7 minute read

REFRIGERATION

REFRIGERATION

Lucas Curry and Memo Cervantes engineer a working refrigerator

Embracing the hands-on nature of the practical program, Form 7 students Lucas Curry and Memo Cervantes set out to engineer a refrigerator. This ambitious project brought many obstacles, prompting Lucas and Memo to apply their knowledge of electricity, physics, and computer principles. They persevered and managed to build a functional device through research, study, and creative problem-solving.

“If you break any problem down into small enough parts...even the biggest problems become simple and easily solvable.”

- Lucas Curry

Delphian Magazine: What inspired you to engineer a refrigerator?

Lucas Curry: I found a video online of someone doing it, and it seemed like a crazy idea at first. But as I thought about it more, it seemed like something cool to learn more about.

Memo Cervantes: Lucas showed me the video, which looked interesting, and convinced me that we should try it. I didn’t think it would work and that it would be a total failure.

Regardless, we decided it would be fun to try anyway. I remember we didn’t even totally know where to start, but after each step, we just kept asking, “Okay, what’s next?”

DM: What is the basic process?

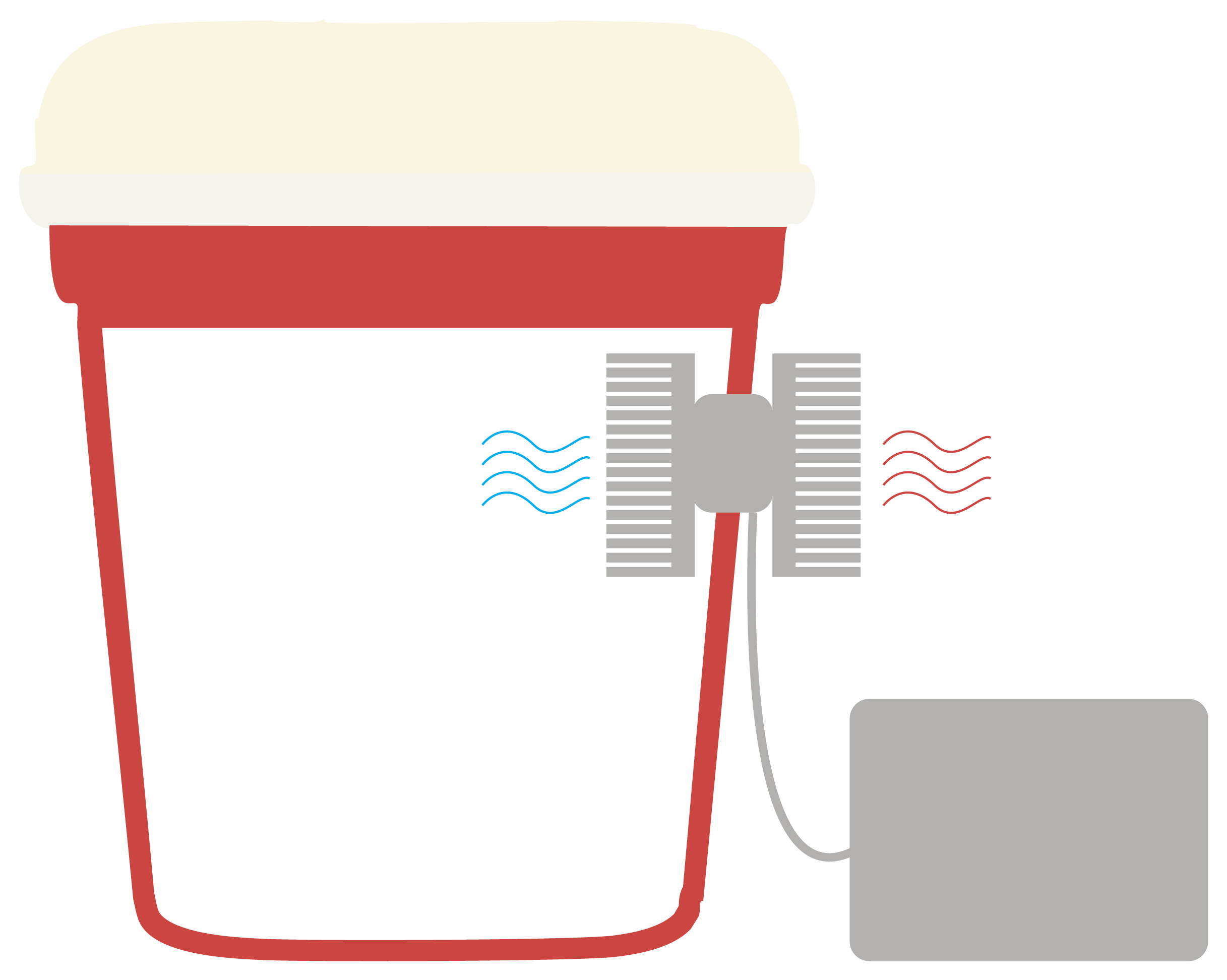

MC: First, you take an insulated container—we used an old beach cooler— and wire a few specialized parts called heat sinks on opposite ends of a thermoelectric module called a Peltier plate. Then you plug the plate into an electrical source. Once an electrical current runs through the heat sinks, they work to expel heat from the container, and you have a fridge.

DM: What are Peltier plates and heat sinks, and where did you find them?

LC: A Peltier plate is a thermal control module that allows you to control, change, and maintain a target temperature. A heat sink is a piece of metal that helps conduct heat towards or away from a device. We scavenged our parts by taking apart six old computers until we found pieces that would suit our purposes.

They work the following way: when electricity runs through a Peltier plate, one side gets hot and the other cool. To cool down a fridge, you have to connect them so the cool side will work to expel the heat from inside the refrigerator.

DM: How easy was it to install the heat sinks?

MC: Because the heat sinks we found were all different sizes from different computers, there was some trial and error when attaching them, which proved challenging. Each heat sink plate needed different-sized holes drilled, and we didn’t get the measurements quite right at first, so we had to start again. Eventually, we figured it out and installed them correctly.

LC: When we were installing them, we were also challenged to construct a structure that would hold the heat sinks in place on the Peltier plate without affecting the way the heat was transferred. To do this, we learned that we would need thermal paste to fill the gaps.

MC: At first, we didn’t know that you could buy thermal paste, so we went on a research tangent trying to figure out how to make it.

LC: Once we had the thermal paste, it was a bit challenging to use because it oozed everywhere and was messy, but it helped get everything set in place correctly, and got the electrical currents to conduct as we needed them to.

DM: What came next?

LC: The next part was probably the trickiest. We had to figure out how to get the wiring and electricity just right because neither one of us was very familiar with wiring. We had to learn basics like how to strip a wire and properly connect it to create a working circuit.

MC: Then, when we first plugged it in, it didn’t work at all. The Peltier plate started overheating, and instead of cooling, the fridge started heating, and our heat sinks started getting hot and breaking. We unplugged it and did some troubleshooting. We found that we were getting too much voltage from our electrical source, so we switched to a low-voltage generator, which allowed us to manually control exactly how much voltage was used at a time.

LC: Once we were using the generator, we experimented with the amount of voltage we used, adding or subtracting for controlled amounts of time and measuring the results.

MC: Finally, we got it right, and we were able to maintain a 20-25 degree temperature difference from room temperature, which is in the same range as that of a commercial refrigerator.

DM: What was your biggest takeaway from all the challenges you faced on this project?

LC: It really helped me realize that if you break any problem, no matter how big, down into small enough parts and tackle them individually, one step at a time, even the biggest problems become simple and easily solvable.

MC: I learned so many things, but one of the biggest things I got from this project was an improved ability to learn new things. Going into this project, I didn’t know much about computers, electronics, or engineering.

For instance, before this project, I didn’t know what the individual parts of computers did. It was all just a bunch of chips, fans, and wires through which you send an electric current. Through this project, I learned about the individual parts and realized how useful all the parts are, not just in computers but in building other things.

I also learned a lot about managing electricity safely—what’s hot and what’s not.

Learning this came about first out of safety because I didn’t want to get burned, but it made the whole subject of electricity simpler for me to understand, observe, and explore.

DM: Was there anything you learned that surprised you?

MC: Once we had it working, I was surprised at how easy it was to build a fridge. Something that seemed complex before was actually pretty easy to put together.

DM: What academic courses helped set you up for this project?

LC: I think the Study Technology courses that teach you how to learn at a gradient and all the science courses I did before doing this project were really helpful. For example, it was really interesting to take the concepts I learned from the Physics: Heating and Cooling course and apply them practically to making a fridge.

MC: The Study Technology courses are a prerequisite for these kinds of projects because they prepared me to learn everything I needed for this project. For example, I had to learn what each thing was supposed to do and how to put it together to work correctly. I couldn’t have done that without understanding how to study, specifically how to study on a gradient, doing one step after another, and fully defining and understanding all the technical words.

DM: Any advice for other students who may want to do projects similar to this one?

MC: I suggest tackling the subject no matter what the outcome will be. Maybe you fail, maybe you succeed. But at the end of the project, you will learn something new, and your ability to learn something new will improve. In my opinion, that is the whole purpose of the practical program.