21 minute read

Section

Ritchie Bros. Acquires Euro Auctions, Expands Its Reach in EMEA Region

Ritchie Bros. and Euro Auctions have jointly announced that they have entered into an agreement under which Ritchie Bros. will acquire Euro Auctions group for an enterprise value of approximately $1.08 billion.

Founded in 1998, Euro Auctions conducts unreserved heavy equipment auctions with onsite and online bidding under the brands Euro Auctions and Yoder & Frey, with more than 200 employees in 14 countries. In 2020, the company conducted 60 auctions, selling close to 90,000 items across its nine locations in the United Kingdom, Northern Ireland, Germany, Spain, the United Arab Emirates, Australia and the United States.

Similar to Ritchie Bros., Euro Auctions also sells items through a timed auction format and a daily marketplace with Buy Now and Make Offer options.

“Ritchie Bros. and Euro Auctions are an ideal fit with a united goal to make asset insights, service offerings and disposition solutions easier than ever,” said Ann Fandozzi, Ritchie Bros. CEO.

“Euro Auctions has an incredibly talented team, with expertise in asset sourcing, auction operations, sales and customer service. Their ‘can do’ attitude and entrepreneurial spirit combined with technology has helped them adapt and grow, in much the same way as we have. This acquisition significantly accelerates our strategy to drive revenue and earnings growth and add shareholder value by continuing to expand our capabilities in new channels, sectors, regions and customer segments.”

Euro Auctions Founder and Director Derek Keys added, “Dave Ritchie and his brothers were a big inspiration for my brothers and I in the creation of Euro Auctions. We modeled much of what we do off Dave’s customer-centric philosophy, which still runs through Ritchie Bros. today. Bringing us together will drive value for customers, as we provide more equipment, solutions, and services to the many industries and regions in which we operate.”

Ritchie Bros. will be retaining Euro Auctions employees and its brand, both of which are highly regarded in the EMEA region. This will expand Ritchie Bros.’ overall footprint and access to equipment, while also tapping into new revenue streams with service offerings to Euro Auctions customers, including inventory management services, data solutions, financing, warranty, insurance, inspections, refurbishing, shipping and more. “Euro Auctions has an incredibly talented team, with expertise in asset sourcing, auction operations, sales and customer service.” Transaction Terms Under the terms of the transaction, Ritchie Bros. will Ann Fandozzi acquire 100 percent of the Ritchie Bros. equity of the companies comprised within the Euro Auctions group for an enterprise value of approximately $1.08 billion in cash. This represents an implied multiple of ~15.3x 2021E EBITDA (nonGAAP measure), including run rate synergies. Ritchie Bros. intends to finance the transaction through a combination of cash on hand and new debt; and has bridge financing commitments from Goldman Sachs Bank USA, subject to customary terms and conditions to facilitate the transaction close. Following the close of the transaction and the required financing, Ritchie Bros. is expected to have an adjusted net debt to adjusted EBITDA ratio (non-GAAP measure) of approximately 3.9x. Ritchie Bros. has secured employment arrangements with key management of the Euro Auctions business, including Derek Keys, who will continue to be involved for a minimum of three years post-closing. It is intended that Jonnie Keys will assume a senior leadership position, and Lynden and Trevor Keys will be retained as sourcing leads. The transaction was approved by the board of directors of Ritchie Bros. and is expected to close in late 2021 or early 2022, subject to regulatory clearances and the satisfaction of other customary closing conditions.

Strategic Rationale for the Acquisition

• Accelerates our Journey — “This acquisition will accelerate our journey, strengthen our strategic pillars and further establishes Ritchie Bros. as the trusted global marketplace for insights, service and transaction solutions for commercial assets. Euro Auctions is an ideal and complementary brand to expand Ritchie Bros.’ global footprint. This combination will bring unprecedented and diversified choice to customers around the world, facilitating better price discovery and more equipment selection. Euro Auctions has considerable presence across Europe and the Middle East, particularly in the U.K. and Germany and will serve as a platform to accelerate international growth.” • Accelerates Inventory Management System Adoption — Ritchie Bros. suite of tools and digital services will unlock value for Euro Auctions customers post acquisition, providing a more robust offering for customers. Tools and services include a free business inventory management system from RB Asset Solutions, data analytics tools like Market Trends and RB Asset Valuator, financing from Ritchie Bros. Financial Services, as well as shipping, insurance, warranties, refurb and inspection services. • Global Platform for At-Risk — The combined entity will be able to leverage industry best practices and decades of equipment expertise, while providing access to more capital to quickly offer robust atrisk consignment options for customers globally, regardless of transaction size.

Advisors

Goldman Sachs & Co. LLC is serving as exclusive financial advisor to Ritchie Bros., Norton Rose Fulbright LLP and Skadden, Arps, Slate, Meagher & Flom LLP are serving as legal advisors, and KPMG LLP is serving as accounting, tax and IT advisor. Jefferies International Limited is serving as financial advisor to the vendors of Euro Auctions, and A&L Goodbody LLP as legal advisor.

For more information, visit RitchieBros.com.

As part of its ongoing efforts to inspire members and association partners in developing strategies to build a bigger, better workforce, AEM is offering its second-annual Workforce Solutions Summit.

This one-day virtual summit — scheduled for Aug. 19, 2021 — will offer valuable information and insights, as well as research-based solutions, to organizations looking to recruit, train and retain employees.

“It’s critically important for our industry to take a proactive and informed approach to workforce development activities, as well as developing the employees of tomorrow,” said AEM Senior Director of Workforce Solutions Julie Davis. “Manufacturing offers a wealth of incredible career opportunities, and this summit serves as a uniquely valuable forum for industry stakeholders to learn how to effectively recruit talent and promote the skilled trades.”

Feature speakers at this year’s Workforce Solutions Summit include: •YourExecutiveCoach.com’s Janyne Peek-Emsick, who will focus on the neuroscience of conflict • McKinsey & Company’s Bryan Hancock, who will discuss the future of work • Microsoft’s Lauren Gardner, who will cover diversity and inclusion • Workforce Alliance of South Central Kansas’s Keith Lawing, who will talk about connecting with local workforce development • Career Research Group’s Chris Czarnik, who will present on best practices related to employee retention and recruitment

In addition, several company representatives are scheduled to share strategies they are employing in order to influence workforce success in their organizations and communities. They include: • Linamar • UGDSB • GPS Education Partners • Komatsu Mining Corp.

AEM also will offer hands-on Workforce Pre-Summit Workshops on Aug. 17 and Aug. 18. Capacity is limited, so interested attendees should add the workshops to their order when registering for the Workforce Solutions Summit.

“Our Workforce Summit will cover topics to help our members and the industry develop a pipeline of talent to help them move their businesses forward, and many of the ideas presented can be easily implemented,” continued Davis.

“Ultimately, this summit is designed for all roles who have a stake in growing and developing a successful workforce — executives and company leaders, operation leads, training and hiring managers, and human resources and recruiting professionals,” she said. “Because finding talent is more than just a human resources issue, it’s a business issue.”

Sponsors for this year’s Workforce Solutions Summit are Apprenticeship Works!, GPS Education Partners, Green Mountain Lion Corporation and Ultra Consultants.

For additional information, download the summit agenda and the pre-summit workshop agenda, or contact AEM’s Julie Davis at jdavis@aem.org.

Pages 17-23 Aggregate Production and Recycling Section

For more information on crushing, screening and recycling equipment, visit CEG's Web site at www.constructionequipmentguide.com.

Six New Cat Pulverizers Deliver Concrete Demolition

Caterpillar’s new generation of primary and secondary pulverizers deliver up to 52 percent faster cycle times, producing more tons-per-liter of fuel burned.

The new Cat Pulverizer line includes three new rotatable primary models — P318, P324 and P332 — which feature 360-degree rotation, and three new fixed secondary models — P218, P224 and P232. Both pulverizer series are designed to fit 19.8 to 55 ton (18to 50-t) machines.

The new pulverizer design is built around the same SpeedBooster technology found in Cat multi-processors. This feature quickly closes the jaw when there is no load. When the jaw comes into contact with material, the SpeedBooster hydraulic valve automatically switches to power mode for maximum power, quickly shattering concrete.

Up to 26 Percent Greater Performance Grab Material From Any Angle

Cat secondary pulverizers deliver up to 44 percent faster cycle times and up to 20 percent better force in concrete demolition, resulting in up to 15 percent greater performance in secondary material processing applications, the manufacturer said. Wide jaw openings allow operators to grab more material from any angle, increasing processing speed and improving overall material throughput.

Delivering efficient and profitable demolition of concrete structures, new Cat primary pulverizers balance speed and power by offering up to 52 percent faster cycle times and 21 percent higher force than the previous models, according to the manufacturer.

Bidirectional 360-degree rotation for the P300 series models positions the jaw to grab material from any angle for producing material properly sized for further processing. Integral rebar knives quickly shear through pipes, rebar and other embedded materials to improve demolition efficiency.

More Time Working

Delivering the production, reliability, durability and value

expected from Cat products, both new pulverizer series feature bolt-on wear components that can be quickly replaced in the field with no hard-face welding required for maintenance, so the pulverizers spend more time working. Increasing reliability and longevity, all hydraulic components are protected inside a housing with a bolt-on removable panel that provides complete access for servicing. Integrated into all new pulverizers, Cat asset tracking is available for quick attachment locating. Easy-to-establish site boundaries increase attachment security by sending an alert if the asset is moved beyond a set perimeter. Asset tracking allows for efficient management of the entire attachment fleet, quickly viewed through VisionLink with Product Link subscribed equipment. Capable of working on a range of excavators, these new pulverizers are designed to increase efficiency when powered by Cat hydraulic excavators. An integrated solution, Cat Next Gen excavators include pulverizer settings in the controls, allowing the excavator to quickly recognize the attachment and automatically establish the proper operating settings. Along with Cat excavators, these new pulverizers are covered by Cat dealers. For more information, visit www.cat.com.

Lake Erie Portable Screeners Lands Contract With Dept. of Defense

Lake Erie Portable Screeners, manufacturer of the Pitbull line of portable, heavyduty screeners and material processing equipment, has been awarded a contract with the U.S. Department of Defense under the Heavy Equipment Procurement Program.

“We’re pleased that the government has reviewed our screening equipment and has formally recognized the quality and serviceability of Lake Erie Portable Screeners’ machines in issuing this contract,” said Rick York, president of Lake Erie Portable Screeners.

A government representative contacted Lake Erie Portable Screeners to initiate the final stages of the contract in April. York said that the five-year contract award involved an extensive review by the Department of Defense.

“The process began in 2017 when we submitted the initial application” he said. “During the approval process, three of our machines found their way to government facilities for review and we assume, testing. One went to 29 Palms in California and two went to government facilities in Virginia. Unbeknownst to us, officials had also stopped by our booth at the 2020 ConExpo in Las Vegas for an inspection of the machines we had on display, including our newly introduced Pitbull 5700.

The Heavy Equipment Procurement Program contract award not only provides a purchase mechanism for the U.S. Department of Defense, but it also extends to nations formally recognized as friendly to the United States, positioning Lake Erie Portable Screeners products, for international equipment sales.

The Department of Defense’s Heavy Equipment Procurement Program contract adds to the company’s list of governmentapproved purchasing programs. Lake Erie Portable Screeners has also recently been approved for Pennsylvania’s COSTARS program, adding the company’s machines to the state’s vendor list for pre-approved Cooperative Purchasing Program, streamlining the governmental procurement process. The HGACBuy program is available through the Houston-Galveston Area Council, or H-GAC, a regional council of governments operating under the laws of the State of Texas. The H-GAC Board awards all contracts for products and services, which can then be made available to local governments nationwide through HGACBuy. The move benefits all Lake Erie customers in the continental United States participating in the program, including departments of transportation, townships, municipalities, city governments, schools and park departments.

Engineered and manufactured at the company's headquarters in Lake City, Pa., Lake Erie Portable Screeners offers a product line of portable screeners, grizzlies, conveyors and feeders. Power options for the company’s screeners include diesel, propane or electric.

For more information, visit www.pitbullscreeners.com. CEG

Rick York, president of Lake Erie Portable Screeners, announced the company has been awarded a contract from the U.S. Department of Defense under the Heavy Equipment Procurement Program.

Page 18 • August 15, 2021 • www.constructionequipmentguide.com •Recycling Section • Construction Equipment Guide Power Meets Portability in McCloskey’s New I4C Compact Impact Crusher

The 44-in. impact crusher has been designed with a deeper chamber, creating greater tramp release space. With an aggressive blow bar and apron design, four-bar variable speed rotor and three crush zones with an optional fourth strike, the I4C can be set up as a primary or secondary crusher in some of the toughest materials.

McCloskey International has unveiled the I4C, the latest entry into McCloskey’s impact crusher line. In a class of its own, it brings the power and productivity of an 44.3 in. (112.5 cm) impactor to a compact footprint for maximum maneuverability.

Taking the original impact crusher design and transforming it into a heavy duty compact product that is even more flexible and productive, the new mobile crushers maximize the efficiency of any project site, according to the manufacturer.

Built to the same high standards as full-size crushers, the new I4C delivers additional convenience and choice to suit every customer’s needs. McCloskey engineers have adapted the design to meet the evolving requirements of today’s projects and operations by developing more compact products while maintaining the same high standard of McCloskey durability, reliability and quality.

The I4C compact impact crushers have a number of features that enhance their operation. The 44 in. impact crusher has been designed with a deeper chamber, creating greater tramp release space. With an aggressive blow bar and apron design, four-bar variable speed rotor and three crush zones with an optional fourth strike, the I4C can be set up as a primary or secondary crusher in some of the toughest materials.

A new asymmetric feeder reduces bridging that can occur in some applications and, combined with the single unit feeder-hopper construction, delivers better motion and vibration for the material as it moves into the impact chamber. Maximum efficiency of material flow is delivered end-toend with the I4C — from the feeder to the new curved belt on the main conveyor that better manages material delivered to its 4m high stockpile.

With quick release and ground level access, the conveyor belt also is easy to maintain and service.

As with all McCloskey equipment, safety is paramount, and the I4C is equipped with a number of features to ensure the workplace and the operator are secure. A chamber door safety sensor, built in safety shutdown functions, chamber safety arm and an innovative platform for changing blow bars all contribute to the safe operation and maintenance of the equipment.

Simplicity is key, with ease-of-use and safety considerations built into the low voltage electrical system, hydraulics and control panel. Higher engine power delivers cost efficiency by delivering maximum production levels and is, size-for-size, McCloskey’s most powerful impact crusher, according to the manufacturer.

“Listening to our customers is a core element of our design engineering across all product lines. We are bringing to the I4C to market to respond to the demand for a heavy duty, high production impact crusher with high mobility and enriched safety features. The I4C is an exciting entrant to the category, and we look forward to working with our global dealer network to fulfill the demand for these products,” said Toni Laaksonen, senior vice president, McCloskey International.

For maintenance ease the vast majority of components are identical between models to simplify spare parts. Ground level access allows for quick service and maintenance, reducing the downtime for the operation.

These compact, mobile crushers are suited particularly to construction and demolition recycling, asphalt recycling and aggregates. The new impactors deliver high performance and expanded versatility in a highly mobile lineup to customers around the world. With their fast set-up time and ability to nimbly move around in tight spaces, the crusher’s small footprint is uniquely suited to heavy duty applications where mobility and high production are key.

For more information, visit www.mccloskey international.com.

A Different Look... IROCK Crushers Launches Its New Website, New Logo

IROCK Crushers has launched its new website and logo design.

Current leadership has recently embarked on rebranding IROCK Crushers. The company is now close to 30 years old and has evolved in its offerings, customers and innovations. In the last five years, the product line has greatly expanded to serve the crushing and screening industry.

“The IROCK leadership team is totally committed to telling the IROCK story through the new website and new branding. The industry is undergoing significant Visitors can efficiently change and IROCK is posi- find information on tioned to deliver a new way of doing model specifications, business. We are committed to our equipment features, dealers and cus- on-site equipment photostomers and providing them the and 3D renderings... most efficient way to access equipment details as well as continuing to meet their needs for service and parts,” said Ken Taylor, president, IROCK Crushers.

IROCK’s new website is designed with the customer in mind, featuring user-friendly access on any device, ease of navigation and a quick way to view details on any IROCK product to download and share.

Visitors can efficiently find information on model specifications, equipment features, on-site equipment photos and 3D renderings, customer story video testimonials and contact information for parts and service.

“We are very excited about our new website and are confident that current and new customers will be able to navigate easily to find the perfect mix of solutions and services from IROCK Crushers. Our team is also inspired with the launch of the IROCK rebrand and the new logo design. The new design is a symbol of our strength and growth, and the conical piles more accurately represent what IROCK equipment can produce for its customers,” said Chris Larson, general manager, IROCK Crushers.

IROCK provides mobile and portable crushing plants, screening plants, conveying equipment, and other related products for the demolition, recycling and aggregate industries. IROCK’s robust equipment will increase production and profits while also reducing downtime and operational expenses, according to the manufacturer.

For more information, visit www.irockcrushers.com.

FAE STUMP CUTTERS: COMPACT DESIGN, POWERFUL RESULTS

See you in North Hall. N-1448.

Sep. 28-30 2021, Louisville (KY) Contact us to fi nd the right FAE product for you: (770) 407-2014 – info@faeusa.com

fae-group.com

Metso Outotec Unveils Nordtrack Mobile Screen, Crusher

Metso Outotec is adding two new products to its Nordtrack mobile crushing and screening range.

The Nordtrack S2.5 mobile screen is a small size, versatile scalping screen designed for small job sites and a variety of applications. With a compact and light-weight structure, a highly efficient two-deck screen, and a wide selection of different screening media, it is the perfect solution for construction contractors with frequent changes in site locations or simply as a rental unit, according to the manufacturer.

The second new addition to the range is the Nordtrack I908 mobile impact crusher. Its design is optimized for the smaller-sized material reduction job sites, and it accepts different kinds of feed material — from asphalt recycling to concrete crushing, as well as traditional rock crushing.

The same base model with an integrated screen on the chassis, the Nordtrack I908S, was introduced earlier, and it has been one of the best-selling Nordtrack units, especially in Europe.

“I am very pleased to say that the Nordtrack range has been extremely well received by our customers,” said Vesa Tuloisela, who heads the Nordtrack product offering at Metso Outotec.

“It has proven to be a flexible solution meeting different requirements. Nordtrack sales have been developing very well despite the pandemic; in fact, we have exceeded sales targets in some areas. However, we are always listening carefully to customer feedback. These two new products represent a concrete outcome of those discussions.

“We want to grow our recycling customer base, offer attractive solutions for the rental business and for construction contractors globally.”

The products are launching in the Nordtrack Liveroom, which is Metso Outotec’s new 360-degree digital event experience platform. Liveroom features 3D demonstrations of the Nordtrack range as well as a wealth of information on the aftermarket offering.

Both new products are already available globally through Metso Outotec and distributors.

For more information, visit www.mogroup.com/ nordtrack.

Construction Equipment Guide• Recycling Section• www.constructionequipmentguide.com • August 15, 2021 • Page 21 JSC Aluminum Alloys Rely On Sennebogen 825M for Projects

On-site logistics for JSC Aluminium Alloys.

There’s no time for downtime at JSC Aluminium Alloys, one of the largest aluminum alloy producers in Russia. Operating conditions at the mill are challenging and the three material handlers that take on most of the site’s loading and logistics tasks are on the run around the clock.

That’s why Andrey Tsidenov, the general director of the plant, chose Sennebogen 825 M machines for the job.

Tsidenov said his mill is no place for equipment that relies on sensitive electronics to keep producing efficiently. Sennebogen’s full line of material handlers is purpose-built for just such working environments. In these machines, smart hydraulics take the place of computers and black boxes to lift and carry loads smoothly, quickly and cost-effectively.

Keeping Equipment Up-to-Date

Located in Podolsk, near Moscow, JSC Aluminium Alloys employs 320 people and produces approximately 49,600 tons per year of finished aluminum products. Up to a half of the company's production is exported to Asian countries and North America. The raw material is used in profiles for aluminum frameworks, special tools and even engines.

Tsidenov attaches great importance to the continual updating of production technologies and equipment. In 2010, the company acquired a rotary kiln system, which opened opportunity and a new revenue stream including slag processing. Following this addition, the company began upgrading its material handling fleet with its three Sennebogen 825 M material handlers. The third of these went into operation in Spring of last year.

Versatile, Powerful

The 825 M is a rubber-tired 57,600 lb. (26,127 kg), 197 HP (145 kW) machine. Equipped with a Sennebogen K12 boom, it has a reach of almost 40 ft. (12 m) and the machines are able to move between workstations on the 9-acre mill site at speeds up to 12.5 mph (20 kph).

Tsidenov’s Sennebogen fleet supports all transport and logistics processes at the mill. The machines work three shifts every day unloading the raw materials and distributing them to sorting plants, loading scrap for remelt and loading finished products for shipment.

Compact Maneuverability

The mill’s head of transport, Andrei Frolushkin, agrees that Sennebogen’s “computer free” engineering is essential for the working conditions in the factory.

The design of the site, originally built in the 1950s, also attracted the management to the compact size of the 825s. Road height is low and limited by masts and pipes. The 825s’ low travel height and maneuverability allow it to travel through the difficult paths with the boom and stick fully extended in transport position.

After seven years of experience with Sennebogen, Frolushkin is sure that Sennebogen technology is the best choice for JSC Aluminium Alloys.

“Their reliable maintenance, robust construction and simplicity definitely convinced us," he said.

For more information, visit www.sennebogen-na.com.

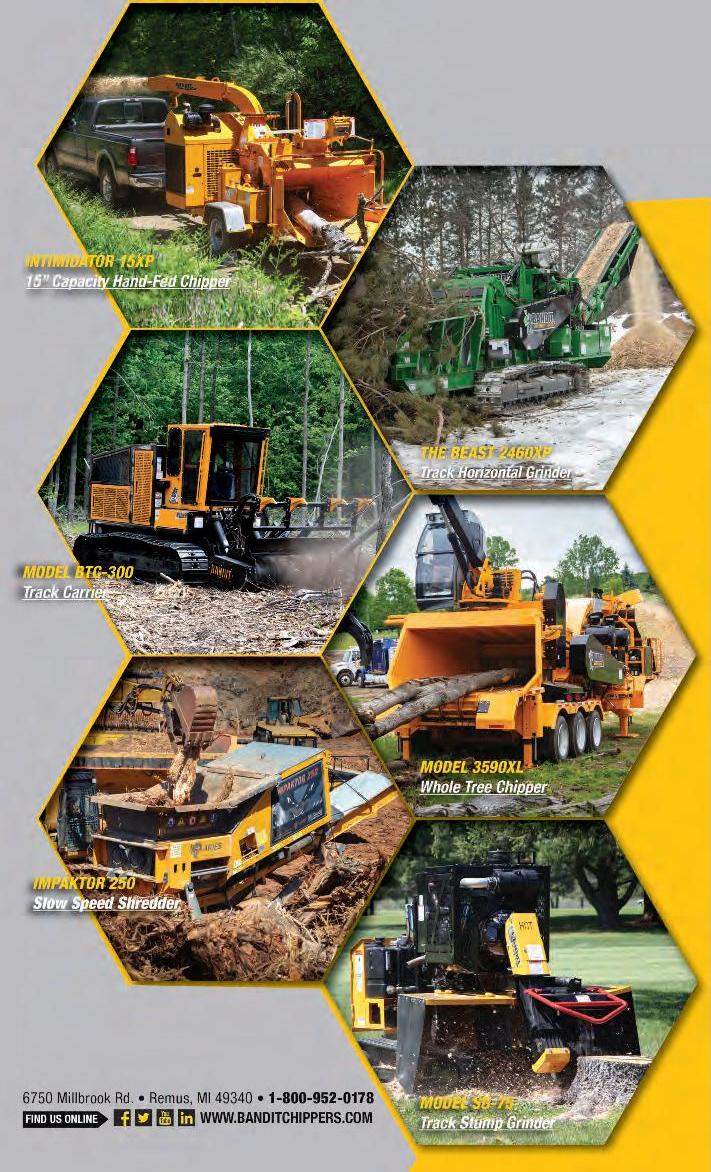

TREES, BRANCHES, LIMBS, AND STUMPS ARE NO MATCH FOR A BANDIT®

From roadways to right-of-ways, lot clearing to road clearing, get your work done faster and more efficiently than ever before with Bandit® machinery! Choose from different styles and sizes to suit your needs. Call today to reserve yours or to request a demonstration.

SMALL EQUIPMENT DEALERS

(Brush Chippers, Stump Grinders, Skid Steer Attachments)

bobcatofnorthtexas.com