13 minute read

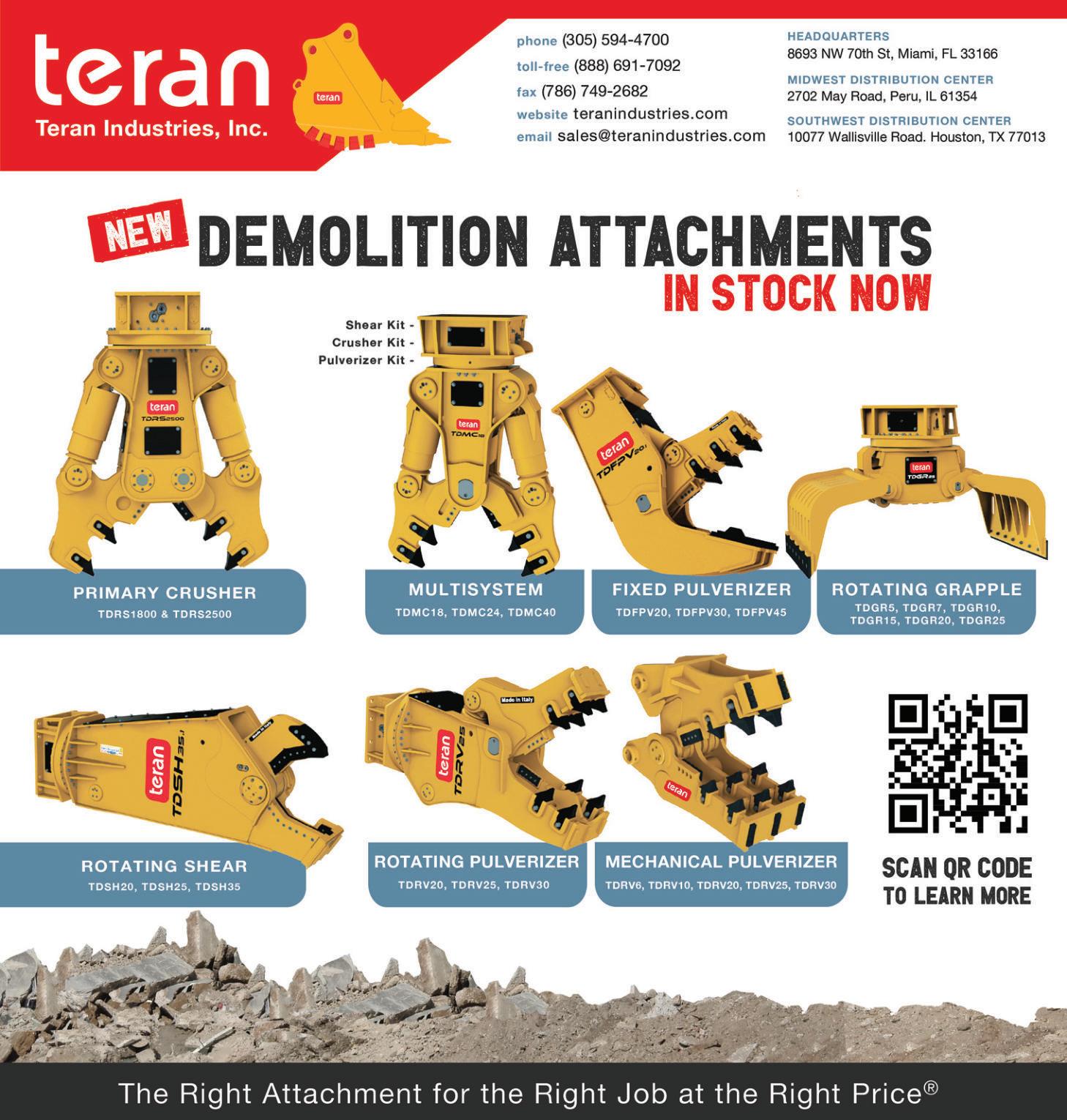

Attachments & Parts Section

Ziehl-Abegg Inc., a manufacturer of motors and fans for commercial ventilation systems, has picked Winston-Salem, N.C., for an expansion that will bring hundreds of new jobs to the city.

The company announced Nov. 16 the establishment of its North American headquarters just east of the city and moving production from nearby Greensboro. The move is part of a significant expansion by Ziehl-Abegg in North America.

Founded in 1910 as a motor manufacturer, Ziehl-Abegg produces industrial fan systems and motors, and has almost 5,000 employees worldwide. The company makes fans for various commercial applications, including hospitals, schools, data centers and various agricultural uses.

From approximately 200 current employees in the state’s Piedmont Triad, the global company plans to grow to more than 500 plant workers, and local officials told the WinstonSalem Journal that in 10 years it could have 800 hires.

“This is a home run for us in a number of ways,” WinstonSalem Mayor Allen Joines told the newspaper. “It is a manufacturing company investing $100 million and with jobs that pay $50,000 to $60,000 per year. It is exactly the type of company we want as part of our economic fabric.”

He added that Ziehl-Abegg has selected a 500,000-sq.-ft. build-to-suit property in the Union Cross Industrial Center off Interstate 40 and Union Cross Road, between the Caterpillar manufacturing plant and Glenn High School. The site will house Ziehl-Abegg’s headquarters, manufacturing and distribution operations.

“Megatrends such as digitalization, climate change and urbanization are leading to a growth in demand and call for a significant increase in our production capacities,” explained Joachim Ley, Ziehl-Abegg’s chief operating officer. “The U.S. market is fundamentally very important for us and is driving the expansion in North America.”

In a statement, North Carolina Gov. Roy Cooper noted, “The company’s increased investment is a great vote of confidence in our thriving economy, central East Coast location, and skilled manufacturing workforce.”

The news is the most recent example of large businesses making roots in the Piedmont Triad. Earlier, Toyota made a $2.5 billion investment in a battery manufacturing plant near the town of Liberty, south of Greensboro, with plans to begin production in 2025.

Triad Ripe for Manufacturing Expansion

The Journal reported that Ley said his company would start with 189 employees at the new site, but add to that number “very rapidly.”

When the company negotiated with local officials on economic development incentives, it promised to move 200 jobs from its Greensboro site and add another 300 positions over five years.

Mirco Herrmann, the managing director of the North American market of Ziehl-Abegg, said the company’s experience working in the state’s Piedmont Triad made the new site “a prime location to consider for our expansion in the U.S.

“Forsyth County offers the talent that fosters our success as a company, and is committed to developing the manufacturing workforce here, so we know there will always be great

people with the right skills to grow our team,” he added. The new positions include assembly technicians, engineers, finance, quality assurance, machinists, maintenance and various administrative personnel, according to the Winston-Salem news source. The new jobs have the potential to create an annual payroll impact of more than $11.2 million for the region. Mark Owens, president and chief executive of Greater Winston-Salem Inc., said the company’s decision “underscores the advantages that manufacturers have in this area — from infrastructure and logistics to availability of talent to a supportive business climate.” Greater Winston-Salem is the local chamber of commerce and business-recruitment agency. “We are confident that we can continue to deliver these benefits as the industry grows,” he told the Journal. A performance-based grant of $400,000 from the One North Carolina Fund, dependent on a capital investment from the German manufacturer of $24.5 million, will help with Ziehl-Abegg’s expansion in the state. Winston-Salem is providing about $630,000 in incentives, the Journal reported, and Forsyth County is paying $430,000 in incentives. The money paid out by Winston-Salem and Forsyth County is based on increased property tax revenues. “We are excited to welcome Ziehl-Abegg and its new good-paying jobs to Forsyth County,” state Sen. Joyce Krawiec said in a news release. “This company has been a great workforce development partner in our region and we’re eager to work alongside them as they lay down roots in Winston-Salem.” Honeycutt Uses YouTube Channel to Share 270T Projects

As a school principal who grew up on a farm in North Carolina, Lance Honeycutt is passionate about education and heavy machinery. Both were at the front of his mind when he created his YouTube channel called Honeycutt’s Brush & More in 2021. The channel showcases projects he completes on his family’s farm and for his customers as the owner of Honeycutt’s Brush. Most of his content involves a JCB 270T he purchased from Company Wrench.

Honeycutt started the channel with a video titled, “Brush Cutting a Neglected Pond.” He uses a GoPro camera to show his progress from multiple angles.

Shortly after this video, Honeycutt realized he needed something more than a brush cutter for most of the jobs he wanted to showcase on his channel. He contacted Company Wrench Sales Territory Manager Will Byrd to demo a JCB F60HF mulcher with carbide teeth because he needed a low maintenance, rugged attachment that would handle thicker material.

Testing Mulcher

Honeycutt wanted to assess the JCB F60HF’s capabilities in a challenging environment, so he used it in an area filled with trees on his family’s farm. Previously, a chainsaw was the only equipment he could use to cut through the large, thick trees and brush in the area.

After receiving instructions on how to operate the mulcher from Byrd, Honeycutt entered the cab and quickly cut his first tree to pieces.

He cut and mulched large trees for several hours before deciding to purchase the mulcher. He showed part of the demo in a video titled “Testing Out a JCB Mulcher,” which features more than 14,000 views.

“That mulcher is far and away better than the brush cutter I was using,” Honeycutt said. “Mr. Byrd brought it here himself so I could try it out. When I tested it out, I fell in love with it. Trees take years to decompose, but with this mulcher you can cut the tree down to nothing in minutes.”

Almost a year later, he has used the JCB 270T and F60HF on multiple customer job sites to clear brush and trees to form paths for trails, increase sight lines for deer hunters, and create functional space for property owners. Videos featuring the JCB F60HF quickly became the most viewed due to the attachment’s impressive capabilities.

At the time of this writing, Honeycutt has received nearly 200,000 views on his mulching videos alone.

Growing Confidence

Honeycutt’s comfort with the JCB 270T has only grown since he purchased it nearly a year ago. He has used it for a variety of jobs, including loading bales of hay for his family, moving a fallen tree after a storm and fixing a drainage issue at the church next door.

Honeycutt's channel serves as an educational hub for forestry and mulching enthusiasts. He shows maintenance he performs on the JCB 270T and its attachments to both inform his audience and learn tips from them in the comments.

For more information, visit Honeycutt’s Brush & More YouTube channel.

Pages 51-55S E C T I O NAttachments

For more information about these attachments and more, visit our Attachments Section on our Web site at www.constructionequipmentguide.com

John Deere Introduces New FR27 Disc Saw Felling Head

John Deere’s newest forestry attachment offering is the FR27 disc saw felling head.

Now standard on the John Deere 953M and 959M feller buncher models, and available as an upgrade on the on the 853M, 859M and 903M feller bunchers, this felling head attachment has a larger cut capacity compared to previous felling head models. Building upon the success of the FR24B, John Deere has designed the durable FR27 as a solution aimed to increase productivity on the job.

“We are always looking for ways to enhance operator efficiency and machine capacity. By introducing a larger felling head solution to our line-up with the FR27, we are providing our customers with a larger, more durable attachment to help increase their bottomline,” said Jim O’Halloran, global product marketing manager, tracked feller bunchers and harvesters & disc saw felling heads, John Deere.

“The newly designed FR27 enables loggers of all experience levels to tackle even the most ambitious jobs with confidence knowing their machines are built to endure larger timber and excel in a variety of forestry applications.”

The FR27 disc saw felling head is designed to take on a variety of timber applications, from large single stem cutting to mid-sized accumulation, and boasts an all-new design and overall rebranding from previous John Deere felling head models. In addition, this robust, high rotation felling head features excellent cut and accumulation capacity, offering top-of-the-line productivity compared to previous models, according to the manufacturer.

The FR27 features a cutting capacity of up to 27.2 in. and an accumulation capacity of up to 7.5 ft, improving capability in the woods.

Building upon the success of the field proven FR24B, the FR27 features an updated frame and wrist design, which includes a tall horn, long harvesting arms and continuous hose routings that promote easy machine clean-out. The hardened saw housing wear plates are now standard and offer improved saw housing wear resistance.

Additionally, the FR27 offers bolt-on saw housing for improved serviceability, with three separate saw housing sections with integrated skis getting you back on the job sooner. The incorporated large side chip exhaust chute minimizes build up and plugging, keeping your machine up and running. The side chip exhaust chute also includes a cover that can be added or removed depending on application

Starting now, the FR27 are available for purchase on the 800 and 900 M-Series feller bunchers models.

For more information, visit www.JohnDeere.com/.

The FR27 disc saw felling head is designed to take on a variety of timber applications, from large single stem cutting to mid-sized accumulation, and boasts an all-new design and overall rebranding from previous John Deere felling head models.

Premier Manufacturer of Equipment Attachments from 2,500 lbs to 120,000 lbs

EXCAVATORS • LOADERS DOZERS • SKID STEER LOADERS CTL’S • BACKHOE LOADERS

Buckets Grapples

Compaction

Takeuchi Launches New Line of Hydraulic Hammers

Takeuchi has added seven soundsuppressed hydraulic hammer models to the Takeuchi attachment program, helping compact track loader and compact excavator owners accomplish even more with their machines.

“Hydraulic hammers are invaluable attachments for breaking up asphalt, concrete, rocks and other hard materials,” said Lee Padgett, product manager of Takeuchi-US.

“Contractors and others who perform demolition and excavation will find these hammers match perfectly with a wide range of Takeuchi machines. And, because our hammers are sound suppressed, they can be operated in quieter environments with less noise disruption throughout the surrounding area.”

Takeuchi’s new hydraulic hammer line includes seven models with excellent power-to-weight ratios suitable for a variety of applications, according to the manufacturer.

The TKB52-S, TKB72-S and TKB102-S are compatible with compact excavators ranging from the TB210R to the TB230. The TKB-302S, TKB402-S and TKB802-S work well with compact track loader models ranging from the TL6R to the TL12V2/R2 and compact excavator models ranging from the TB235-2 to the TB290. Finally, the TKB1702-S is compatible with the TB2150 and TB2150R compact excavators.

Providing excellent noise and vibration insulation, the sound-suppressed design of every Takeuchi hammer also protects it from dust and debris. Constant blow energy, or “CBE” allows for a wide range of oil flow settings and protects the hammer against high back pressure. An integrated, mem-

brane-type hydraulic accumulator eliminates nitrogen leakage and the need to recharge for lower operating costs and consistent impact energy. The compact and medium hammer range feature fewer internal parts and no tie rods, as well as a 3in-1 lower tool bushing, for enhanced durability and simpler maintenance. A single retaining pin makes it easier and faster to replace the tool and tool bushing on site when necessary. Swivel couplings on the mediumrange TKB302-S, TKB402-S and TKB802-S models allow hoses to move freely, reducing the load on both the hoses and hose couplings for longer component life. “Our new hydraulic hammers Takeuchi’s new hydraulic hammer line includes seven models with excellent power-to-weight offer the same quality and durability ratios suitable for a variety of applications, according to the manufacturer. that our dealers and their customers have come to expect from Takeuchi,” Padgett said. “Rest assured, when you purchase or rent a Takeuchi-branded hammer, you’re getting a reliable, dependable attachment that can improve your uptime and productivity.” For more information, visit www.takeuchi-us.com.

Doosan’s DX225LC-7X ‘engcon Ready’ Option Now Available

engcon, a global manufacturer of tiltrotators, quick couplers and accessories for excavators, announced the launch of the engcon Ready option for the Doosan DX225LC-7X series of excavators.

The option is the result of a collaboration between Doosan and engcon to provide an integrated solution between the tiltrotator control system and machine, with all the built-in functions and features.

The collaboration with Doosan has been ongoing now for some time. The engineering teams on both sides have been working closely together from the start of the project when the features were decided, to the finish and start of production.

The Doosan DX225LC-7X is a fully electro-hydraulic excavator with factory provided 2D machine control and the latest Doosan technology. As a part of this technology offering, the machine is also engcon Ready. engcon Ready means that the machine can easily be equipped with engcon’s MIG2 Grips and the 3rd generation control system, DC3. Making the machine ready and prepared for the latest technology offering from engcon.

The control system and machine controllers communicate over CAN (Controller Area Network) making it possible to exchange a large amount of data between the two systems at very high speeds. Enabling a deeply integrated solution for the benefit of the customer.

“The deep integration allows engcon and Doosan to create a better operator experience,” said Fredrik Eklind, control system product owner at engcon.

“It allows the operator to get an overview and configure the functions of the MIG2 Grips directly in the Doosan machine display. engcon’s high precision tilt and rotation sensors are also directly integrated with the Doosan semiautomatic machine control solution, weighing and assist features. There is no need for a third party sensor to be installed in the attachment, making it truly integrated with the machine.”

The deep integration and preparation allow for shortened lead times at the dealers while providing a complete offering to the customer.

Stephane Dieu, excavator product manager for Europe, said, “engcon tiltrotators as an attachment is growing in popularity globally and especially in Europe. Making sure that our most advanced machine was prepared for this attachment was important and having it integrated with the rest of our machine technology offering was crucial.

“With the technologies combined the customer can see both improved productivity and flexibility. Shortening the lead times is something that both engcon and Doosan have been working on over many years and with the DX225LC7X being engcon Ready the upgrade is quicker than ever.”

For more information, visit www.engcon.com.

The Doosan DX225LC-7X is engcon Ready, which means that the machine can easily be equipped with engcon’s MIG2 Grips and the 3rd generation control system, DC3.