1 minute read

Chassis

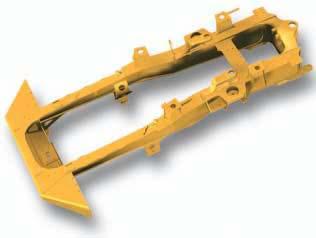

The chassis system consists of the frame, hitch, steering and suspension. These components work together to form the basis of a true off-road hauler. Heavy-duty front and rear frames are joined by the rotating hitch to eliminate frame twist and to ensure good ground contact. Self-compensating hydromechanical articulated steering provides steering accuracy in high-speed operations as well as rough terrain mobility. Operator comfort for high average speeds is maximized by the three-point suspension concept with independent wheel movement. Advantages • Rotating hitch gives superb off-road mobility and eliminates frame twist. • The combination of the hitch and articulated steering provides good traction and off-road mobility in demanding applications. • Heavy-duty frame designed for severe off-road operations. • High hitch placement maximizes stability and ground clearance. • Permanent greased hitch bearings eliminate all service, leaving more time for production and reducing operating cost.

Heavy-duty frames designed for severe off-road operations. Unlike conventional rigid trucks, the hitch minimizes torsional stress which eliminates frame twist. Therefore, our manufactured frame can be made of high-strength steel with high torsional rigidity for reduced weight and high strength. The A25D and A30D feature a new frame design optimized for robot welding, resulting in higher production quality and longer service life.

Advertisement

Front Frame The front frame is built with brackets to secure electrical wiring and hydraulic lines for trouble-free operation. The cab is mounted on four optimally positioned frame brackets that prevent frame vibrations from reaching the cab frame structure.

Rear Frame The heavy-duty trailer frame carries the weight of the loaded body. Unmatched trailer frame design with straddle mounted bogie beam (A) reduces stresses on frame rail distributing the load evenly to the bogie axles.

A A A A