12 minute read

Available in 4 tine models

GET MORE EQUIPMENT

0% APR FOR 60 MONTHS * with Rebates up to $8,000

On select new compact track loaders, skid-steer loaders and excavators Plus $1,700 in Bobcat attachment credits

Compact Tractors: TAKE HOME A FREE FRONT-END LOADER ** or get 0% APR for up to 84 months ** with no down payment. Plus, receive a $400 rebate by adding two 3-point implements to the purchase of your new compact tractor.

VersaHANDLER ® Telescopic Tool Carrier:

0% APR for up to 48 months ** Or In lieu of fi nancing receive rebates up to $4,000*

Utility Vehicles: 0% APR for up to 48 months **

IOWA JP Scherrman, Inc. Farley • 563-744-3393 Reiser Implement, Inc. Waukon • 563-568-4526

SOUTH DAKOTA Bobcat of Brookings, Inc. Brookings • 605-697-5544 Bobcat of Watertown Watertown • 605-886-5844 Pfeifer’s Implement Co. Sioux Falls • 605-338-6351 AUTHORIZED BOBCAT DEALERS

MINNESOTA

Alex Power Equipment

Alexandria • 320-763-4994 Bobcat of Otter Tail County Fergus Falls • 218-739-4505 Farm-Rite Equipment, Inc.

Dassel • 320-275-2737 Farm-Rite Equipment, Inc. Long Prairie • 320-732-3715 Farm-Rite Equipment, Inc.

Willmar • 320-235-3672

Lano Equipment of Norwood Norwood Young America • 952-467-2181 Miller Sellner Slayton, LLC Slayton • 507-836-8571 Tri-State Bobcat Burnsville • 952-894-0894 Tri-State Bobcat Little Canada • 651-407-3727

WISCONSIN Carter & Gruenewald Co., Inc. Brooklyn • 608-455-2411 Carter & Gruenewald Co., Inc. Juda • 608-934-5201 K&L Bobcat, Inc Darlington • 608-776-4044 Komro Sales & Service Durand • 715-672-4263 Komro Sales & Service Whitehall • 715-538-1495 Miller Implement Co., Inc. St. Nazianz • 920-773-2800 Miller Implement Co., Inc. & Motorsports of Fond du Lac Fond du Lac • 920-922-8521 Tri-State Bobcat Hudson • 715-531-0801

Visit Bobcat.com/Offers or stop by today for details.

Silo allows Hamminks exibility with uid product storage

By Jerry Nelson jerry.n@dairystar.com

BRUCE, S.D. – There once was a time when dairy farmers stored their milk in galvanized steel cans. As milk production grew, so did the need for onfarm milk storage. The venerable milk can was gradually replaced by stainless-steel bulk milk tanks. Most dairy farms have at least one barrel-shaped bulk milk tank. When a dairy expands, it can boost milk storage capacity by trading up to a bigger tank or by installing an additional tank. Wim Hammink and his wife, Nicolene, and their son, Tom, milk a total of about 4,000 cows between their two farm sites located near Bruce. A couple of years ago, the Hamminks expanded their herd and found themselves in need of additional milk storage. Instead of adding another horizontal milk tank, the Hamminks went in different direction: up. The Hamminks decided the best solution to their storage problem was to install a 20,000-gallon milk silo. “After we expanded our herd, we had no extra milk storage capacity,” said Wim Hammink. “Our two 6,500-gallon milk tanks could hold only one day’s worth of production. We would have to dump milk if we weren’t picked up every day.” Cost was another factor in the Hamminks’ decision to install a milk silo. “The per-gallon cost for installing a milk silo is about two-thirds of that for a horizontal tank,” Hammink said. “Processing plants have used milk silos for many years, so it’s a well-tested technology.” In January 2019, a new milk silo was hoisted Wim Hammink onto a concrete pad at the Hamminks’ south dairy facility where they milk 3,000 Jersey and Jersey crossbred cows. “The footprint of a milk silo is much smaller than that of a traditional tank,” Hammink said. “We had to pour deep footings for the silo. The concrete slab where the silo sits is 6 feet thick.” The timing for the installation of the Hamminks’ milk silo proved to be fortunate.

JERRY NELSON/DAIRY STAR

Hammink Dairy uses a 20,000-gallon milk silo at the farm where they milk 3,000 head of Jersey and Jersey crossbred cows near Bruce, South Dakota. Without the silo, the dairy could store only one day’s worth of milk producƟ on.

JERRY NELSON/DAIRY STAR

The milk silo (leŌ ) takes up only a small porƟ on of the milk room at Hammink Dairy near Bruce, South Dakota. Should the milk in either of the two 6,500-gallon horizontal tanks get too warm, it can be pumped into the silo and cooled with the silo’s exterior chiller.

“In April 2019, we had a really bad snowstorm and the milk trucks couldn’t get through,” Hammink said. “By the time the roads got cleared, we had seven semi loads of milk stored on our farm. We ended up dumping just one semi load of milk. Without the silo, we would have had to dump four loads. That helped justify the cost of the new silo.” The Hamminks’ milk silo features the latest technology. “The silo will send us an email when it’s getting close to full,” Hammink said. “It will also send the same email to the milk hauler. Our milk buyer, Valley Queen Cheese Factory, does an excellent job of keeping us cleaned out of milk.” The Hamminks chose to add an optional exterior tank chiller to their silo. “Our milk goes from the cows to a plate cooler and then to a glycol chiller,” Hammink said. “By the time it gets to our tanks or the silo, the milk is at 38 degrees. The silo has a sensor that will alert us if the milk’s temperature goes above 40 degrees. It will also kick on the exterior milk chiller to get the temperature back down to 38. In the summertime, when the weather is hot and the silo is empty, the temperature alarm might go off when we begin to pump milk into the silo. The exterior chiller will also kick in. The alarm will switch off as soon as there’s enough milk in the silo to cool the warm stainless steel.” There is another bonus to having

Turn to HAMMINKS | Page 4

A floor that works as hard as you do!

(3) Used McHale V660 Round Balers (1) 10,000 bales • (1) 3,700 bales • (1) Demo unit like new 300 bales In stock and ready to work

New Artex spreaders in stock!

EASY TO CLEAN! IMPERVIOUS TO MILK AND WATER!

WE ALL KNOW THE CONCRETE IS BAD!! WE ALL KNOW T

WE CAN REFURBISH IT! PARLORS, FEED BUNKS, MILKING AREAS, VET AREAS, NEW OR OLD FACILITIES

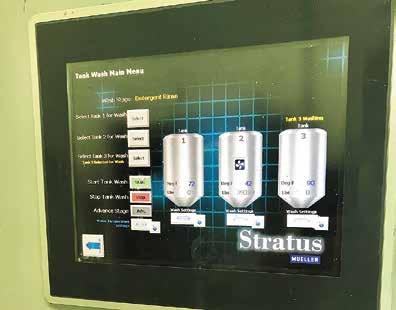

Page 4 • Dairy Star - Third Section • Saturday, August 22, 2020 ConƟ nued from HAMMINKS | Page 3 extra storage and cooling capacity. “If the milk should get too warm in one of our horizontal tanks, we can pump it over to the silo and cool it back down,” Hammink said. “It’s nice to have that backup capability.” Keeping the interior of the milk silo clean and sanitized is no more dif cult than any other milk tank, Hammink said. “If anything, I think it’s easier to clean a milk silo,” Hammink said. “There is a powerful spray nozzle at the top of the tank that applies the usual cycle of hot water rinses and sanitizers. In a silo, the water and the sanitizers naturally run down the walls. Gravity works against you in a horizontal tank.” Because the Hamminks’ silo can hold multiple truckloads of milk, it is common for their hauler to only partially empty the immense upright storage tank. “Whenever the hauler takes milk out of the silo but doesn’t empty it, the hoses have to be rinsed and sanitized with a special wash cycle,” Hammink said. “Ours was one of the rst milk silos to be installed in this area. We worked closely with the state inspec

JERRY NELSON/DAIRY STAR

An exterior chiller automaƟ cally kicks in should the temperature of the milk rise above 40 degrees. The Hamminks decided to add the opƟ onal exterior chiller to their new milk silo.

JERRY NELSON/DAIRY STAR

A computerized controller keeps track of the temperature and the milk levels in the two tanks and the silo at Hammink Dairy near Bruce, South Dakota. The controller will send an email when the tanks are geƫ ng full or if the milk temperature rises above 40 degrees.

tors to ensure that everything was done according to their speci cations.” The Hamminks had considered going to a system where their chilled milk is loaded directly into a waiting truck but decided against it. “Your milk holding capacity is limited to the number of empty milk trailers on the farm,” Hammink said. “That number is usually one. The milk hauler doesn’t want to invest a lot of money in trailers that would spend a good deal of their time sitting empty. If we had been using direct loading during that snowstorm, we would have been forced to dump seven semi loads of milk.” Mike Van’t Hof owns a milk hauling business that serves dairy farmers in eastern South Dakota, southwestern Minnesota and northwestern Iowa. Van’t Hof has two customers that use milk silos. “The plus side of a silo is that you have more room and more exibility,” Van’t Hof said. “The downside is that it takes a long time to empty a silo and get it washed. I tell dairy farmers to put in a silo that’s sized for one day’s worth of milk production, then add another one just like it. You need to have time to empty the silo and wash it properly. I f you can do that, a milk silo is a win-win for everyone. Milk silos are a good thing, but they come with a learning curve and growing pains.” After using their milk silo for more than a year and a half, the Hamminks have just one regret. “I only wish that we had gone with a bigger silo,” Hammink said.

WATER TANKS

USED EQUIPMENT

AVAILABLE IN 3 SIZES: 218 GALLON 866 GALLON 1317 GALLON Also Available: x Bunker Silos x Manure Storage x Feed Bunks x Grain Storage x Cattle Guards x Foot Baths 1-800-325-8456

Vermeer 18 Wheel V-Rake

$ 8,500 Massey-Ferguson 2756

$ 17,500

NH 355 Grinder Mixer Good condition, gears on unload need work - $ 2,000

2008 John Deere 7550 Forage Harvestor Pro-Drive, with Hay Head, 2009, 6R30” Corn Head, Kernal Processor, 2054 Engine Hours, 1385 Cutter Hours, $ 195,500

2011 Gehl V270, Cab, Heat, AC, 4000 hours $ 27,500

ASV RT60 Track Loader Cab, Heat, 14 pin, 551 hours, 67” dirt bucket $ 47,000

What’s right for you?

DeLaval Parlor P500

DeLaval VMS ™ V300

The dairy industry’s only parallel parlor with three cow-Å ow control options and no sequence gates in the Å oor. DeLaval P500 features newly developed synchronized milking process with these patented technologies:

• DeLaval SynchroArc™ • DeLaval SynchroSweep™ • DeLaval SynchroControl™ • DeLaval InService™ All-Inclusive (ISAI)

A SYSTEM APPROACH

• Contributes to Improved Farm Profi tability • Contributes to More Milk per Labor Hour • Contributes to Healthier Cows • Contributes to Highest Milk Quality

Big John Bedding Separator

FEATURES

• SMART control panel technology • Automatic weight control arms • New HD basket with screen • Reduce bedding costs • Increase liquid storage capacity • Environmentally friendly • Readily available bedding materials on a daily basis Systems from 90 to 10,000 cows Over 80 local installations Over 4,000 working installations worldwide

Proven again and again to achieve 36-39.4% dry matter

SEPARATOR

Jamesway

Dura Chain Scraper Vertical Pump Prop Agitator Hammermills Moov Feed Pusher

BY

The Moov feed pushing robot is a fully automatic robot so there is no need for wires or steel strips set into the fl oor.

CF1000A Calf Feeders

DeLaval calf feeder CF1000A features the most powerful computer available for calf feeding - the ALPRO ® computer.