12 minute read

A broad vision of sustainability

A broad vision of sustainability

Sustainability is a mindset that inspires businesses to think dynamically about both the bottom line and the impact on our planet. By considering filtration, waste management technology and sustainability from other industries, we get a broader vision of what sustainability can be, or should be, for the optical industry. By Jamal J. El-Hindi

Prior to the “green era”, sustainability had been in practice even when the priority was not the environment. Waste management, filtration, dust colletion and more have been a means to collect or reuse precious resources throughout the manufacturing process. Although environmental conservation has not always been a priority in manufacturing, it has been a means to conserve natural resources and save money.

In the wire industry, companies go through great lengths to collect their waste and strip everything but the raw metals so they can reuse them. Metal manufacturing mills use huge amounts of water every day, with tanks that hold hundreds of thousands of liters.

Without the environment in mind, these companies had to find ways to reuse this water, especially when expensive coolant and additives were used. The optical industry is like many other industries, requiring ways to reuse water and coolants, disposing of hazardous materials, and trying to reduce waste.

The difference now, of course, is that we are in the “green era”, and we now know the harm our impact has on our planet. The idea of sustainability is not just about reusing resources or making efforts to stop pollution, it has become a mindset. Sustainability is about changing the way you think about business and how your choices not only impact the bottom line, but how they impact the future of our planet and all of us who live on it.

Filtration and technology

Filtration among industries has been a profound part of the manufacturing process for a long time. So much, that large industries turn to specialized filtration companies to provide entire filtration systems. In the optical industry, especially in the United States, we have only recently seen a rise in smaller labs expanding in size. This transformation brings all sorts of new obstacles to overcome, making it more practical to implement filtration practices from other industries. Most smaller labs got along just fine without any special equipment for filtration or waste. As a lab gets bigger, however, it generates more waste, or plastic swarf. Swarf generated from lens grinding takes up a lot of volume, and as labs grow, we see costs such as garbage disposal, hazardous waste removal, coolant, storage, and water increase. Just the increased volume of swarf alone can cost labs a lot of money, not to mention how much coolant is being thrown away with that swarf. As a lab grows, filtration and waste management become more important. In the optical industry, the main forms of filtration are typically media filtration or centrifuge filtration.

Centrifuges

Centrifuges have been a big player in filtration for a long time, designed to use g-forces to separate particles that vary in density. We use centrifuges for many different applications. They work best when the dirt load is heavy, such as paint sludge, sometimes heavy metal sludge, and a lot with glass manufacturing. In fact, centrifuge technology was the main form of filtration in the optical industry when the lenses were made from glass.

Since then, however, lenses started being manufactured from plastics, which creates a much lighter swarf discharge. This is why media filtration was brought into the industry. Plastic separates much better through some sort of medium, or media (like a coffee filter). There are all sorts of different media filters, but for manufacturing you need some type of media filter that can handle enough liquid volume for your production. Different filtration technology offers different advantages, such as a gravity filter with a longer discharge ramp provides more time for the swarf to dewater, preventing more coolant from getting thrown away in a landfill. These offer an eco-friendlier filtration process.

Waste management and technology

In recent years, the optical industry started implementing more waste management technology. Swarf compaction, for example, started as a means to reduce the volume of swarf waste, but quickly became a means to retrieve more coolant. We are starting to see labs investing in briquetting technology as a goal to reduce their ecological footprint and help the environment. This has also proven to save manufacturers thousands in coolant costs per month, making it a perfect choice for sustainable manufacturing.

Briquetters

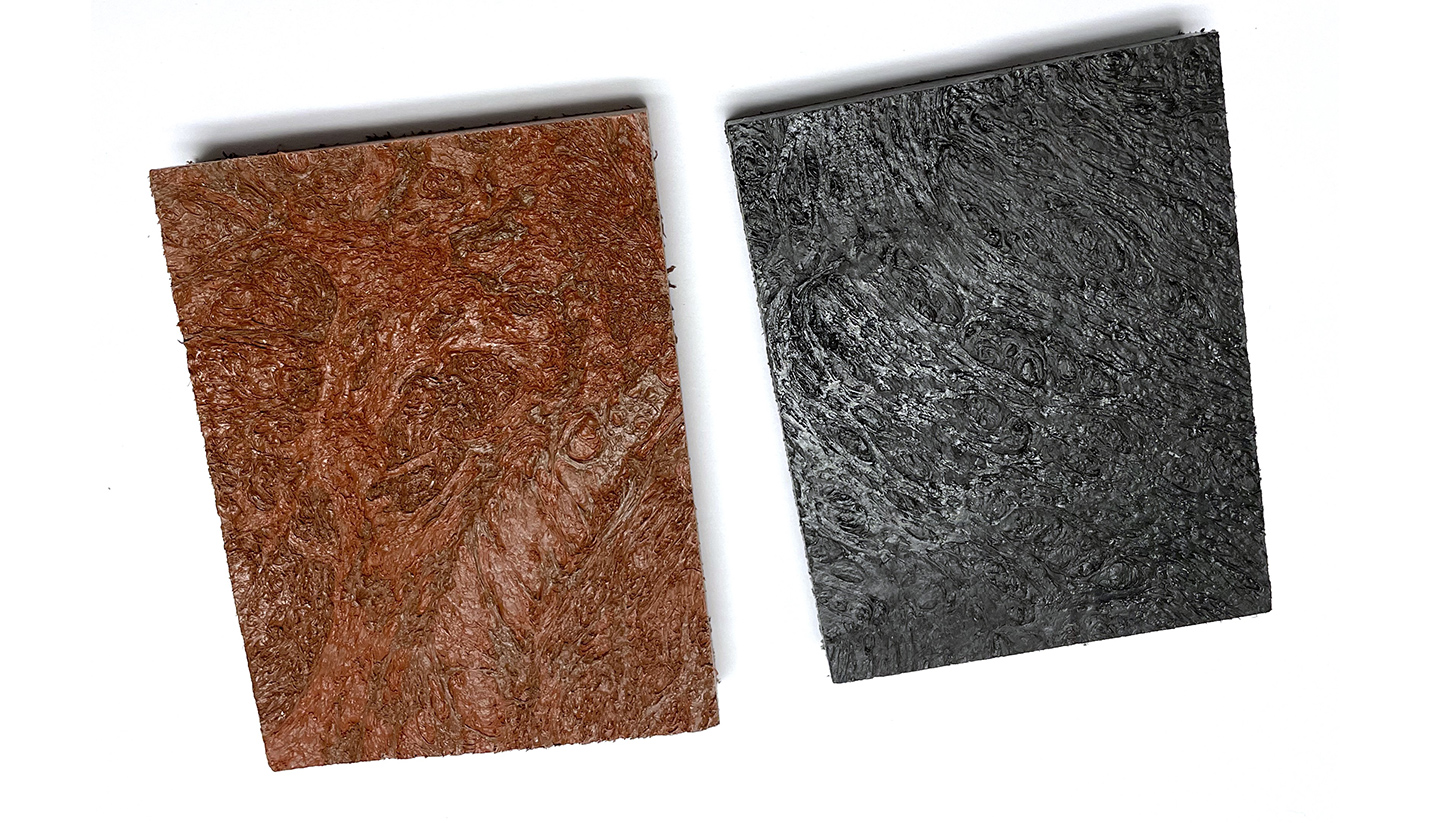

The waste from making lenses takes up a lot of landfill space. Plastics, such as polycarbonate and other thermoplastics used in lens manufacturing do not decompose for hundreds of years. They are also saturated in coolant if not properly dried, which leaches into the ground. Reducing the volume of swarf waste and reclaiming coolant is what brought the briquetting technology to the optical industry.

However, the problem with briquetters is that most are not designed for optical swarf. The first few in the industry were sawdust briquetters, which proved just how difficult lens swarf is to deal with. After several years of development, there are now more options for compacting swarf and retrieving more coolant than ever. With swarf volumes being reduced to a 20:1 reduction, and squeezing nearly all coolant out of the swarf, this may be one of the most environmentally friendly advances in the industry.

Wastewater

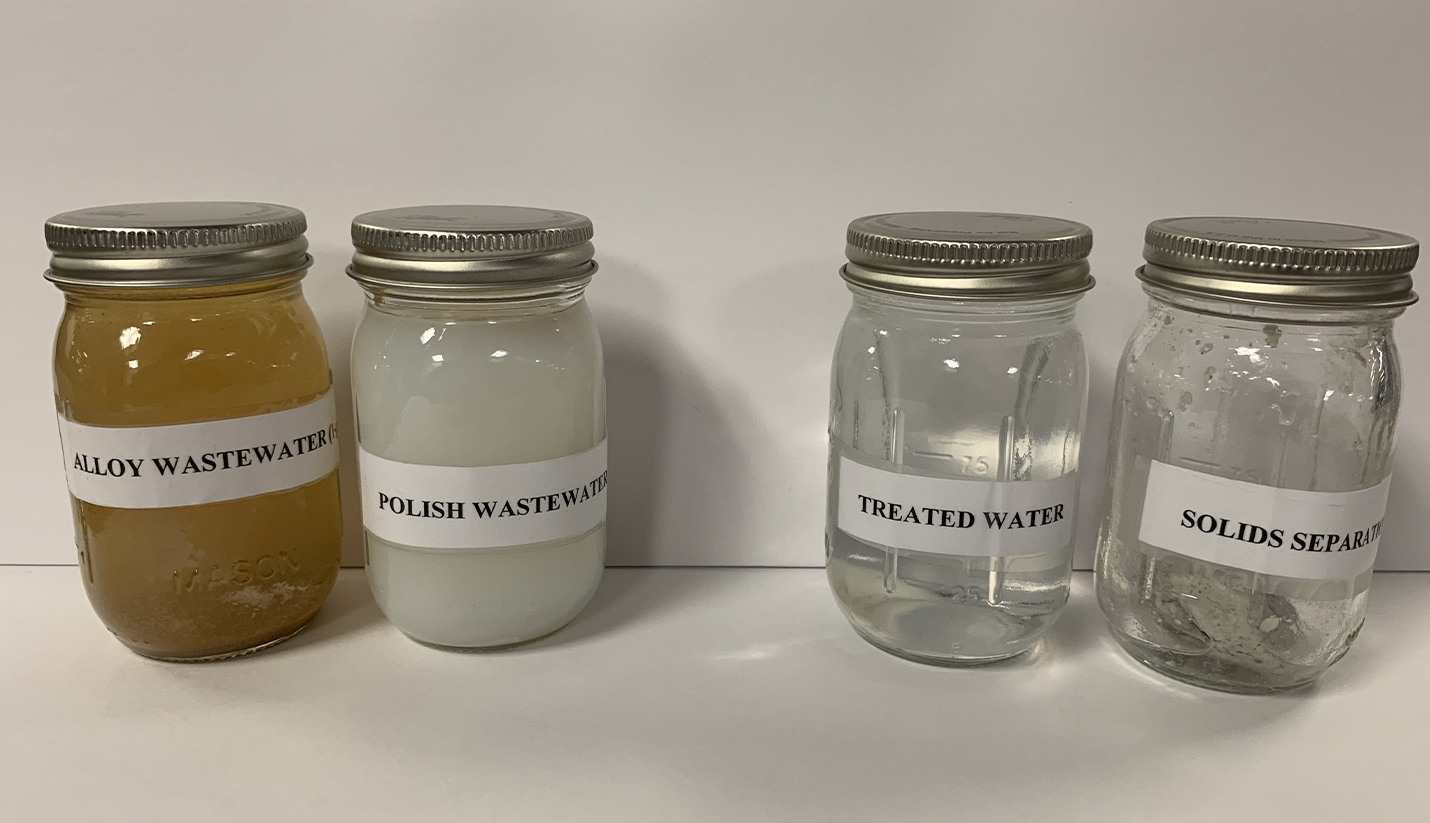

The optical industry also has to deal with wastewater and hazardous materials, such as alloy water, spent polish, and other chemicals used in the manufacturing process.

Some labs simply outsource their wastewater treatment by having companies pick up their hazardous materials. This is an expensive solution and the reason why some labs pour those hazardous materials down the drain instead. As environmental regulations increase and government focuses their lens on optical manufacturing, optical labs will be forced to make some difficult decisions.

Optical is certainly not the first industry to encounter these hazards. The same issues have been present in several other industries for many years. Filtration specialists have been creating solutions for these issues, and only in recent history did we see some of that technology spreading to the optical industry.

Wastewater filtration equipment was originally designed for much larger industries that typically have more space and more wastewater to treat. Technology adapted to the optical industry must be functional and small enough to fit in an already crowded optical lab. Due to this challenge, there are now new technologies available.

Wastewater evaporators and wastewater treatment systems seem to be the leading products available to labs currently. Evaporators – although taking time and a lot of electricity – are great for isolating hazardous materials and removing them from the water, making hazardous waste a lot easier and less expensive to deal with.

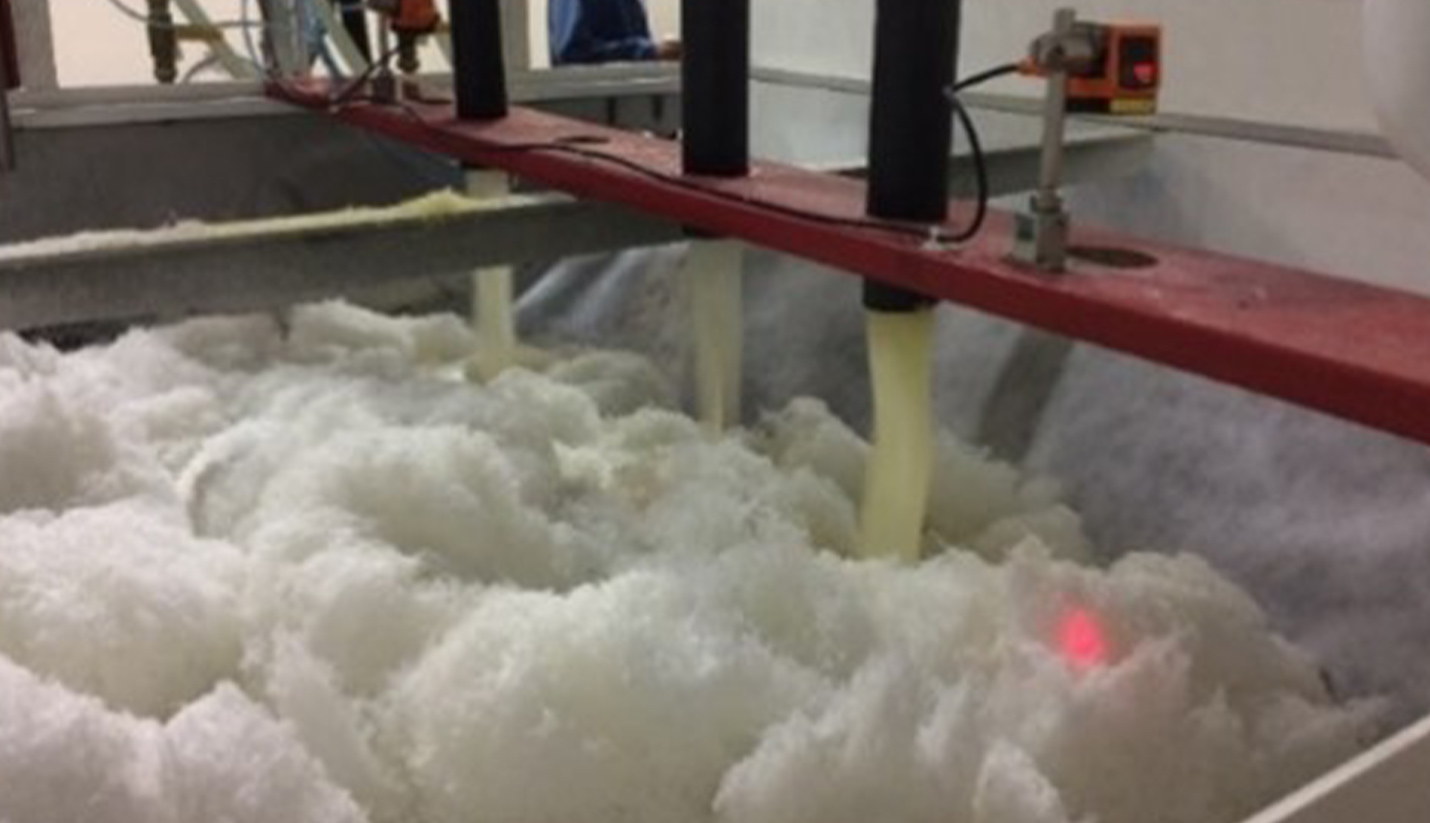

Another wastewater treatment system uses a method that large wastewater treatment plants have been using for decades. They use an environmentally safe clay-based chemistry to latch on to the hazardous materials in the water, separating them entirely. The hazardous material can then be extracted by several different filtration methods. One of the prominent methods is using a centrifuge, which separates and condenses the waste material. This allows each lab to safely discharge the wastewater knowing it is free of hazardous materials. This technology is now conveniently provided as a turn-key system for labs to treat their own hazardous process water, with the benefit of a smaller footprint.

Sustainability in other industries

Although the technology available in the optical industry has come a long way, there is still a lot of waste and costs that should be addressed. We can learn much from what other companies have done in other industries to address similar issues.

A vibratory finishing company had an issue with their sustainability plan. They were using a distillation system to treat their hazardous materials; however, their new green initiative took a look at the process and saw how much energy the distilling was using and how much waste they were storing. The distillation system could not treat the hazardous waste fast enough to keep up with what they were producing.

A solution we offered allowed them to treat their hazardous materials with a clay based proprietary chemistry and separated it in a media filter. This procedure used less energy and allowed them to process enough every night that they would no longer need to store their waste. This solution not only made them more sustainable, but actually saved them more money.

In the aluminum industry, there has been a tremendous amount of growth in recent years. Aluminum manufacturing requires fairly clean coolant compared to other metal industries, therefore, filtration has always been a priority. As an equipment supplier to the aluminum industry, this growth is showing new trends in sustainability that we have not seen before.

Not only do these large companies use their buying power to choose equipment that supports sustainability, but we also see them using their influence to change the technology their suppliers provide. Their purchasing power is being used to drive change in the industry by pushing the machine manufacturers to change.

The major players in this industry said they will not move forward with the current media filtration without the promise of a reusable media. Of course, this is not a new technology, instead it has been done many times in the past. However, the problem is that it was never a true sustainable solution due to heavy maintenance and costs to use it. It also did not clean as effectively as disposable media filters. The large aluminum manufacturers forced the filtration companies to re-think their technology and work towards a sustainable solution. Today, this new technology is being installed and will be run in several new aluminum mills. It will no doubt be passed on to the filters supplied to all the other industries these suppliers provide, including the optical industry.

Another company in the wire industry had a similar story. In copper wire manufacturing, the idea of reclaiming your waste has been a priority for some time. They use large compactors to turn scrap into usable material. They also use large media filters to collect the copper sludge during the manufacturing process. In the past they would purchase media rewinders, which collect the disposable media paper into a roll, so they can burn it to collect more copper from the spent media paper.

One company asked if there was a better way to collect the copper. The burning of the paper was creating hazardous smoke, and the effort to clean the smoke was going to be a hefty cost. Working together, we developed a method that provides better drying, scraping and blowing of the copper fines, so that most of the copper is removed before it rolls up to be thrown away.

This technology is now available to any industry looking to reclaim materials and has also prompted other ways to utilize waste reclamation.

Where do we go from here?

One of the best aspects of working at a filtration company is seeing the need for different solutions among various industries. It always surprises me when veterans of one industry have no concept of a solution that has been in existence in another industry for so long.

Technology in filtration and waste management is improving, and new solutions are becoming available. As we adopt more concepts from other industries, new technologies for smaller labs are available, giving the smaller labs the opportunity to utilize media filtration and compaction technology.

The wastewater treatment systems are becoming more affordable for both larger and smaller labs with some changes to the technology to support smaller labs.

Recycling companies are emerging and starting to offer recycling options for swarf waste. One company in particular, NXTsolve, out of Irving Texas, is taking swarf briquettes and using the material to make several products, presently affecting a highly favorable sustainability impact within the ophthalmic industry.

Their CEO, Anders Hultman, stated “We have identified and created solutions to some of the most notable waste stream recycling challenges for the industry. Swarf holds a prominent position on our priority list, and we have developed a processing technology to integrate swarf into the production of environmentally sustainable products. We are experiencing substantial collaboration efforts from industry partners as it is clear: our values align well. We maintain a commitment to ongoing innovation as we strive to broaden our contributions of value to the industry.”

Recycling is a large step in making the optical industry more sustainable. With advances in other technologies, recycling swarf waste is the last step to creating a zero ecological footprint. Some labs have already achieved this by partnering with companies like NXTsolve, but now we need more. Recycling companies can only produce as much as they can sell, and therefore run into issues with expansion. If the optical industry can align together and take a note from other industries, it may be possible to influence the technology and push recycling and sustainability forward. ◆

Lead Picture: malp/stock.adobe.com