6 minute read

Mind the Scope Gap

Coordinating Lighting as Ceiling Get More Complex

By JP Bedell, SDA Lighting & Control

Images courtesy of the author

Over the last five years, we've seen a proliferation of ceiling systems and new ceiling materials emerging on the market. While acoustical tile systems have been around for decades, we're seeing a much wider variety of materials and finishes on the market.

I’m willing to bet anyone reading this article has already designed projects with wood slat, metal panel and acoustically dense materials. These more advanced systems are finally starting to attract not only interest but specification by architects and interior designers. Architects are choosing these systems for many reasons, including approved acoustics (necessary for WELL building certification), more aesthetically pleasing materials and finishes, and more interesting architectural shapes.

These designer systems, from manufacturers like Armstrong, Rulan, USG, CertainTEED, Rockfon, Hunter Douglas, Arktura, and many more, promise easy-on-the-contractor installation with beautiful results. Of the major ceiling system vendors, only Armstrong has launched partnership programs with lighting manufacturers. More on that later.

All of this has led to a problem for lighting specifiers – properly integrating lighting into this plethora of ceiling materials. If an advanced ceiling system has been specified, odds are the design team is looking for a seamless integration of lighting into the system. There are many types of lighting you can integrate into advanced ceilings, but for the purposes of this piece, I want to stick to two broad types – recessed downlighting and recessed linear lighting.

Before we get into systemic integration of lighting, we should talk a little bit about the variety of materials.

Thicker + Softer Materials (High NRC)

Fiberglass Panels

Thicker: Typically 1" to 2" thick

Softer: Very soft and lightweight core

Noise Reduction Coefficient (NRC): 0.90 – 1.00+

Uses: Smooth tiles, clouds, and baffles

Example:

USG Halcyon ClimaPlus (1" thick, very soft feel)

CertainTeed Symphony® f

------------------------------------

Stone Wool / Rock Wool

Thicker: Often 1" or more

Soft but denser than fiberglass

NRC: 0.85 – 1.05

Uses: Drop-in tiles, baffles, and wall panels

Example:

Rockfon Sonar or Rockfon Koral

Good fire resistance and moisture stability

------------------------------------

PET Felt Systems

Thicker: Around 9--18 mm standard, but some go thicker

Soft to touch – like compressed fabric

NRC: Varies – often 0.75 – 0.95 with air gap or backing

Uses: Clouds, baffles, decorative panels

Example:

Turf Design baffles

FilzFelt wall and ceiling systems

------------------------------------

Thinner + Harder Materials (Lower NRC)

Mineral Fiber (Standard)

Thinner: 5/8" to 3/4" typical

Harder surface

NRC: 0.55 – 0.70 unless treated

Example:

Armstrong Fine Fissured, USG Radar

Often the default in offices and schools

----------------------------------------

Metal Panels

Thin, but can be backed with acoustic fleece or fiberglass

Hard, but perforation + backing = decent NRC (~0.70)

Example:

Hunter Douglas Techstyle

Armstrong MetalWorks

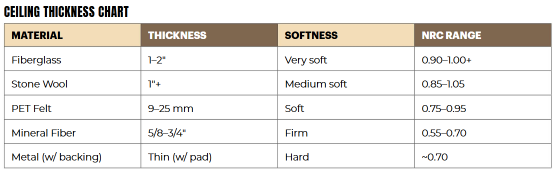

Ceiling thickness is the first thing lighting designers will notice, because recessed downlights/adjustables will have limitations on how thick a ceiling the light can mount into without compromising the ability to service the fixture or aim it properly.

But, I would encourage you to look at the softness of the material as well. The chart above is obviously an over-simplification, but I recently had a project encounter issues not because the material was too thick, but because it was too spongy, and the insertion of the fixture trim caused the ceiling tiles to pucker. Beyond issues of rigidity, there’s suspension itself. It’s important to understand how your fixture is supported and where the conflicts are for the ceiling system.

These sound like basic specification questions. But in an environment where all design teams are forced to work too quickly and most collaboration happens behind screens, instead of in person with material samples in hand, it’s no wonder these kinds of coordination details get missed.

SPECIFICATION COLLABORATION

To get a better idea of the challenges working with new and different ceiling materials and systems, I spoke to designers.

"We never see the ceiling submission," said Bill Kuchler, lighting designer with Syska Hennessy in New York.

This speaks to the larger issue of how designs come together today. More and more coordination is happening in video calls. Less and less takes place in person.

Clients rarely want to pay for architects and consultants to come together in one place, material samples in hand, so they can discuss how the job will be built. But a big, expensive, inefficient meeting like that might illuminate how lighting fixtures should install into different materials. It’s a classic case of measure twice, cut once.

In today's extremely budget- and litigation-cautious design and construction environment, designers and consultants are very careful about taking full responsibility over approvals. The lighting consultant can fairly say they don’t specify the ceiling, and the architect can say they don’t specify the lighting. This leaves coordination to the contractor, who often doesn’t have the time or inclination to review every piece of material on the project.

HOW LIGHTING MANUFACTURERS CAN HELP

More and better supplemental documentation. "Manufacturers' installation instructions are heavily biased toward electrical installation," Bill explained. When it comes to physical installation and mechanical connections, manufacturers err on the side of basic documentation. To a degree, this makes sense. How many different ceilings can you put on one set of installation instructions?

But as ceiling types proliferate, manufacturers could help themselves by creating supplemental documentation as new installation scenarios arise. This is extra work, of course, but it's also what can separate a spec-grade manufacturer from a commodity manufacturer.

Millwork+. Often manufacturers have the option for a millwork collar installation. I would encourage them to think about what I am calling millwork+ (feel free to steal): essentially a collar and trim that expects a tight hole cut in the ceiling material, but allows for a micro flange to cover imperfections.

Collaborate and Communicate. Connect with ceiling manufacturers and offer partnerships and collaborations for cleaner and simpler installations. Imagine systems that could integrate power drops and locations for remote drivers?

On a more mundane level, help the design process by asking about ceiling types at the time of orders.

Demand Slow Communication. Beyond the ceiling coordination issue, as building systems become more complicated and integrated, it’s incumbent on design teams to demand the time and space necessary to test and mockup unique installation scenarios. Better to have the in-person meeting, have your rep get the samples out, and discover problems over a conference table than get the notice that 200 downlights weren’t installed properly.