3 minute read

Support and embed safer working behaviours

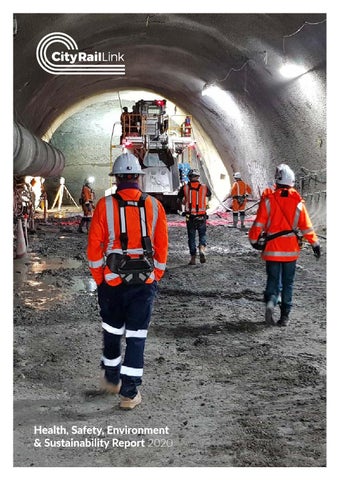

Link Alliance workers at Aotea Station site

To support robust H&S processes, it is vital that everyone working on the project understands expected safety behaviours.

Over the past year, CRL Ltd and its construction partners have developed and promoted a number of initiatives to better understand and influence safe working behaviours. This has been a collaborative approach involving the project's supply chain and WorkSafe, and has included increased training, mentoring, and developing a thorough safety induction programme.

It is fair to say that COVID-19 brought immense challenges during the year. The project is extremely proud of its team for its contributions to keep workers and the wider community safe - contributions which also had to recognise the scale and complexity of CRL operations and the international organisational structure of the Link Alliance.

The project is on track to meet behavioural targets set in the CRL Health & Safety Strategy.

Construction workers follow COVID-19 protocols at Mt Eden

Case Study

Managing the impacts of COVID-19 in construction

Led by the Construction Accord group, CRL Ltd and a team of wider industry representatives worked with Construction Health & Safety New Zealand to develop stringent COVID-19 H&S protocols.

All CRL construction stopped during the Alert Level 4 lockdown in April. However, design and planning work was able to continue during this five-week period, giving the project time to develop protocols, revise construction programmes, and plan for a safe and successful construction restart. Protocols emphasised health monitoring, physical distancing, enhanced cleaning and additional personal protective equipment (PPE).

The protocols have allowed construction work to safely continue under New Zealand's COVID-19 alert levels. The protocols were comprehensive and could be used consistently across different construction sites. As well, they gave clarity to regulators and other agencies about how the industry sector managed work during COVID-19 alert levels.

In addition to protecting workers' physical health on-site, significant effort was placed on supporting their mental health and wellbeing. This was particularly important as many of the team - from overseas and other parts of Aotearoa - were separated from their whänau and friends. Support was provided through regular online discussions, sharing personal strategies for staying connected, internal newsletters and active promotion of the Employee Assistance Programme and mental health support networks.

COVID-19 protocols in place at the Mt Eden site

Mobile Plant Hygiene

DISINFECTANT

• Operators are to sanitise controls on commencement of operation.

• Operators must ensure plant and equipment is cleaned regularly.

Internal windows, door handles, handrails, steering wheels, control

levers, buttons, computers are cleaned regularly with disinfectant

and cloths provided.

• Where possible, operators should not alternate between different

items of plant.

LA0048_24.04.20 Protocols were implemented on-site to ensure mobile plant users' safety

Workers attend a H&S induction at Te Manawa

Case Study

Behavioural safety training

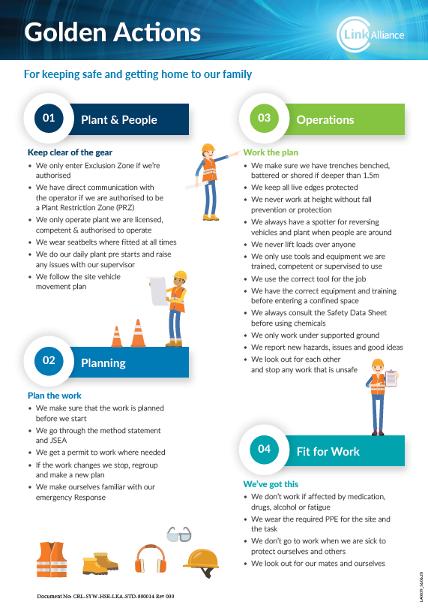

The Link Alliance's induction to main works is the first experience for workers joining the CRL team. The induction is designed to communicate the project's values and objectives, and what workers can expect when they arrive on-site.

An integral part of the induction is concentrated on safety outcomes. It includes an interactive Behavioural Safety module which focuses on how workers can respond positively when potentially unsafe situations occur by illustrating where work conditions or activities might deviate from what was originally planned.

Short snippets were filmed during which professional actors played out specific scenes leading up to a significant near miss event. During the induction, inductees are put into teams to discuss how they would react in each situation.

The induction facilitator then uses those discussions to reinforce the Link Alliance's 'Golden Actions', which are the core behavioural attributes promoted and encouraged across all its worksites.

Positive induction feedback indicated the safety training was an engaging and memorable way to bring to life behavioural principles on-site, and that the scenarios used in the exercise are realistic.

Case Study

Exclusion lighting on plant

An exclusion zone around operational plant is a common control measure to help keep people and plant safe. To further improve this control, Contract 2 contractor, Connectus, added exclusion zone lighting on its road-based plant.

This simple but effective mechanism provided an immediate visual demarcation to both a vehicle's driver and other workers near the exclusion zone, thus reinforcing safer worker behaviour.

This technology is now being deployed by the Link Alliance on operating plant within Karangahape Station's mined tunnels.