35 minute read

TECHNICAL FOCUS

from FC&A March 21

THE DEVIL IS IN THE DETAIL: A MANUFACTURER’S PERSPECTIVE

The UK construction industry is continuing to weather the impact of the coronavirus pandemic but is still facing ongoing challenges when it comes to design detail and the specification process. All too often, information is missing from drawings, leaving decisions to those on the ground, who may invariably take the opportunity to reduce costs by substituting products. This can lead to a loss of design intent and quality. However, it doesn’t have to be this way. How then can manufacturers play their part in the specification process and ensure that value engineering is not simply cost cutting at the expense of quality – but rather, a method of ensuring the client gets the best possible value for money with products that improve the functionality and quality of the project? Lisa Sherburne-Kilby, Commercial Operations Director, Masonry UK at Leviat (the home of Ancon and Halfen), investigates.

Advertisement

LEVIAT

In her report, ‘Building A Safer Future’, Dame Judith Hackitt said that the term ‘value engineering’ should be driven out of construction, saying that she would be “happy to never hear [it] again”. The term has divided the industry because simply reducing cost at the expense of quality is not value engineering. The process can, in some instances, involve substituting or swapping quality products for cheaper and inferior alternatives that do not meet relevant industry standards because seemingly they appear ‘better value’. In the long term, this can compromise the overall effectiveness of a building and have more serious implications in terms of fire, health and safety. Product substitution should only occur where there is a clear comparison in performance against the required specification.

Transparency and collaboration

In its simplest terms, true value engineering is problem-solving, which is why the relationship between building product manufacturer and specifier has never been more important. At Leviat, one of our core values is customer focus that we express as ‘we put our customer at the heart of it all’; this means we are committed to understanding and achieving their vision. We will review an engineer’s or architect’s principal concepts and advise the suitability of products, highlighting any design concerns early so they do not become costly surprises later in the supply process. A well-engineered and -understood product will add value and not cause a contractor issues during installation or the building owner during its lifecycle.

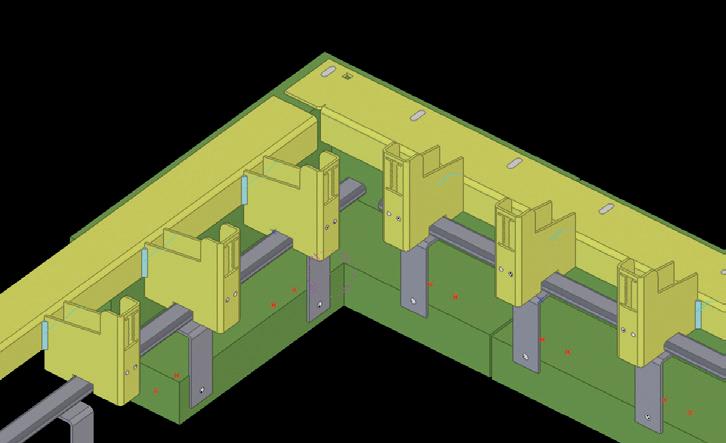

Whilst being able to provide a range of standard products which specifiers can select to a set performance and criteria is part of what we do, a large part of our work is ‘designed bespoke’ to overcome engineering challenges. In other words, we will take a standard product, adapt it for a project and then ensure it is fit for purpose.

This was the case on a project in Nightingale Place, south London. In order to help the customer avoid the need for additional restraint fixings into the post-tensioned (PT) slab and the use of expansion bolts into high-stress zones, we created a stiffened channel to the underside of our brackets allowing flexibility of the joint position.

In short, all our designs start from the principle of providing an engineered solution that the customer will be confident safely delivers the performance aspirations for the project. Each project is unique in its needs which is why many of our product innovations are driven by our understanding of frequent design demands in complex projects or novel solutions to unusual design challenges and then offering that new product solution to the wider market.

Early engagement

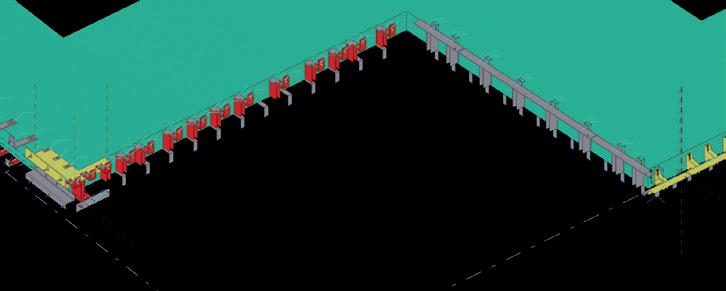

As a manufacturer, the earlier our technical engineers and sales team engage in the specification process, the better, so we can have an understanding of the facts at the front end and be able to identify the areas which are most at risk of costs escalating. To reduce the risk of surprise, we need to align our design with the client’s design in order to allow for flexibility on site. 3D modelling software enables collaboration during the design stage as it gives all parties a view on how products will fit together and if there is likely to be any clashes or interferences.

In an ideal world, collaboration and early engagement amongst all stakeholders on a construction project should become the norm as it will ensure all parties have a deeper understanding of a project resulting in a more accurate specification process and huge benefits to the end outcome. Furthermore, when practiced correctly and at the early stages of a build, value engineering will optimise the value of a project, improving performance and quality.

As a manufacturer of engineered construction technology, we take our responsibilities very seriously. The design and construction of buildings is a joint responsibility across the entire supply chain from architects and designers to contractor, consultants and manufacturers. Organisations such as the CPA (Construction Products Association) are helping to bridge the divide that has existed – following two years of engagement with industry, they have developed a Code for Construction Product Information (CCPI) and are about to undertake a consultation on its new 11-point agenda. This is aiming to set a level playing field for all construction product manufacturers to ensure that the information they provide, in whatever format that might be, is clear, accurate, up to date and unambiguous. This mirrors how we operate and, as such, we welcome this step towards creating a better built environment.

THE ARTS AND CRAFTS OF SECONDARY GLAZING IN A BEAUTIFUL FAMILY HOME

A quaint family home in the South Downs conservation area has recently seen upgrades to its noise and thermal insulation with Selectaglaze secondary glazing, making it much more peaceful and cosy to live and relax in.

SELECTAGLAZE

www.selectaglaze.co.uk 01727 837271

The property was built between 1650 and 1660 as two farm cottages. Then in 1907, the building was purchased by Architect, William Frederick Unsworth (18511912), who based his studio there as well as making it his home. Over the years, the building was extended to the front and sides and given a new look and feel in line with the emerging Arts and Crafts movement. The building is quite striking with a large sweeping catslide roof to the rear, hanging pin tiles to the front and square leaded iron casements, set in dark oak frames.

Whilst looking around and discussing their plight of finding a solution for the windows, an acquaintance was quite bemused by the fact that the owners had been told that secondary glazing could only be supplied in white; he suggested that contact was made with Selectaglaze.

A total of 13 Series 10 two- and threepane horizontal sliders were specified and installed across the front elevation openings in 8014 matt sepia. Noise ingress was reduced by installing the units with a 100mm cavity and 6.8 laminated glass. Draughts have been dramatically reduced with the high-performance seals and close fitting of the secondary glazing.

Selectaglaze is the leading specialist in secondary glazing, established in 1966 and Royal Warrant Holder since 2004.

enquiries@selectaglaze.co.uk

NEW DOORS FOR A NEW AGE

With the world in turmoil, changing attitudes, social and economic upheaval everywhere, you could be forgiven for thinking that innovation within the interior doors market was likely to be on hold for a while. However, at Vicaima, the desire to move forward and push boundaries in design and performance has never lost momentum, even in the face of such challenges. And so, with the introduction of the 2021 Interior Door Selector; Vicaima brings new doors for a new age.

VICAIMA

Vicaima’s latest brochure contains over 100 pages of inspiration for professionals looking to transform homes, hotels and other private and public spaces that are fit for tomorrow. With its easy-to-navigate layout, ideas and solutions go hand-in-hand. Whether the criteria is for cost-effective simplicity or high-end performance and trend-setting designs, the 2021 Interior Door Selector (IDS) has something for everyone.

What’s new in the 2021 IDS?

While some existing ranges have been developed, Vicaima has also taken the opportunity to introduce some striking new interior door products for 2021. Using its expertise and understanding of design trends and modern build requirements, this fresh approach allows specifiers the opportunity to expand their senses with ideas that engage in both sight and touch; either capturing nature or taking it to another level. These new ranges include:

Naturdor Stained Extra: Vertical and horizontal semi-translucent stained veneers

Heritage Oak: Real oak veneer with random grain and knots

Dekordor 3D Vertical: Embossed face in two new oak designs

Dekordor SD Touch: Subtle textured foil in rich tones

Visual Sensations: Cross directional woodgrain in forest and alpine designs.

Naturally, all the new designs in the Vicaima range for 2021 are available to meet the latest performance specifications. With certified solutions in fire, security and acoustics, it really is the complete package.

CUSTOM COLOUR MIXING WITH OSMO

Country Colour just got even more exciting. Along with the 19 standard colours Osmo offers, the exterior wood finish Country Colour is now available in over 2000 custom colours, which are made to order from your local Osmo dealer.

OSMO

www.osmouk.com 01296 481220

No matter what finish you want to give your life – Osmo has the right colours. The best part is you get to choose: soft, warm or bold. Our do-it-yourself mixtures make it all really easy to create new colours. Country Colour will bring out the best in wood surfaces in the home and garden.

What nature has invented we cannot make any better. This is why Osmo focuses on oil- and wax-based finishes that work naturally. The oil penetrates deep into the wood, protecting it from inside; the waxes form a microporous surface – allowing the wood to ‘breathe’. At the same time, we pay attention to the right balance between good application properties and safety for you and your family: only quality oils and waxes are used. Not to forget, our production guarantees quality: the high content of colour pigments offers hiding power from the very first coat.

sales@osmouk.com

THE NEXT EVOLUTION IN STAIR NOSING DESIGN FOR SPECIFICATION

Quantum Flooring is excited to announce the release of its new and most innovative stair nosing to date, which marks a new evolution in stair nosing specification.

QUANTUM FLOORING

Q-Range DUO measures 55 x 55mm for both the tread and the riser. This complies with BS 8300:2:2018, The Equality Act and Part M and Part K of the Building Regulations. Like all of Quantum’s Q-Range Stair Nosings, Q-Range DUO has an all-over tread design. This helps to reduce the risk of slips on stairways.

The Q-Range DUO profiles are available in three different versions:

QRd-SF153 is for use with resilient floorcoverings

QRd-SF153r has a ramp back for use with no floorcovering

QRd-HF153 is for use with carpet or carpet tile.

This range ensures that these stair nosings can be used with practically any floorcovering.

Q-Range DUO offers a solid colour for the whole stair nosing by matching the riser colour along with the slip-resistant tread, which is recommended as best practice. There is a choice of 25 colours, from an LRV of 6 to 81. This offers a wide range of options when specifying for any project.

SPECIFICATION SHEET:

Material/finish: QRd-SF153, QRd-SF153r, QRd-HF153 Inserts: Colour/light reflectance value (LRV): Black (6), Claret (6), Dark Blue (11), Desert (77), Fawn (21), Flint (15), Granite (11), Spruce (11), Ivory (51), Jade (30), Light Grey (26), Lime (53), Mist (64). Peat (10), Photoluminescent (69), Polar Grey (49), Poppy (13), Regency (11), Royal Blue (16), Rustic (10), Sky (52), Sun (56), Mist (64), Yellow (97), Photoluminescent (69), Desert (77), White (81) Adhesive: Q-Fix/approved similar.

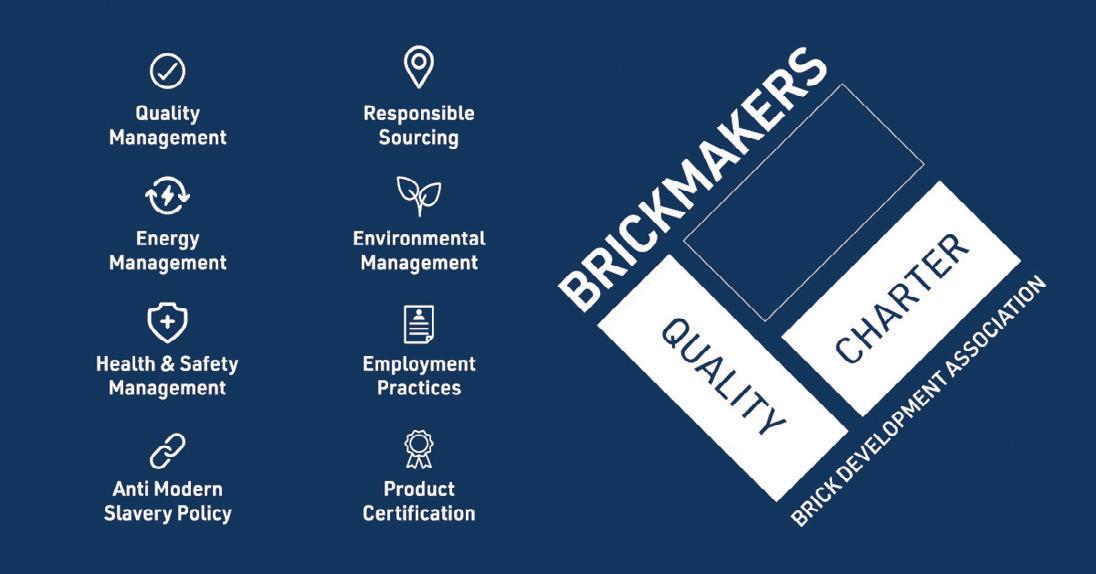

BDA LAUNCHES BRICKMAKERS QUALITY CHARTER FOR MANUFACTURERS

The Brick Development Association has launched a new Brickmakers Quality Charter (BQC) to provide the whole UK supply chain, from client to end-user, with assurances as to the product, manufacturing and ethical standards of BQC holders.

THE BRICK DEVELOPMENT ASSOCIATION (BDA)

Supported in the UK by the Builders Merchants Federation, the Association of Brickwork Contractors and others, any clay brick manufacturer, irrespective of where they operate, can apply for the BQC.

To be approved and accepted, companies must demonstrate their compliance with a range of existing, internationally-recognised protocols and standards. They are:

1. Business Quality Management System (ISO 9001) 2. Responsible Sourcing System (BES 6001) 3. Energy Management System (ISO 50001) 4. Environmental Management System (ISO 14001) 5. Health & Safety Management System (ISO 45001 or OHSAS 18001 or the BCC H&S Pledge) 6. Employment Practice System (that meets the brickmaker’s national standard) 7. Anti-Modern Slavery Policy and Procedures (that meets the brickmaker’s national standard) 8. CPR Compliance in all clay brick products (CE Mark or UKCA/UKNI Mark to EN771-1).

The charter also aims to help firms meet the incoming stringent requirements mooted through Environmental, Social and Governmental (ESG) thinking. BDA Chief Executive, Keith Aldis, outlines the thinking behind the charter, saying: “Use of the charter provides merchants and customers with a massively valuable ‘shortcut’, identifying responsible clay brick and other clay product manufacturers.

“We have noticed a growing percentage of imported bricks that are coming into the UK from a global supply chain of which we know very little about. With a postBrexit focus on self-reliance, coupled with international cooperation through competitive trade, we are convinced that there is greater room for error when purchasing and using clay bricks from unregulated and largely unrecognised sources. We want to make sure that the UK and European sectors that are using clay bricks continue to enjoy the high reputation it has built up over decades.”

The BQC rules reflect this new global trade reality. All clay brick manufacturers wishing to participate will be subject to an initial desktop audit of relevant certifications. Those meeting the basic requirements will be awarded the charter, all be it at varying levels which will allow firms room to improve whilst recognising that they meet the basic requirements.

Keith continues: “Clay brick is one of the few building materials that are proven to last for centuries. We want to ensure that this doyen of UK construction and housebuilding is manufactured, marketed, sold and used with due diligence, and with assurances having been provided to clients, specifiers and customers. We want there to be no question mark over the consistent quality of this wonderful material.

ABOUT THE BRICK DEVELOPMENT ASSOCIATION (BDA):

The BDA is the national authority on clay bricks. Its membership accounts for almost 100% of the industry’s productivity in the UK, which deliver excellent quality through a reliable supply chain. As such, the BDA collates the latest and most authoritative statistical data on UK clay brick production, distribution and sustainability commitments.

UK brick manufacturers provide free technical guides, advice and CPDs through the BDA. Whether your procurement teams seek advice on how best to manage the supply of bricks; your architects seek guidance on design specifications; or your on-site teams seek certainty about good site practice and workmanship, the BDA is your source of impartial, expert information.

“We have had a universallypositive reaction from manufacturers and are delighted to be able to point to the fact that all of our members – representing over 98% of UK clay brick manufacturing and 90% of UK clay brick use – are ready to meet those standards and we welcome other manufacturers doing so too.”

MAGPLY PUTS IN STRONG PERFORMANCE AT BAT AND BALL COMMUNITY CENTRE

MAGPLY

A refurbishment at the Bat and Ball Community Centre in Sevenoaks features Magply boards as the substrate for a through-coloured render system. The work is being led by the BJF Group, with Theis + Khan Architects responsible for design work. Site Agent for the BJF Group, David Murray, said: “The refurbishment included a steel-framed structure around the low-pitched roof, in the form of a parapet. There is insulation over the old corrugated roof to improve energy performance and a new single-ply membrane running into internal gutters. A membrane was fitted across the outside of the steel framework, along with four by two (100 x 50mm) timbers, to which our dry liner fixed the Magply boards.”

www.magply.co.uk 01621 776252

MULTIBOARD FINDS ITS CALLING FOR KETTERING CONVENT CONVERSION

MARMOX

The ease of installation and all-round performance characteristics offered by Marmox Multiboard have led to a leading dry-lining contractor recommending the versatile tile-backer boards to a client engaged in the redevelopment of a former convent near Kettering. Bedford-based Conroy Dry Lining originally learnt about Multiboard through the trade press, but the directors of the family-run business became converts after purchasing a pack for a trial installation. Now, the company is making rapid progress employing large quantities of the 12.5 x 1200 x 2400mm boards, plus metal washers, for the bathrooms within the 60, three-storey townhouses as well as the apartments being created in the old listed building.

john@magply.co.uk

www.marmox.co.uk 01634 835290 sales@marmox.co.uk

F. BALL PRODUCTS USED TO CREATE INSPIRING LEARNING SPACE

F. BALL AND CO.

Products from F. Ball and Co. have been used to install grey, pink and blue Paragon and Balsan carpet tiles in the sixth-form study room at The Charter School in North Dulwich, London. Forbo vinyl sheet was also installed in a number of classrooms, using Stopgap 700 Superflex levelling compound and Styccobond F46 pressuresensitive adhesive. In five of the school’s classrooms, Styccobond F46 pressuresensitive adhesive was also used to install grey vinyl sheet. The classrooms’ raised access panel subfloors were first primed using a general-purpose primer, before being smoothed using Stopgap 700 Superflex levelling compound.

www.f-ball.co.uk 01538 361633 mail@f-ball.co.uk

HYGIENICALLY-CLEAN PAINT FROM CROWN PAINTS

CROWN TRADE

Crown Trade’s Clean Extreme Anti-Bacterial paint range offers the best of both worlds – a paint with added anti-bacterial protection which will not diminish over time, no matter how many times it is scrubbed clean. Healthcare settings, workplaces, schools and hospitality venues all demand exceptional levels of cleanliness and need to be able to withstand more intensive cleaning regimes than ever. Crown Trade’s Clean Extreme Anti-Bacterial paint, which is formulated to help create hygienically-clean walls and ceilings, offers the solution. It is enhanced through the use of the independently-tested SteriTouch silver ion technology, which not only inhibits the growth of any bacteria that comes into contact with the surface but also prevents bacteria from multiplying. And, unlike other anti-bacterial paints available, its ‘built-in’ silver ion anti-bacterial protection can’t be washed off no matter how many times the surface is scrubbed clean. It also offers exceptional stain resistance for ease of maintenance.

SOUND ABSORPTION PARTITIONING FROM STYLE

STYLE

The British Council has moved into a creative new office facility in S9, an ‘Outstanding’ BREEAM-rated building in the International Quarter London (IQL). Prioritising the adaptability of available space, partitioning expert Style was brought in early to work with 5plus Architects and main contractor, BW Interiors. As a result, the expansive ground floor concourse benefits from seven bespoke, 5m-high Dorma Hüppe movable wall elements. Operating on a complex tracking layout, they can be used to form an innovative display screen, to create individual exhibition boards, or to screen the cafe from the conference suites. One side of the panels is finished with magnetic, writable laminate, encouraging casual meetings where teams can collaborate and share ideas, whilst the other side includes an Autex board, providing essential acoustic sound absorption in this high-ceilinged space. Elsewhere, Style installed a further eight Dorma Hüppe 60 dB semi-automatic movable wall systems, creating various-sized meeting spaces.

NEWTON LATENT DEFECTS GUARANTEE IS THE ULTIMATE IN WATERPROOFING INSURANCE

Newton Waterproofing, a UK-leading independent designer and supplier of guaranteed structural waterproofing systems, has launched its new Latent Defects Insurance – and it is the only such policy available through a UK waterproofing supplier.

NEWTON WATERPROOFING

With experience of more than 170 years, the family-run business based in Tonbridge has been providing clients with an unrivalled service for decades. Now, the Newton Latent Defects Insurance will provide customers with the ultimate protection.

Newton Waterproofing’s MD, Warren Muschialli, said: “In 2019, the construction insurance guarantees market underwent significant change, with a number of insurers withdrawing from the sector. Early in 2020, there was a further reduction in the number of rated insurers able to provide insurance for waterproofing.

“By its very nature, waterproofing is a risky business, and it’s very tough to find good guarantees in the waterproofing sector. A lot of companies will provide self-guarantees, but there is no insurance provided, while others will provide warranties that are not insurance-backed. But, with our Newton Latent Defects Insurance, we have managed to provide a unique policy which is backed by an A-rated, UKbased insurer.”

Peace of mind guaranteed

With a policy term of up to 12 years, the Latent Defects Insurance is available on qualifying projects which use multiple Newton waterproofing products to achieve a minimum score of 3.0 on the Newton Waterproofing Index (NWI). The NWI is a unique specification tool that provides specifiers and designers with a scoring system to accurately assess the level of risk and potential success involved in any waterproofing design. The application for the guarantee is made via the installer directly to Newton’s A-rated insurer, and for the first two years of the policy, the responsibility for repairing any leaks and defects lies with the installing contractor. Once this period has expired, all repairs are the responsibility of the insurer. Newton’s Specialist Contractors have been specifically audited to ensure that they meet the necessary requirements to be able to provide the guarantee, while Newton’s waterproofing solutions and products have also successfully passed a rigorous auditing process to ensure that they are of sufficient quality to support the guarantee. “Instead of a 10-year policy term, we are offering a 12-year option which gives us a competitive edge,” said Warren. “No other waterproofing supplier in the UK can provide this level of protection, and this is the best waterproofing guarantee on the market from a UK insurer that you can get. It comes through us and is backed by us – we are the broker’s client, so the specifier knows that we will take responsibility for the waterproofing.”

www.newtonwaterproofing.co.uk

Value added every step of the way

Specifying Newton will provide you with class-leading waterproofing products, all covered by a Newton Product Warranty, as well as the peace of mind of dealing with a business with over 170 years’ experience.

Newton’s nationwide network of specialist contractors also provide meaningful installation guarantees and, if required, the Newton Insurance Backed Guarantee too. The Newton Latent Defects Insurance is then available as the ultimate level of protection.

“We have always prided ourselves on providing specifiers, contractors and homeowners with the best products and service, and adding value at all stages of the waterproofing process – from design, supply, installation, guarantees and sustainability,” added Warren.

“Now we can supply a meaningful, single-point waterproofing guarantee that provides complete protection for the client, the specifier and the contractor. And as it’s underwritten by our A-rated insurer, there is no better protection available in UK waterproofing – and it makes Newton Waterproofing the safest partner when specifying below-ground waterproofing.”

Newton provides the best waterproofing systems for all structures, from new and existing domestic properties to large-scale commercial developments. For the right waterproofing help and advice with your next project, contact Newton Waterproofing.

WHAT WILL INSPIRE YOUR NEXT NATURAL STONE PROJECT?

When Goldman Sachs called upon Gross Max and the City of London to provide plans to landscape the area surrounding its newly-built headquarters, nobody could envision the unique designs they would dream up.

MARSHALLS

The aim was to create a harmonious outdoor space for workers and visitors to move around and relax. A space that felt like it belonged, marrying with the surroundings. Marshalls was honoured when approached by Gross Max and the City of London to be part of the team needed to make its plans a reality.

Intricate features including a bespoke retaining wall and planters

Hand masonry, skilled engraving, 3D printing and excellent craftsmanship were all called upon to help deliver a design-led, functional scheme that pays homage to the local history and surrounding streets.

Seven bespoke Callisto granite planters were etched into Farringdon Street and Shoe Lane’s plans. Each planter was given a flamed texture finish, with one of the planters chosen to include a carved and hand-painted address for 25 Shoe Lane. Anti-skate details were sympathetically incorporated into the design curves that cleverly replicate the outline of the Goldman Sachs building, all housed within 3500m2 of Scoutmoor paving.

A highly intricate, interlocking and overlapping retaining wall features on the aptly-named ‘Stonecutter Street’, which integrates two flights of steps and an intermediate landing. The designs embrace the interchanging levels of the area, creating the illusion of a seamless space. A desire to create a look as though the feature had come straight from the quarry was proposed – a nod to the Stonecutter Street that they would sit upon. Prospero granite was chosen as the canvas with hand masonry providing the unique split-faced finish texture.

What would seem like irregularplaced large solid blocks of natural stone interrupting the perimeter, and providing an integrated security solution were also included in the designs.

Taking a plan and making it a reality

Christian O’Keefe, Contract Project Engineer at City of London, said: “The level of detail from the Marshalls team facilitated us with the design and construction of these bespoke products. 3D modelling, unit scheduling, design parameters, logistics and installation guidance were among the key features provided as part of the overall service that aided to deliver this worldclass public space.

“The City has a long standingrelationship with Marshalls, a marketleading supplier of natural stone products, providing the highest quality and sustainable stone in the world. Marshalls were our first choice of suppliers for this major public realm project, where both bespoke elements and standard paving choices are abundant throughout. "The team, headed up by Dave Stanger, Gordon Hines and Jason Taljaard, provided the knowledge, technical expertise and passion to convey this landscape architect’s vision into delivered bespoke products to the streets of the City of London.”

Dave Stanger, Trading Director at Marshalls, added: “These are exactly the sort of projects we love to get involved with. Designs that challenge us and make individuals from different skillsets come together to make them a reality. These sorts of projects call upon our skilled designers to collaborate with landscape architects and contractors. They allow us to utilise the close working relationships we have forged with our suppliers and the expertise and passion we have for natural stone.”

BUILDING DELIVERED ON BUDGET AND AHEAD OF SCHEDULE FOR GEORGE ELIOT HOSPITAL

George Eliot Hospital required a new 30-bed ward for orthopaedic elective and general elective patients as part of the trust’s five-year estate strategy. A high-quality, HTM and DDA-compliant building was required urgently.

WERNICK BUILDINGS

Wernick Buildings was appointed under a Pre-Contract Services Agreement to design the building through to RIBA Stage 3. After demonstrating that it could provide an economically-viable, single-storey solution, Wernick was formally appointed as principal contractor.

By engaging with a modular provider before producing a design, the hospital was able to work with Wernick to take full advantage of the benefits of modular construction, which included maximising the amount of fit-out that could take place in the factory to reduce time on site. It also facilitated closer collaboration on the building’s specialist requirements, for example, using the hospital’s preferred contractors to provide medical gasses.

Manufacturing the building in a factory environment gave the project several advantages. Firstly, the building could be constructed while the foundations were being prepared, drastically reducing programme length. Manufacture was also not affected by site conditions like the weather, making the programme even more reliable.

The building comprised 33 modules, including a unit to link the new wards to an existing building on site, which were manufactured in Wernick’s dedicated factory in Port Talbot. These were transported to site by lorry, then craned into position and bolted together to form the complete building.

While the initial programme was 20 weeks, the coronavirus outbreak made the hospital’s requirement more urgent. By implementing longer hours and working weekends, Wernick condensed the programme to just 14 weeks.

Determined to deliver the project on time, Wernick worked with its sub-contractors and the hospital to devise working methods that would allow them to continue work on site, including strict social distancing measures. These new working methods were communicated through daily briefings and site signage. The closer collaboration early in the process, which had minimised the amount of work needed on site, also facilitated safer working while maintaining the programme. Reduced time on site also meant minimum disruption to the rest of the hospital during this crucial period.

The completed single-storey building, delivered on time and on budget, consists of 1000m2 of gross internal floor space comprising 33 modular units. The fit-out includes bedhead trunking incorporating medical gasses, nurse call systems, access control and CCTV, fire escape ramps and nurse stations. Externally, the building is finished to match existing buildings on site.

Kirstie Webb, Head of Estates & Facilities for George Eliot NHS Trust, commented: “Excellent product, finished ahead of time and within budget. This is particularly impressive as it coincided with the COVID-19 pandemic first wave.”

Modular construction based on a timber frame is a more flexible system and can meet a large variety of needs, explains TG Escapes.

TG ESCAPES

As a modern method of construction, sectional modular buildings using timber frame are far more versatile than you might think. Each building can be designed to the specific needs of the customer and make best use of the available space. This means that there is no limit to how this construction method can be used.

TG Escapes provides modular ecobuildings in education, leisure and business with over 700 complete projects in the UK. All our buildings have been designed by our in-house architects delivering projects from 60m2 to 2000m2. They include flat and pitched roofs, two storeys, large-span studios and intimate breakout spaces. They are used for canteens, chapels, changing facilities, kiosks, training centres, cafes as well as offices and classrooms.

TG Escapes’ sectional modular process saves time and money versus a traditional build. This means less time on site, causing less disruption, which is particularly important in education where educational continuity is paramount.

“The school and city council really liked the end-product concepts and we worked to benchmark TG Escapes against other providers as well as visiting a scheme in progress beforehand,” comments one building consultancy project manager.

Fully inclusive turnkey service

TG Escapes offers a full design and build service undertaking all principal designer and principal contractor duties. Our turnkey solutions include planning permissions (where required), site preparation by dedicated groundworks experts and full safety compliance. We have a dedicated team including inhouse design and pre-contract resource committed to supporting consultants with tenders, grants and bids. We offer a variety of finishes including timber or composite cladding, render in a range of colours and brick slips.

“TG Escapes were very efficient and accommodating, the team fitted into the school perfectly and the children loved watching the builders work on the new project,” explains a chartered building surveyor.

Our buildings are permanent structures built using sustainable materials. Our timber frames are highly insulated and perform exceptionally well versus a cavity wall construction. Our buildings are designed to be aesthetically pleasing, ergonomic and highly practical but, just as importantly, they are built to last 60 years or more with appropriate maintenance.

Education needs and approaches may well be very different in the future and our timber buildings are far more adaptable than a rigid brick option.

A significant consequence of the way in which our buildings are constructed is that they are highly energy-efficient to run and are classed at least as A-rated structures. With suitable PV solar panels, these buildings can be classified as netzero in operation.

We provide several warranties upon the completion of the build. Each building comes with a 10-year structural warranty (covering foundations, floors, walls), and we provide an additional one-year warranty for all fixtures and fittings. Our roofs use an Evalon single-ply membrane from an international leader in rubber roof manufacture.

A Construction Line Gold member, an approved partner of the Institute of School Business Leadership (ISBL) and a member of the British Educational Suppliers Association (BESA), customers score us 4.9 out of 5 based on 154 reviews.

One estates and facilities manager confirms the quality involved: “Working with

OMNIE RENEWABLES WARMING TRIO OF FIVE-BED HOMES IN NORTHAMPTONSHIRE

OMNIE

A development of three detached, five-bedroom homes in the market town of Raunds near Northampton is utilising renewable heat packages featuring air source heat pumps, delivered by whole-house systems specialist, OMNIE, part of the Ridgespear Group. The solution makes use of quiet running heat pumps positioned at the rear of each home, with OMNIE’s Staple underfloor heating system installed over Cellecta Tectris insulation on the ground-floor slabs with the manufacturer’s versatile LowBoard panels and pipework serving the bedroom levels. The installation has been carried out by the developer’s in-house team, with OMNIE completing the commissioning work.

www.omnie.co.uk 01392 363605 projects@omnie.co.uk

VORTICE LAUNCHES THE UVLOGIKA ENVIRONMENTAL SANITISER

VORTICE

Never before has there been so much emphasis on the sanitisation and disinfection of surfaces we come into contact with. The ongoing battle against COVID-19 means it is essential for our health and wellbeing that surfaces are sanitised efficiently, especially in public spaces. VORTICE has now introduced the UVLOGIKA – an environmental sanitiser suitable for the disinfection of surfaces in domestic, commercial and industrial environments. The UVLOGIKA system is a UV-C lamp that eliminates up to 99% of bacteria, viruses and other microorganisms without any emission of ozone. Its compact dimensions make the unit discreet enough to be installed in a variety of applications such as classrooms, lifts and hospital waiting rooms.

CREATE A SPECTACULAR KITCHEN WITH KÖNIGSTONE’S SMOKY DARK SURFACE

KÖNIGSTONE

Königstone, with an impressive reputation for high-quality surface materials and worktops, now supplies stunning semiprecious materials for spectacular kitchens. Königstone has access to beautiful materials from across the globe, and these breathtaking surfaces will truly set the kitchen apart from the rest. Whether homeowners opt for a bold splashback, a contrasting feature within a worktop or even a whole worktop or feature wall, the materials available are sure to transform the kitchen. The intricate patterns and transparency of the materials allow these one-of-a-kind pieces to be backlit. The illumination creates a striking effect by highlighting the captivating natural characteristics of these beautiful features.

Wire Rope Stainless Handrails

Frameless Glass

Stand-Offs

Pro-Railing stainless steel handrail component system requires no welding. Simply cut, glue & screw on site to create stunning handrail & balustrades, that will look great for years to come. Whatever the project we have a cost effective solution.

BRAND-NEW IDENTITY FOR AMRON ARCHITECTURAL

Over the past few months, Amron Architectural has been hard at work developing its brand. Although its name will stay the same, there’s a lot of change in store for the architectural metal mesh supplier. To find out more about the company’s brand-new identity, FC&A’s Editor, Rebecca Kemp, sat down with Amron Architectural’s Managing Director, Jonathan Reed.

AMRON ARCHITECTURAL

RK: What is the history behind the Amron Architectural brand? JR: The history of Amron Architectural is built around our customers. As a husbandand-wife startup in 2002, our humble beginnings have seen us gain expertise across the built environment and develop relationships with some of the industry’s most influential brands.

RK: What was the drive for this re-brand? JR: The Amron Architectural brand has undergone a significant and exciting transformation. Deconstructing what the business and our services really meant to us allowed us to take a creative and versatile look and feel, ensuring our new identity has been developed to highlight our ambitious plans for the future.

RK: What do you hope to achieve from this re-brand? JR: We represent ourselves as a business that understands the built environment, the issues, the people and, most importantly, the challenges facing this industry. With an extensive range of products and knowledge to educate our audience, our ethos influences choice, engagement and inspiration. These core values support the work we are doing, our future work and defining a prosperous future for our team and customers.

RK: What has changed about the Amron Architectural brand? JR: Our name will stay the same, but what we look like and sound like is changing. Metal mesh is a popular material for interiors and exteriors – not only is it versatile, but it also offers a design functionality like no other. The new look is bold, fresh, simplified, creative and versatile: words that all reflect our product and service offering.

RK: What can we expect to see from you throughout this year? JR: Throughout the year, Amron will continue to educate the market with new and innovative products. We will also be releasing new and exciting initiatives including ‘Ask Amron’, where new and existing customers can request one of our many educational offerings to help with their project – whether it be a ‘Lunch and Learn’, a ‘Mesh Surgery’ or simply just a chat. The concept helps encourage customers to ask for advice to obtain the best creative mesh solution for any project. We want to help create a memorable distinction and make a difference in developing projects for the built environment.

DR. SCHUTZ PU SEALER – MAKING LONGER-LASTING FLOORING

Dr. Schutz, the German floor care company, offers PU Sealer, an innovative solution that quickly and easily transforms tired, damaged or old floors, at a fraction of the time and cost of an entire floor replacement.

DR SCHUTZ

www.drschutz.co.uk

As well as renovating any floor with a fresh and lasting finish, PU Sealer offers added protection for flooring areas prone to high traffic. Such areas with a heavy foot volume tend to wear very quickly when they don’t have a hardwearing product applied. Not only can this cost money, but it can be a time-consuming issue to fix. By applying the PU Sealer, flooring can be kept in a great condition for many years.

The water-based, ecofriendly PU Sealer can be applied to most types of flooring, including vinyl, tiled and epoxy resin. Adding 40 microns of protective thickness to floors, PU Sealer extends the lifespan by up to six times and provides a lasting clear matt finish. Thanks to the permanent sealing, it protects against friction and discolouration from chemical spillages.

Due to the product's special water-based substance, the PU Sealer also reduces dirt adhesion and the time needed for day-to-day maintenance.

01296 437827

CA GROUP APPOINTS INDUSTRY EXPERT JON DORE TO ITS THRIVING COMMERCIAL TEAM

CA GROUP

Jon Dore, one of the building envelope sector’s most prominent commercial experts, is to join CA Group as the firm’s Business Development Manager in a newly-created role that will see further expansion of its existing commercial department. Jon will make the move this month, with his new position designed to draw upon his technical engineering background and 25year global construction experience in the building envelope sector, focusing on UK contracts, supply chain relationships and product application. Working alongside the sales, development, technical and marketing teams, he will be responsible for supporting and developing the firm’s client base, growing market share and innovative product application..

STO INSULATION SOLUTION ACHIEVES EXCELLENT MARKS ON CARDIFF SCHOOL PROJECTS

STO

A trio of Welsh schools have received upgrades to their thermal insulation thanks to a package of products provided by Sto. Ysgol Glan Morfa, Howardian Primary School and Ysgol Hamadryad in Cardiff have had the company’s StoTherm Mineral external wall insulation system applied to significantly improve their thermal performance. StoTherm Mineral external wall insulation system features mineral fibre insulation boards and combines unrivalled fire protection and high thermal performance with excellent impact resistance, making it ideal for both new-build and refurbishment projects. It was installed using Sto-Rotofix Plus, a unique and easily adjustable spiral fixing which can accommodate any unevenness in the substrate to create a perfectly smooth outer finish.

DEANESTOR DELIVERS £750,000 CONTRACT FOR LUXURY APARTMENT SCHEME IN MANCHESTER

DEANESTOR

Deanestor has completed a £750,000 bespoke kitchen and bedroom fit-out contract at Affinity Living’s luxury urban living scheme in the centre of Manchester. Built by Sir Robert McAlpine and designed by architect firm Denton Corker Marshall, Riverside provides 190 studios and one-, two- and three-bed apartments for rent in a stunning 16-storey tower overlooking the river and the cityscape. The sleek, high-end open-plan kitchens have marbled white granite-effect worktops, an oak-effect finish to the breakfast bars for two to six people, and moulded cabinet doors with integrated handles. The base units and drawer fronts were finished in contemporary indigo blue and contrasting white for the wall cabinets.