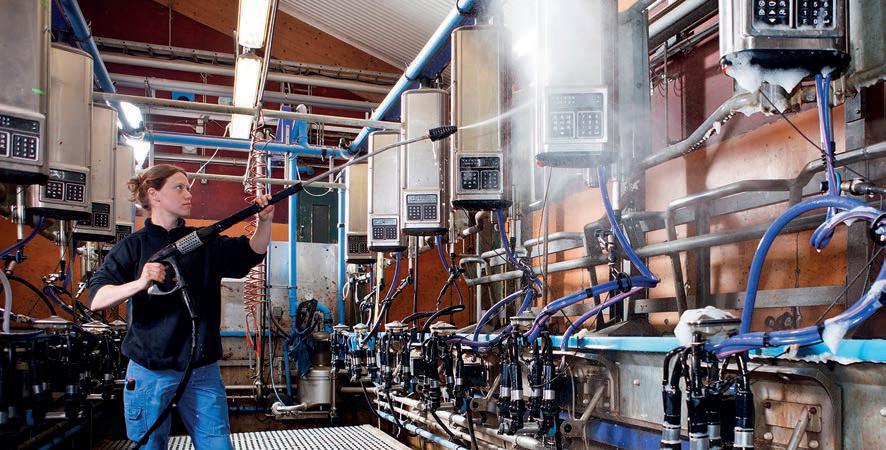

Dairy farms should eliminate chlorine-based products in nal rinses to reduce the risk of chlorate residues in milk products. e latest advice from the Milking

Equipment Association (MEA) states that cleaning and disinfection of milking equipment should avoid or replace the use of chlorine in the nal rinses.

MEA chair John Baines says:

“EU Legislation has set a new maximum residue limit for chlorates in milk products to ensure that levels do not exceed 0.1mg/kg.

“Chlorates are breakdown products from chlorine-based chemicals used in milking equipment cleaning and disinfection. e risk of chlorate residues is highest in heavily processed products, especially milk powders and infant formula. e European Food

Safety Authority has advised that exposure to chlorates for long periods of time can lead to iodine de ciencies in infants.”

Red Tractor standards state that milking equipment should be le free of chemical residues by implementing a nal rinse with potable (drinking quality) water.

When water is used directly from mains supply, it may not be necessary to use any disinfectant in nal rinses. It is a requirement to add disinfectant to private supply water or where there are doubts about water quality.

In this case, sodium hypochlorite has been the traditional disinfectant added to nal rinses.

Mr Baines says for farms cleaning milking equipment manually, the absence of careful measurement of chemicals may result in unsafe levels of chlorine in nal rinses.

More chlorine

He adds: “Using more chlorine will not necessarily improve the cleanliness of milking equipment.”

With automatic cleaning control systems, correct installation, calibration and maintenance of equipment is paramount to regulate the use of disinfectants.

“Automated equipment should be installed, calibrated and serviced by trained dairy technicians, ideally with a Milking Systems Technician Accreditation (MSTA) to ensure correct concentrations of chemicals are used,” says Mr Baines.

Where chlorine-based disinfectants are used in nal rinses, Mr Baines advises that chlorine-free alternatives such as peracetic acid should be considered.

He says: “ e MEA accepts that the use of chlorine-based products is not prohibited. However, milk buyers expect that farms reduce the risk of chlorate residues by using a peracetic acid in nal rinses, boiling water cleaning, or disinfection.”

Mr Baines says robotic technology has taken the lead on cleaning without chlorine, choosing to use a boiling water alternative. Acid or alkali is added to the early stage of the cleaning to prevent fat or mineral deposits. Most importantly, the high temperature disinfects equipment surfaces, meaning that no disinfectant is required. is removes the risk of chlorates in milk products.

“While technology has some of the answers, installation, calibration and maintenance of all milking systems should be carried out according to manufacturer’s guidelines, by MSTA-accredited technicians.”

Practical advice

rDo not use hypochloritebased disinfectants in the final rinse of parlours and bulk milk tanks rFollowing disinfection, make sure all milk-contact surfaces are rinsed with clean potable water, for example, direct from mains supply rWhere private water supplies are used, or there are doubts about water quality, use alternatives to hypochlorite such as peracetic acid, which degrades over time and does not leave residues

The Milking Equipment Association says cleaning and disinfection of milking equipment should avoid or replace the use of chlorine in the final rinses.

Reduce risk of chlorate residues

What is the legislation?

JA new chlorate maximum residue limit (MRL) for liquid milk came into force in June 2020 under EU legislation and applies to the UK post-Brexit.

The MRL for liquid milk (raw or pasteurised) is 0.1mg/kg. The MRL for foods intended for infants and young children is still set at 0.01mg/kg.

Compliance with MRLs will be checked by the Health and Safety Executive and some milk processors have already added questions about best practices to reduce residues into their Red Tractor Assurance audits.

Historical advice to disinfect parlour systems and bulk milk tanks with hypochlorite as a final rinse is no longer in line with Red Tractor Assurance standards and industry recommendations.

Green Bedding