11 minute read

SAMMI expertise plays vital role in transshipment market

Italian equipment manufacturer SAMMI offers a wide range of products and services, including: Mechanical conveyors: belt v conveyors; pipe conveyors; tripper car; spillage chains; and bucket elevators. Mobile bulk handling equipment: v radial stackers; reclaimers; shiploaders; and barge loaders/unloaders. Other equipment/ services: hoppers; v crushing & screening; dust control/suppression; drives & controls; weighing; sampling & inspection; storage systems; and engineering consultancy.

Of particular note is SAMMI’s experience in designing complete cargo handling solutions for floating transfer stations (FTS), for a range of cargoes: coal, iron ore sulphur, clinker, limestone, etc. These technologies include: turnkey solutions for hoppers; belt feeders and conveyors; shiploaders (with conveyor capacities of up to 2,500tph [tonnes per hour]; and electrical & automation control systems.

Below are just a few examples of SAMMI transshipment projects:

In 2005, SAMMI supplied fixed belts v for transshipper Bulk Pioneer The work, was for customer Shipping Services S.r.l., for end-user Berau Mining Coal, and took place in Indonesia. It comprised: a solution for bulk material, extractors, hoppers, shiploaders, and belt conveyors. A system of conveyor belts for coal transport was supplied, with a capacity of 1,000tph, capable of loading Capesize vessels from 180,000dwt to nine holds and Panamax vessels from 80,000dwt to seven holds, through the two loading hoppers, extractors, fixed belts conveyor up to the two mobile shiploaders.

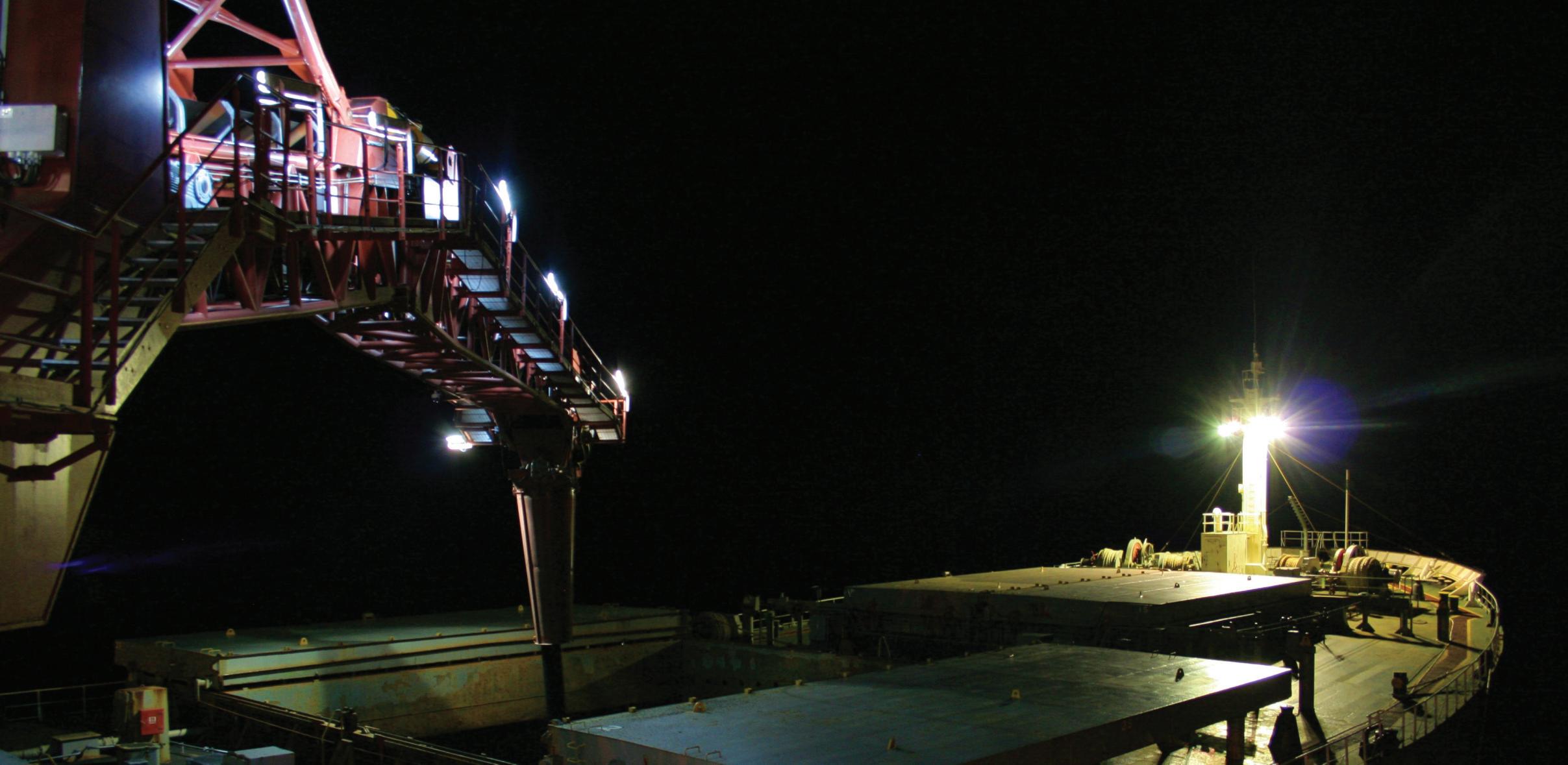

In 2010/11, SAMMI worked for Capo v Noli Transportes Maritimos Lda, with end-user Berau Mining Coal. It supplied a raw material transfer conveyor system for transshipper Bulk Java, in Indonesia. This solution was for bulk material, extractors, hoppers, shiploaders, and belt conveyors. The project encompassed a new transfer conveyor system of raw material installed on new geared pontoon Bulk Java (the transshipper) for coal transport. The capacity is 2,000tph, capable of loading Capesize vessels from 180,000dwt to nine holds and Panamax vessels from 80,000dwt to seven holds.

DETAILS

The conveyor system is equipped with two shiploaders, one installed at fore and one at aft. When loading oceangoing vessels (OGVs), the shiploaders have the chute axis distant 30m from the centre of the foundation column and a jib inclination ranging from +12° to –10° (that can be controlled by means of hydraulic cylinders). The rotation speed at the top of the shiploader is approximately 10m/min and the acceleration/ deceleration time is five seconds.

The rotation is controlled by three hydraulic gearboxes fed by a hydraulic power pack. The equipment is provided with a hydraulic brake system, used while in operating conditions, and with a mechanical brake while in rest conditions (‘service brake’). In operating conditions the rotation range of the shiploader is about –43° from the transversal position. The rotation of the shiploaders is limited by two magnetic limit switches (for each unit): the first generates an acoustic signal and a deceleration of the shiploader, the second stops the shiploader within the above mentioned braking time. The shiploader is installed on a high thickness steel column; the seat of the slewing bearing is placed on the top of this column.

The slewing bearing is provided with an internal teeth-range. The rotating part consists of a platform placed on top of the slewing bearing on which the support structure of the shiploader is installed. A hydraulic cylinder, manually calibrated, is provided for belt tensioning. While in rest position the shiploader is supported by two rest saddles.

In 2011/12, SAMMI worked v for Sinoway International Company Limited, with enduser Berau Mining Coal. The project, in Indonesia, was a self-unloading system for transshipper Bulk Borneo, and comprised a solution for bulk material, extractors, hoppers, shiploaders, and belt conveyors. The plant concerned a transshipment system to be installed on new geared pontoon Bulk Borneo (the transshipper) for coal transport, with a capacity of 2,000tph, capable of loading Capesize vessels from 180,000dwt to nine holds and Panamax vessels from 80,000dwt to seven holds. Operations take place through the two grab cranes which feed the receiving hoppers TR1/TR2 and from each hopper the handled material is extracted by means of two belt conveyors BC1/BC2 and conveyed into a single belt conveyor BC3 transversely placed extractors.

DETAILS modes: manual mode, for plant maintenance and start-up tuning. In this case the plant is fully under control of the operator, whom have the responsibility and can operate the plant both from control cabin and locally by means of a remote control. Semi-automatic mode. The single machines run in automatic mode under PLC supervision, start and stop are manually commanded from main operator panel, boom luffing and rotation of shiploaders by means of a remote control (under PLC supervision). Selection of operating modes no.1 and no.2 is made by manual selector installed on the main operator panel. to discharge the material on two belt conveyors BC4/BC5, each of which feeds a shiploader (SHP1 e SHP2). The air draught of the shiploaders from sea level is approximately 18.5m. When operating to load Panamax and Capesize vessels, the plant operates with two shiploaders having a span between supporting column and chute axis of approximately 30m. The material flow can be divided on both shiploaders SHP1 and SHP2.

On the discharging section of conveyor BC3 a flow-regulating by-pass is provided to discharge the material on two belt conveyors BC4/BC5, each of which feeds a shiploader (SHP1 e SHP2). The air draught of the shiploaders from sea level is approximately 18.5m. When operating to load Panamax and Capesize vessels, the plant operates with two shiploader having span between supporting column and chute axis of approximately 30m, and the material flow can be divided on both shiploaders SHP1 and SHP2.

On belt conveyor BC3 a belt scale is provided for the monitoring of material flow. On both conveyors BC1 and BC2 a metal detector is provided to detect unexpected metal parts. When detecting a ferrous part or component, metal detectors control unit generate a signal which will stop the line. A sampling system is provided on belt conveyor BC3.

The plant can operate in the following

In 2011/12, SAMMI worked for v Sinoway International Company Limited, with end-user Berau Mining Coal. The solution was for a selfunloading system for transshipper Bulk Sumatra, and comprised a solution for bulk material, extractors, hoppers, shiploaders, belt conveyors. The project comprised design, full supply (MEC-ELE-AUT-OLE) and commissioning of belt conveyor system Bulk Sumatra for coal transport. The capacity was 2,400tph, capable of loading Capesize vessels from 180,000dwt to nine holds and Panamax vessels from 80,000dwt to seven holds, through the two grab cranes which feed the receiving hoppers TR1/TR2 and from each hopper the handled material is extracted by means of two belt conveyors BC1/BC2 and conveyed into a single belt conveyor BC3 placed transversely extractors.

Details

On the discharging section of conveyor BC3 a flow-regulating by-pass is provided

On belt conveyor BC3 a belt scale is provided for the monitoring of material flow. On both conveyors BC1 and BC2 a metal detector is provided to detect unexpected metal parts. When detecting a ferrous part or component, metal detectors control unit generate a signal which will stop the line. A sampling system is provided on belt conveyor BC3.

On plant start-up, the operator can select three different operating cycles, as described below: o discharge on vessel’s bulk with shiploader SHP1 and conveyors BC1/BC2 working at 600tph each (total 1,200tph); o discharge on vessel’s bulk with shiploader SHP2 and conveyors BC1/BC2 working at 600tph each (total 1,200tph); o discharge on vessel’s bulk with shiploader SHP1 and SHP2, conveyors BC1/BC2 working at 1,200tph each (total 2,400tph). o Otherwise the operator can select a ‘special cycle’ and, depending on the line selected (i.e. working with a single or both shiploaders), manually input the corresponding speed of conveyors BC1–BC2 by means of inverters. Selection of the four operating cycles above mentioned can be made by push button placed on the main operator panel.

In 2011/12, SAMMI worked for v Coeclerici Logistics S.p.a, with endusers Limited Liability Company and Coeclerici Logistics Russia. The solution was a 750tph offshore conveyor belt system for transshipper Bulk Kremi, with continuous shiploader (crusher & prilled sulphur handling). This was for bulk materials, shiploaders, hoppers, belt conveyors, and extractors. The project in Ukraine comprised a complete material handling system for FTS Bulk Kremi 1. The work included design, full supply (MEC-ELE-AUT), commissioning and service. The equipment was installed on a 14,000dwt flat top pontoon crane. The transshipper is equipped with two cranes, two hoppers, two extractors, one longitudinal belt, one transversal belt, one longitudinal belt and a loader. It is designed for a capacity of 750tph of sulphur, but also able to transport coal and iron ore in different specific weights, using the inverters in the extractors, treating mainly 90% sulphur, 5% carbon and 5% iron ore. The system allows the loading of OGV up to Panamax, so an 18m air draught with a draught at full load of 6.5m. The shiploader can be traversed up to 50° to step over cranes between holds of ships with cranes and allows the loading using a retractable chute.

Solution

SAMMI in 2010 applied in design and supply of an offshore vessel loading system. The scope of work included a complete handling and shiploading system which is suitable to transport and load sulphur on vessels from Handy up to Panamax size. The plant will be installed on the Bulk Kremi transshipper and includes hoppers, belt conveyors and a shiploader, with a total span of 30 metres when fully extended. System specifications: o boom with slewing, shuttling and luffing functions; o material transfer from the feed chute at the pivot structure to the boom tip; o retractable loading chute, for efficient material distribution and to reduce dust emissions; o luffing angle up to 50° to pass over vessel’s mast or cranes to enable quick hold changes during loading; and o design fully in accordance with directive Atex 94/9/EC regulations.

In 2011, the company was awarded a contract for the design and supply of a turnkey coal handling for a rated capacity of 2,000tph of coal, to be installed in a new transshipper presently under construction. As for the project Bulk Java, the system will include double charging hoppers, belt conveyors and two continuous shiploaders both slewing and luffing-type. Operational tests were carried out in which the shiploader was completely assembled in the workshop together with its electrical and hydraulic power elements, to test that all slewing, luffing and shuttle functions operate as they should.

The main advantage of carrying out these types of workshop tests is that they significantly reduce the time required in the shipyard for the assembly, commissioning and fine-tuning of the system. This further underscores SAMMI’s commitment to meeting all the expectations of its customers. SAMMI’s technical solutions are all engineered to offer reliable, efficient and cost-effective operations.

In 2010/11, SAMMI worked for Capo v Noli Transportes Maritimos Lda, with end-user Berau Mining Coal. The project was a transfer conveyor system of raw material for transshipper Bulk Java. The solution was for bulk material, extractors, hoppers, shiploaders, and belt conveyors. The project included a new transfer conveyor system of raw material installed on new geared pontoon Bulk Java (the transshipper) for coal transport, capacity 2,000tph, capable of loading Cape Size from 180,000dwt to nine holds and Panamax from 80,000dwt to seven holds. It took place in Indonesia.

Details

The conveyor system is equipped with two shiploaders, one installed at fore and one at aft. When loading OGVs, the shiploaders have the chute axis distant 30m from the centre of the foundation column and a jib inclination ranging from +12° to –10° (that can be controlled by means of hydraulic cylinders). The rotation speed at the top of the shiploader is approximately 10m/min and the acceleration/deceleration time is five seconds.

The rotation is controlled by three hydraulic gearboxes fed by a hydraulic power pack. The equipment is provided with a hydraulic brake system, used while in operating conditions, and with a mechanical brake while in rest conditions (‘service brake’).

In operating conditions the rotation range of the shiploader is about –43° from the transversal position. The rotation of the shiploaders is limited by two magnetic limit switches (for each unit): the first generates an acoustic signal and a deceleration of the shiploader, the second stops the shiploader within the above mentioned braking time. The shiploader is installed on a high thickness steel column; the seat of the slewing bearing is placed on the top of this column.

The slewing bearing is provided with an internal teeth-range. The rotating part consists of a platform placed on top of the slewing bearing on which the support structure of the shiploader is installed. A hydraulic cylinder, manually calibrated, is provided for belt tensioning. While in rest position the shiploader is supported by two rest saddles.