13 minute read

Attachments & Parts Section

At the center of any construction alternative power discussion is diesel. Diesel remains the go-to power on job sites — according to the Diesel Technology Forum, 98 percent of construction’s energy use in the United States comes from diesel.

But with global initiatives under way to reduce carbon emissions to net zero by 2050, it’s up to construction industry manufacturers to find ways to lessen diesel’s carbon impact. A range of solutions is being considered: • Replacing the diesel engine altogether • Reconfiguring the engine to run on lower-carbon fuels • Making the diesel engine as efficient as possible

All will be necessary.

The challenges numerous. Unlike some sectors, construction doesn’t rely on a core piece of equipment, but rather on a vast fleet that ranges from mini excavators to massive off-highway trucks. And a job site can be anywhere from midtown Manhattan to rural Wyoming. This is why so many diesel alternatives are being offered, including electric, hydrogen, biodiesel and other biofuels.

Over the next decade or so, one (or more) of these alternatives will establish themselves as having the greatest long-term potential.

“What’s coming? The answer is probably all of them,” said Jeremy Harsin, construction market director at AEM member company Cummins. “The combination of duty cycle and available infrastructure is going to decide what wins out, but they’re probably all going to have their place in the world.” Electric Has Arrived

Zero emissions, low noise, instant response, fewer components to break down, all on a platform that delivers the same breakout force of a diesel-powered unit — electric power sounds like a major win. That’s why much of the alternative power activity in construction has centered on electric, particularly in the compact equipment segment.

“Battery power density is increasing all the time and we’re seeing a number of different technologies that make better use of battery energy,” said Ray Gallant, vice president of product management and productivity at AEM member company Volvo Construction Equipment.

“Electric is happening now as machines are starting to be commercially available,” said Chris Sleight, managing director at AEM member Off-Highway Research. Although now quite expensive compared to their diesel counterparts, “at some point the economic argument will be there,” Sleight added.

Electric options are certainly growing. Volvo, for example, started selling its electric compact excavators and wheel loaders into North America this year and recently expanded its offering to five machines.

Electric also has made its way to mid-size and larger construction equipment. Electric machines, however, have some significant downsides. The ones most critical to contractors are limited run-time-per-charge and recharging time. Although the electric charging infrastructure is the most developed of all alternative powers in the United States, today’s electric car owners still have range anxiety when they get into rural areas. Since many job sites aren’t even on the grid, many OEMs are selling chargers with their electric machines. Solar charging also is being examined.

And electric’s strong sustainability argument can break down when one gets to the batteries themselves. First, several minerals are extracted to create the batteries, including copper, lithium and nickel.

Second, proper end-of-life battery disposal is still in question, not to mention that battery materials have residual value. Cat, for one, said it is looking at repurposing batteries from high-power applications for a lower-power second life.

Electric machines also will require a reworking of the dealer parts and service offering and technician training. In addition, residual value is central to any equipment cost equation; the verdict is still uncertain whether the value of electric — or indeed any alternative-powered machine — will hold up in the resale market. Impending Rise of Hydrogen

Current construction equipment prototypes use hydrogen in two ways: either as a fuel cell that charges a battery-electric machine or to fuel an internal combustion engine. In a hydrogen fuel cell, hydrogen and oxygen react to produce electricity, with water as its only by-product. In the second way, hydrogen is used as a direct engine fuel, much like diesel.

While hydrogen must be compressed and transported at low temperatures, “it’s a portable fuel so you can get it to where it’s needed,” Sleight said.

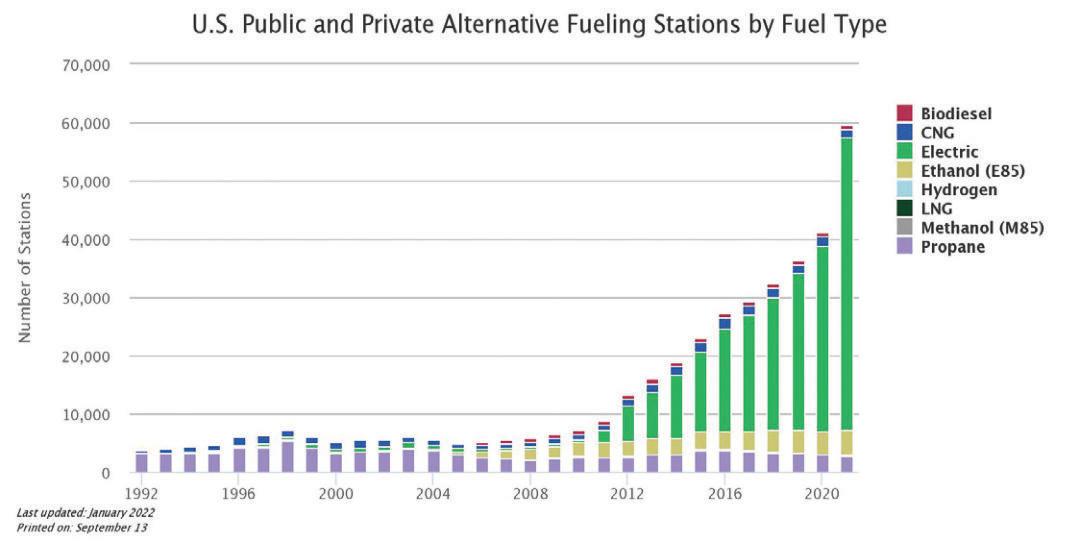

But infrastructure challenges also are part of the hydrogen story. The number of hydrogen fueling stations is a hard-tosee sliver looking at this chart from the U.S. Department of Energy. Almost all of them — approximately 70 — are in California.

Construction equipment powered by hydrogen fuel cells

and hydrogen-fueled engines are — at least at this point — in the prototype stage. Low-Carbon Fuels Can Be Used in Same Basic Engine Hydrogen-powered engines also illustrate another way to reduce engine emissions: modify a conventional engine to be able to burn cleaner fuels. According to proponents, this approach doesn’t require wholesale changes of jobsite practices, machine componentry or fueling infrastructure. This approach offers scale, since the many of the compoInfrastructure challenges also are part of the hydrogen story. The number of hydrogen fueling stations is a hard-to-see sliver looking at this chart from the U.S. Department of Energy. Almost all of them — approximately 70 — are in California. nents are similar. And it holds promise for off-highway engines since Cummins commonly adopts cross platform technologies, Harsin said. Don’t Overlook Diesel? Current prices and world political stability issues aside, diesel remains the construction stalwart. Despite its “dirty diesel” perception, Cummins said it’s worth a reminder that compared with Tier I engines, today’s Tier IV Final engines offer a 96 percent reduction of oxides of nitrogen and a 97 percent reduction in particulate matter. The United States also is likely to see Tier V emissions regulations by the end of the decade, Harsin said. California has already discussed enacting a Tier V regulation in 2024 with implementation to start in 2028. Another consideration is the gradual retirement of construction’s aging fleet. Construction machines have a relatively long life; there are plenty of Tier III engine-powered machines still plugging away on job sites. Cat, for example, estimated the average age of its field population to be 11.3 years. “There’s a lot of good work being done in the diesel space. It’s about lowering our emissions overall. Everything doesn’t have to be zero emission,” said Gallant.

Pages 33-39S E C T I O NAttachments & Par ts

For more information about these attachments and more, visit our Attachments Section on our Web site at www.constructionequipmentguide.com

Werk-Brau NOX Tiltrotators Feature Compact Design

New Werk-Brau Nox tiltrotators provide 360-degrees of endless rotation with a tilt angle of 2 x 50-degrees allowing greater versatility with a wide range of attachments.

With a strong, compact design, this versatile tool transforms excavators into multi-functional carriers that work in deep trenches, under or between existing pipes and tubes, and in other confined space applications.

Ideal for use with fork tines, grabs, grippers, buckets, and more, this technology allow operators to complete projects without repositioning the carrier. This allows faster, safer, more efficient project completion, shaving up to 25 percent from the project time, according to the manufacturer.

A range of Werk-Brau NOX tiltrotators are available for excavators in various classes and categories, from 3 to 25 tons.

With integrated hydraulics and no components protruding from the compact design, the risk of damaging hydraulic cylinders, hoses or other components is very small. There are minimal wear parts, and only two fittings that require grease, so maintenance time and consumables are minimized.

A special cast housing provides stability and a long service life, even in adverse conditions. An elliptical rotary actuator provides a low overall height and a narrow width with no cylinders. The wider tilt angle allows greater flexibility. A robust, low-mainte-

nance worm drive is designed for difficult tasks. Industrial valves provide long service life. Safety is assured due to the D-Lock coupler, which locks front and rear pins and does not require a safety pin. D-Lock couplers are to ISO 13031, Australian standard AS4772-2008, European EN474 standard, and all major contractor policies. The NOXPROP+ control system provides convenient and effective control of the NOX tiltrotator, quick coupler and mounted attachments. Easily retrofittable for every excavator, the attached touchscreen allows individual assignment of functions and easy menu navigation. Integrated GPS, LTE, Bluetooth and WiFi antennas link the machine to the digital working world. When combined with SmartTag, the system can be connected to fleet management systems. A range of Werk-Brau NOX tiltrotators are available for excavators in various classes NOXPROP+ is pre-equipped for future and categories, from 3 to 25 tons. assistance functions such as dynamic scales, 2D height and depth display, BPM and fleet management or copilot systems. For more information, call 800/537-9561, e-mail sales@Werk-Brau.com or visit www.Werk-Brau.com.

Ditch Witch MT164 Brings Power, Flexibility to Job Sites

Built to help power and fiber-optic contractors easily create a clean, narrow trench in one pass, the new Ditch Witch MT164 microtrencher attachment offers maximum compact cable installation performance.

Equipped with a standard hydraulic plunge and option to offset the frame, the MT164 provides variable depth control and gives contractors the ability to cut right up next to a curb, increasing productivity. The MT164 can trench up to 2 in. wide by 16 in. deep, allowing crews to cut deep enough to get through a standard-sized curb. It also can be set up for a push or pull application depending on the job site.

The microtrencher’s compact footprint provides operators increased flexibility with minimal disruption to surrounding infrastructure in urban areas. Additionally, contractors can more easily cross-cut roads, trenching from curb to curb.

The MT164 is part of a complete microtrenching system that includes a construction-grade lineup of the Ditch Witch SK3000 stand-on skid steer and the Ditch Witch HX75 vacuum excavator.

For more information, visit www.ditchwitch.com/trenchers/micro/mt164.

Mini-Excavator... Mini-Excavator...

XBoom Coupler® SystemXBoom Coupler® System

Do This? Do This?

Quick Change Quick Change from Excavator... from Excavator... To Rigid Boom, To Rigid Boom, Universal Skid-Steer Universal Skid-Steer Tool Carrier! Tool Carrier!

It Can Now!It Can Now!

(800) 526-8538 (800) 526-8538

Amulet.comAmulet.com Available for most late-model brands up to 13K-Lbs

The XBoom Coupler® is an Exclusive, Patented product. XBoom Coupler® is a Registered Trade Mark and all product name(s), logo(s) and content is Copyright Protected © 2018.

Pettibone Cary-Lift 204i Forklift Can Equip Scrap Baler

The Pettibone Cary-Lift 204i rough terrain forklift can be equipped with a scrap baler attachment for handling debris and materials in demolition and recycling applications.

The machine is purpose-built to deliver numerous safety and performance benefits, according to the manufacturer.

The Cary-Lift 204i features an overhead lift arm design, giving the operator full front visibility when lifting or transporting loads — a sharp contrast to the lift arms on wheel loaders, which are located directly in front of the vehicle. Additionally, Cary-Lift forks are capable of tilting down 90 degrees for specialized lifting tasks.

The 204i is powered by a 200-hp Cummins QSB6.7 Tier IV diesel engine with DOC and SCR aftertreatment. The unit includes an engine-driven fan, cooling package and engine block heater as standard equipment.

The machine provides a maximum load capacity of 20,000 lbs. and max lift height of 16 ft. Offering 4-wheel drive with 2-wheel, 4-wheel and crab hydraulic power steering modes — and with the wheelbase limited to just 12 ft. — the 204i can achieve a turning radius of 21 ft. 6 in.

Unlike forward-reaching articulated loaders, the CaryLift’s heavy-duty, solid steel frame design allows it to take full loads into sharp turns without sacrificing load capacity or stability, according to the manufacturer.

Hydraulic frame sway control and side shift capabilities further stabilize loads by leveling the lifting frame when driving on uneven ground. The sway cylinder moves 7 degrees both right and left of center. Dual joysticks provide intuitive controls to efficiently shift gears and control the hydraulics.

An optional feature for the Cary-Lift 204i is X-Command, a new Pettibone telematics program that offers real-time access to machine data, thereby saving time, money and hassle for equipment owners and maintenance technicians.

For more information, call 906/353-4800 or 800/4673884, or visit www.gopettibone.com.

The Cary-Lift 204i features an overhead lift arm design, giving the operator full front visibility when lifting or transporting loads.

From towering sand dunes and refreshing lakes to forested retreats and cool caverns, Oklahoma’s state parks are ready to whisk adventurers away on great outdoor experiences.

Whether lacing up a pair of hiking boots or looking for some relaxing fun in the sun, the scenic beauty of these varied ecoregions and impressive natural resources is sure to provide breathtaking moments. But how exactly do these environments remain so picturesque?

Enter Josh Baker, a forestry technician with one of the Oklahoma State Parks Department’s regional construction crews. Baker and his colleagues utilize two of Diamond Mowers’ SK Disc Mulcher Pro X attachments on their compact track loaders (CTLs) to not only shred Cedar, Cottonwood, Oak and Salt Cedar trees common in their service areas, but also clear roadways, campsites, hiking trails, fence lines, mower pathways and more.

“Our experience with these disc mulchers has been exceptional,” said Baker. “They have impressed us with their ability to maintain and elevate the look of our state parks and are well-constructed to take the abuse that forestry work puts our equipment through.”

Before purchasing their Diamond Mowers disc mulchers, Baker and his team were limited to cutting everything they encountered by hand. Then they realize Diamond attachments were ideal for use in rural environments — the versatile 60 in. attachments can cut through trees as large as 14 in. in diameter and continuously mulch material up to 6 in. in diameter.

Four-point hardened steel teeth inside the deck shell act like axe blades to slice though broken branches and trees, while their aggressive design effectively grabs and pulls in material for processing.

“The mulchers are quite easy to use and have become a huge asset to our fleet,”

The Oklahoma State Parks Department’s regional construction crews utilize two of Diamond Mowers’ SK Disc Mulcher Pro X attachments on their compact track loaders (CTLs) to not only shred Cedar, Cottonwood, Oak and Salt Cedar trees common in their service areas, but also clear roadways, campsites, hiking trails, fence lines, mower pathways and more.

added Baker. “They attach to our CTLs quickly and easily, and after watching a few tutorial videos on proper operating techniques, they were a breeze to get the hang of.”

Baker noted that the difference between what the mulchers do compared to cutting everything by hand is “unmatched.” Between land clearing, site preparation, forestry management and even storm and disaster cleanup, the Disc Mulcher Pro X’s versatility has proven to be a key ally for tackling a variety of applications.

The SK Disc Mulcher Pro X is available in two sizes: a 48 in. unit optimal for smaller skid-steers operating in compact spaces, and a 60 in. unit ideal for tackling projects in open, rural areas where there’s a need to clear large areas quickly. It is available with three motor options and is compatible with both standard and high-flow hydraulic machines.

When asked about the value and cost of the disc mulchers, Baker reiterated how important they’ve been to him and his team.

“The design of the attachments and their ease of operation has allowed us to increase efficiency like never before. If I were in the market for a mulcher, I’d purchase this one and be extremely happy,” said Baker.

Diamond Mowers offers a wide range of specialized cutting attachments compatible with most tractor, skid-steer, wheel loader, and excavator brands.

For more information, visit DiamondMowers.com.