3 minute read

Groundfix

Groundfix flexes technical muscle

in spectacular slab repair

Advertisement

When the basement car-park slab in central Auckland’s Vodafone building started showing signs of structural distress, more than a few alarm bells went off. However, thanks to the skill of Groundfix things were remedied quickly and effectively.

1CONSTRUCTION EXCELLENCE AWARDS 2015 HIGHLY COMMENDED CATEGORY 1

PROJECT: Basement Carpark Remedial Works, Auckland CONTRACTOR: Groundfix Between August and October 2014 specialist ground engineering firm Groundfix went about the task of installing 68 tension piles to hold down the enormous basement slab in Vodafone’s building. The piles (each with a capacity of 500 kilonewtons ultimate limit state) were driven between eight and 10 metres deep.

The job was complicated by the fact the basement had to remain a functioning car park throughout the works. At no point was the number of car parks allowed to drop below 75 percent of existing capacity. Other stringent client requirements revolved around noise levels, dust and deliveries.

From an engineering perspective, a major issue faced by the project team was the presence of ground water. In fact, the water table was two metres above the top of the basement slab. To get around this, a bespoke dewatering system was devised – made up of well points, an extraction manifold, a pumping station and exhaust water pipework.

Importantly, the well points were constructed in ‘dead areas’ created by internal building support columns, stairwells and ramps to help minimise the impact on car parking spaces.

Groundfix director Justin Wilson points out that if the dewatering process had failed the entire project would have

been compromised. Multiple redundancies were therefore built into the dewatering system, including an alarmed control panel, two electric water pumps and a diesel powered water pump.

“The second electric pump and diesel pump were designed to provide redundancy,” says Justin.

High pressure pipe bungs were also used to help further reduce the risk of dewatering failure. The manifold system employed by the project team removed the requirement to move water extraction hoses around the car park as works progressed and also allowed for live connections into the pumping extraction system.

For its part, the exhaust water pipework took extracted groundwater from the pumping station to a discharge chamber in an adjacent underground car park.

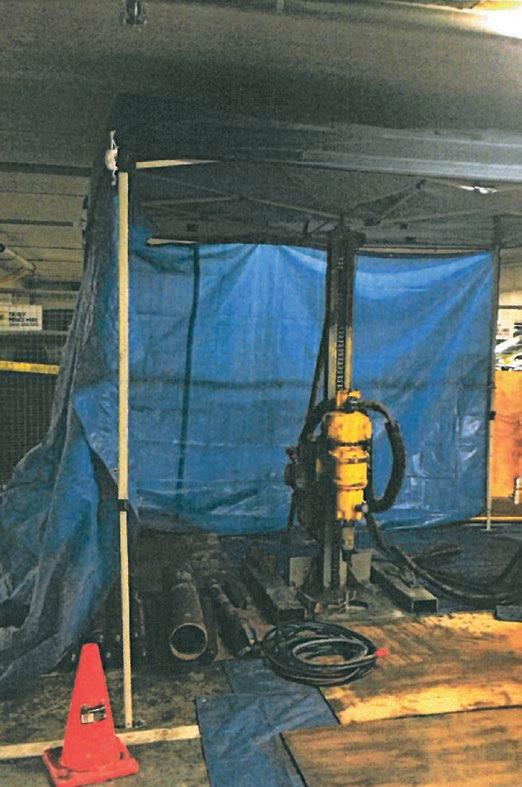

Drilling was a necessary feature of the construction works. Before the tension piles could be installed a modified diamond drilling rig was used to cut pile holes. Here, Groundfix displayed considerable innovative prowess. Not only did the project team adapt its drilling techniques to reduce excessive noise, it also turned on a dime when the drilling process threw up unexpected issues.

With two holes (for example) course gravel was discovered 1.5 to two metres underneath the slab. This turned out to be an old back-filled sump pit. Groundfix injected grout via tremmie pipe to fill the voids. Once the grout had set, these holes were re-drilled to full depth.

Top of mind for Groundfix was that the top layer of reinforcing within the slab had to remain undamaged. Groundfix came up trumps by keeping the cored holes as small as possible and using a state-of-the-art steel reinforcement mapping tool. The result? Absolutely no steel in the top layer of the slab was disturbed.

Other construction challenges were presented by the complex head arrangement of the tension piles. Special hat brackets were fabricated to help get around this issue. Not only this, a unique waterproofing arrangement was employed for the tension pile heads, says Justin.

Significant efforts were also made to reduce the environmental impact of the works. One initiative was to reduce the borehole diameter, which reduced both the volume of cement grout required and plant power consumption. Other environmental measures included a recirculation system for waste water and using low emissions equipment on site.

From the outset, the building owners, project management personnel, consultants (including structural / geotechnical engineering advisors) and Groundfix established excellent lines of communication.

Building co-owner Newcrest was especially impressed with Groundfix’s ‘phased’ approach to the construction works. Development director Lincoln Fraser says doing things this way greatly minimised impact on the building’s tenants as well as the general public and that “by adopting an open, honest and very clearly communicated approach Groundfix made the works hassle free”.

“We were particularly impressed with the attention to detail and the clean, tidy and safe manner in which the guys operated and [their] positive can-do attitude.” l