4 minute read

McConnell Dowell

cement river’s sparkling reputation

Advertisement

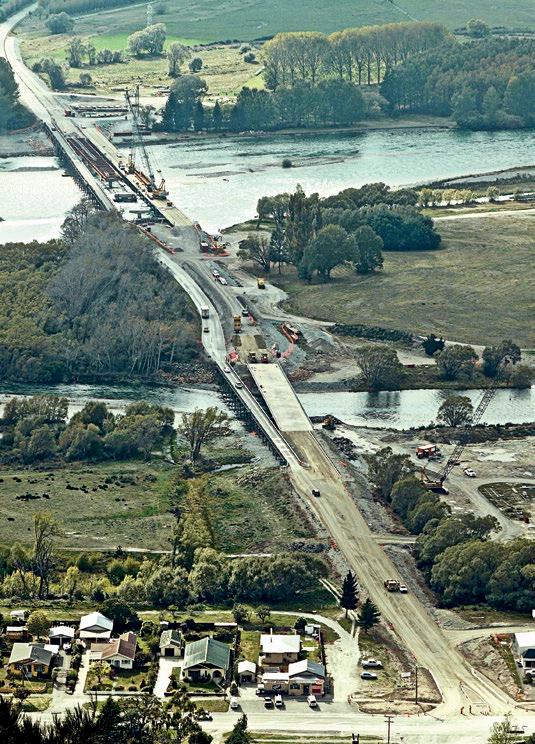

In 2014, a rickety pair of timber bridges on the Waitaki River bowed out after 132 years of service. In their stead emerged two magnificent ‘weathering steel’ constructions – a first for the South Island that will keep locals and tourists well serviced for another century.

3CONSTRUCTION EXCELLENCE AWARDS 2015 WINNER CATEGORY 3

PROJECT: Waitaki Bridges Replacement, Otago CONTRACTOR: McConnell Dowell T he $20.1 million road bridges (with pedestrian walkways) connect the hamlets of Kurow and Hakataramea. Built and engineered by civil construction firm McConnell Dowell, bridge design was courtesy of URS with geotechnical expertise from Tonkin & Taylor.

McConnell Dowell’s engineering solution had to account for the variable nature of the Waitaki River. This body of water experiences high water flow and is prone to flooding.

Under the hood of the bridges are piles that consist of 1.8 metre diameter concrete filled cylinders. Positioned along the length of both bridges, the piles are driven to a depth of 22 to 25 metres. They connect to bored concrete piers with moment transfer below river bed level.

Project superintendent Mike Simpson says the piling solution supports granular river bed materials and is large enough that natural obstructions can be broken up and removed.

Topping off the ‘steel ladder’ bridge construction are precast concrete planks and in-situ concrete decks. The upshot is two bridges that are arguably stronger than the eddies swirling beneath them!

Uniquely, beams and decks are high strength ‘weathering steel’, especially sourced from China. Mike says these form a protective rust patina to almost eliminate corrosion.

“The rusting process starts in the same way as conventional

steel, but the specific alloying elements in weathering steel produce a stable rust layer that adheres to the base metal. Over time – two to five years – the orange-brown appearance changes to a characteristic dark brown,” he says.

A side benefit is that the “earthy tones” of the steel will blend naturally into the surrounding landscape for the lifetime of the bridge.

Building bridges can be challenging at the best of times, not least because of climatic conditions. One of the more unpredictable aspects of the build was coping with high winds whistling down the Waitaki Valley. To get around this, beam lifts were done off the project’s temporary bridge first thing in the morning – while things were calmer.

There was no question the old wooden bridges had reached the end of their functional life, but they were still historically significant. As part of the job, McConnell Dowell had to deconstruct the old bridges and abide by strict preservation conditions set down by Heritage New Zealand.

When it came to removing old timber piles, McConnell Dowell developed a system that vibrated the piles out without snapping them off. This allowed full recovery without any being washed away and undermining river flows.

Two sections of the old wooden bridges were then erected on Kurow Island as tangible evidence for future generations.

Community engagement was a focus for McConnell Dowell from day one of the build. Public concerns were carefully listened to and, as a good corporate citizen, it went the extra mile to involve locals in what was happening.

Among other local initiatives, the firm constructed cycle tracks and widened car parks on the island between the two bridges; replaced and enlarged a nearby boat ramp; hosted community functions; and even built a play bridge at the local preschool – much to the youngsters’ delight.

Local resident Sandy Cameron more than captured community feeling.

“[We] felt embraced by McConnell Dowell and the community has embraced them. They have been quite exceptional,” she says.

Extra care and attention was paid to the environment during the build. Importantly, a proactive and open relationship was formed with Environment Canterbury, which monitored inriver works.

Among other environmental controls, a dedicated fuel/ chemical storage area was created on site with concrete bunding and roofing to contain spills. Erosion and sediment control measures were also used to prevent discharge into the river.

“We used biodegradable hydraulic oil in our vibration hydraulic hammers to minimise any pollution from burst hydraulic lines,” says Mike. And special care was taken when working with concrete, by de-watering to a concrete skip.

Delivered ahead of schedule and within budget, the ribbon was officially cut in November 2014 with a grand opening.

It’s clear that McConnell Dowell has engineered two highly functional bridges. This alone is enough for a standing ovation. The fact it was done in a way that reflects the heritage and pristine natural beauty of the Waitaki Valley is call for an encore. l