17 minute read

MARTIN FRANEK

TRANSPORT COORDINATOR MARTIN FRANEK

03:58 AM - DON´T WASTE TIME WITH SLEEPING! !

Advertisement

For me is sleeping the biggest waste of time. I love Wednesdays and Fridays for the most of the year, because of early ice-hockey match. At 4:30 we meet with guys in the locker room, we have to dress up and than we go to warm up skating and shooting to be ready for the match. One hour of my favourite sport so early in the morning makes me happy, I don´t feel tired, I don´t feel pain and every time it´s nice to be on ice!

06:00 - 6:30 AM - NEDCON IS MORE THAN WORK

I’m almost 7 years at NEDCON and I work in the Shipping department. Since I have a baby, I arrive at 6 am. This way I can spend more time in the afternoon with my family and I very much appreciate it that the working times are not strictly fixed. There is a human approach at NEDCON. My duty at NEDCON is planning and ordering containers for loading based on CP requirements and related activities. It’s not only sitting on the chair, but also cooperating with colleagues in our hall, solving issues during loading or physically checking every loaded container. In the last months we experienced a big increase of containers. I needed help from other colleagues with some work. Luckily we have a very good cooperation in our team and we are always willing to help each other.

09:00 AM - „SHIPPING“ COFFEE TIME

At this time, everybody should be at work and after some morning duties, there is some space to discuss with colleagues. We try to gor for coffee together and to find some minutes to talk about non-working activities. In case of nice weather, we can use our outdoor seating and enjoy the sun.

12:00 PM - LUNCH BREAK FUN

Before noon, we are ready to go to our canteen for a lunch. We, from Shipping, would like to stretch our legs with walk around the factory to the mainbuilding, where the canteen is situated. After lunch begins our „lunch break fun“ which means petanque contest between transport coordinators. Every day is different, nobody is the favorite and we play interesting and balanced battles, sometimes on improved playground. After I beat my colleagues, I can happily go to my „machine“ and hardly work ;-)

15:00 PM - FAMILY AFTERNOON

Since August 2021 my life has changed, because my daughter was born. I look forward to her smile every day I´m leaving my work. It starts to be more and more funny nowadays, because she begins to communicate with us. We would like to spent some time in the nature or in the garden. Important for me is, to spent time with my family.

19:00 PM - STAY FIT

I don´t like to do nothing, I rest not so much – would like to be still in motion. If I „get“ time for myself, I regularly spend my time at an outside workout gym. I can „turn off thoughts“ and release excess energy. After „my time“ I would like to help my wife and take care about my daughter. We play together some more, read a fairy tale, I put her to bed and get her ready for bed.

22:00 PM - EVENING RELAXATION

Late in the evening, I finally „meet“ my wife. As we are busy during weekends with some trips and meeting friends, we have to do some housework. Of course better is sometimes to talk each other, watch some movie and cook something delicious and drink beer.

PROGRAM MANAGER CS PROJECTS JARNO HUMMELINK

By Gerard Kant

Can you briefly tell us about yourself?

I am Jarno Hummelink, 32 years old and I live in the village Zieuwent about 20 km from NEDCON in Doetinchem. I live there together with my girlfriend Esther and our 9-month-old son Julian. The past year I have spent much of my free time in renovating our home, this can also be called a hobby of mine. In addition, I like to do fun things with the family, and I try occasionally to do some sport (running).

How did you end up at NEDCON at the time? When exactly was this?

I first came to NEDCON in 2007, for a work placement as part of my studies in Technical Business Administration. After this internship, I had a side job at NEDCON for about a year. Then in 2013 I was approached by NEDCON, where I first worked part-time to also finish my studies. This all took a little longer than planned, but in the end I have actually been working full time at NEDCON since 2015.

What was/were your positions within NEDCON?

I started as a trainee, then I have been an administrative assistant, Sales Engineer, Account Solutions Engineer and now I am Program Manager for the CS projects.

AND NOW ABOUT YOUR HOBBY: ORGANIZING THE OVER DE TOP FESTIVAL IN LICHTENVOORDE!

How did you come up with the idea of organizing a festival?

As with many good ideas, this one also came about in the pub. The Over De Top Festival had run 3 editions at that time and the team looking for replacement and expansion. After I had an intake meeting over a few beers, it seemed a good fit from both sides.

Since when have you been doing this?

Since 2014, so already 8 years. In which, unfortunately, we were not able to run an edition in 2020 and 2021 due to corona.

What makes this hobby special for you?

The special and fun part is that you meet so many different kinds of peole, both before and behind the scenes. Every year we are amazed by the willingness and atmosphere that all this entails.

Where and when is the festival organized?

With the exception of the last two corona years, our festival takes place annually during the Whitsun weekend in Lichtenvoorde. So, we recently concluded another edition!

How many visitors do you attract and what type of visitors are they?

We have been growing every year so far, this year we are aiming for about 6,000 visitors. Everyone is welcome whether you are 3 or 103. We try to put together a program as broad as possible, for both young and old. From Blues, Electro, Disco to Jazz, but also the Heavy Metal fans can enjoy themselves.

How long did it take you to establish a good festival?

We have grown gradually and therefore each year we can learn from the previous edition and put down new ideas in the right way. The cool thing is that when there is a mishap, we have still been able to bring it to a good end thanks to the flexibility of all our volunteers.

What is involved in organizing a festival?

It goes from arranging the permit with the municipality to the crushing pump for the toilets and everything in between. We are usually busy 4 months after the festival with the organization of the next edition.

What does the core team look like and how many people do you need during the festival?

The core team consists of 11 people. Around and during the festival weekend we are with 200+ volunteers.

What is your specific function in the organization team?

I am responsible for everything related to money and numbers, so I am the treasurer. Within the organization they also call me the ‘’penny pincher’’! ;-)

What makes the Over De Top festival unique compared to other festivals?

We try to create a festival that offers something for everyone, we deviate from the mainstream. Think of theater, a children’s afternoon but also crazy activities and of course very diverse music.

For you, what is the best act that has been at the festival so far?

I don’t always get to see everything about the acts during the festival, although the backstage preparation often gives a glimpse of the act in question. One of the acts that stuck out to me was a Mexican band that turned old-skool Rock into Country music, something that has been done more and more in recent years. At the time, it was very surprising and innovative.

I heard something about ‘’Jarno’s transvestite show’’. Can you tell a little more about this?

Haha, you are well informed I hear! This was typically one of those bands that is just a little different from “normal”, these guys had dressed up to the nines to be women. Besides their exceptional appearance, they could also make damn fine music. With that, this was really an act that fits the Over De Top festival. My part, by the way, was just paying the bill and picking up the confetti from the ground, days after the festival ;-).

Can you tell us another anecdote about what happened to you during this festival?

A few editions back we had underestimated the high number of visitors in combination with their thirst. At the time we discovered this, the beer truck had yet to leave Boekelo. This threatened a temporary reclamation what we wanted to avoid at all costs! So we went to all the pubs in Lichtenvoorde to pick up the cold kegs of beer. The unlit agricultural vehicle full of cold kegs was, once back on the field, received under loud cheering from the public.

Should the Feestfabriek (organizer of the Zwarte Cross festival) start to worry already?

Haha, our ambition is to preserve the unique character of the festival and that includes the small scale. We still want to grow, but we do not aspire to the visitor numbers that they have.

And next year another festival? Is the date already known so we can put it in the agenda?

Yes, definitely. We are assuming that next year will be another successful edition. So put the 27th en 28th of May 2023 (Whitsun weekend) 2023 in your agenda! ■

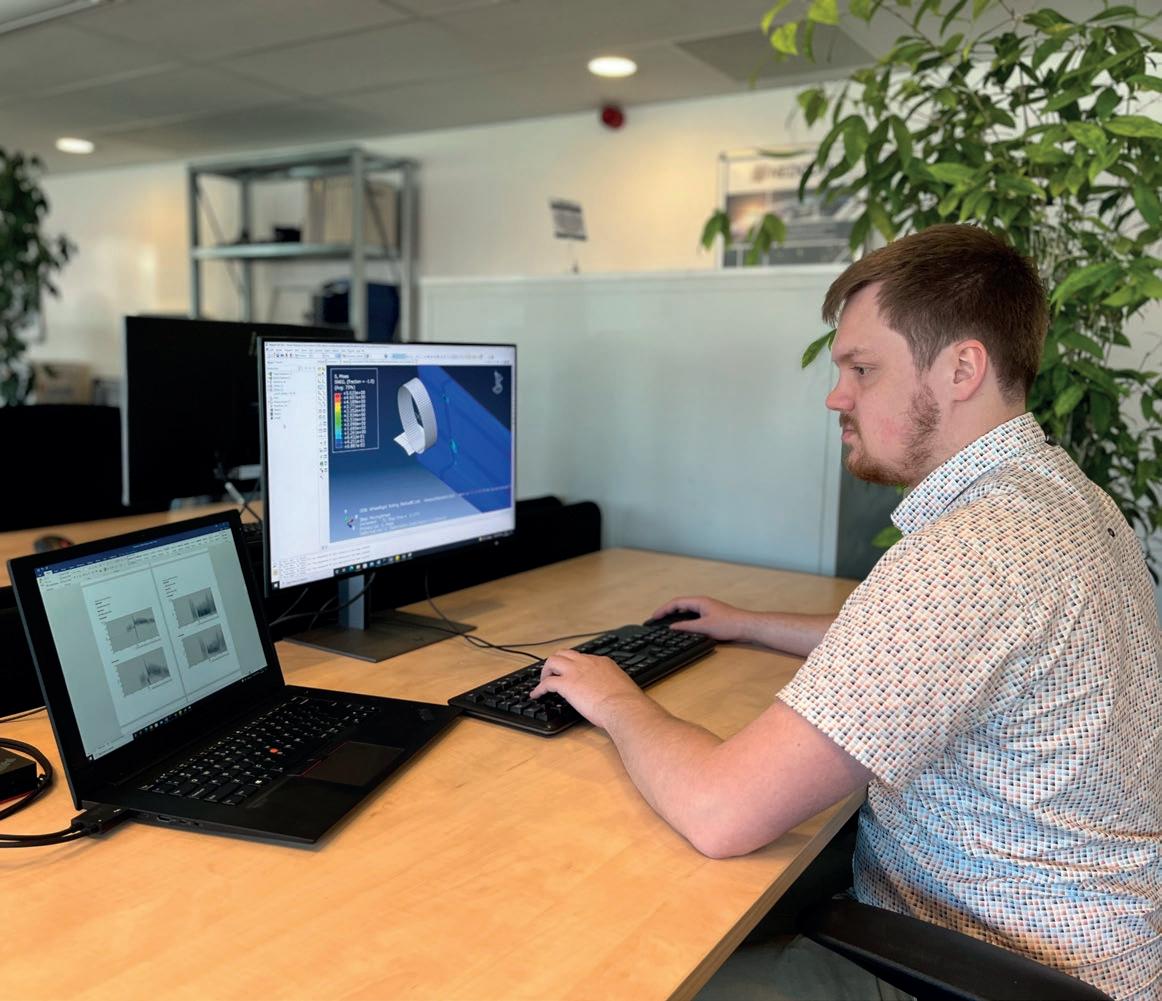

HOW WE STAY SAFE AND COMPETITIVE WITH COMPUTER SIMULATION PRODUCT DEVELOPMENT: USING FEM SOFTWARE ABAQUS

Since the consolidation of various product development and standardization disciplines into the Products & Technology department, the department has also expanded to include new colleagues. This brings in new knowledge that contributes to developments that help us to take big steps forward,

as you can read in the following story. By Willem Schreurs

In this edition of the NEDCONNECT, we take a look behind the scenes at a development that actually started back in 2017. A typical research and development project that was initiated by a sales project and where the research ultimately improved the development greatly.

Optimizing rail tickness to save costs in projects

Project Siemens Henkel, a NR5 system with pallet shuttle rails. At that time, a project of unprecedented size for NEDCON. More than 560 kilometers of rail on which the pallet shuttles ride. Optimization of rail thickness means considerable cost savings for this volume. A thinner rail, however, means a risk of crack formation if the shuttle frequently drives over the rail. A special test setup, in which a shuttle continuously drives over the rail with a full load and also applies the peak load that occurs when the shuttle enters and exits the crane, ensured that frequent testing could take place. Partly because crack formation was allowed up to 100mm. The testing at that time showed that in practice the rails were better than could be calculated in 2017. With that knowledge a special entry guide was developed that can handle the peak load when entering from the crane. Therefore the rail itself could be made thinner for this project.

Virtually driving over a rail

While Finite Element Method (FEM) analyses could already be carried out using the 3D drawing package SolidWorks, this knowledge was also used to invest in advanced FEM software Abaqus. This makes it possible to virtually drive a shuttle on a rail, simulating the complete behavior of the shuttle and rail. Previously, calculations were made where the load on 1 specific rail location and for just 1 wheel. Now it is possible to have all wheels moving on the rail at the same time and to see also the impact of the different wheel loads on each other.

An advantage in the Siemens Henkel project was that relatively few cyles were required, which made it possible to use thin rails. In systems with a higher number of cycles, thicker rails are used. The thicker rail has the consequence that the entry guide is activated less quickly, so that you cannot use that great advantage of the entry guide as well. Where in the past such optimization meant a lot of long term testing, now Abaqus comes into the picture.

From months of testing to results in a week

Fatigue problems with pallet shuttle rails can be broken down into two topics. The “driving onto the rail’’ and the “driving on the rails’’. This second part has seen a spectacular development. We are now able to virtually drive a shuttle on a rail by means of FEM simulations, only this still took quite some time.

The analysis of a particular combination of a type of shuttle and a rail with a certain shape and material thickness had to be done manually for each simulation. To be able to do the correct analysis with this was several days of work per situation.

Diameter of a wheel driving on a rail with defined parameters.

VIDEO

Are you curious to see what this simulation looks like? Scan the QR code!

Screenshot from an analysis where stress is determined at each position in the rail.

Now it is possible to have the software create this automatically using a list of defined parameters. Generating a model for a specific shape shuttle, shuttle weight, rail thickness and lip height now only takes a few seconds. To get an optimized result, 9 analyses need to be performed, each taking about half a day.

The total analysis can now be carried out in approximately one week where traditional testing could take up to several months.

The result of this analysis is that for a shuttle with a total of 8 wheels, it is known exactly what stress occurs in the rail at each position of the wheel over the entire rail length. This result is translated into a software tool that indicates for all configurations how many cycles a rail can handle. This will allow the most optimized rail to be used for each project in the future.

The other part of the research on rail optimization, entering the entry guide, is analyzed in a similar way. Here, a model is created that can simulate the entry of the shuttle on the rail. The complexity involved here is great. Consider the small difference in height that the shuttle has to overcome when it drives from the crane on the rail. In reality, this is only a few millimeters but this “falling” of the shuttle results in the shuttle bouncing into the entry guide. This causes a stress peak that affects the durability of the system. It is expected that this can soon be analyzed as well so that a full simulation of the shuttle in the rail can be performed.

Impulse for project optimization

The first shuttle and rail combination has now been extensively analyzed and is available for use. This technique can now be further applied to the shuttles and rails of other system partners, enabling us to offer a standard optimized solution for a wide range of possibilities. This makes the theoretical research practical and this development gives an impulse to the speed and possibilities with which a project can be optimized for our customers. ■

Example graph of the result. Depending on the given parameters “thickness” and “flange” the number of shifts determined for a specific shuttle with a given load is determined. This allows the customer to select the most appropriate version depending on the desired number of shifts.

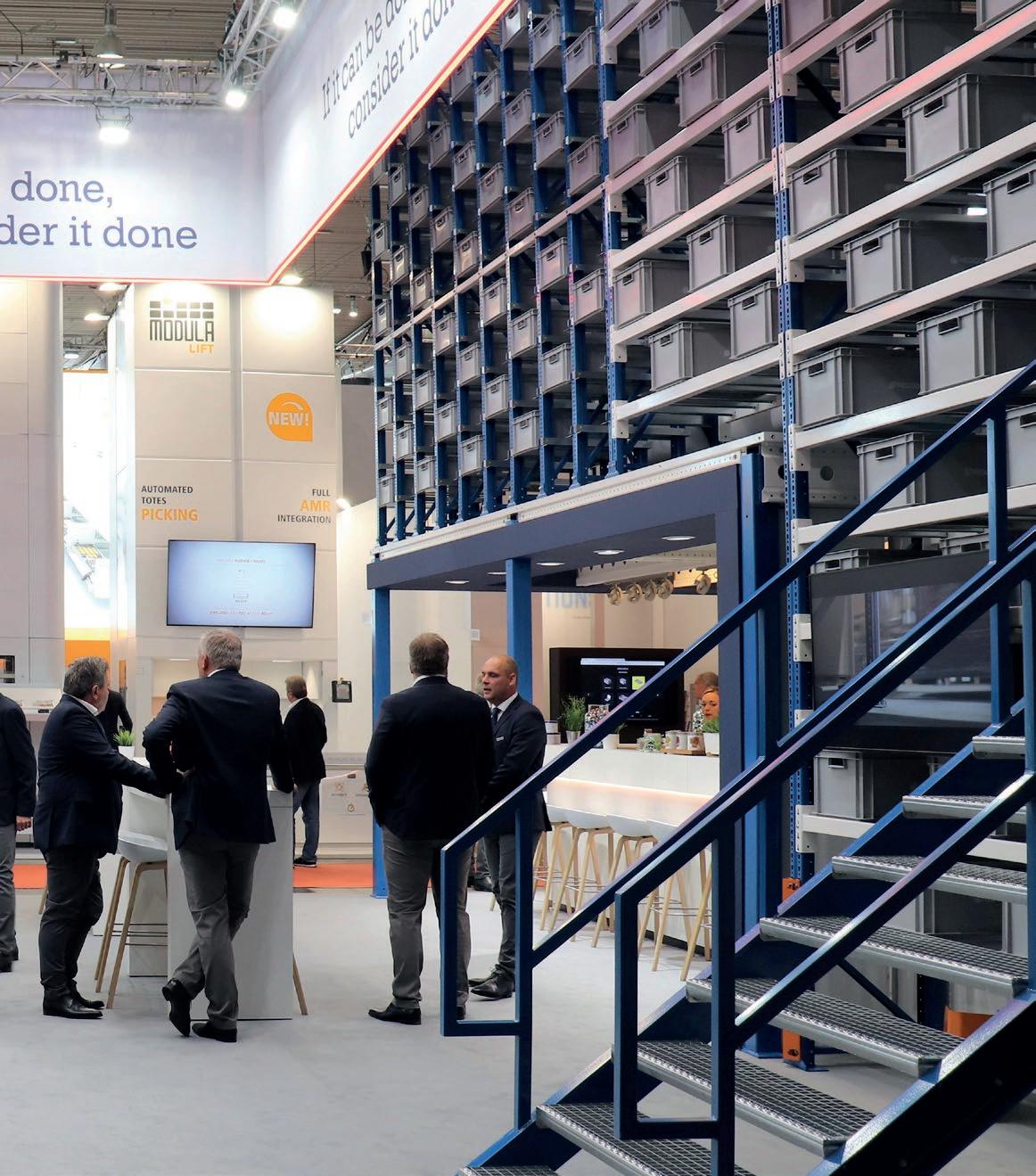

NEDCON USA PRESENT AT MODEX IN ATLANTA

After two years of either a trade show that was a bust or no show at all, the 2022 Modex April 28-31 2022 in Atlanta, was a refreshing change. The show was very well attended by both exhibitors and attendees. After a few years of essentially no trade shows, the enthusiasm and energy was evident. Customers and suppliers had a chance to reconnect and spend some time face to face discussing old projects, new projects, new technology and just catching up. You really got the sense everyone was glad to be back.

New technologies

Over the past two years, it has been a challenge to engage with our customers, this year at Modex it allowed us to reconnect in person and see and talk too many of our customers, both System Integrators and end-users. It was evident that NEDCON’s reputation and relationships are still strong and our expertise is appreciated. It was evident the industry was not sitting still while the pandemic was making our everyday lives a challenge. There was new technology on display and there were many discussions of prototype and emerging technology. It was evident that the AMR/ACR robotics is becoming more prevalent in the US by the amount of exhibitors that show cased these solutions. We saw many different rack solutions for these systems and had conversations concerning the requirements different suppliers’ desire. The common theme was our rack was high precision but for these solutions, we did not need to be as precise. The thought was that this solution had plateaued, but it has seen a resurgence here of late.

Challenging steel and transport market

Another topic that was on everyone’s minds was the challenges in the steel and transportation

markets. The conversations seem to focus on when we might see a leveling out of the pricing of steel and when we might see a decline in transportation cost. The consent was the industry understands these challenges, but is trying to manage the rapid fluctuations the best they can. This can be a daunting task in a market that is very busy. A couple of System Integrators that are actively looking for US based high precision rack manufactures visited us. This is being driven by the high transport cost and the challenges seen in the port on the West Cost.

Successful again

Once again, the booth was very nicely done. We had fresh flowers and plants to give that warm and welcoming feeling, we had snacks and beverages in the afternoon so we could mingle with our customers and talk about all kinds of topics. In all, it was a success and we were all glad to be back. Thanks to Team NEDCON USA for putting together a great 2022 Modex. The next Show is ProMat held March 20-23 in Chicago’s McCormick Place.

Team NEDCON USA ■

ˇ