3 minute read

FOCUS: VersaDrive: Less Doing, More Done

Imagine yourself looking up at a communications tower knowing you need to drill 4 x 14mm holes to attach a bracket. You need to climb up with a 12kg magnetic-based drill, drill the hole and then work out how to thread it—it’s heavy and dangerous work.

Then, along comes Alpha VersaDrive; your job just got a whole lot easier, and quicker!

Alpha VersaDrive is the world’s 1st modular quick-change cutting and drilling system.

You have never seen anything like this before, Alpha Tools is revolutionising on-site cutting and drilling processes. This game-changing system allows cutting and drilling tools to be used across multiple tool platforms such as impact wrenches, drills and drivers along with rotary drills, magnetic-based drills and pillar drills. Custom-engineered quick-change adaptors connect the tool platform to any one of the Alpha VersaDrive attachment tools saving time, money and increasing productivity.

When you get to the top of the tower with your Alpha VersaDrive kit you can now use your standard, portable power tools to get the job done fast and most importantly, safely.

Investing in Alpha VersaDrive removes the challenges of on-site drilling, hole-making and threading in one easy system. Quality Product Development

Drives Quality Work

The non-slip 11.0mm hex shank design fits into all standard drill chucks and has three concentric lock positions allowing perfect alignment and accuracy when tooling with any of the modular adaptors.

The high-grade steel tool attachments have been specifically designed to outperform the closest comparable products on the market, producing up to 15X faster results, longer life and more holes per product.

Revolutionising Traditional Work Practices

One of Australia’s largest national engineering firms contacted Alpha Tools, wanting a solution to the time-consuming and costly refurbishment of heat exchangers used in alumina production.

Usually, the time and cost taken to refurbish these units are significant and expensive, especially when it comes to cleaning, machining, and preparing tube sheets and baffle plates.

The refurbishment’s cleaning, machining, and preparation phase generally lasts 60 hours and requires 10 machine operators.

However, a new procedure implemented with the Alpha VersaDrive range resulted in a sizeable 300-hour reduction per unit in both time and manpower.

There are several other safety benefits when using these high-performing products, including a massive reduction in noise usually produced by traditional techniques and potential injury caused by vibration.

Tube sheets-1000 holes

The reaming of tube sheets at this Australian engineering firm initially took 2 days (4 shifts), equalling 48 hours. Due to breakage, this process consumed at least 3 reamers.

The Alpha VersaDrive range has now reduced their process to half a day, which is less than 1 shift (6 hours) —that’s a mammoth saving of 42 hours!

In total, 1 reamer completed 4000 holes (4 tube sheets). With each reamer costing $1000, this company could save $5000 (5 reamers).

Baffle plates-internal (Steel LP 3000 holes and Duplex HP 4000 holes)

The costly and time-consuming procedure for baffle plates initially took 10 days (20 shifts), equalling 240 hours. This process ate through 40 carbide burrs ($67 each) and 2 die grinders ($100 each).

The Alpha VersaDrive range slashed the lengthy process down to just 3 days (6 shifts) and equalling to 72 hours, compared to a whopping 240 hours previously. The new procedure only consumed 2 no3 reamers per entire heater — that’s 2000 holes per reamer.

In total, that’s $880 saved and a monumental 168 hours of hard labour diverted. This does not include significant dollar amounts saved due to Personal Protective Equipment (PPE), which is now no longer needed for this operation.

Discover Alpha VersaDrive Sets

We offer a number of different Alpha VersaDrive sets that will get you started, including impact starter kits, tapping kits and installation kits as well as imperial and metric sets that cater to a wide range of applications and industries.

Bonus

Bonus

Bonus

Why should I use cutting fluid?

What is cutting fluid?

Cutting fluid is a staple accessory that all tradespeople should have in their toolbox arsenal. It plays a vital role in metalworking processes, including drilling, tapping, threading and cutting.

During machining, large amounts of heat is generated due to friction between the tool face and the workpiece, as well as the high speed of cutting and drilling.

The heat generated needs to be displaced or eliminated to protect the tool and the work surface.

Cutting fluids are a type of coolant and lubricant that are designed to reduce the friction between the tool and the workpiece. A generous amount of cutting fluid is usually applied before the work commences and in some cases, during the work.

What are the advantages of using cutting fluid?

Cutting fluids and oils are designed to maximise the life of drilling and cutting equipment, helping them to work under extreme amounts of pressure and torque, improving performance, improving machine finish, reducing tip welding and preventing pitting.

Not to mention, cutting fluids are also equipped with anti-corrosion properties that shield machined surfaces from oxidation and can even save power consumption through their capability of minimising the forces during machining.

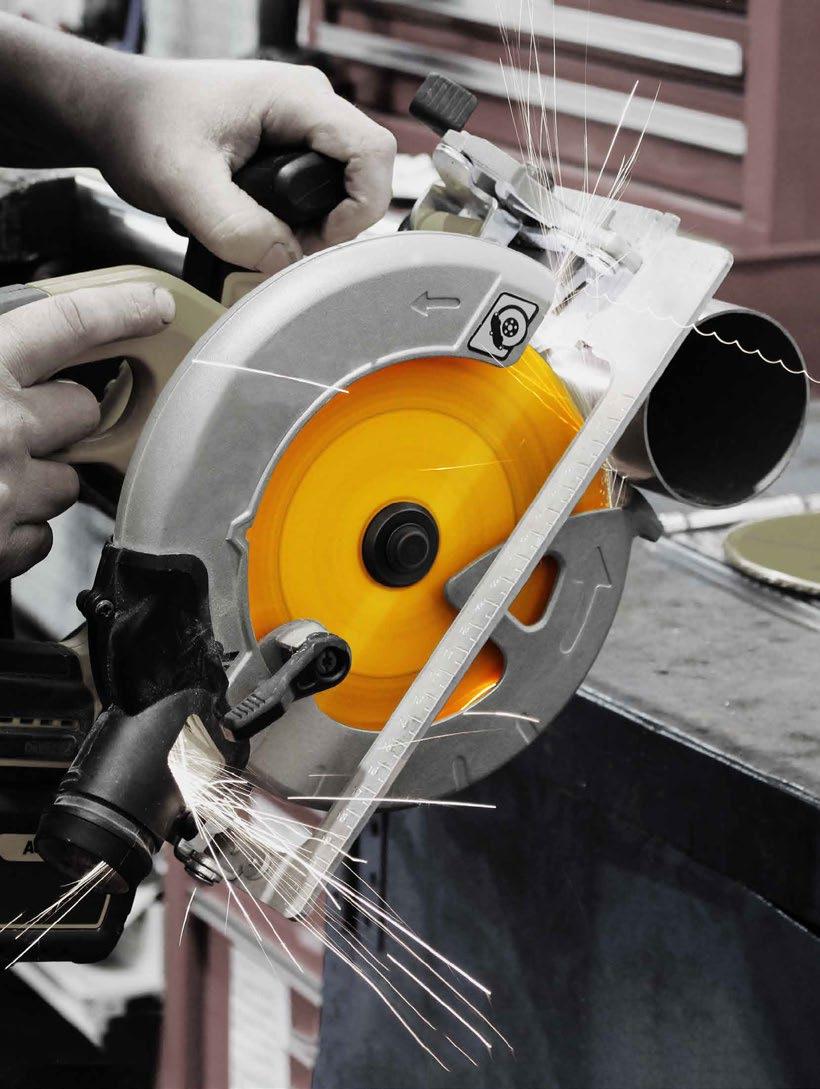

DUAL STEP SAW BLADE TECHNOLOGY

• Less vibration for straight, accurate cutting

• Prevention of chipping on blade teeth

NORMAL SAW BLADE

2 STEP SAW BLADE

This space causes vibration in cutting

Thicker blade minimises vibration when cutting