3 minute read

McClungLoganHelps Grow Md. e-Fleet

FLEET from page 12 purchasing resource called Sourcewell. Phillips knew that Volvo CE also worked with Sourcewell, so he said it was a painless process that got them a sizable discount on the machines.

“We can just tell our dealer rep what we’re looking for, and they’ll provide a quote,” he said. “When we told him how interested we are in electric, he called us as soon as they became available.”

That rep, Nick Lepore of McClung Logan Equipment Co., helped Phillips’team grow their Volvo fleet over the past few years to three large excavators and the two new electric compact machines, while also incorporating customer support agreements to keep everything running smoothly.

Phillips said his equipment operators have been impressed by how quiet the electric machines are and how instant the torque is. They’ve told him that they are easy to use, maintenance is simple, and the performance is just as good as a conventional diesel machine.

“We requested some additional training for our mechanics to learn about the electrical components, and any fears they had were put to rest,” said Phillips.

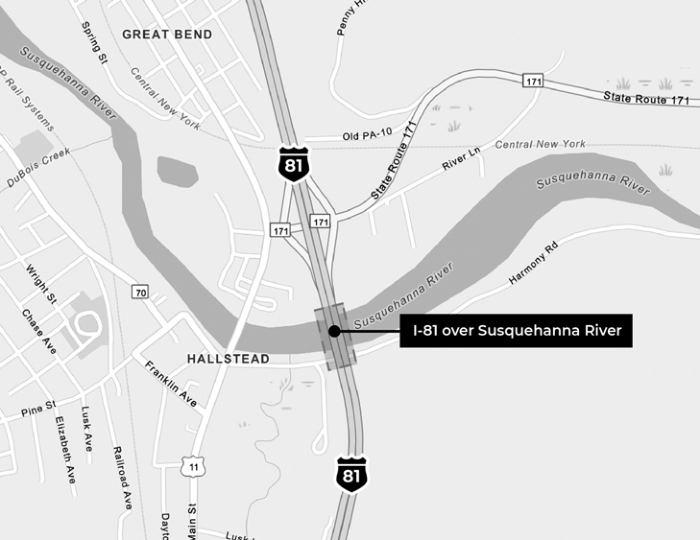

• Replacing all guiderails, barriers and signage in the corridor.

• Improvements to nearby Susquehanna Street, Pennsylvania Highway 171, and Pa. 1029/Randolph Road.

Both the northbound and southbound lanes of I-81 will be impacted, PennDOT noted, adding that motorists can expect two lanes of traffic to be maintained in both directions, except for limited single-lane closures which will occur during off-peak hours.

To handle the I-81 Susquehanna Bridges project, PennDOT contracted with BPD-I, comprised of Bridging Pennsylvania Constructors, H&K Group, a heavy civil contractor from Shippack, Pa., and Pittsburgh’s Fay S&B USA Construction.

Some of the major subcontractors on the project include Westerville, Ohio’s Kokosing Construction Co., Wagman Heavy Civil, from York, Pa., and lead designer, Michael Baker International, based in Pittsburgh.

PennDOT to Pay for MBP3 Plan Annually for 35 Years

The I-81 Susquehanna River Bridges project is one component of Pennsylvania’s Major Bridge P3 (MBP3) initiative, approved by the state P3 board in November 2020, for the replacement or rehabilitation of nine major interstate bridges through a progressive P3 delivery model.

At that time, PennDOT planned to make annual payments to pay for the work and financing costs on these bridges using mandatory tolling, as was permitted by the Pennsylvania P3 law at the time. In 2022, however, Act 84, an amendment to the P3 law, eliminated mandatory tolling of existing free lanes. That prompted PennDOT to move the bridge projects in the MBP3 forward without tolling and pay for them using existing funds to make annual payments to the development entity over 35 years.

Because the L25 Electric wheel loader and ECR25 Electric excavator do not have diesel engines, maintenance is significantly simpler and less expensive. Volvo CE said the lifetime of battery-electric components should be equal to or better than that of the diesel engine on a conventional machine.

Prioritizing the Planet

Volvo CE electric machines can be charged using the same type of 120- and 220-volt outlets that are found in many homes, as well as with a growing number of mobile charging products. M-NCPCC worked with local power companies to install charging stations on the department campus, and a solar farm and greenhouse-turned-learningcenter further demonstrate the county’s commitment to their alternative power transition and the environment as a whole.

“We work with our public schools to teach kids about growing food, how solar power works and all kinds of great things,” said Phillips. “Our campus even has solar-powered outdoor workstations where people can come plug in their computers or phones and work out in nature.”

The Prince George’s County parks team has two full-time positions dedicated to sustainability, and they are working on grant applications and state funding for various regenerative infrastructure projects.

“Collaboration is what will make these changes successful,” said Phillips. “We know there’s no time to waste, and we’re excited that electrification is finally happening in the heavy equipment realm. I can’t wait to try out even bigger machines with alternative power sources.”

He said Volvo CE was a logical choice for them to turn to because of the OEM’s six-machine lineup of electric compact equipment. Volvo CE also recently announced an electric conversion for a mid-size wheel loader, and announced at ConExpo that its mid-size electric excavator is starting customer pilots in the United States, including with Waste Management.

For more information, visit www.volvoce.com.