3 minute read

TECHNICAL INFORMATION

from About Us

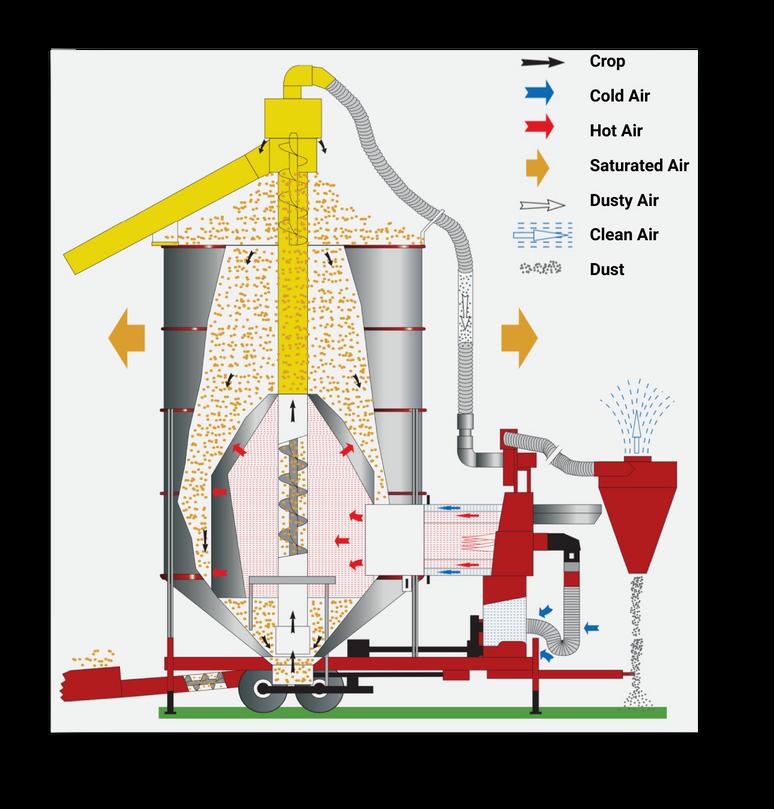

The Pedrotti Master Drier is constructed with a heavy duty chassis fitted with stabilising screw jacks and incorporating level bubbles. The drying chamber is fabricated from “Inox” perforated stainless steel and is framed for strength. Internal rotating agitators ensure continual grain recirculation giving facility for fast unloading

Advertisement

The centre auger is driven by short belts incorporating a gearbox giving a more positive drive On all RS models the top auger is raised and lowered by a geared winch unit which engages with the centre auger drive and is automatically securely fastened in one operation The same principle applies to the top screen.

Air Circulation

The centrifugal fan is quiet in operation and gives maximum possible air circulation throughout the drying chamber. The fan disengagement is very simple. A fan cover is provided on tractor drive models and an on/off switch for electric drive machines, this gives total control of air movement, especially during the loading/unloading process.

Heat Requirements

The burner system incorporates a fail safe control system with photo cell cut off. Oil fired burners have a twin or triple jet oscillating principle controlled by independent solenoids with the possibility to interchange jets to meet any heat requirement. These dual fuel burners can be operated with diesel or kerosene and are economical, estimated at 5 litres per ton, giving 5% moisture extraction.

Drive Alternatives

The automatic temperature system is directly related to moisture and is controlled by three pre-set thermostats which are individually programmed to meet crop requirements and have automatic cut-off facilities for control of heat All controls are mounted in weatherproof panels, incorporating operating and safety systems

Industrial in design, strength and performance, delivered with our unrivaled Master Care 3-Year Warranty Package.

Temperature Control

There are a number of drive options available to you when choosing your next Mobile Drier, with inovative and efficient technology used in the manufacturing and build process helping you get the most from your drier throughout your busy drying period

Independent Engine Drive

Dual Dive (Electric Drive With Inbuilt 3 Phase Generator)

Scan the QR code to find more information on the Master Dryer range!

Electric Three Phase ( Mastermatic Complete Automation)

Generator (Mastermatic Complete Automation)

Horsch is an established manufacturer of high-end sprayers. Horsch enters the three-point crop care market with the newly developed mounted sprayer Leeb CS. CS stands for CompactSprayer and the sprayer is designed to be both compact and manoeuvrable - ideal for smaller fields, completing their range. The Leeb CS models include three different tank sizes -1,400, 1,800l, 2,200l with an additional front tanks to soon be offered. You can find more information on the Horsch Leeb sprayer range by scanning the QR code to the right!

Boom widths available form 18m-30m, featuring a 25cm nozzle design. Being new to the Horsch range, the Leeb CS mounted sprayer relies on proven technology from existing models. Including active boom control system, continuous internal cleaning system and induction tank. The sprayer also features hydraulically driven pumps and the same user interface as that used on the Leeb LT & GS.

The Horsch brand is known for innovation and build quality and there are products in the range for all types and sizes of enterprise, from smaller family farms to large estates. Chemical application is increasingly expensive, and for all sizes of farm the priority is to get as much of the chemical as possible on to the target. Horsch sprayers have industry-leading technology to ensure this happens, but it’s the incredibly stable boom and 25cm nozzle spacing that impresses most.

The Leeb GS will be available from Edwards & Farmer Ltd in early spring, get in touch with the sales team for more information.

AsoneofthemorerecentadditionstotheEdwards&FarmerLtdportfolio, TerraTechLtdtakeprideinofferingarangeofBritishbuiltcropestablishmentandsoil managementmachineryforthearableandgrasslandsectors.

Meetingtheneedsofmodernagriculture,ourmachinesaredesignedtoenablefarmers toreducecropestablishmentandinputcosts,saveonlabourandmaintenance,and ultimatelyproduceabettercrop.

Crop Establishment

Whether you’re looking to improve your soil structure, or create a seedbed using min-till or deep till systems, we have a range of subsoilers, cultivators, presses and rollers to suit

Our aim is to help you get the seed in the ground with positive soil contact, promoting germination and allowing the roots to grow downwards This makes for stronger, healthier plants, more resilient to drought and disease, producing greater yields

3m

Soil Management

The effective management of grass leys and pastures will significantly improve their performance. If you’re looking to improve your soil structure or level uneven fields and bury stones, then our low disturbance subsoilers and ballast rollers will do the job.

Freeing your pastures or leys from soil compaction can reduce the impact of drought and lodging on your grass. A healthy soil structure promotes drainage and deep rooting. Rolling to level the surface can prevent stones and soil from entering your silage, helping improve the quality and animal health. We believe grass should be treated as a crop, and managed accordingly.

BERTHOUD manufacture a range of spraying solutions that provide outstanding application quality and have been designed for easy use and maintenance, saving you time and money.

We have a range of used BERTHOUD Sprayers in stock, call our sales team on 01743 718762 to discuss your requirements or get in touch to talk about the wide range of new sprayers available for 2023.

Scan the QR code fort he latest stock list!

AIR-RIDE ULTIMATE VERSATILITY

Low weight and soil compaction • Superb clearance

Spirit

HARRIER BUILT TO PERFORM Front & Rear oscillating axles for maximum traction

Advanced Sprayers. Healthier Crops.