62 minute read

Annual five-year index of articles

Index of Articles: 20162020

Advertisement

Back issues, or photocopies of articles when back issues are out of stock, are available from:

Circulation Department Barks Publications, Inc., 17 N. State St., Suite 1650, Chicago, Ill. 60602 (312) 321-9440 Fax (866) 228-7274 www.barks.com See page 4 for prices

Accounting

U.S. accounting then and now. William

H. Wiersema. January 2016, p. 35. Tax-saving ideas for U.S. Businesses.

William H. Wiersema. March 2016, p. 32. Pricing today. William H. Wiersema.

April 2016, p. 29. Structuring foreign operations. William

H. Wiersema. May 2016, p. 37. S corporation or limited liability company? William H. Wiersema. August 2016, p. 33. The tax bene ts of research. William H.

Wiersema. September 2016, p. 33. Time to change your accounting? William H. Wiersema. December 2016, p. 29. The new role of the CPA. William H.

Wiersema. January 2017, p. 36. Paid more for doing better. William H.

Wiersema. February 2017, p. 34. Accounting for innovation. William H.

Wiersema. March 2017, p. 31. What’s the market value of your business? William H. Wiersema. April 2017, p. 31. Strategies for structuring your business.

William H. Wiersema. June 2017, p. 41. Cooking the books. William H.

Wiersema. August 2017, p. 41. Material world. William H. Wiersema.

September 2017, p. 32. Evaluating lines of a business. William

H. Wiersema. December 2017, p. 34. New accounting rules. William H.

Wiersema. January 2018, p. 37. What’s new in the new tax law? William

H. Wiersema. February 2018, p. 14. Streamlining your accounting. William

H. Wiersema. February 2018, p. 35. Mergers and acquisitions under the new tax law. William H. Wiersema. April 2018, p. 38. Better budgeting. William H.

Wiersema. May 2018, p. 41. Money-saving tips for the smart manager. William H. Wiersema. June 2018, p. 42. Accounting for safety. William H.

Wiersema. July 2018, p. 32. Do costing standards help or hurt? William H. Wiersema. August 2018, p. 39. Taxing questions. William H.

Wiersema. October 2018, p. 36. What’s new, nancially, for buyers of businesses. William H. Wiersema.

November 2018, p. 39. U.S. sales taxes in a new age. William H.

Wiersema. March 2019, p. 46. New revenue accounting for service shops. William H. Wiersema. November 2019, p. 36. The nancial side of selling a business.

William H. Wiersema. August 2019, p. 39. Financial planning tips for the new year.

William H. Wiersema. December 2019, p. 37. Repair or replace? William H.

Wiersema. January 2020, p. 38. Executive incentives today. William H.

Wiersema. June 2020, p. 47. Rethinking retirement. William H.

Wiersema. July 2020, p. 33. The new uncertainty about “revenue”

William H. Wiersema. October 2020, p. 37. Buying or selling a business post-Covid.

William H. Wiersema. November 2020, p. 35. Financial reporting in a pandemic. William H. Wiersema. December 2020, p. 35.

Associations, Conventions & Trade Shows

E cient building management. Nina

Kellerman. February 2016, p. 12. DistribuTECH 2016. Bill O’Leary. March 2016, p. 40. Innovation on display. Charlie Barks.

March 2016, p. 44. Manufacturing meeting in Milwaukee.

Feature | Plant Life

—Gerd Altmann / Pixabay image Ransomware and other threats against manufacturing

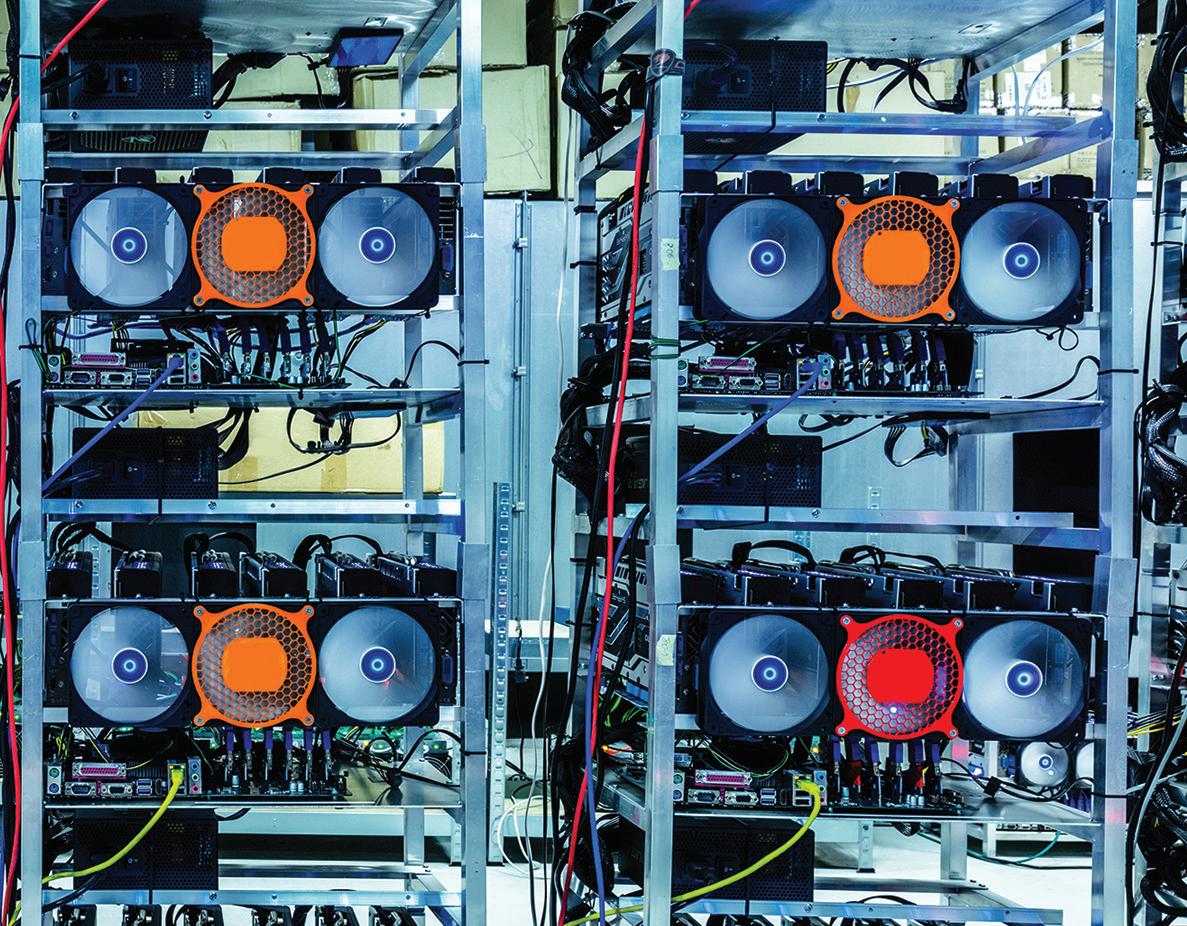

Cybersecurity research indicates that ransomware and cyber attacks against manufacturing facilities have tripled in the past year. Plant operators must be aware of the threat and plan ahead.

By Selena Cotte, EA Managing Editor

Malicious software known as ransomware is a growing threat to international businesses. The malware works by infecting one’s computer, either threatening to leak information or block access until a fee, or ransom, is paid. Typically such software is installed through misleading links, sketchy e-mails, or other sneaky tactics. But hackers can also come through no action of your own.

With more and more manufacturing facilities relying on the Industrial Internet of Things and automated equipment, there is more risk than ever of such an attack. Cybersecurity research firm Dragos reported last month that a number of cyber risks for plants were increasing, typically targeting the industrial control systems, or ICSs, at the affected plants. Access to the ICS would allow a hacker to stop any industrial process and halt production altogether.

Who is at risk?

As of October, the company also identified 262 vulnerabilities impacting industrial equipment found in manufacturing environments. Nearly half of the advisories regarded a potential loss of view and/or loss of control within a compromised environment. Of those vulnerabilities, “70 percent require access

10 ELECTRICAL APPARATUS | DECEMBER 2020 to the victim network to exploit; 26 percent require an adversary to have access to the vulnerable device itself; and 8 percent require an adversary to be on the local area network to facilitate exploitation,” the report noted.

In its report, Dragos identified several groups associated with cyber attacks, including CHRYSENE, PARISITE, MAGNALLIUM, WASSONITE, and XENOTIME. Affected industries are commonly power plants or are related to electrical generation; related to governmental work; aerospace and other high-tech production; and manufacturing generally in tense parts of the world or country.

Why manufacturing?

You may be asking, “What do a bunch of cyber criminals want with my plant?” Well, consider that manufacturing is a center point in many industries. Slowdowns at the plant can cause big problems all the way down the supply chain. If one wanted to cause chaos and disorder, a manufacturing facility would be a convenient and unsuspecting target. While one may wish to roll the dice instead of springing for a pricey cybersecurity system, it is just this lack of preparedness that makes plants so vulnerable. However, it is probably true that if you are not working in an affected or tense industry that could later be affected, it may not be necessary to act quite yet. Regularly assess your vulnerability, your potential work-arounds, and any other systems that may be in play to determine your safety. As with many things, an old adage can be invoked: An ounce of prevention is worth a pound of a cure. EA

12PlantLife.indd 1 11/20/2020 1:52:46 PM

Charlie Barks, Kevin Jones, & Joseph Charlie Barks, Kevin Jones, & Joseph

Ho . April 2016, p. 9. Taking stock of maintainability. Jane

Powell Campbell. April 2016, p. 36. Getting technical in Toronto. Kevin

Jones. May 2016, p. 12. Parks, recreation & food! Elizabeth Van

Ness & Joseph S. Ho . May 2016, p. 15. What’s in the booths? Elizabeth Van

Ness. June 2016, p. 18. Bringing the world to Milwaukee. Charlie Barks. June 2016, p. 53. Water, water everywhere. Charlie

Barks. August 2016, p. 14. Taking the global view in Toronto. August 2016, p. 16. The view from the exhibit oor. August 2016, p. 40. On the leading edge of electrotechnology. Charlie Barks. September 2016, p. 18. How CWIEME gained a foothold in

North America. Kevin Jones. September 2016, p. 20.

Partners in energy effi ciency

Zeller Technologies of St. Louis

The nuclear option Motor effi ciency tests The coronavirus crisis Improving pump effi ciency Smart Grid resources

04cov.indd 1 11/30/2020 7:45:25 AM

Another look at the 2016 EASA ConvenAnother look at the 2016 EASA Convention. September 2016, p. 44. The future of manufacturing on display.

The Electrical Apparatus sta . October 2016, p. 12. A manufacturing show for everyone.

The Electrical Apparatus sta . October 2016, p. 32. Leading-edge technology on display. November 2016, p. 44. Striking a chord. Christopher Wachter.

March 2017, p. 34. Cool running. The Electrical Apparatus sta . April 2017, p. 38. Electrical expos join forces. Kevin

Jones. April 2017, p. 42. Let’s get technical. Kevin Jones. May 2017, p. 16. Meet me in Tampa. Charlie Barks. May 2017, p. 17. Caution: robot crossing. Charlie Barks & Selena Cotte. May 2017, p. 48. The latest in electromechanical service, repair, and replacement. The Electrical Apparatus sta . June 2017, p. 24. What was hot at EASA. The Electrical

Apparatus sta . August 2018, p. 52. Powerful connections. The Electrical

Apparatus sta . June 2017, p. 60. Down to the wire. The Electrical Apparatus sta . July 2017, p. 10. Fluid agenda. Charlie Barks. August 2017, p. 12. Water conference to splash back into

Chicago. Selena Cotte. August 2017, p. 14. Internet of Things is the talk of Tampa.

Bill O’Leary. August 2017, p. 20. Expanding opportunities in service.

Richard L. Nailen. August 2017, p. 21. Fun in the sun. The Electrical Apparatus sta . August 2017, p. 52. Speaking of coils. Kevin Jones. September 2017, p. 23. Piping hot. Elizabeth Van Ness. October 2017, p. 44. Energy-e ciency is so last year. Kevin

Jones & Selena Cotte. November 2017, p. 16. The world of electric machines comes to the Midwest. The Electrical Apparatus sta . November 2017, p. 18. Helping the young to build their dreams.

Kevin Jones. November 2017, p. 32. A glimpse of the future of water. Bill

O’Leary. November 2017, p. 34. Metalwork. The Electrical Apparatus sta . December 2017, p. 40. HVAC/R expo to blow into the Windy

City. The Electrical Apparatus sta .

January 2018, p. 40. A “record-breaking” AHR 2018. Selena

Cotte & Matt Raebel. March 2018, p. 40. Bright ideas in Las Vegas. Charlie

Barks. March 2018, p. 50. Shooting the breeze at Windpower 2018.

Kevin Jones & Matt Raebel. April 2018, p. 44. A city built on manufacturing. Richard

L. Nailen. May 2018, p. 45. Exploring the “right way.” Kevin Jones.

May 2018, p. 46. Renewables meet coal. Jane Powell.

May 2018, p. 54 Wind power industry seeks to move to the next level. The Electrical Apparatus sta . June 2018, p. 14. EASA exhibitors, 2018. The Electrical

Apparatus sta . June 2018, p. 45. The smart conventioneer. Bill O’Leary.

June 2018, p. 61. Where business met fun. Matt Raebel.

June 2018, p. 64. Cutting-edge safety: what’s next in products & programs. Matt Raebel. July 2018, p. 14. U.S. wind takes a victory lap. Kevin

Jones & Selena Cotte. July 2018, p. 19. Hydrate, regenerate, educate. Matt

Raebel. August 2018, p. 20. Picturing EASA. The Electrical Apparatus sta . August 2018, p. 48. What was hot at EASA. The Electrical

Apparatus sta . August 2018, p. 52. Something for everyone at IMTS 2018.

Elizabeth Van Ness. September 2018, p. 18. CWIEME Chicago postponed. Kevin

Jones & Matt Raebel. September 2018, p. 20. Global in more ways than one. The Electrical Apparatus sta . October 2018, p. 18. Weftec 2018. Elizabeth Van Ness. November 2018, p. 20. AHR Expo coming to Atlanta. Kristine

Weller. December 2018, p. 51. Striving for a greener future. Charlie

Barks & Selena Cotte. January 2019, p. 40. Get smart! Bill O’Leary. March 2019, p. 14. Something for everyone at Automate 2019. Selena Cotte. March 2019, p. 50. Something in the wind. Kevin Jones.

April 2019, p. 19. Heating up Atlanta. Kristine Weller &

Bill O’Leary. April 2019, p. 36. Old will meet new at EASA 2019. Kevin

Jones. May 2019, p. 21. A full plate. Selena Cotte. May 2019, p. 43. Winding it up in Wisconsin. The Electrical Apparatus sta . June 2019, p. 12. Picture this: what’s new in robotics. The

Electrical Apparatus sta . June 2019, p. 20. Changes afoot at EASA 2019. Matt

Raebel. June 2019, p. 27.

Please turn to next page

A BARKS PUBLICATION

AUGUST 2020 / $5 Electrical Apparatus More than Motors

The power

of water

Beyond wind. Charlie Barks. July 2019, p. 12. Viva La EASA! Selena Cotte. August 2019, p. 42. EVs and EV batteries in the spotlight.

Matt Raebel. August 2019, p. 54. Manufacturing event tightens its focus.

Kevin Jones. September 2019, p. 10. Electric vehicles and hybrids come of age. Charlie Barks. October 2019, p. 16. Reliability matters. Bill O’Leary. November 2019, p. 16. In manufacturing, uncertainty rules.

Kevin Jones. November 2019, p. 21. Water tech everywhere. Selena Cotte.

November 2019, p. 39. New technology with a personal touch.

David Miller. December 2019, p. 14. What’s cool in HVAC/R. The Electrical

Apparatus sta . January 2020, p. 18. Meetings and conventions are rapidly going virtual. Kevin Jones. June 2020, p. 9. Coronavirus crisis presents an occasion to trim regulations. Kevin Jones. July 2020, p. 6. EV batteries power up. Charlie Barks.

July 2020, p. 14. Rewind still needn’t compromise ef ciency. Kevin Jones. August 2020, p. 6. “See you at the Zoom meeting.” The

Electrical Apparatus sta . August 2020, p. 18. HVAC/R associations at center of Covid-19 ght. Kevin Jones. October 2020, p. 8. Business advice from industry associations. Kevin Jones. November 2020, p. 4.

Automation

Automation nation. Bill O’Leary. March 2017, p. 41. Caution: robot crossing. Charlie Barks & Selena Cotte. May 2017, p. 48. Automation safety. Charlie Barks. June 2017, p. 22. What goes into a plant. Selena Cotte.

December 2017, p. 37. The digital tide. Bill O’Leary. January 2018, p. 47. The thing about the Industrial Internet of Things. Selena Cotte. April 2018, p. 24. A world of opportunity in robotics. Matt

Raebel. September 2018, p. 42. “Domo arigato, misuta robotto.” Selena

Cotte. September 2018, p. 48. Future perfect. Selena Cotte. October 2018, p. 25. Smart for all. Selena Cotte. October 2018, p. 48. Welcome, our new robot coworkers.

Selena Cotte. January 2020, p. 46. Becoming a cyborg. Selena Cotte. September 2020, p. 10. Controlling international operations.

William H. Wiersema. October 2016, p. 30. More than motors: HVAC/R. The Electrical Apparatus sta . January 2018, p. 16. Money for growth. William H.

Wiersema. March 2018, p. 36. Mergers and acquisitions under the new tax law. William H. Wiersema. April 2018, p. 38. When a foreign company does business in the U.S. William H. Wiersema. October 2019, p. 38. The M&A Wave. Kevin Jones. November 2020, p. 21.

Business Management

(See also Accounting, Computers, and

Safety & Health) E cient building management. Nina

Kellerman. February 2016, p. 12. E ciency in the motor shop. Elizabeth

Van Ness. February 2016, p. 16. Improving operational e ciency. William H. Wiersema. February 2016, p. 32. Innovation roundup. Elizabeth Van

Ness & Joseph S. Ho . March 2016, p. 13. R&D is the place to be. Bill O’Leary.

March 2016, p. 38. Onward and upward. May 2016, p. 24. Pitfalls in selling a business. William H.

Wiersema. June 2016, p. 37. Does your employee make more than $47,476? Charlie Barks. July 2016, p. 10. Maximize your meeting of the minds.

Bill O’Leary. August 2016, p. 10. Dealing with jerks. Bill O’Leary. September 2016, p. 16. Expatriate games. Bill O’Leary. October 2016, p. 38. Southern crossings. Bill O’Leary. October 2016, p. 44. Bene ting from retirement plans. William H. Wiersema. November 2016, p. 33. Dress the part. Bill O’Leary. November 2016, p. 46. Find your bottleneck(s). Bill O’Leary.

December 2016, p. 41. Who are your stakeholders? Bill

O’Leary. January 2017, p. 18. The new role of the CPA. William H.

Wiersema. January 2017, p. 36. Poka-yoke Go. Bill O’Leary. February 2017, p. 19. Paid more for doing better. William H.

Wiersema. February 2017, p. 34. Concerted activity and social media policy. Bill O’Leary. March 2017, p. 17.

Feature | Business Growth The M&A wave

Batteries

Innovations in battery technology. Richard L. Nailen. March 2017, p. 25. Spare some change? Charlie Barks.

January 2018, p. 10. Utility batteries not driven by price alone. David Miller. May 2020, p. 44. EV batteries power up. Charlie Barks.

July 2020, p. 14. Tesla’s Battery Day proves to be a mixed bag. David Miller. December 2020, p. 10.

Freeman Enclosure Systems, of Batavia, Ohio, a manufacturer of custom generator enclosures and fuel tanks, is one of several acquisitions made in recent years by IES Infrastructure Solutions of Massillon, Ohio. —IES Infrastructure Solutions photo

Over the past decade, private equity and strategic buyers have been changing the landscape of the electromechanical service industry. What’s next?

By Kevin Jones, EA Senior Editor

Mention the phrase “mergers and acquisitions” to some people and they might picture Gordon Gekko in “Wall Street” — the corporate titan and 1980s icon who prowled the business landscape and mercilessly snatched up companies he could strip of assets and sell at a tidy profit before moving on to his next victim. He viewed his actions as commendable because, as Gekko famously said, “greed is good.”

As with all things Hollywood, though, the reality of mergers and acquisitions is far more complex and nuanced than the big-screen fantasy would have us believe. The world of mergers and acquisitions is populated by far more good guys than bad. Whether or not greed is good is a question best left to the philosophers; there’s a strong case to be made, though, that mergers and acquisitions occupy an important niche in the economic ecosystem, matching up buyers and sellers efficiently and providing the capital that makes it possible for business owners and buyers to achieve their financial goals.

Broadly speaking, mergers and acquisitions in the U.S. appear to have hit a speed bump in recent months, as the Covid-19 pandemic has brought about a tightening of credit and the Presidential and Congressional elections have raised uncertainty about possible changes in the Tax Code.

As Electrical Apparatus Contributing Editor William Wiersema observes in his contribution this month (“Buying or selling a business post-Covid,” page 35), economic conditions nationwide have “suppressed valuations and debt availability,” causing deals to be “renegotiated or even stopped entirely.” In the broader economy, a former seller’s market may be undergoing a transformation into a buyer’s market, Bill writes. Buyers and sellers alike need to adjust to a new reality and adjust their strategies and expectations accordingly.

But that’s the state of the broader economy, which in Bill’s perceptive analysis includes industries as diverse as online retailers, sellers of personal protective equipment, home fitness, home remodeling products, and airlines. If we narrow our focus and look solely at the business of selling and servicing electrical and mechanical machines and systems, the picture is more difficult to bring into view, because the

Please turn to next page

in HVAC, refrigeration, some traction, some mining or excavating.” An overview of a family of electric motors few of us are familiar with – reluctance machines - was presented by EASA’s Mike Howell, and as he said, “We don’t see very often in service centers,” but they are “going to become more prevalent. They’ve been around since the 1800s, but only in the last few decades have become more widely used. Advancement in power electronics has made that possible. The basic principle is that torque is produced by the tendency of a rotor to move to a position where the inductance of an excited winding is maximized and the current is least.” The two types of motors involved The rotor has salient poles but no winding or permanent magnets. The stator winding may be 1-, 2-, 3-, 4-,. or 5-phase configuration. Speed depends upon the frequency and the number of rotor poles. Pole numbers are always different in the stator and rotor. Such a machine is not self-starting and can suffer from excessive torque ripple (a major issue) or noise. Winding for a larger number of phases can reduce torque ripple, but the controls become much more complex and costly. Added Howell, “There’s a lot of interest in sensorless vector control – very challenging.” The synchronous reluctance machine (also known as the “synduction” machine) has a stator bore that is slotted but otherwise smooth, with a polyphase winding (either concentric or distributed) in the slots. The concept dates from the late 19th century. “The stator looks like any induction machine,” explained Howell, “with either a concentric or lap winding,” and draws a set of polyphase, balanced sine are the switched reluctance and the wave currents. Stator and rotor always contain the synchronous reluctance designs. In same number of poles. It’s easier to understand than he first type, also called the “vari- the switched reluctance type. It also is not self-startable reluctance motor,” both stator ing, however. Lacking any rotor windings, it relies on and rotor contain salient poles. rotor saliency to produce torque. Ratings can be up Each stator pole has its own “fractional slot” concentrated winding. Mike Howell to 600-800 hp, mostly 4-pole (although a wide speed range is possible). Most have smaller air gaps than Current pulses are applied to each in turn. comparable induction machines and are constructed in the same ba-

“This concept originated back in the 1830s,” ex- sic frame sizes as standard squirrel-cage motors. Applications include plained Howell, “but it can’t operate without a very extruders, mixers, fans, pumps, and compressors. One downside is special electronic drive. Applications for these are magnetic noise. — Richard Nailen

Pump failures and pump modifications

Appropriately, since pump drives are such a common motor application, EASA’s pump expert, Gene Vogel, offered two presentations this year. One of them, “Why Pumps Fail,” offered three main reasons: seal failure, impeller damage, and bearing failure.

“The mechanical seal is a very simple device,” said Vogel, but it is subject to five common causes of trouble of which “the big one is heat.” The others: “abrasive pumpage, vibration, chemical attack, and improper assembly.” Conditions involved include surface speed, pressure between seal faces, force exerted on seal faces by pumpage pressure, friction coefficient of seal material (carbon-ceramic, silicon carbide, tungsten carbide), pumpage temperature, and flow rate.

“Abrasive pumpage” most often results from suspended solids. Abrasive crystals can settle out of salt water, for example – especially damaging to carbon faces. Vibration may result from unbalance, misalignment, or cavitation. Improper assembly can cut the edges of O-rings.

“One of the things you don’t want to do,” warned Vogel, “is to add grease.” And “the stationary seat of a seal has to be perpendicular to the shaft axis.” Seal tension adjustment may be improper. “Generally it should be set according to the application,” Vogel said. Also, “a seal face is a lapped surface. Be careful to preserve that smoothness. Always rinse the surface off with water.”

Impeller failures include erosion, corrosion (chemical attack), and cavitation – a complex condition. “And Among the slides presented by Gene Vogel was one showing several types of impeller damage.

they can get loose on the shaft,” Vogel warned. “Think of the impeller as having these ‘inspection zones’: the suction eye, leading edge of the vane, and the wear ring, around the O.D. of the suction eye. On the back side, the outside shrouds, discharge area, shaft bore, and keyway. That will help you assess damage.”

Erosion is highly influenced by flow velocity on exposed surfaces. Most often oxidation and corrosion affect all exposed surfaces. With bronze impellers, de-zincification is common.

“You’ll see surface redness, indicating exposed copper where the zinc is eaten away.” For impeller repair, a ceramic epoxy should be used to restore surfaces; once damage starts and the surface becomes rough, the damage will accelerate. But, Vogel added, “I’ve never seen de-zincification in a water pump.” And “hard water does not cause pump erosion, because the contaminant is at a particle level, not a molecular level.” One audience member asked, For thrust balancing, which is best: back-to-back or face-to-face bearing assembly? Vogel’s answer was that it depends on the shaft and bearing housing assembly. The application itself doesn’t care. Another question: Is it only corrosion that causes dezincification? The answer was yes, that’s a form of corrosion. Chlorine is one causative agent. Finally, the question was asked, Can shaft currents from a VFD work their way into the pump and cause corrosion? To which the answer was that galvanic corrosion can ensue from any voltage source. — Richard Nailen

20 ELECTRICAL APPARATUS | AUGUST 2020

08easa.indd 4 7/23/2020 7:02:56 AM

Share the wealth. Bill O’Leary. April 2017, p. 42. Preparing for new penalties on imports.

William H. Wiersema. May 2017, p. 37. Be considerate toward your elders. Bill

O’Leary. May 2017, p. 54. Branding 101. Bill O’Leary. June 2017, p. 63. Beware of labor pitfalls. William H.

Wiersema. July 2017, p. 29. What’s new in service shop software?

Charlie Barks. August 2017, p. 49. Are you a servant-leader? Bill O’Leary.

August 2017, p. 59. Managing change. Selena Cotte. September 2017, p. 16. Fill the leadership pipeline. Bill O’Leary.

September 2017, p. 18. Europe gets it together. Pan Demetrakakes. October 2017, p. 12. U.S. taxation for foreign businesses.

William H. Wiersema. October 2017, p. 37. Global perspective. Bill O’Leary. October 2017, p. 39. Inspiration abroad. Selena Cotte. October 2017, p. 46. Why companies underperform. William

H. Wiersema. November 2017, p. 30. To pay or not to pay. Bill O’Leary. November 2017, p. 42. Taking ownership. Bill O’Leary. December 2017, p. 38. Spare some change? Charlie Barks.

January 2018, p. 10. More than an assembly line. Selena

Cotte. January 2018, p. 20. Coping with change. Bill O’Leary. January 2018, p. 42. Resourcefulness and value. Bill O’Leary.

February 2018, p. 38. Balance the old with the new. Bill

O’Leary. March 2018, p. 46. The cost of competition. Bill O’Leary.

April 2018, p. 42. The inside looking in. Bill O’Leary. April 2018, p. 48. The art of negotiation. Bill O’Leary. May 2018, p. 58. Money-saving tips for the smart manager. William H. Wiersema. June 2018, p. 42. Time to buy, or sell? The Electrical Apparatus sta . June 2018, p. 56. Virtual teamwork. Bill O’Leary. June 2018, p. 60. Corporate unity. Bill O’Leary. July 2018, p. 43. Strategic exibility. Bill O’Leary. August 2018, p. 57. The right niche. William H. Wiersema.

September 2018, p. 36. Shifting responsibilities. Bill O’Leary.

September 2018, p. 38. Downward and onward! Bill O’Leary.

October 2018, p. 39. What’s new, nancially, for buyers of businesses. William H. Wiersema.

November 2018, p. 39. Contract service: What’s in it for you?

By the Electrical Apparatus sta . November 2018, p. 42. Learning made easy. Bill O’Leary. November 2018, p. 46. Where’s the cash? William H.

Wiersema. December 2018, p. 32. To rent or to buy? Bill O’Leary. December 2018, p. 42. E cient time use. Bill O’Leary. January 2019, p. 16. Planning for retirement. William H.

Wiersema. January 2019, p. 37. Perking up the work force. Bill O’Leary.

January 2019, p. 45. Structuring a new venture. William H.

Wiersema. February 2019, p. 37. Striving for a score of zero. Selena Cotte.

February 2019, p. 42. The diagnostic plant tour. William H.

Wiersema. April 2019, p. 33. My boss, my friend? Bill O’Leary. April 2019, p. 45. Predictive nancial tools. William H.

Wiersema. May 2019, p. 41. Which type are you? Bill O’Leary. May 2019, p. 47. Managing by the numbers. William H.

Wiersema. June 2019, p. 52. “Brother, can you spare a loan?”€ Bill

O’Leary. June 2019, p. 74. Hands-on or hands-0 ? Bill O’Leary.

July 2019, p. 47. Helping rms go international. Bill

O’Leary. October 2019, p. 25. Managing, the Japanese way. Bill

O’Leary. October 2019, p. 43. Ending child labor worldwide. Selena

Cotte. October 2019, p. 44. How to say goodbye. Bill O’Leary. November 2019, p. 46. When employees become owners. Selena Cotte. January 2020, p. 14. Field customer service for manufacturers.

Selena Cotte. February 2020, p. 20. The show must go on. Selena Cotte.

April 2020, p. 38. The Covid-19 pandemic has hit quarterly nancial results unevenly. Kevin

Jones. June 2020, p. 9. Executive incentives today. William H.

Wiersema. June 2020, p. 47. Pandemic provides a boost for remote condition monitoring. Kevin Jones.

July 2020, p. 10. Product, product everywhere. Selena

Cotte. August 2020, p. 42. Major electrical manufacturers express their social responsibility.

Kevin Jones. November 2020, p. 8.

The value of giving back. Selena Cotte.

November 2020, p. 13.

A BARKS PUBLICATION

SEPTEMBER 2020 / $5 Electrical Apparatus More than Motors

What’s new in robotics New product showcase Business recovery Winding insulation life Smart water management The innovation

issue

Remote management for plants. Selena

Cotte. November 2020, p. 40. Ransomware and other threats against manufacturing. Selena Cotte. December 2020, p. 10. Are your virtual meetings secure? Selena Cotte. December 2020, p. 38.

Circuits & Circuitry

The truth about arc-fault circuit interrupters. Richard L. Nailen. May 2020, p. 31. The “whisker” problem. Richard L.

Nailen. August 2020, p. 31.

Codes & Standards

IEEE’s insulation maintenance guide and its shortcomings. Richard L.

Nailen. February 2016, p. 27. What’s become of the Color Books?

Richard L. Nailen. April 2016, p. 24. The Canadian standards system. Richard L. Nailen. May 2016, p. 20. The problem with “free.” Richard L.

Nailen. June 2016, p. 50. A brief look at the 2017 NEC. Richard L.

Nailen. October 2016, p. 25. The problem with AFCIs. Richard L.

Nailen. November 2016, p. 27. Smart grid, dumb standards? Richard

L. Nailen. March 2017, p. 14. Welcome to the wide world of standards. Richard L. Nailen. October 2017, p. 25. A quarter-century of EPAct. Pan

Demetrakakes. December 2017, p. 12. Current a airs. Pan Demetrakakes.

April 2018, p. 21. Are motors being properly repaired?

Richard L. Nailen. April 2018, p. 33. Work in progress. Richard L. Nailen.

August 2018, p. 33. Keeping up with changing motor standards. Richard L. Nailen. September 2019, p. 31. The 2020 NEC is a mixed bag. Richard L.

Nailen. November 2019, p. 18. The high cost of standards. Richard L.

Nailen. November 2019, p. 31. How well do we understand ambient?

Richard L. Nailen. June 2020, p. 41. What’s become of IEEE 1415? Richard

L. Nailen. July 2020, p. 19. Harmonization: still a ways to go. Richard L. Nailen. October 2020, p. 19.

Computers

(See also Information Technology) The problem with Internet motor forums. Richard L. Nailen. August 2017, p. 43. The inside looking in. Bill O’Leary. April 2018, p. 48. Virtual teamwork. Bill O’Leary. June 2018, p. 60. Learn to code, lineman? David Miller.

February 2020, p. 13. Webinar woes: An etiquette guide. Selena Cotte. June 2020, p.20. How online should you be? Selena

Cotte. November 2020, p. 12.

Controls & Control systems

The digital tide. Bill O’Leary. January 2018, p. 47.

Drives & Inverters

quency drives. Bill O’Leary. September 2016, p. 24. Pump speed variation: look beyond the

ASD. Richard L. Nailen. February 2017, p. 31. Drive to succeed. Pan Demetrakakes.

September 2018, p. 14.

Electric Vehicles

Energy-e ciency is so last year. Kevin

Jones & Selena Cotte. November 2017, p. 16. EV-olution. The Electrical Apparatus sta . March 2018, p. 16. Tesla’s safety problem. Matt Raebel.

November 2018, p. 45. Will electric motor workers be the auto mechanics of the future? David Miller.

January 2019, p. 16. Charge ’em up. David Miller. March 2019, p. 16. Lightning in a bottle. David Miller. July 2019, p. 23. Driving towards a greener tomorrow.

Bill O’Leary. July 2019, p. 29. What EA readers are saying about EVs.

July 2019, p. 35. “Gentlemen, charge your engines!” William H. Wiersema. July 2019, p. 42. When auto plants go electric. Selena

Cotte. July 2019, p. 50. Electric vehicles and hybrids come of age.

Charlie Barks. October 2019, p. 16. Code check: ICC projects an EV- lled future. Charlie Barks. March 2020, p. 37. The future of EV charging. Selena Cotte.

July 2020, p. 16. Electric vehicle roundup. Electric Apparatus editorial sta . July 2020, p. 23. Electri cation of buses hits a speed bump. Kevin Jones. July 2020, p. 24. “Not for the faint of heart.” Selena

Cotte. July 2020, p. 26. Amidst pandemic, governments play outsized role in EV prospects. David

Miller. October 2020, p. 16.

Elevator Technology

Elevator evolution. Pan Demetrakakes.

June 2018, p. 25. A legacy of quality. Selena Cotte. June 2018, p. 31. What’s up with elevators. Charlie

Barks. May 2020, p. 14.

Emergencies

Weathering the storm. Bill O’Leary.

April 2016, p. 32. Charge culture. Bill O’Leary. August 2017, p. 58.

Energy

LEED-ing the way. Joseph S. Ho . February 2016, p. 23. Shedding energy costs. Charlie Barks.

August 2016, p. 23. Winds of change across the pond. Charlie Barks. October 2017, p. 18. “Are we there yet?” Richard L. Nailen.

December 2017, p. 27. Spare some change? Charlie Barks.

January 2018, p. 10. Loyola LEED buildings. Selena Cotte &

Charlie Barks. February 2018, p. 21. LEEDing questions. The Electrical Apparatus sta . February 2018, p. 25. What’s current in wind. The Electrical

Apparatus sta . April 2018, p. 14. Shooting the breeze at Windpower 2018.

Kevin Jones & Matt Raebel. April 2018, p. 44. Renewables meet coal. Jane Powell.

May 2018, p. 54 Wind power industry seeks to move to the next level. The Electrical Apparatus sta . June 2018, p. 14. U.S. wind takes a victory lap. Kevin

Jones & Selena Cotte. July 2018, p. 19. Winds of opportunity. Bill O’Leary. July 2018, p. 21. Coal under pressure. David Miller. December 2018, p. 12. An ancient source of renewable energy.

The Electrical Apparatus sta . December 2018, p. 36. When did we start caring about e ciency? David Miller. February 2019, p. 19. Mining the sun. David Miller. April 2019, p. 14. From waste to fuel. Selena Cotte. April 2019, p. 21. Does the U.S. have an energy strategy?

Richard L. Nailen. April 2019, p. 27. Where’s new with solar? The Electrical

Apparatus sta . April 2019, p. 42. Energy waves. Bill O’Leary. April 2019, p. 50. All about the green. David Miller. May 2019, p. 14. Decentralized generation with geothermal HVAC/R. David Miller. March 2020, p. 18. The many sources of clean energy. Selena Cotte. August 2020, p. 10. Hydrogen pipe dreams. David Miller.

August 2020, p. 13.

Energy Legislation

A quarter-century of EPAct. Pan

Demetrakakes. December 2017, p. 12. Current a airs. Pan Demetrakakes.

April 2018, p. 21. Renewables surpass coal but employment still falls. Kevin Jones. June 2020, p. 23. Moving forward with green energy projects. Kevin Jones. June 2020, p. 51.

Generators

(See Motors & Generators)

Facility Management

E cient building management. Nina

Kellerman. February 2016, p. 12. Play ball! Bill O’Leary. May 2018, p. 29.

HVAC/R

What’s cool in HVAC/R. The Electrical

Apparatus sta . January 2020, p. 18. Utilities help customers improve

HVAC/R e ciency. Kevin Jones.

March 2020, p. 6.

A BARKS PUBLICATION

MAY 2020 / $5 Electrical Apparatus More than Motors

Essential business

in the time of coronavirus

Jack Klaus, project and application engineer,

What’s smart in HVAC/R? reviews some data collected from Zeller’s ABB Ability motor sensor service. Selena Cotte. Selena Cotte.

ELECTRICAL APPARATUS / APRIL 2020 23

March 2020, p. 12.04zeller.indd 3 3/21/2020 5:56:36 PM

How to get a start in the HVAC/R trade.

Kevin Jones. March 2020, p. 13.

HVAC/R society o ers information you can use. Kevin Jones. March 2020, p. 24.

HVAC/R heats up local economy. David

Miller. March 2020, p. 25.

E cient pumps, e cient HVAC/R. Kevin Jones. March 2020, p. 39.

Information Technology

(See also Computers) Be social. Bill O’Leary. January 2016, p. 38. Space Invaders. Bill O’Leary. May 2016, p. 44. Hello, may I interest you in a blog? Bill

O’Leary. August 2016, p. 42. How to handle the Internet of things. Bill

O’Leary. September 2016, p. 36. The rise and fall of the Bitcoin empire.

Bill O’Leary. October 2016, p. 36. Block party. Bill O’Leary. December 2016, p. 36. Ride the Rift. Bill O’Leary. January 2017, p. 14. Software sense and sensibility. Bill

O’Leary. February 2017, p. 15. Alternate realities. Charlie Barks.

March 2017, p. 36. Automation nation. Bill O’Leary. March 2017, p. 41. Web crawl. Bill O’Leary. April 2017, p. 46. Let’s have a (virtual) meeting! Bill

O’Leary. May 2017, p. 55. Big data. Big decisions. Bill O’Leary.

July 2017, p. 34. Internet of Things is the talk of Tampa.

Bill O’Leary. August 2017, p. 20. What’s new in service shop software?

Charlie Barks. August 2017, p. 49. 3-D Printing ’round the world. Bill

O’Leary. October 2017, p. 42. The digital tide. Bill O’Leary. January 2018, p. 47. The inside looking in. Bill O’Leary. April 2018, p. 48. Virtual teamwork. Bill O’Leary. June 2018, p. 60. Smart machines and you. Bill O’Leary.

September 2018, p. 40. Let’s get social. Bill O’Leary. December 2018, p. 49. Alexa goes to work. Bill O’Leary. February 2019, p. 40. Your personality, on display. Bill

O’Leary. June 2019, p. 77. Mind your e-manners. Bill O’Leary. September 2019, p. 41. Privacy vs. monitoring on the Internet of Things. Matt Raebel. September 2019, p. 43

Please turn to next page

Location, location, location. Bill

O’Leary. October 2019, p. 46. 5G, explained. Selena Cotte. December 2019, p. 43. The next phase of IIoT. Selena Cotte.

December 2019, p. 45. Keeping up with new tech. Selena Cotte.

January 2020, p. 43. Privacy and the Internet of Things.

Charlie Barks. July 2020, p. 37. Ransomware and other threats against manufacturing. Selena Cotte. December 2020, p. 10.

Instruments

(See Testing & Measuring)

Insulation

(See Motors & Generators)

Inventory Control

The problem with slow-moving inventory. William H. Wiersema. July 2016, p. 32.

Maintenance

Where tradition meets the modern. Joseph S. Ho . January 2016, p. 19. Stop, look, and listen. Richard L. Nailen.

March 2016, p. 25. Taking stock of maintainability. Jane

Powell Campbell. April 2016, p. 36. Shedding energy costs. Charlie Barks.

August 2016, p. 23. Find your bottleneck(s). Bill O’Leary.

December 2016, p. 41.

Manufacturing

Manufacturing meeting in Milwaukee.

Charlie Barks, Kevin Jones & Joseph

Ho . April 2016, p. 9. The future of manufacturing on display.

The Electrical Apparatus sta . October 2016, p. 12. A manufacturing show for everyone.

The Electrical Apparatus sta . October 2016, p. 32. Brexit and U.K. manufacturing. Charlie

Barks. October 2016, p. 34. Innovation afoot. Bill O’Leary. March 2017, p. 19. Broad horizons. Kevin Jones. June 2017, p. 28. Managing change. Selena Cotte. September 2017, p. 16. Flex time. Pan Demetrakakes. September 2017, p. 21. Going the custom route. Charlie Barks.

September 2017, p. 26. Inspiration abroad. Selena Cotte. October 2017, p. 46. It’s beginning to look a lot like Christmas. Selena Cotte. November 2017, p. 41. Accustomed to transforming. Charlie

Barks. December 2017, p. 21. What goes into a plant. Selena Cotte.

December 2017, p. 37. Blacksmithing in the 21st century. Selena Cotte. December 2017, p. 39. More than an assembly line. Selena

Cotte. January 2018, p. 20. Origins of the e cient factory. Selena

Cotte. February 2018, p. 44. Buying in. Pan Demetrakakes. March 2018, p. 10. Innovation on the factory oor. The

Electrical Apparatus Sta . March 2018, p. 24.

—LEWA Inc. photo

In pharmaceutical processing, a good pump is at the center of a successful operation.

By Selena Cotte, EA Managing Editor

Next time you pop an ibuprofen, or fill a prescription for an antibiotic, consider where that pill came from.

Many therapeutic drugs originate from plants, and come a long way to the capsules we ingest without much thought, such as opiates, which are derived from the notorious opium flower. Most require deep chemical interven-

Pharmaceutical manufacturing needs equipment that is reliable, easy to clean and drain, and manufactured according to strict, tightly regulated guidelines from the FDA. Pumps, a vital piece of most process manufacturing, must be especially sanitary, efficient, and capable of a tion, taking years variety of functions. of research and development to so perfectly aid a medical problem while causing the least harm.

No matter where the drug came from, in order to be legally prescribed in the United States, it has to be tightly controlled and regulated--no one is (legally) mixing up life-saving or aiding cocktails in their basement. Every pill of a kind has to be the same exact kind, with no contaminants and consistent dosing. The pharmaceutical industry has regulated its manufacturing process with such precision that we hardly give a second thought to the Advil we’re taking, or the Tums we reach for. We have a headache or heartburn, and 30 minutes or so later, we have the same relief we expect. This has been no easy feat.

The pharmaceutical industry has a history that closely mirrors the Industrial Revolution. While herbal remedies and old family secrets reigned supreme in the olden days, the mid-19th century saw a booming market of wholesale manufacture, both due to scientific possibilities that did not previously exist, and the infrastructure to distribute more sophisticated products around the country through newly built railroads.

As opposed to the leaves and serums of the more distant past, this era saw more emphasis on applied research and intentional drug discovery as a result of more advanced chemistry knowledge. However, the work would mostly be done by small scale manufacturers until the early 20th century, when more stringent regulations came in from the U.S. government through the Pure Food and Drugs Act, which outlawed national distribution of mislabeled products (passed in 1906); and later on the Federal Food, Drug & Cosmetic Act, which required pre-market testing to prove drug safety and efficacy (passed in 1938, a year after 100+ people died from consuming a healing elixir we now consider antifreeze).

From then on, it became impractical for small-time operations to continue work in the pharmacology field, as research and quality control are expensive, specialized skills. Thus, the

Please turn to next page

ELECTRICAL APPARATUS | AUGUST 2020 25

08pharma.indd 1 7/23/2020 10:51:03 AM

Strong impressions. Bill O’Leary, March Strong impressions. Bill O’Leary, March 2018, p. 25. The thing about the Industrial Internet of Things. Selena Cotte. April 2018, p. 24. A city built on manufacturing. Richard

L. Nailen. May 2018, p. 45. Opioids on the job. Selena Cotte. May 2018, p. 62. Walking tour. Selena Cotte. June 2018, p. 23. A legacy of quality. Selena Cotte. June 2018, p. 31. What’s next in 3D printing? The Electrical Apparatus sta . July 2018, p. 36. Taking learning to the plant oor. Selena Cotte. July 2018, p. 42. Upward mobility in manufacturing.

Selena Cotte. August 2018, p. 60. Something for everyone at IMTS 2018.

Elizabeth Van Ness. September 2018, p. 18. Transformers built to last. Selena Cotte.

September 2018, p. 23. A world of opportunity in robotics. Matt

Raebel. September 2018, p. 42. “Domo arigato, misuta robotto.” Selena

Cotte. September 2018, p. 48. Global in more ways than one. The Electrical Apparatus sta . October 2018, p. 18. Future perfect. Selena Cotte. October 2018, p. 25. CNC machining and the shop. Bill

O’Leary & Matt Raebel. October 2018, p. 42. Smart for all. Selena Cotte. October 2018, p. 48. Better together. Bill O’Leary. November 2018, p. 25. Tari ti . Selena Cotte. November 2018, p. 50. One size does not t all. Selena Cotte.

December 2018, p. 48. Middle-of-the-road brewer. Bill O’Leary.

March 2019, p. 24. An e cient team of beer lovers. Matt

Raebel. March 2019, p. 26. Classic yet re ned. Selena Cotte. March 2019, p. 29. Where quirkiness belies careful planning. Selena Cotte. March 2019, p. 32. A passion for beer—and sound maintenance. Charlie Barks. March 2019, p. 35. Guess who’s back in town? Selena

Cotte. March 2019, p. 51. What happens when the power goes out? Selena Cotte. April 2019, p. 38. What to make of trends in manufacturing? Selena Cotte. June 2019, p. 75. Made in America: the rise and fall of factory towns. David Miller. August 2019, p. 29. The decline of the manufacturing union job. Selena Cotte. August 2019, p. 49. The metals industry today. William H.

Wiersema. September 2019, p. 38. What’s old is new. Selena Cotte. September 2019, p. 46. In manufacturing, uncertainty rules.

Kevin Jones. November 2019, p. 21. The reshoring revolution. David Miller.

January 2020, p. 23. Just one word: plastics. William H.

Wiersema. February 2020, p. 35. Coronavirus and the supply chain. Selena Cotte. March 2020, p. 40. The end of an era for manufacturing?

Selena Cotte. June 2020, p. 55. Beyond Fordism. David Miller. July 2020, p. 40. Machine, print me a cheeseburger. Selena Cotte. October 2020, p. 12. Food and beverage Manufacturing gets exible. David Miller. October 2020, p. 40.

Motor Performance

Managing motor overloads. Richard L.

Nailen. January 2016, p. 23. The motor e ciency numbers game.

Richard L. Nailen. September 2016, p. 27. What’s next in a-c motor improvement?

Richard L. Nailen. December 2016, p. 23. Motor e ciency myths. Richard L.

Nailen. April 2017, p. 33. Motor air gap: a necessary evil. Richard

L. Nailen. May 2018, p. 34. Starts per hour: not as simple as it looks.

Richard L. Nailen. June 2018, p. 35. How practical is the “calibrated” motor?

Richard L. Nailen. December 2018, p. 27. E ciency comparisons may not be easy.

Richard L. Nailen. February 2019, p. 31. When did we start caring about e ciency? David Miller. February 2019, p. 19. E ciency comparisons may not be easy.

Richard L. Nailen. February 2019, p. 31. How clear is your crystal ball? Richard

L. Nailen. March 2019, p. 39. What goes up . . . must stop sometime.

Richard L. Nailen. August 2019, p. 33. Some reminders about motor e ciency.

Richard L. Nailen. July 2020, p. 27.

Motor Protection

When voltage varies. Richard L. Nailen.

November 2017, p. 25.

Motors & Generators

(See also Motor performance and Motor

—David Nance, USDA ARS image

From farm to factory: How motors bring food to the table

Food, one of the most ubiquitous elements of the human experience, goes through a long industrialized process to get from soil to bowl.

By Selena Cotte, EA Managing Editor

Whether you enjoy the ritual of cooking an elaborate and thoughtout dinner, or merely eat the same brand of frozen pasta for lunch everyday, you probably understand the importance of easily accessible (and tasty) foods. In most cases, when it comes to figuring out the logistics of sustenance, our lives are too complex to manage much more than just grocery store trips — largely as a result of industrialization. For your average American, food cultivation and processing isn’t manageable with all of the other duties we take on, aside from harvesting the occasional tomato plant or two.

It wasn’t always like this: Once, we were all responsible for our own hunting and gathering, more dependent on whether our family members or local community did their duty in shooting game and picking non-poisonous mushrooms than on shipments and efficient agricultural and factory conditions. While this history is quite ancient, and had evolved long before industrialization became possible, it still illustrates the different, backstage role that food and eating plays in our daily lives. We are more removed from it than ever — but perhaps we depend on its reliability more than ever as well.

Even if you do fancy yourself a farmer, your options would be far more limited if you stuck to that which you produced yourself. Want guacamole but don’t live in a region with avocados? Your dreams don’t have to be dreams with the intricate processing and distribution at play that allow you to either collect your own ingredients at a local market — or pick up a pre-made dip that will satisfy in a pinch.

Like most modern industries, this minor convenience is the result of a complicated industrial chain, beginning in nature still, but taking several mechanical detours through the way. This article hopes to cover some of the major intersections between electromechanical equipment and the journey of food, beginning with farming and agriculture.

How will independent service shops survive?

Webinar etiquette Ambient temperature New product showcase Speaking ‘engineerese’ Executive incentives

06cov.indd 1 11/30/2020 7:48:13 AM

protection.) protection.) Safe motor storage. Richard L. Nailen.

June 2016, p. 31. Peas in a pod: Are they really? Richard

L. Nailen. August 2016, p. 27. From concept to customer: How a new motor comes to market. Richard L.

Nailen. December 2016, p. 14. Solving the rotor bar dilemma. Richard

L. Nailen. January 2017, p. 25. What makes insulation “sealed”? Richard L. Nailen. May 2017, p. 33. Another look at the conventional synchronous motor. Richard L. Nailen.

June 2017, p. 35. The problem with Internet motor forums. Richard L. Nailen. August 2017, p. 43. Cool it! Richard L. Nailen. January 2018, p. 24. The in uence of rotor bar materials.

Richard L. Nailen. February 2018, p. 29. Motor voltage: nameplate rating vs. supply. Richard L. Nailen. March 2018, p. 31. For servos, there’s no place like home.

Pan Demetrakakes. May 2018, p. 12. Servomotors. The Electrical Apparatus sta . May 2018, p. 18. The market for metric. David Miller. October 2018, p. 14. The metric di erence. Richard L.

Nailen. October 2018, p. 31. “Minor” motor insulation is also important. Richard L. Nailen. November 2018, p. 31. How practical is the calibrated motor?

Richard L. Nailen. December 2018, p. 27. Applying apparatus outdoors. Richard

L. Nailen. January 2019, p. 25. What’s in a nameplate? Richard L.

Nailen. June 2019, p. 45. Developments in cast copper rotors.

Richard L. Nailen. July 2019, p. 36. Still waiting for the high-temperature superconducting motor. Richard L.

Nailen. September 2019, p. 12. Spooks on the power line. Richard L.

Nailen. November 2019, p. 29. Motor life: not a simple concept. Richard

L. Nailen. December 2019, p. 31. Good, better, best. Richard L. Nailen.

January 2020, p. 27. Understanding a motor’s service factor.

Richard L. Nailen. October 2020, p. 21. From farm to factory: How motors bring food to the table. Selena Cotte. October 2020, p. 25. A question of motor size. Richard L.

Nailen. November 2020, p. 29. “Revolutionary motor technology”: marketing or reality? Kevin Jones &

Selena Cotte. December 2020, p. 23. Large, medium, small: What’s the

di erence? Richard L. Nailen. December 2020, p. 29. What do we mean by “cyclic load”?

Richard L. Nailen. December 2020, p. 42.

Power Systems

What’s become of the Color Books?

Richard L. Nailen. April 2016, p. 24. When does “low voltage” become “high”?

Richard L. Nailen. May 2016, p. 31. The Smart Grid and power quality. Richard L. Nailen. May 2016, p. 45. The re ant menace. Richard L. Nailen.

July 2016, p. 23. A Smart Grid user’s manual? Richard L.

Nailen. February 2017, p. 18. How important is terminal screw tightness? Richard L. Nailen. February 2017, p. 27. Smart Grid, dumb standards? Richard

L. Nailen. March 2017, p. 14. Innovations in battery technology. Richard L. Nailen. March 2017, p. 25. Describing the indescribable. Richard L.

Nailen. January 2019, p. 20. Spooks on the power line. Richard L.

Nailen. November 2019, p. 29.

Power Transmission, Mechanical

Dressing for industrial V-belts: yes or no? Richard L. Nailen. April 2017, p. 27. Transformers built to last. Selena Cotte.

September 2018, p. 23.

Pumping Systems

Pump speed variation: look beyond the

ASD. Richard L. Nailen. February 2017, p. 31. Be safe around pumps. Charlie Barks.

August 2017, p. 56. Staying in the ow. Pam Demetrakakes.

August 2018, p. 14. Record oil production pushes demand for pumps. Kevin Jones. November 2019, p. 45. Pumps and motors: a match made in heaven. Kevin Jones. December 2019, p. 44. Pump rms lead in workforce development. Kevin Jones. January 2020, p. 44. New pump e ciency rule now in e ect.

Kevin Jones. February 2020, p. 43. E cient pumps, e cient HVAC/R. Kevin Jones. March 2020, p. 39. Improving pump e ciency. Kevin

Jones. April 2020, p.36. When “ ushables” clog the pumps. Kevin Jones. May 2020. p. 46. Pool pump season is here. Kevin Jones.

June 2020, p. 53. EVs no place for pumps? Wrong! Kevin

Jones. July 2020, p. 39. Pharmaceutical grade pumps: Just what the doctor ordered. Selena Cotte. August 2020, p. 25. New guidance for pump e ciency incentives. Kevin Jones. August 2020, p. 40. Know your food and beverage pumps.

David Miller. October 2020, p. 41. Delivering water responsibly. Kevin

Jones. November 2020, p. 41. Trends in pump design. Kevin Jones.

December 2020, p. 39. Winds of change. Kevin Jones. October 2016, p. 21. The Big Green Machine. Bill O’Leary.

February 2016, p. 14. Recondition it. Bill O’Leary. February 2016, p. 36. Innovation roundup. Elizabeth Van

Ness & Joseph Ho . March 2016, p. 13. Beam me up. Bill O’Leary. November 2016, p. 12. Visions of shop equipment. Kevin

Jones. December 2016, p. 12 Holiday product showcase. The Electrical Apparatus sta . December 2016, p. 31. Solving the rotor bar dilemma. Richard

L. Nailen. January 2017, p. 25.

A BARKS PUBLICATION

JULY 2020 / $5 Electrical Apparatus More than Motors

The road ahead for electric vehicles

The future of EV charging Automated manufacturing Pumps in electric vehicles Reviewing motor effi ciency Rethinking retirement

07cover.indd 1 11/30/2020 7:49:05 AM

More than motors: HVAC/R. The Electrical Apparatus sta . January 2018, p. 16. The x is in. Pan Demetrakakes. January 2018, p. 21. Are motors being properly repaired?

Richard L. Nailen. April 2018, p. 33. What does motor “reconditioning” involve? Richard L. Nailen. July 2018, p. 26. Motor repair standards: still evolving?

Richard L. Nailen. May 2019, p.34. A republic, if we can x it. David Miller.

June 2019, p. 37. Industrial-use drones: a primer. Selena

Cotte. February 2020, p. 41. The future of the small, independent shop. David Miller. June 2020, p. 33,

Safety & Health

Staying current with OSHA. Joseph S.

Ho . January 2016, p. 37. Getting a grip on hand and power tools.

Joseph S. Ho . February 2016, p. 34. Why emergency preparedness can make the di erence. Joseph S. Ho . March 2016, p. 36. Keep it down! Joseph S. Ho . April 2016, p. 31. Keep your eyes on the road. Joseph S.

Ho . May 2016, p. 49. Dealing with summer heat and humidity. Joseph S. Ho . June 2016, p. 40. The re ant menace. Richard L. Nailen.

July 2016, p. 23. Shedding light on workplace dangers.

Joseph S. Ho . July 2016, p. 37. Steering clear of accidents. Joseph S.

Ho . August 2016, p. 35. Addressing machine hazards. Joseph S.

Ho . September 2016, p. 35. Avoiding hazards overseas. Joseph S.

Ho . October 2016, p. 46. Get some sleep! The Electrical Apparatus sta . November 2016, p. 38. Self-balancing scooters receive the UL thumbs-up. Charlie Barks. December 2016, p. 33. Getting a grip on hand protection. Charlie Barks. December 2016, p. 44. Changing of the guard. Charlie Barks.

January 2017, p. 38. Wearable safety. Charlie Barks. February 2017, p. 37. Alternate realities. Charlie Barks.

March 2017, p. 36. What’s all that racket? Charlie Barks.

April 2017, p. 20. Hurricane relief. Charlie Barks. May 2017, p. 44. Ocular rift. Bill O’Leary. June 2017, p. 20. Automation safety. Charlie Barks. June 2017, p. 22. What’s next for safety? Charlie Barks.

July 2017, p. 31. Be safe around pumps. Charlie Barks.

August 2017, p. 56. Smart meters: the larger conspiracy.

Richard L. Nailen. August 2017, p. 62. Drilling down. The Electrical Apparatus sta . September 2017, p. 17. OSHA’s stricter ruling on “dangerous dust.” Charlie Barks. November 2017, p. 44. OSHA Update. Charlie Barks. March 2018, p. 38. Dangers lurking online. Charlie Barks.

May 2018, p. 60. Opioids on the job. Selena Cotte. May 2018, p. 62. Cutting-edge safety: what’s next in products & programs. Matt Raebel. July 2018, p. 14. Accounting for safety. William H.

Wiersema. July 2018, p. 32. The great safety debate. Matt Raebel.

August 2018, p. 56. Tesla’s safety problem. Matt Raebel.

November 2018, p. 45. One size does not t all. Selena Cotte.

December 2018, p. 48. Promoting un-safety by accident. Elizabeth Van Ness. January 2019, p. 20. Solar safety 101. Charlie Barks. March 2019, p. 54. Emotional balancing act. Bill O’Leary.

March 2019, p. 55. Sinister silica. Matt Raebel. May 2019, p. 45. Privacy vs. monitoring on the Internet of Things. Matt Raebel. September 2019, p. 43. Crane smarts. Bill O’Leary. November 2019, p. 44. The importance of environmental protection. Selena Cotte. November 2019, p. 48. Field safety 101. Kevin Jones. February 2020, p. 40. Hydro uorocarbon bill hits a road block. Selena Cotte. April 2020, p. 40. The Security Industry Association.

Charlie Barks. May 2020, p. 26. The Covid-19 stimulus. William H.

Wiersema. May 2020, p. 38. Clean plant, healthy employees. Kevin

Jones. May 2020, p. 41. Invoking the Defense Production Act.

Selena Cotte. May 2020, p. 43. When “ ushables” clog the pumps. Kevin Jones. May 2020, p. 46. 3D printers: The medical industry’s latest resource. Selena Cotte. May 2020, p. 50. No rest for the regulators. Kevin Jones.

July 2020, p. 43. Safe manufacturing post-Covid-19. William H. Wiersema. August 2020, p. 36. Anti-nuclear meltdown. David Miller.

August 2020, p. 43. Robots boost plant safety post-Covid.

David Miller. November 2020, p. 42.

Service & Sales Companies

(Featured in full-length articles) Advanced Motor Solutions, Hamilton,

Ontario. Diverse team, diverse market.

Selena Cotte. February 2020, p. 23. Automation & Control Technologies,

Perrysburg, Ohio. Two of a kind. Bill

O’Leary. May 2019, p. 27. Arizona Electric Motor Service, Tucson,

Arizona. From “The Service” to motor service. July 2017, p. 17. BlueRidge.ai, Fulton, Md. Motor intelligence. Charlie Barks. September 2019, p. 25 Blue Ridge Electric Service, Winchester,

Va. Charlie Barks. September 2019, p. 25. Close the Loop, Hebron, Ky. Toner Power.

March 2016, p. 19. Controls and Electric Motor Company,

Joplin. Mo. Weathering the storm. Bill

O’Leary. April 2016, p. 32. EEMSCO, Evansville, Ind. A lesson in longevity. Kevin Jones. April 2016, p. 19.

the manufacturer’s exact recommendations if possible, and also ensure you are not over lubricating.

A struggle to connect...

...to power, that is. While farms commonly make use of heavy duty electrical equipment, not all of them have the energy infrastructure to handle all that force.

“WWhen it comes to applications like these, the availability of power becomes an issue,” said Ben Morris, director of sales and marketing at Single Phase Power Solutions, manufacturer of the Belle motor. “The electrical grid is not that great in rural areas where a lot of farming is, and more and more of farming is moving toward these large farms with large equipment that is outgrowing the ability of their power sources.”

Some farms are reliant on diesel to solve this challenge, but this can get pricey — not to mention environmental concerns about oil and gas becoming more pressing, leaving many to seek a more sustainable solution.

“Many have turned to diesel generators that are dirty, not environmentally friendly, expensive to run — costing thousands of dollars a month,” Morris said.

SPPS, which markets its Belle motor for a variety of industries, has strong ties to agricultural work, and has developed a proprietary 1-to-3 power source solution to this precise challenge that “lowers operating cost, is environmentally cleaner, and more energy efficient,” according to Morris.

While it would be exorbitantly unreasonable for most farmers to replace that infrastructure entirely, SPPS uses its patented generator solution at a fraction of the cost. “The power source itself, it takes a single phase input, our 100 horsepower Belle motor is coupled to a three-phase generator, and as the motor turns, it produces three-phase electricity,” Morris said. “This reduces their cost — so, if they were previously doing it with diesel, and they want to install a new system anyway, this reduces cost but is still more efficient.”

Environmental changes

As climate change becomes more of a threat, many farms must adapt beyond the elimination of diesel generators. For instance, a change in rainfall has the potential to wipe out a farm’s productivity if the farmers do not anticipate changes and implement new systems.

Please turn to next page

Single Phase Power Solutions offers a patented solution to farms with sparse access to energy: A 1-to-3 power generator that allows farmers to better utilize the electricity it does have access to.

—Single Phase Power Solutions image

ELECTRICAL APPARATUS | OCTOBER 2020 29 Electric Motor Co., Redwood Falls, 10AgMotors.indd 5Minn. Rural pride. 9/22/2020 11:08:17 AM Selena Cotte. December 2019, p. 25. Electric Motor Technologies, Cincinnati, Ohio. Entering a new phase. Kevin

Jones. August 2019, p. 23. Flanders, Evansville, Ind. A patriarch’s vision ful lled. Kevin Jones. August 2018, p. 25. Industrial Repair Service, Cumming,

Ga. Poised for growth. Charlie Barks.

April 2018, p. 27. L&S Electric, Inc., Wausau, Wis. Above and beyond. Kevin Jones. February 2019, p. 25. Motor shops then and now. Charlie

Barks. January 2016, p. 11.

Please turn to next page

Innovative motor designs

Spelled right—but still wrong? Richard L.

Nailen. December 2019, p. 18. The how and why of locked-rotor testing.

Richard L. Nailen. February 2020, p. 29. Call it “engineerese.” Richard L. Nailen.

June 2020, p. 18. How well do we understand ambient.

Richard L. Nailen. June 2020, p. 41.

Testing & Measuring

Product showcase Trends in pump design The various motor sizes Secure virtual meetings Financial reporting

Is condition monitoring a cure-all? Richard L. Nailen. September 2018, p. 29. Pandemic provides a boost for remote condition monitoring. Kevin Jones.

July 2020, p. 10.

INDEX continued

Roy’s Electrical Service, Cheswold, Del.

Inspired leadership. Joseph S. Ho .

June 2016, p. 27. Scotty’s Electric Motor Repair, Orland, Calif. An instinct for success. Bill

O’Leary. December 2018, p. 21. Servotech, Middletown, Conn. Big opportunities in small motors. Bill

O’Leary. November 2016, p. 21. Shermco Industries, Irving, Tex.

Growth through diversi cation. Joseph

S. Ho . December 2016, p. 17. Sloan Electromechanical Services &

Sales, San Diego, Calif. Conserve, preserve, and serve. Bill O’Leary. February 2016, p. 19. Vaughn Electric Co., Union City, Tenn.

Diverse interests. Kevin Jones. November 2017, p. 19. Whelco Industrial, Perrysburg, Ohio.

Two of a kind. Bill O’Leary. May 2019, p. 27. York Repair, Bay City, Mich. One shop’s experience with variable-frequency drives. Bill O’Leary. September 2016, p. 24. IPS acquires Precision Electric Motor

Works. Kevin Jones. April 2020, p. 10.

Solid-State Electronics

(See Controls & Control systems)

Terminology

How long is a long time? Richard L.

Nailen. January 2016, p. 8. Be careful with size comparisons. Richard L. Nailen. April 2016, p. 14. Avoid the “sin of omission” Richard L.

Nailen. July 2016, p. 38. The magic of one-third. Richard L.

Nailen. January 2017, p. 39. Spell-checking isn’t always enough. Richard L. Nailen. April 2017, p. 40. Instruction manuals: a word to the unwise. Richard L. Nailen. July 2017, p. 23. Looking again at “motor design life.”

Richard L. Nailen. July 2017, p. 40. Equipment and apparatus: What’s the di erence? Richard L. Nailen. October 2017, p. 47. High Voltage? Not Necessarily. Richard

L. Nailen. January 2018, p. 39. How not to “say it right.” Richard L.

Nailen. April 2018, p. 46. A common language? Richard L. Nailen.

October 2018, p. 40. Describing the indescribable. Richard L.

Nailen. January 2019, p. 20. Does that product make the grade? Richard L. Nailen. April 2019, p. 40. In ation isn’t just an economic concern.

Richard L. Nailen. July 2019, p. 46.

Training

An electric—and eclectic—life. Bill

O’Leary. May 2016, p. 25. Earth, Wind & Hire. Bill O’Leary. July 2016, p. 17. Strength in numbers. Bill O’Leary. July 2016, p. 28. Hey, who needs training? Bill O’Leary.

July 2016, p. 34. Return to civilian life. Bill O’Leary. July 2017, p. 10. Union and corporate assistance for veterans. Selena Cotte. July 2017, p. 13. The good, the bad, and the ADDIE. Bill

O’Leary. July 2017, p. 33. Inspiration abroad. Selena Cotte. October 2017, p. 46. More than motors: HVAC/R. The Electrical Apparatus sta . January 2018, p. 16. Training pain. Pam Demetrakakes. July 2018, p. 10. The state of the workforce. Selena Cotte.

July 2018, p. 11. Winds of opportunity. Bill O’Leary. July 2018, p. 21. Taking learning to the plant oor. Selena

Cotte. July 2018, p. 42. Shifting responsibilities. Bill O’Leary.

September 2018, p. 38. Will electric motor workers be the auto mechanics of the future? David Miller.

January 2019, p. 16. Education that provides a boost. Matt

Raebel. January 2019, p. 21. “Get ’em while they’re young.”€ Selena

Cotte, January 2019, p. 48. Pump rms lead in workforce development. Kevin Jones. January 2020, p. 44. How to get a start in the HVAC/R trade.

Kevin Jones. March 2020, p. 13. HVAC/R heats up local economy. David

Miller. March 2020, p. 25. More ways than ever to “earn while you learn.” Kevin Jones. April 2020, p. 12. Organizations o er free online training.

Kevin Jones. May 2020, p. 48.

Feature | More Than Accounting

Financial reporting in a pandemic

— Freepik/Vecteezy images

How to account for unusual events such as the disbursement of Paycheck Protection Program funds

By William H. Wiersema, CPA, EA Contributing Editor

Financial statements for 2020 pose new challenges. Considering the business e ects of Covid-19, companies are having an unusual year. While some experience windfalls, others are troubled, particularly retailers and services dependent on public interaction. For them, just as cash ow slowed, nancing tightened up.

To maintain employment, the U.S. government e ectively provided grants to troubled companies through its Paycheck Protection Program (PPP), initiated in March. Eligible businesses could obtain 2.5 months’ payroll to spend on payroll, utilities, and rent or mortgage interest within 8 to 24 weeks of receipt. Following that, borrowers can apply to the U.S. Small Business Administration (SBA) to have the loans forgiven.

Not surprisingly, the presentation of nancial results this year will depart from the past. Because PPP is unique, the accounting is unfamiliar, particularly the grant aspect. Under this mindset, companies may record PPP in di erent ways, often incorrectly. Aside from PPP, concerns arise regarding asset values and disclosure of business uncertainties.

To avoid being blindsided, management should know the accounting applicable to the pandemic to implement it properly. Generally Accepted Accounting Principles (GAAP), which are the published standards, provide the framework for proper nancial statement presentation. The rules include PPP accounting, going concern documentation, and asset valuation.

This article intends to give everyone adequate time to understand the impact and consult with a quali ed advisor relative to speci c circumstances.

Account for PPP

Accounting for PPP has been diverse. Some borrowers assume that PPP funds replace revenue lost in the pandemic and accordingly classify loan proceeds as revenue. However, recognizing PPP applies to payroll, rent, and other qualifying items, some other borrowers charge those expenses against the loan balance rather than write them o on the income statement. Still others keep the funds and the liability o their books entirely, potentially calling into question their need for PPP funds.

On the other hand, GAAP requires borrowers wait for nal SBA approval. Under the preferred treatment, the loan becomes income only when and to the extent forgiven. At that point, it is classi ed as a non-operating gain on debt extinguishment without o setting the quali ed spending.

This conservative treatment is consistent with past practices. For example, GAAP recognizes business interruption insurance proceeds as income only after contingencies resolve. Non-operating income can occur in a period di erent from the loss. Moreover, classifying PPP as a loan until forgiven is consistent with the SBA rules for the disposition in business combinations. The PPP lender escrows sales proceeds until the SBA approves forgiveness. Please turn to next page The spike in distance learning is more than just a temporary anomaly. Kevin

Jones. June 2020, p. 22. Still too soon to assume training events are in-person. Kevin Jones. August 2020, p. 23. University incubators at center of food development. Kevin Jones. October 2020, p. 14. Assessing the talent of technicians.

Charlie Barks. November 2020, p. 19. Fast-track electrician training is gaining favor. Kevin Jones. November 2020, p. 46.

Feature | Circuits & Circuitry

The truth about arc-fault circuit interrupters

The decision to use a simple electrical safety device turns out to be far more complicated than it first appears

By Richard L. Nailen, EA Engineering Editor

The premise is simple: Electrical fires kill people; arc-fault circuit interrupters (AFCIs) prevent electrical fires; therefore AFCIs save lives. To tell the whole truth, however, we must add one word in several places: some AFCIs prevent some electrical fires and therefore save some lives. Any safety measure comes at a cost, and its cost-effectiveness must be justified. If it’s your life or that of a loved one, you may say that the sometimes-substantial cost of AFCI protection is well worth it. But, just as with protection against any other hazard, the choice is not so simple. Speed limit enforcement, better road conditions, automatic vehicle braking systems – you name it; all such improvements theoretically reduce highway traffic deaths. But no matter how much money is spent on such things, the only way to provide perfect motorist safety is to keep the car in the garage.

Several kinds of electrical arcing fault are possible. All are capable of causing a fire. No statistics exist as to their relative importance. One is an unwanted current path between conductors representing two sides of a circuit. Those involved in preparation of the National Electrical Code refer to this as a parallel arc fault, whereas most of us consider it a short circuit, which may involve no arc at all. The voltage involved will be whatever is present across that circuit – 120, 480, 4,160, etc. The possible arc current will be whatever that voltage can drive through the combined impedance of the arc plus all the circuit elements in the conducting path.

A second possible arcing fault is between one conductor and some earth (ground) or neutral surface. The nature of that fault path again determines the relationship between voltage and current. An arc may or may not occur.

Third is the series arc involving a break in a single current-carrying conductor. Impedance of the arc will add to that in the rest of the circuit to limit arc current, which cannot exceed whatever current was flowing in the conductor before the break occurred.

The physics of arcing

Only one of these three conditions necessarily involves formation of an arc. A decades-long debate about how to detect presence of such an arc, and how to provide suitable circuit protection, continues today within the NEC code-making panels and throughout the electrical industry.

ELECTRICAL APPARATUS / MAY 2020

05AFCI.indd 1

Utilities

Arcing may have occurred here – but was it cause, or consequence?

— Electrical Apparatus file photo

Finally, an overloaded conductor may overheat without the occurrence of any break or arc. More often, a joint between two conductors may develop a high enough resistance to reach a dangerously high temperature. This is the “glowing connection” phenomenon. Little was known about such behavior until both the Dept. of Housing and Urban Development and the Consumer Product Safety Commission initiated studies by the National Bureau of Standards. The NBS issued its report in October 1977, titled “Exploratory Study of Glowing Electrical Connections.” Their tests showed that such terminal connections could reach temperatures of 450°F to 750°F. The NBS conclusions: Such glowing “may exist for protracted periods of time (hours, days, months) without breaking the electrical circuit” and that the condition “will not blow fuses, trip circuit breakers,” or cause GFCI operation (it was too early to deal with the AFCI). This phenomenon can not only heat a termination or splice to incandescence without any interruption of normal current flow; it can seldom be detected after the fact, and it is independent of the functioning of any appliance (except one seriously overloaded). Any kind of arc is a bridge of

Please turn to next page

31

4/23/2020 11:36:25 AM

(See also Service & Sales Companies) The language of the Smart Grid. Richard

L. Nailen. February 2016, p. 40. Can everything be “smart”? Richard L.

Nailen. August 2016, p. 43. Are we ready for “microgrids”? Richard L. Nailen. November 2016, p. 40. A Smart Grid user’s manual? Richard L.

Nailen. February 2017, p. 18. Smart Grid, dumb standards? Richard L.

Nailen, March 2017, p. 15. Is there a blackout in your future? Richard L. Nailen. August 2017, p. 35. Smart meters: the larger conspiracy.

Richard L. Nailen. August 2017, p. 62. Electric utilities face uncertain future.

Richard L. Nailen. September 2017, p. 27. The “newest new thing”: intra-grid sensors. Richard L. Nailen. November 2017, p. 46. Smart Grid concepts not always clear.

Richard L. Nailen. February 2018, p. 18. “Let’s talk about it” Richard L. Nailen.

May 2018, p. 56. Are smart meters still an issue? Richard

L. Nailen. August 2018, p. 46. Smart meters aren’t the only concern.

Richard L. Nailen. December 2018, p. 43. Peas in a pod? Richard L. Nailen. March 2019, p. 48. Safety in numbers? Richard L. Nailen.

June 2019, p. 24. India’s Smart Grid mission. Charlie

Barks. October 2019, p. 12. How a ordable is the “smart” home?

Richard L. Nailen. January 2020, p. 20. Utilities help customers improve

HVAC/R e ciency. Kevin Jones.

March 2020, p. 6. A game with many players. Richard L.

Nailen. April 2020, p. 44. Disconnects suspended; charitable giving increases. Kevin Jones. May 2020, p. 20. Moving forward with green energy projects. Kevin Jones. June 2020, p. 51. (See Drives & Inverters)

Water/Wastewater Treatment

Water, water everywhere. Charlie Barks.

August 2016, p. 14. Fluid agenda. Charlie Barks. August 2017, p. 12. Water conference to splash back into

Chicago. Selena Cotte. August 2017, p. 14. A glimpse of the future of water. Bill

O’Leary. November 2017, p. 34. Hydrate, regenerate, educate. Matt

Raebel. August 2018, p. 20. Wastewater 101: The basics. The Electrical Apparatus sta . August 2018, p. 42. Water’s ebb and ow. David Miller. November 2018, p. 12. Weftec 2018. Elizabeth Van Ness. November 2018, p. 20. Where the water pros meet. Charlie

Barks. August 2019, p. 12. A glossary of water-quality terms. Charlie Barks. August 2019, p. 16. In search of pure water. Bill O’Leary. August 2019, p. 48. What’s new in water sanitation. Kevin

Jones. August 2020, p. 29. Great news: Beer is sustainable. David

Miller. October 2020, p. 10.

Workforce

Will electric motor workers be the auto mechanics of the future? David Miller.

January 2019, p. 16.

A BARKS PUBLICATION

OCTOBER 2020 / $5 Electrical Apparatus More than Motors

From farm to factory:

How motors bring food to the table

Machines that print food? Stimulus spending for EVs Harmonization of effi ciency A motor’s service factor Uncertainty about revenue

10cov01.indd 1 11/30/2020 7:53:37 AM

Education that provides a boost. Matt

Raebel. January 2019, p. 21. Planning for retirement. William H.

Wiersema. January 2019, p. 37. Perking up the work force. Bill O’Leary.

January 2019, p. 45. “Get ’em while they’re young.” Selena

Cotte. January 2009, p. 48. EA

Back issues, or photocopies of articles when back issues are out of stock, are available from:

Circulation Department Barks Publications, Inc., 17 N. State St., Suite 1650, Chicago, Ill. 60602 (312) 321-9440 Fax (866) 228-7274 www.barks.com See page 4 for prices