7 minute read

Tech That Protects

How Agilent’s Resolve handheld raman spectrometer is saving lives around the world

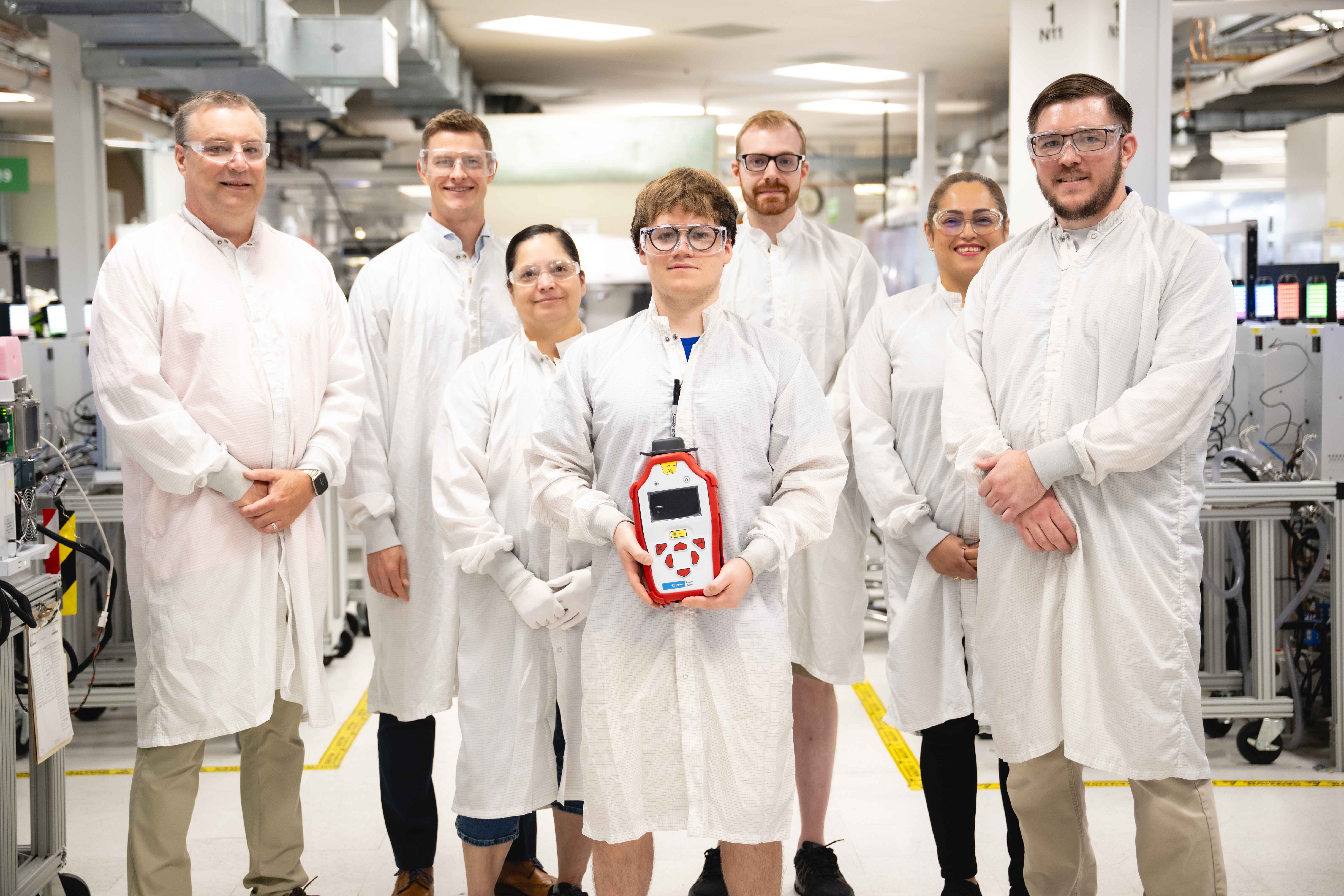

BY PETER OSBORNE | PHOTOS BY DR. ROBERT LAY, THEREALROBLAY PHOTOGRAPHY

It was 11 p.m. when Robert Stokes got the call. A border agency had intercepted large containers of an unknown material, making it dangerous to test directly. Opening the containers could mix the substance with air and create a hazard.

The agency scanned the containers with its Resolve handheld raman spectrometer and sent the spectral data to Agilent Technologies’ 24-hour Reachback support service. Stokes, on duty that night for the global network of Ph.D. scientists, analyzed the results.

“It was one of these date drugs,” Stokes remembers. “A material that’s dropped into people’s drinks to make them incapacitated and then potentially vulnerable to assault or worse.”

When the operation concluded hours later, Stokes sat back and realized the impact: “There would have been something like two million doses of that material on the streets if our technology hadn’t helped intercept it.”

This is the real-world power of Agilent’s Resolve handheld raman spectrometer, which just earned the title of 2025’s Coolest Thing Made in Delaware from the annual Delaware State Chamber competition, decided in a March Madness-style bracket by voters across the state.

The rugged, field-portable device provides emergency responders the ability to quickly analyze unknown powders and liquids through sealed, opaque containers without destroying the sample during hazardous materials operations. It’s protecting communities worldwide from a Delaware manufacturing base and has been ranked by the U.S. Department of Homeland Security as the top-performing handheld Raman system available.

Technology That Delivers Results

The Resolve uses proprietary Spatially Offset Raman Spectroscopy (SORS) technology to identify materials through opaque containers. Here’s how it works: The unit shoots a laser into the substance at different angles — one offset to see through the barrier, another straight ahead to reach the substance behind it. The device subtracts the barrier’s spectrum from the total reading, giving an accurate match from its extensive library of known materials.

“It’s like a tricorder from ‘Star Trek,’” explains Stokes, Agilent’s director of detection security. “You can walk up to any object or material — whether it’s on a surface or inside a container — point at it, and the spectrometer will identify what that material is.”

The analysis takes less than 28 seconds. No sample preparation. No opening dangerous containers. No exposure to unknown substances.

Eric Aubrey, who sells these devices across the U.S. and Canada from Delaware, puts it simply: “It’s like witchcraft when you see it in person. Everyone who sees the demonstration wants to buy it.”

That proved true shortly after Aubrey demonstrated the device to the hazmat team in Virginia Beach. He received a call about an eviction warrant where something looked suspicious. The Resolve quickly identified 10 pounds of ammonium nitrate. The suspect also had aluminum powder and fireworks — enough explosive material to level a building. The discovery led to an immediate arrest and a hospital trip that saved the homeowner’s life, because officials trusted the Resolve’s readings and knew he was in danger before he showed symptoms.

More Than Law Enforcement

While security applications grab headlines, the Resolve serves unexpected purposes that showcase its versatility. Aubrey has seen farmers use it to distinguish between legal hemp and illegal levels of THC, enabling them to adjust nutrients to stay within regulations. Army surgeons may be able to test supposedly expired blood bags in the field, potentially saving lives when fresh supplies aren’t available.

The device eliminates guesswork in dangerous situations. “Operators would have to spend additional time testing with traditional methods,” Aubrey explains. “With Resolve, you’re in and out much quicker. You can scan through dark containers without possible exposure to unknown substances.”

Stories like the date-rape drug interception play out regularly across multiple agencies. The 24-hour Reachback service connects field operators with Agilent scientists during live operations, whether it’s a planned raid or an emergency response.

The Delaware Connection

The device is part of serious manufacturing capability at Agilent’s Little Falls campus in Wilmington. While only a handful of people work directly on the Resolve, they’re part of Agilent’s substantial Delaware presence — nearly 800 employees — making it a significant local employer.

Grant Bucy, a manufacturing technician who builds the devices, personifies Delaware’s workforce development success. Starting at Delaware Technical Community College, he joined Agilent and now refines technology that literally saves lives.

“We want to make sure that when we test it, it goes through all the steps without any hiccups,” Bucy explains. The testing process reflects life-or-death stakes: 10 hours in freezing temperatures, 10 hours of overheating, thermal stress tests, and constant scanning to ensure consistent performance under extreme conditions.

The precision required is extraordinary. As Adam Blackford, associate vice president of instrument manufacturing and Delaware sites general manager, puts it: “One droplet of a sample in an Olympic swimming pool … we can detect it.”

Technology With Serious Credentials

The Resolve builds on nearly a century of scientific development. The breakthrough for seeing through barriers came in the 2000s, when Czech professor Pavel Matousek at Oxford invented SORS technology. Between 2013 and 2016, the U.S. Department of Defense funded development to make the technology portable and handheld.

The technology keeps evolving. Agilent releases library updates every six months, adding new threats as they emerge — recent fentanyl variants, nitazines (1,000 times more powerful than morphine), and even creative smuggling attempts including concealed animal parts like ivory and rhino horns, or a kilogram of methamphetamine hidden inside bicycle seats headed to Indonesia from Kenya.

“Emerging threats are driving growth,” Aubrey notes. “The technology is easily adaptable to combat new threats.”

The Business Reality

At $70,000 per unit, the Resolve represents a serious investment. “Budget becomes an issue,” Aubrey acknowledges. But consider the alternative: the Virginia Beach explosive discovery, the 2 million prevented date-rape drug doses, the lives saved through rapid identification of dangerous substances.

Many communities solve the cost challenge through cooperation. Police, fire departments, and port authorities often pool resources. But the device pays for itself the first time it prevents a disaster or saves a life.

That kind of value is exactly what decision-makers look for.

“When we set out to purchase a new Raman instrument, we looked at our current instrument at the time and the issues we had encountered in the past such as reliability in the field, lengthy result times, and ease of use for the field user,” says Brandon Pursell, hazardous materials program administrator for Montgomery County, Pa.

“Whenever we buy a new instrument, we understand we are making a very large commitment on something that may not get replaced for up to 10 years. ... When we go to justify such a purchase, we need to know our choice is not only fiscally responsible but will also deliver when called upon at an incident. ... After working with the Resolve, our committee unanimously decided that it would be the best instrument for our team.”

The Department of Homeland Security’s independent assessment ranked the Resolve as the top-performing handheld Raman system available. For agencies that need the best performance, cost becomes secondary to capability.

Building Delaware’s Future

Agilent actively develops local talent through partnerships with Delaware Technical Community College and university programs. In two years, 160 Delaware students have toured the facility, discovering that modern manufacturing incorporates 3D printing, robotics, and cutting-edge processes.

The company continues expanding its Delaware presence. Stokes hints at “very big news” within six months involving aviation security and another “world first” technology that will be manufactured in Delaware — proof that the state continues attracting advanced technology development.

The Resolve’s success demonstrates what happens when global innovation meets Delaware manufacturing capability. While the core technology was developed elsewhere, the precision manufacturing, quality testing, and continuous improvement happen right here in Little Falls.

The Impact Continues

The Resolve earned its “Coolest Thing Made in Delaware” title through measurable results. Whether preventing explosive disasters, stopping millions of doses of dangerous drugs, or enabling rapid response to unknown threats, this device shows Delaware manufacturing creates technology that protects communities.

In a world where threats hide behind innocent-looking packages, the Resolve gives responders superpowers. It showcases Delaware’s role in a global safety network, where local precision manufacturing enables worldwide protection — one detection at a time.