7 minute read

India’s Printrove installs Kornit Storm HD6

The print-on-demand, drop shipping fulfillment company installed its first Kornit machine. By Sha Jumari.

Based in India, Printrove has installed the Kornit Storm HD6. The Kornit Storm HD6 is a direct-to-garment (DTG) printing system that includes six colour channels (CMYK, Red, Green) plus white, for a wider gamut and improved spot colour matching. First globally launched in 2018, the Kornit Storm HD6 provides a nonstop production workflow that enables garment loading while printing.

Advertisement

“We mainly chose the Kornit Storm HD6 because of the one-step process. We’ve always believed that anything that can be automated, should be automated. We focus more on efficiency and effectiveness. Kornit fulfilled that criteria for us in which, we didn't need to have a lot of people to carry out the same amount of production. That was the major factor why we chose Kornit over other machines,” said Madhur Chauhan, Printrove.

The Kornit Storm HD6 does away with separate pre-treatment, as this is the only wet on wet digital printer on the market at this time. It is also capable of printing almost all type of fabrics. As this is a non-contact printing process, it can print finished garments, over buttons, zippers, pockets, and much more.

The company has had the machine in working production for about one month now, with installation completed in the midst of the Covid-19 pandemic. “Even though we’ve only put the machine into production for only 25 or so days, it has been an amazing experience. Looking at the way Kornit is working, it stands there like

a beast. Every time we print on other machines where you have to do the pre-treatment – and I really shouldn't be saying this, but the Kornit makes all of the other machines look like fools!” Chauhan quipped. “You could have just integrated everything in just one step, why are you doing so many other things? That was the main thing, one person can carry out the entire production, you just have to load a T-shirt.”

Taking care of the behindthe-scenes

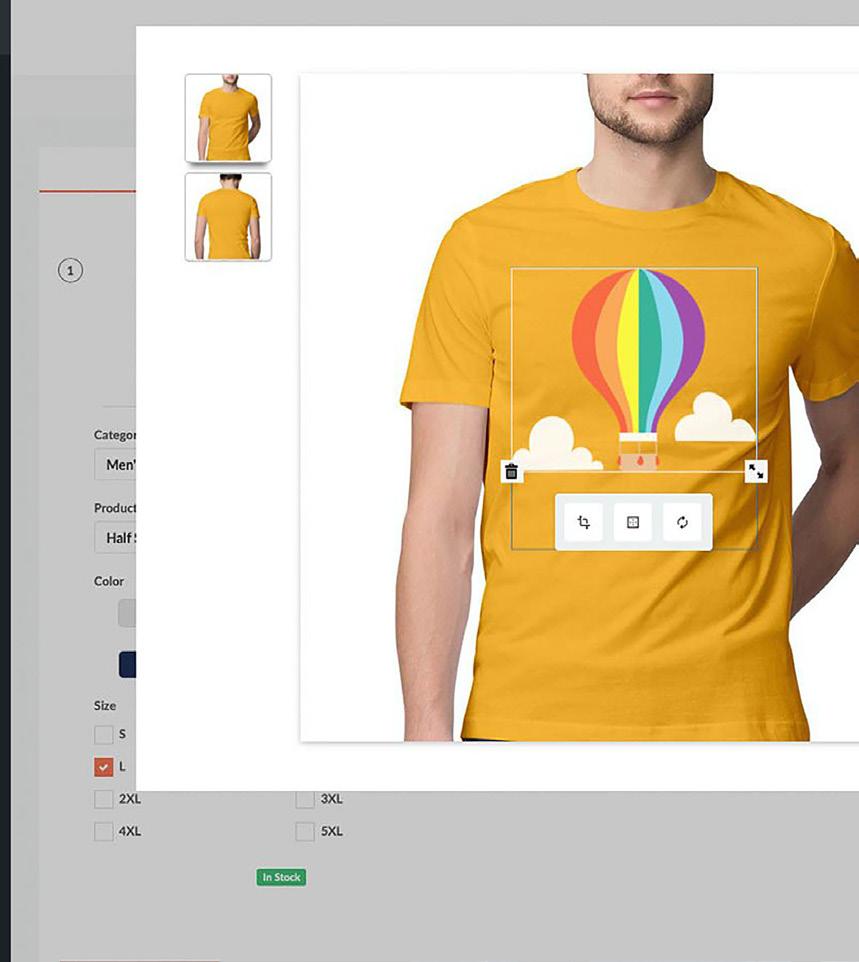

With the tagline: “You design, we print. You sell, we dropship.”, Printrove is a drop shipping business in a B2C capacity. Thus far, it is the only DTG fulfilment supplier in India that has integration with e-commerce platforms such as Shopify. Drop shipping is a

India’s Printrove installs Kornit

form of retail fulfilment business in which the seller accepts customer orders, but do not store the product in stock.

Printrove’s main clientele are e-commerce sellers and merchants who can be designers, entrepreneurs, marketers, artists and even social media influencers. The company prides itself on simplifying print-on-demand drop shipping, making it easier for its customers to start and run their own brand. Printrove takes away the hassle and technical aspect of manufacturing, inventory, and logistics, so that their customers can just focus on building their brand.

“When someone starts a brand and sells products based on their brand, some of the things that they have to think about include: I have to invest on the stock and the machine, I have to market and sell, I have to design – there are so many things to consider just to start a brand. The traditional model for t-shirts was to get into screen printing, print, start trying to sell. We take away all that hassle,” said Chauhan.

customers create that brand experience for their customers? From there we added more customisable products and getting them fulfilled at very affordable prices. Especially with India, it’s a very difficult market to do such fulfilments at those prices,” Chauhan continued.

For now, Printrove’s clients are located in India, although Chauhan revealed that they have been getting enquiries from other countries: “But we just want to make sure we have our systems right first, before we open up to the rest of the world.”

The Beginning

Printrove was first established in 2016 in Chennai by friends Chauhan and Pankaj Bokdia.

“Back then, we got started in the drop shipping business for phone cases. We had a laser cutter and we thought we’ll just cut on phone cases and try to promote vector art on phone cases, because no one was doing that at that time. So that was the first thing we had in mind,” said Chauhan.

“In wanting to make the phone cases, it led us to sublimation. We went into sublimation and got hold of this concept of print-on-demand and drop shipping. People started using our services; they liked the way we were working, the support and the kind of technology we were trying to build at that time. After a while, a lot of merchants began enquiring about T-shirt printing, because no one was doing T-shirt drop shipping in India,” said Chauhan.

“That led us to getting our first DTG printer. We started off with a Chinese DTG printer, but that didn’t work out. After 7 to 10 days, we were not able to print on that at all,” said Chauhan. “We still wanted to carry out this idea of printing on demand for drop shipping, and make this print technology accessible to everyone. We went ahead and got an Epson printer.”

Printrove started getting more orders and could easily turn about 25 to 50 orders a day within just a couple of months. Soon after, they manage to scale up to about 100 orders a day, and Printrove got its second machine. Eventually, the company managed to ramp up production to accommodate four to five machines.

Kornit was always the goal

Before investing in Storm HD6, Printrove only had Epson printers in its DTG arsenal. However, Kornit machines were always on Chauhan’s radar.

“We first got to know about Kornit machines in the initial days when Printrove was looking at DTG printers. Back then, we were inquiring about the prices and learned that it’s quite out of our range at that time,” said Chauhan. “We thought that hey, probably someday when we have those kind of volumes, we can get the Kornit machine. It was never a case of “we’re not buying Kornit”, it was more of a matter of us reaching those volumes

SELL YOUR DESIGNS ANYWHERE Sell online with your own brand on your own store or marketplace. Start your drop shipping business without any upfront cost.

first before it makes economical sense to invest in a Kornit machine.”

Today, the DTG segment takes up about 70-80% of Printrove’s entire order volume. Chauhan added that their other offerings such as phone cases are still an essential part of their business as it provides a good range of products for their customers.

“DTG is a major segment, we will also look at getting into all over sublimation, printing all-over-print (AOP) products on demand, stitching on demand; basically other areas that could help give artists and designers more flexibility on what you can do without having to invest on things. We want them to be able to take their art and reach their audiences, without having to pay attention on all of these machineries, printing operations, fulfilment, etc.,” said Chauhan.

In India, Kornit’s DTG offerings are sold through Arrow Digital Pvt Ltd. Chauhan lauded the pleasant purchasing experience: “The installation has been working great for us. Arrow Digital has helped us, we had a few issues and Arrow Digital were quite quick to help us with resolving those. They were quick to respond as well, and in completing installation of the machine, especially in Covid-19 times. So entirely, the experience has been very good.”

“We are trying to scale up capacities in terms of DTG, and at the same time building out sales so that we can match that kind of capacity. With DTG we would like to explore other machines as well like the Kornit Avalanche and Atlas in the future,” said Chauhan. “For now, we are still excited as to how we are going to operate the Kornit Storm HD6 on an everyday model. And we are looking forward to add more Kornit machines as well in the future.”

The Kornit Storm HD6 is specifically engineered for 24/7 non-stop industrial use. It is equipped with an advanced machine controller that enables multifunction operational efficiency and increases production speed. It features dual-pallets, fully automated processes and an advanced user-friendly frontend.