2 minute read

TMSA solutions for bulk solids handling combined with efficient control

TMSA combines its extensive experience of over five decades with innovation to deliver comprehensive solutions for bulk solids handling, offering high performance, a strong focus on sustainability, and a firm commitment to operational safety, writes Alex Lima de Morais, Commercial Coordinator, Environmental Control and Industrial Dust Removal, TMSA and Fladimir de Souza Barbosa, Commercial Manager, Customized Solutions Unit for Port Terminals, TMSA.

One of its main differentiating factors is the development of systems that combine robustness, efficiency, and effective control of particulate emissions into the environment.

With special attention and ongoing concern for the environment, sustainability is a cross-cutting theme in the company’s discussions, projects, and strategic decisions. TMSA has established a set of standards, best practices, and solutions guided by ESG principles (Environmental, Social, and Governance), promoting socio-environmental awareness and minimizing the impact of its operations.

The company actively monitors its activities and adopts concrete measures in favour of environmental preservation. It uses only electricity from clean and 100% renewable sources and works with a network of suppliers and partners who share the same commitment to sustainability, focusing on generating positive impact both in the market and in the communities in which it operates.

1. TMSA SHIPLOADER WITH ENCLOSED BELT CONVEYOR , SPOT FILTERS, AND DSH DUST SUPPRESSOR

This commitment is reflected in technological solutions applied to ship loading operations at port terminals, where TMSA offers an integrated system composed of a mobile shiploader, enclosed belt conveyor, spot filters, and the DSH dust suppressor. This combination ensures a safe, clean, and efficient operation with excellent cost-effectiveness.

TMSA has a pioneering history in Brazil: it was responsible for building the country’s first port system for loading soybeans, back in 1972. Since then, it has established itself as a benchmark in the supply of fixed or mobile shiploaders, which stand out for their wide range of motion and high productivity — reaching all areas of a vessel’s hold or barge without requiring repositioning of the vessel during loading. The company supplies equipment for solid bulk terminals handling materials such as grains, sugar, iron ore, and various minerals. Currently, approximately 70% of the grains exported through Brazilian ports are handled using TMSA solutions.

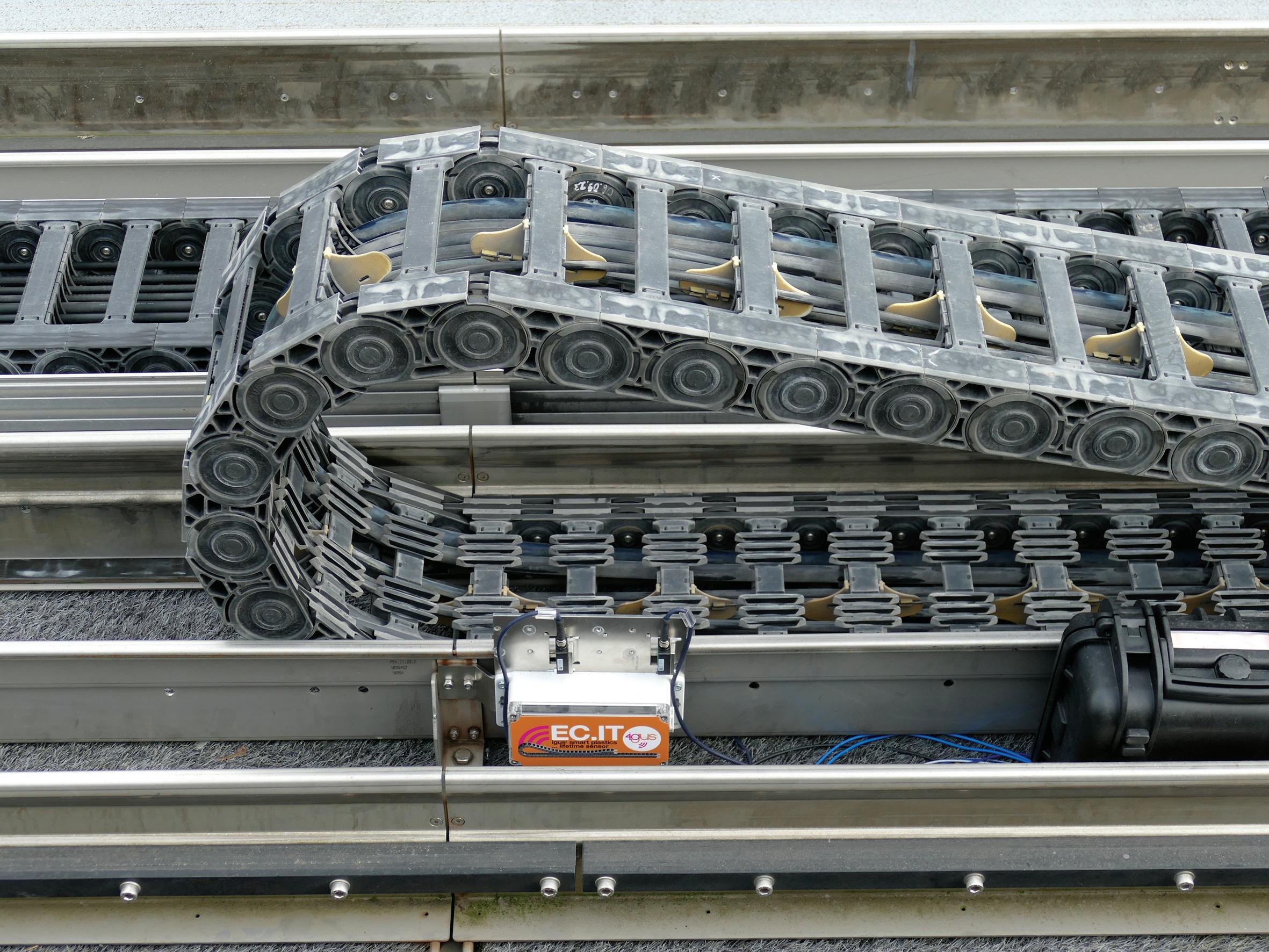

The company’s expertise in enclosed belt conveyors extends to various applications: the conventional model, the multi-product model, and the airsupported return model. All of them are designed with a focus on emission containment, loss reduction, and ease of maintenance and operation. The modular construction of these conveyors also enables fast assembly, seamless integration into the customer’s layout, and simplified implementation of fire suppression systems. Additionally, TMSA’s spot filters are installed directly at emission sources, eliminating the need for complex ductwork, minimizing process losses, and maintaining operational efficiency.

The DSH dust suppression system, installed at the discharge spout outlet, ensures emission control without the need for aspiration systems. It concentrates the material flow into a compact column, reduces fine particle dispersion, and contributes to a cleaner environment