2 minute read

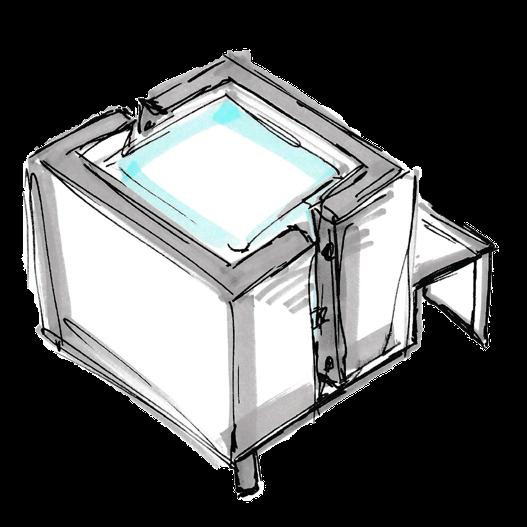

General Arrangement Drawing

general arrangement

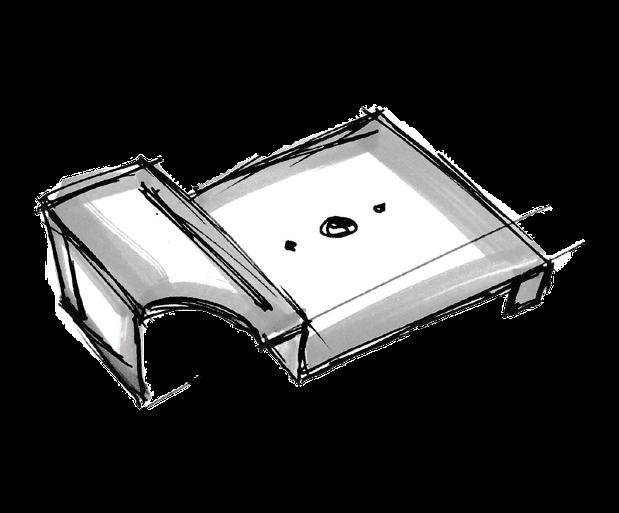

part 1 : bottom housing

Advertisement

• 5000 grade Aluminium • Cast and anodised • Locally manufactured to reduce lead time, as well as maximise ease of communication.

part 2 : ESP32 Open Source developer board

• Premade part • Sourced in bulk - custom right angler headers (available in batches of 2000+) • Other components hand soldered in batches

part 3 : m2 bolts

• Premade part • Fit into tapped bottom housing

part 4 : rotary encoder

• Premade part • Sourced in large quantities in order to reduce cost per unit. • Standard pinout header

part 5 : rotary encoder knob

• 5000 grade Aluminium • Cast • Locally manufactured to reduce lead time, as well as maximise ease of communication. • Interference friction fit to rotary encoder

part 6 : 54mm fader

• Premade part • Custom header created for orders over 1000 units • Bulk bought to reduce cost per unit

part 7 : top plate

• 2mm Sheet Aluminium • Fine Blanked and line bent • CNC tapped and drilled • Interference fit to base plate • Manufactured at same country as base plate, to be able to check fits and give quick feedback.

part 8 : fader top

• Premade Part • Small, simple, low tolerance part, so overseas manufacture to save cost. • Custom metallic coating available from vendors in quantities over 1000 • Interference friction fit to fader

part 9 : m2 nut

• Premade Part • combined with m2x16mm machine screw to secure neopixel.

part 10 : 12 neopixel ring

• Premade part • Sourced in bulk • Custom reverse right angle headers, available in order quantities over 1000 • Secured to base plate using neopixel holder, and cast in wax.

part 11: m2x16 machine screw

• Premade Part • combined with m2 nuts to secure neopixel and fit into tapped holes in top plate.

• part 12 : wax diffuser

• cast mixture of 5pt paraffin wax, 3pt gelatine wax, 1pt recycled powered foamboard diffusion medium. • Batch cast over top plate assembly in reusable custom moulds • Wrapped in protective PVC wrap for packaging/transport.

general assembly :

As this is a small scale manufacture, approx 500-5000 units, components would be externally manufactured and assembly would occur in a traditional batch production method. The advantage of this over a JIT method would be that pre-made parts can be ordered in larger quantities, essential when minimum orders are needed for custom components. By using small temporary production lines to create sub-assemblies, employee time can be maximised, therefore minimising cost of production. The design uses header connections in order to eliminate the need to solder components to the ESP32 dev board, This again accelerates assembly, as well as lowers the skill level needed to assemble the product.