9 minute read

75 YEARS YOUNG

Advertisement

JCB’S 75TH BIRTHDAY

OUT-OF-THIS-WORLD ARTWORK MARKS CELEBRATION

A huge “75” artwork visible from outer space was carved into a Staffordshire stubble field to mark JCB’s 75th birthday – and to help launch a new high-tech precision guidance solution for JCB’s unique Fastrac agricultural tractor.

The giant logo was cultivated in a field eight miles away from the company’s global headquarters at Rocester and covered almost eight acres – equivalent to four football pitches. The birthday tribute was so distinctive is could be seen by imaging satellites orbiting high above the earth.

The special artwork was created ahead of JCB’s 75th anniversary on October 23rd by one of the company’s most famous products – the Fastrac tractor, which was equipped with the new JCB Twin Steer guidance system.

A team of JCB employees was behind the larger-thanlife creation which is close to

the market town of Uttoxeter where the late Joseph Cyril Bamford founded JCB in a lock-up garage on the same day as his son Anthony, now Lord Bamford, was born.

The distinctive tribute was created by uploading a digital version of the artwork prepared by Trimble, JCB Agriculture’s precision farming partner, to the Fastrac tractor’s automatic steering system, which than calculated the guidance paths. The operator only had to turn the tractor at the end of each run and lift and lower the cultivator mounted at the back – the JCB Twin Steer guidance system did the rest.

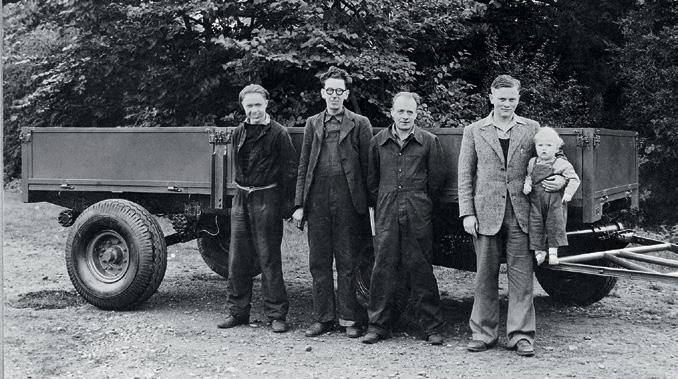

JCB was started by Mr. JCB (top centre) Joseph Cyril Bamford in his shed 75 years ago (top left) and over the years has given the equipment world a series of innovations, such as the Hydradig (far left), the Fastrac tractor (left) and the backhoe, seen here with chairman Anthony Bamford, Joseph’s son.

There cannot be any limit to the successes.”

And so a new era had dawned – and one that would see huge expansion of both manufacturing facilities and product ranges. It started in 1972 with the opening of JCB France. In 1977 the wraps came off the Loadall telescopic handler, a machine which revolutionised the way loads were handled on both construction sites and on farms. The Loadall has gone on to be one of the most successful products in JCB’s history. 1977 also marked the start of a number of high profile visits to JCB by members of the British Royal Family when HRH The Prince of Wales toured the Rocester factory. A year later another landmark was achieved: the construction of JCB’s second factory in the UK, JCB Transmissions in Wrexham.

But it was the decision to start manufacturing in India in 1979 that heralded a period of global expansion as Anthony Bamford spotted the potential of this market. Today JCB has factories in New Delhi, Pune and Jaipur and India is now JCB’s biggest market behind the UK.

Product innovation continued to be the lifeblood of the company and in 1985 the 3CX Sitemaster backhoe loader was launched

HISTORIC BHL

750,000TH UNIT COINCIDES WITH 75 YEARS

In the same year as it celebrates its 75th anniversary, JCB celebrated another unique milestone with the same two digits – the production of its 750,000th backhoe loader. The landmark machine was driven off the line at the company’s factory in Rocester, Staffordshire – the very location where the first JCB backhoe was manufactured almost 70 years ago.

It was in 1953 that company founder, the late Joseph Cyril Bamford, conceived the idea of the JCB backhoe loader, which created a single machine combining a front shovel and rear excavator arm. In its first full year of production in 1954, just 35 of the machines were produced and it took more than 20 years for the first 50,000 to be made. JCB now manufactures backhoe loaders in the UK, India, Brazil and the USA.

“Some of my earliest childhood memories are of watching our first backhoe loaders being produced at Rocester and it’s incredible to think we have now manufactured 750,000,” says JCB chairman Lord Bamford.

The 750,000th model is a Special Edition of JCB’s latest 3CX backhoe

loader, bearing a unique livery and comprehensive specification.

Phil Starbuck, 60, JCB backhoe group leader, joined as an apprentice straight from school in 1975 when JCB had made just over 50,000 backhoe loaders. As Phil - the longest serving employee in the

backhoe loader business unit - joined in the celebrations for the 750,000th model, he reflected on his contribution to the success story.

“I am very proud to be a part of this special production milestone. It is a marvellous achievement and to be part of it is fantastic.”

Shannon Ramczykowski, 22, the most recent recruit to the backhoe loader business, who joined less than a year ago, says: “It is an amazing achievement and I look forward to celebrating more such milestones in the future as I start out on my JCB career.”

and went on to be JCB’s biggest-ever selling backhoe. It’s also the year JCB celebrated the production of its 100,000th backhoe.

In 1988 the wraps came off the JCB GT, a backhoe capable of 100mph and a fantastic promotional tool which continues to draw the crowds wherever it appears around the world. Product development continued unabated with the launch of the 2CX backhoe loader in 1990 followed three years later by the even smaller 1CX.

In 1994 Joseph Cyril Bamford had a rose named in his honour. Called ‘Mr JCB’, the yellow rose was unveiled in the presence of HM The Queen at the Chelsea Flower Show. A year later and JCB was celebrating its 50th anniversary with a visit by HM The Queen to its World HQ, where she unveiled a replica of the Uttoxeter garage where Bamford began his business all those years ago.

In 1997 the innovative Teletruk forklift – which can lift and place loads over obstacles – was launched. In 1998 JCB opened its second factory in Wrexham, Wales, and

As part of the celebrations for its 75th anniversary, JCB engineers restored one of the company’s oldest backhoe loaders, the JCB 1, which was lying in the shed of one of its oldest customers. a year later opened JCB Earthmovers in Cheadle, Staffordshire. In 2000 the first machines began rolling off the production line at JCB’s new North American headquarters in Savannah, Georgia.

On March 1st 2001, flags at JCB factories around the world flew at half-mast following news of the death of the company’s founder Joseph Cyril Bamford. Britain’s Financial Times newspaper said he was blessed with a rare combination of “engineering genius and marketing flair.”

GOOD AS NEW

JCB 1 BACKHOE RESTORATION

As part of the activities to mark its 75th year, JCB restored a vintage JCB 1 backhoe loader to its former glory, presenting it as a unique gift to one of its longest-standing customers.

The UK-based contractor Eric Carnaby & Son, a JCB customer since 1959, has purchased more than 150 JCB machines. The manufacturer thanked the firm for its loyalty by restoring the

Carnaby family’s cherished 1964 JCB 1 backhoe.

The project was kept a secret until George Bamford, grandson of JCB founder Joseph Cyril

Bamford, announced the restoration during a visit to the company’s base in Immingham to collect the machine.

“My family and I are over the moon with the restoration.

Our JCB 1 is precious to us and we’ve been meaning to restore it for some time, but you know how it is – a business to run, and all that,” says Roland Carnaby Junior, director, Eric Carnaby & Son.

Six months later, the backhoe was handed back to the company after a team at JCB’s world headquarters in Rocester, Staffordshire, spent hundreds of hours lovingly restoring it.

“It has been amazing to see an old machine brought back to life by the JCB team. It looks just as it would have done on the day it came off the production line in 1964,” George Bamford says.

Eric Carnaby & Son bought its first JCB backhoe in 1959. The two family businesses have been strongly intertwined throughout the 61-year period, with 95% of the contractor’s fleet now made up of JCB equipment.

SANY POWERS FORWARD

THE CHINESE MANUFACTURER HAS MADE ITS MARK IN THE REGION AS A SUPPLIER OF QUALITY MACHINERY AT COMPETITIVE PRICES, WITH EXPERT SERVICE AND BACK-UP BY ITS DEALER NETWORK. TING SHA, DEPUTY GENERAL MANAGER, SANY MIDDLE EAST, TELLS CMME HOW THE BRAND IS FARING

Sany is among the biggest construction machinery manufacturers in the world and has one of the widest product ranges. Please describe your product offerings in the Middle East region, giving an overview of each category.

Sany has a wide product range like excavators, concrete, hoisting and piling machinery, road-making equipment, port and mining machinery. All of these are available in the Middle East region.

Also, Sany became the world’s largest concrete machinery manufacture in 2012, offering pumps, mixers and other concrete equipment. And of course, we have a large line-up of cranes of all kinds, whether mobile, crawler or rough terrain.

How has Sany’s business performance been in the Middle East market in the years 2018-2019, and until the start of the Covid-19 pandemic?

We enjoy high popularity in the region and you will find Sany kit on almost all important job-sites anywhere you go in the region. Apart from our concrete and lifting equipment, Sany’s excavators, road machinery and port machinery have become really popular in the Middle East market over the last five years.

We are also highly involved with several key projects in every country in the region, as well as in the “One Belt One Road” project.

How has Sany’s performance been in the Middle East since the start of the Covid-19 pandemic? How has Sany responded to the pandemic in terms of the safety aspects?

When the Covid-19 first spread in the Middle East, many projects were shut down or temporarily suspended and our business also slowed down because of it. But our business has gradually come back on track after the pandemic situation was controlled by the governments here and the lockdowns were started to be removed.

Moreover, after the Covid-19 pandemic was gradually brought under control in China and we noticed our overseas dealers running short of PPE, we immediately responded to the situation and started outsourcing the PPE kits form China to other territories worldwide. From all over the China we flew out thousands of PPE kits to dealers all over the world.

Now that we are all having to live with the Covid-19 situation, all of us have been forced to do things online in order to avoid physical contact. So our local dealers are also very active in this and have quickly adapted to the new realities by embracing the challenges.

Sany service engineers and local service teams are standing by at all times, observing the necessary precautions. If and when a customer needs us, we are available as normal even in this pandemic time.