4 minute read

Reliable Pharma Needs Reliable Thermal Protection

from EPM July/August 23

by EPM Magazine

Next Article

When you’re confident in your cold chain distribution, you know your temperature sensitive pharmaceuticals will be kept completely safe - carefully protected, at the right temperature.

From off-the-shelf high-performance thermal packaging and components to custom and fully optimised distribution systems, Topa Thermal helps pharmaceutical manufacturers protect their products as they are shipped worldwide.

2°C to 8°C; 15°C to 25°C; 2°C to 25°C; <-20°C protection

Parcel to Pallet, Freight Optimised Systems

Pre-qualified or Custom-made

24 to 120+ Hours Duration, Designed & Tested to Your World Challenge

For thermal packaging you can rely on, visit topathermal.com

(and tested and re-validated). Wise organisations will employ a diverse team to audit their facilities, with experts from inside and outside their company to leverage their expertise and challenge each others’ assertions.

To regulators under Annex 1, the safety of patients has no cost. There is no economic argument for excusing risk, and with contamination risk for potential patients comes greater financial risk for pharmaceutical manufacturers.

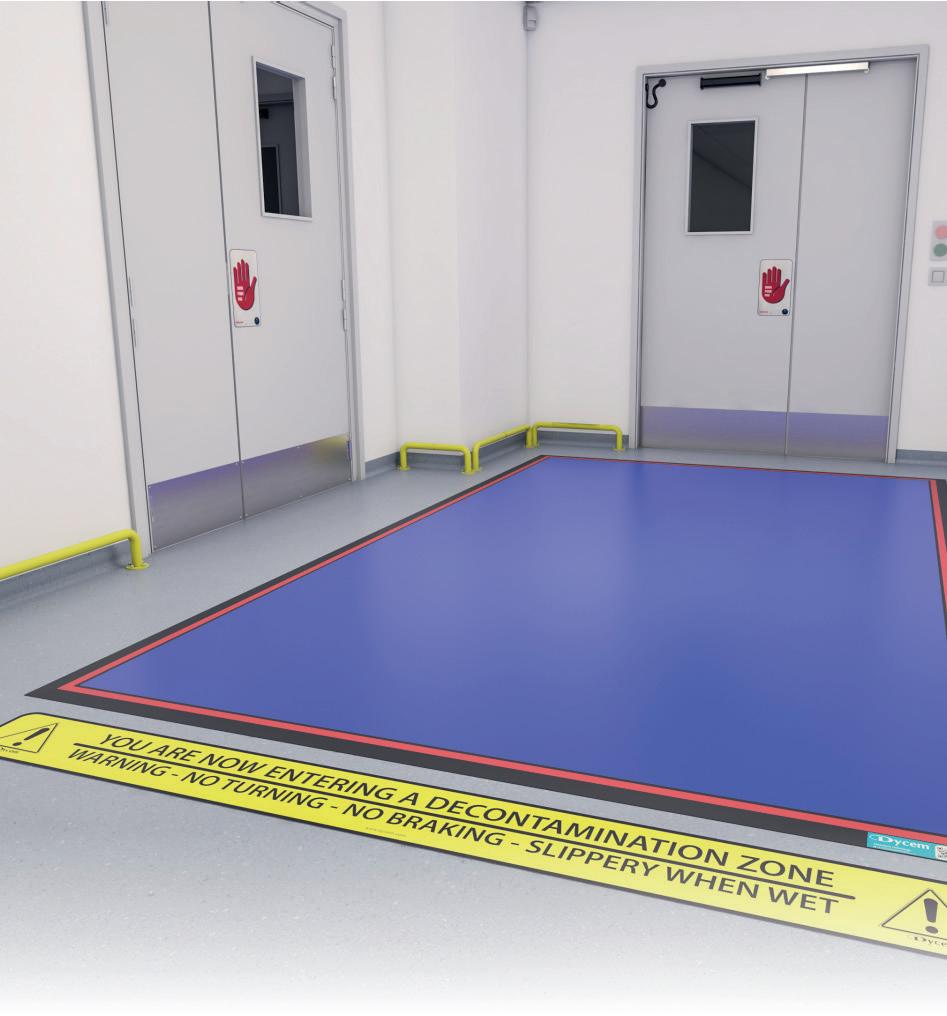

Contamination control is a combination of human procedures and facility technology. Technical solutions should complement procedural changes. There is often a technical solution that will reduce risk in certain aspects of manufacturing, however, we can also evaluate human behaviour, activity, and traffic flow within a facility to make simple changes in process design that complies with GMP.

These two elements work in tandem. Workers can follow the processes and procedures to the letter, but it will not matter if your ventilation system, for example, is substandard or if there is no way to remove waste without interacting with the manufacturing line.

For example, I worked with a company that had developed an impeccable mitigation strategy against cross-contamination. On paper, they did everything correctly regarding procedures and the flow of materials and workers throughout the facility, except for one important thing: a waste pipe along the side of a corridor built at about knee height. It would only take a small seal failure or an accidental stumble to cause a small, barely perceptible leak to begin, which could then be tracked across the facility.

Modernising your production facilities could cost time and capital expenses. However, few things may cost a manufacturer more than a regulatory shutdown, whether that is the loss of a batch or the losses that accrue every moment a production line is closed.

Come August, Annex 1 regulators want to see you have done your work. They want to know that you have read the regulations and evaluated your facility. They want to see what you have done to mitigate contamination and that you have generated the numbers to back your assertions.

Your greatest asset to meet this challenge is a simple spreadsheet.

Evaluating Your Facility By Room

A modern facility is a wonder of science and engineering. It is, of course, complicated and difficult to perceive in its entirety. Breaking the process down into smaller steps makes evaluation manageable.

Take any given room in your facility. It is a tab in your spreadsheet. What is the purpose of the room? What is the flow of people, and how do they get in or out? Is it bidirectional or unidirectional?

The risk is different for each scenario, of course. Is there an airlock? How does raw material flow into the room? How about utilities? How do you clean it? How often is it cleaned?

What is the cleaning process? How do you manage the waste? Where does the waste go? Does it conflict with the flow of people? Is there a potential for risk there?

Asking these questions will achieve a complete, holistic understanding of this room’s problem. Then you solve these problems where conflict occurs. That might be procedural –a bi-directional hallway becomes unidirectional –or a technological solution might be achieved by rerouting pipes or exchanging machinery for something that can be put through an autoclave.

Then, this process is repeated for every room and corridor in your facility. It does not end there, however, as now you have multiple tabs on this spreadsheet, and you must make sure your contamination strategy for one tab does not conflict with another.

Good Enough Will Never Be

The EU GMP Annex 1 revisions will dominate the regulatory world come August. This is a tremendous opportunity to conduct a risk assessment and either improve your production techniques or gather evidence to support your contamination strategy to regulators.

At this stage, hesitancy to act will have dramatic consequences, and many small manufacturers might be gambling on whether their assumptions will be enough to convince regulators. For Annex 1, “good enough” will never be enough, and your only defence will be a global, holistic understanding of your contamination risks.

Logistics is a critical factor across biopharma, but the rapidly growing cell and gene therapy (CGT) industry is currently working through extreme supply chain complexities that therapy manufacturers have never before faced. These therapies are often personalised, such as autologous cell therapies where each batch manufactured is made for and suitable for one specific patient, but even some allogeneic therapies are matched or partially matched to a very small number of potential patients.

Large-batch manufacturing isn’t an option, and production capacity is struggling to meet the rising demand, so each patient becomes a batch in themselves, with their own manufacturing events or slots. This means that all of the events in the patient’s journey need to line up with the manufacturing schedule, which can tie up a slot for weeks, and the logistics must flow seamlessly to support this. Autologous products will be made from a sample of the patient’s own tissue or cells, which ties the ‘raw material’ element to the patient schedule as well as the dispatch of the final treatment.

Unlike biomanufacturing for traditional therapies, advanced therapies often need to be matched to individual patients by the dose. Matthew Lakelin, co-founder and VP Scientific A airs & Product Development at TrakCel, discusses the unique logistical challenges in the space, and how digitising COI and COC can make processes scalable.

Author: Matthew Lakelin, co-founder and VP Scientific A airs & Product Development at TrakCel.