1 minute read

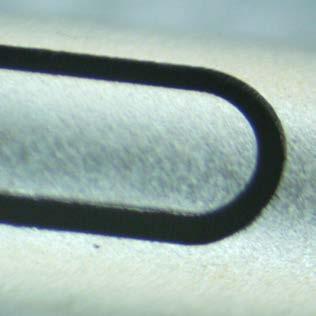

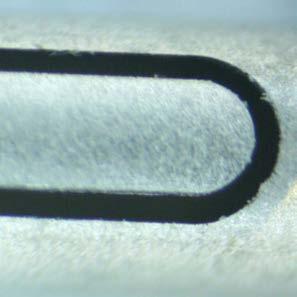

MEDICAL DEVICE MOLD CLEANING & DEBURRING

Cold Jet systems have helped medical industry manufacturers meet stringent industry process demands for quality and consistency. Our systems enable manufacturers to optimize their process by cleaning contaminants from cavities, vents and hard-to-reach places. This is done without the use of chemicals, which eliminates the cross-contamination concerns from chemical residue on the mold and ensures that products are delivered without flaws.

Ev Batteries

Dry ice blasting helps EV battery manufacturers reduce scrap and downtime, improve product quality, and prolong the life of their equipment.

The process is used widely in battery production to clean the agitators on mixers, allowing manufacturers to reclaim and reuse their mixed ingredients. It is also heavily used to surface prep parts prior to bonding, remove adhesives, clean battery cells after electrolyte filling, and deflash parts so they don’t puncture battery separator walls.

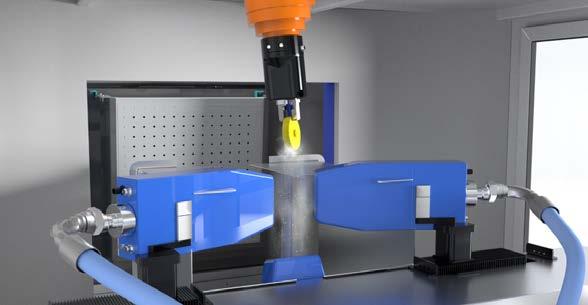

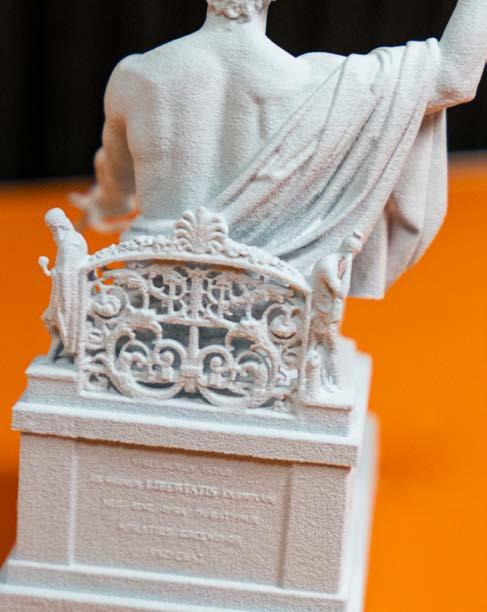

3D PRINTING/ADDITIVE MANUFACTURING

Additive manufacturing technologies are advancing at a record rate, but post-print processes can still rely heavily on manual skilled labor which is time consuming, increases part cost, and reduces efficiency and throughput.

Dry ice cleaning is gentle enough not to abrade the surface or ruin the part, yet aggressive enough to remove support structures, surface imperfections, and parts from powder cake.

Dry ice cleaning is a non-abrasive and environmentally sustainable alternative to traditional cleaning methods that does not produce secondary waste. It is a faster, more effective process than aggressive sanding or using hand picks to clean parts, providing an opportunity for additive manufacturers to grow at scale.

VAT Polymerization (SLA, DLP, MSLA)

Powder Bed Fusion (MJF, SLM, SHS, DMLS, SMS)

Material Extrusion (FDM, FFF, FGF)

Material Jetting (MFM, DOD, POLYJET)

Removal of Support Structures

Removal of Surface Imperfections

De-Powdering Parts

Surface Treatment & Preparation

30+ BY THE NUMBERS YEARS OF DRY ICE INDUSTRY EXPERIENCE