2 minute read

Port Improvements Include Eight New Electric Cranes

“Another eight cranes are destined for Ocean Terminal,” he added. “Expanded gates and paving will allow for two million TEUs of annual container yard capacity. By 2026, these renovations will provide space for expanding trade and vessel operations. We’re also improving the paving surface to hold container stacks. These projects will bring to six the number of neopanamax vessels the Port of Savannah can handle simultaneously. To work the larger ships, GPA will add eight new all electric ship-to-shore cranes at Ocean Terminal by 2026. The taller ship-to-shore cranes will replace three older cranes that are not suited to handling neopanamax vessels.”

The eight cranes will cost $163 million.

Konecranes OYI, a Finnish company, is providing the ship-to-shore cranes.

Last March, the GPA announced that it agreed to spend $170 million on 55 hybrid-engine rubber-tired gantry cranes to outfit the Ocean Terminal, as it is redeveloped into an allcontainer facility.

“This significant investment in new equipment will help prepare the Port of Savannah to handle more ships and cargo while maintaining the world-class service our customers have come to expect,” said GPA Executive Director Griff

Lynch. “These new machines will expand our capabilities, operate at lower cost and leave a smaller carbon footprint than conventional diesel cranes.”

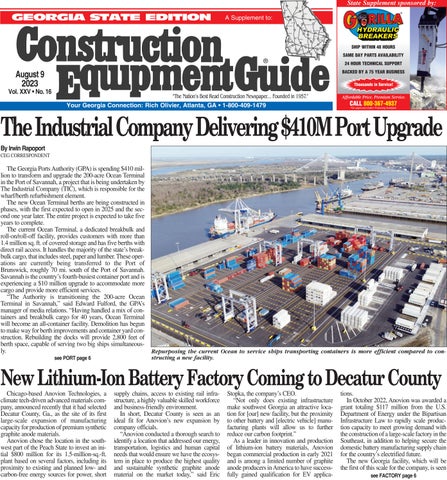

Lynch noted that repurposing the current Ocean to service ships transporting containers is more efficient compared to constructing a new facility.

The cranes will exclusively operate off electric battery power, with diesel generators running only to recharge batteries. This will reduce fuel consumption by an estimated 47 percent compared to all-diesel machines. Per-year, that is a reduction of 8,800 gal. of diesel per crane, or nearly 500,000 gal. annually across the Ocean Terminal fleet.

“This will result in a fuel purchase savings of more than $1.6 million per-year at current rates,” said Fulford.

The new cranes reduce emissions by 50 percent compared to conventional diesel cranes. At an annual average of 4,000 operating hours per RTG, the hybrid engines will avoid yearly emissions of 127 tons per crane, or nearly 7,000 tons across the 55-RTG fleet.

“With every infrastructure expansion, the Georgia Ports Authority seeks to ensure its operations progress toward improved long-term sustainability,” said GPA Board Chairman Joel Wooten. “Economic development, environmental stewardship, governance, and employee and community engagement are all important facets in that effort.”

The gantry cranes will use special “whisper” movement alarms that sound like static, rather than the typical threetone alarms. The combination of hybrid power and quieter alarms will help control the sound of operations for neighboring communities.

“The new cranes can work stacks that are six containers high and seven wide – one container wider than GPA’s current largest RTGs,” said Fulford. “Wider stacks mean fewer rows and a denser, more efficient use of space. The RTGs currently serving Ocean Terminal will be repurposed in other areas of operation.”

A key partner for the GPA is the Georgia Department of Transportation (GDOT), which will play an important role in the terminal’s completion and traffic control around Ocean Terminal.

“GDOT is currently reviewing plans to route port traffic directly from the terminal onto U.S. 17/Interstate 16, avoiding near-port streets, which could minimize community impacts,” said GDOT’s Susan Gardner, senior director of operations and projects. “Directing trucks in this manner will expedite cargo, while preventing unnecessary traffic in neighboring communities.” CEG

(All photos courtesy of Georgia Port Authority.)