6 minute read

Monopole Masts A case study in Ethiopia

Power transmission and distribution project in Ethiopia

A case study for self-supported monopole masts

Advertisement

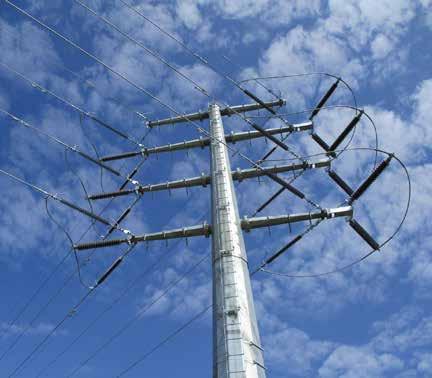

The ongoing project forms part of a large-scale electricity infrastructure upgrade for Ethiopia and focuses on the transmission and distribution of electricity from various substations to surrounding areas of Addis Ababa. These distribution networks convey electricity with high voltages from 132 kV up to 230 kV and span through tough terrains, city centres and densely populated informal settlements.

Structa Group, through its subsidiary, Structa Konsult, was contracted to carry outdata collection, survey, design conceptualisation, detail designs, complete and sign manufacturing drawings, manufacture, and deliver of the masts. The project was a milestone as it was the first time the client considered using these sizable self-supported monopole masts in a high voltage transmission application.

According to Erasmus Cilliers, a senior mechanical engineer of Structa Group, initially, the client thought that it would be a big gamble to switch from the ‘tried and tested’ lattice-type pylon structures to large monopoles. However, the client thrust a spot of bother of sorts – with the lattice-type pylon structures, The masts manufactured for these lines were some of the biggest masts ever manufactured by Structa.

Specialists in the design, supply and installation of electrical distribution towers and masts

Structa Technology is a Level 1 BBBEE Contributor

Contact us first for professional service - backed by years of experience and a wealth of practical knowledge. Our committed team will assist in you in the design and implementation of custom made solutions.

Please contact us at our Meyerton office:

Tel: Email: Web: +27 (0)16 362 9100 masts@structatech.co.za www.structatech.co.za STRUCTA technology

there was concern about the high risk of incidences of vandalism in areas where the poles were to be located to consider. After conveying the experience with these masts in the field, and the rigorous tests that were conducted on the monopoles, administered by Eskom in South Africa, the final decision to settle for the selfsupported monopole mast was a no-brainer. “The masts manufactured for these lines were some of the biggest masts ever manufactured by Structa. They were

The inherent reliability of these masts ensures that little to no maintenance is required.

required to be freestanding and supported two power line circuits with their respective optical ground wires simultaneously by means of eight cross arms,” said Cilliers.

What gives tubular monopoles the edge?

The following are typical advantages of tubular monopoles: low maintenance costs and modifiable, good protection against vandalism and theft, smaller footprints, lower probability of catastrophic failures, and excellent life expectancy. Low maintenance costs and modifiable The inherent reliability of these masts ensures that little to no maintenance is required. “The predominant maintenance is when structures of an existing line are analysed to determine if the same structures can support new conductors with improved electricity characteristics,” said Cilliers.

“Additionally, the capabilities of the structure can be increased by adding noninvasive clamp-on modifications. These modifications are designed, manufactured and supplied on a problem-specific basis. Furthermore, we are in the business of design, manufacture and supply of the

masts, if our clients require more of the masts or new designs we will deliver,” he added.

Vandalism and theft-proof

Self-supported masts are becoming prevalent in structure designs of transmission and communication projects, and this is mainly to counteract high vandalism or theft in areas with the identified risks.

“Theft of steel is one of the leading problems in many countries. That is why towers are being stripped of their steel members and are sold as scrap. Some members of welded towers are also being removed using portable power tools,” noted Cilliers.

However, vandalism does not affect steel masts, as a steel mast cannot be disassembled using regular tools or transported with domestic vehicles. This is because when a mast is surface-mounted in an area identified as high theft or vandalism risk, the foundation gets an additional concrete cap that conceals the bolts.

Smaller footprint

Self-supported masts are designed to support conductors without any external support such as a strut or stay wires. Compared with towers, they have a smaller footprint and only requires a little land space. A piled foundation for specific structures can be used to create a smaller foundation footprint.

Self-supported masts are designed to support conductors without any external support such as a strut or stay wires

*Deming Award

*ELGi is the rst, globally established industrial air compressor manufacturer to have won the Deming Award High durability and longer life expectancy The galvanisation of the masts, paired with the low number of holes and surfaces provides exceptional corrosion protection and significantly extends the life of the structure.

Less installation time

The skills required for the construction process and installation of lattice-type towers and monopole masts are a bit different. Moreover, masts usually require less installation time compared to the assembly procedures of towers. “The installation of towers versus masts is entirely different. A tower is installed by bolting together parts or complete sections on the ground before lifting to the correct heights using cranes and are then bolted together,” Cilliers illuminates.

The ‘gamble’ pays off

Structa manufactures standard masts and towers for voltages of 11kV up to 220kV. The structures designed and manufactured for this project was for voltages between 132kV and 230kV. With the project being in Ethiopia, the design codes selected were international standards and incorporated the strict requirements of the client. Typically, the sections of these type of masts are manufactured from S355JR material being 3mm to 10mm in thickness, with base plates rarely thicker than 60mm.

This project required wall thicknesses of the masts to be between 8mm up to 20mm and base plates from 35mm up to 70mm in thickness. The height of the structures varied between 15.34m to a maximum of 33.5m, and coupled with the large spans, these heights generates heavy moments that the foundations must support effortlessly. The supported tip load of the suspension structures varied between 50kN and 80kN, while the strain monopoles were designed to accommodate tip loads between 170kN to 270kN. That said,Mr. Cilliers is content that the project was delivered to client’s expectations,on time, and to the exact specifications in terms of size and quality.

sales@abyssiniagroup.com

www.abyssiniagroup.com

Abyssinia Group Head Office House No. 40, Westlands Road. P.O. Box 1408-00606 Nairobi, Kenya Tel: +254 719 834 973 / +254 795 758 885

Complete Crushing Plant for Sale:

IRON ORE CRUSHER PLANT MODEL BIC 5114-40 TPH 1. One Grizzly Feeder. 2. One Primary Double Toggle Jaw Crusher. 3. One Secondary Double Toggle Jaw Crusher. 4. One Vibrating Screen-I. 5. One Electrical Control Panel (Main and Control). 6. Jaw Plates for Primary Crusher. 7. Jaw Plates for Secondary Crusher. 8. Perforated sheet of 8 mm and 18 mm

BELT CONVEYOR SYSTEM 1-5 Belt conveyor -5 No’s Complete Structure, Walkway, Belt, Pulley & Motors

For further details contact Abyssinia Group of Industries: +254 719834973/ +254 795758885 or send email to marketing@abyssiniagroup.com