5 minute read

The Future of Steel Detailing: How Advanced Programs Are Revolutionizing the Industry

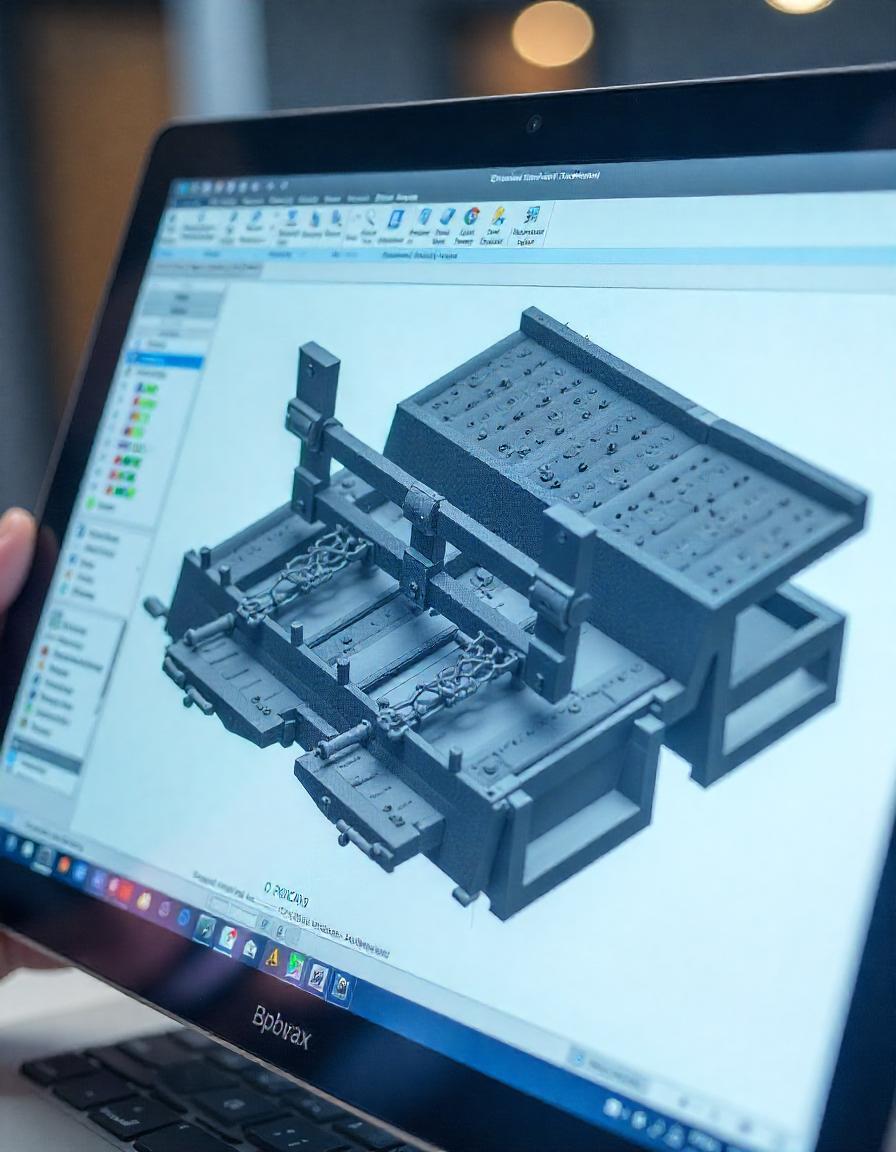

In today’s fast-paced construction industry, precision and efficiency are non-negotiable. Steel detailing program have transformed the way engineers, fabricators, and architects design and execute structural projects.

Gone are the days of manual drafting and error-prone blueprints. Now, advanced software solutions integrate 3D modeling, AI-powered automation, and real-time collaboration, making steel detailing faster, more accurate, and highly efficient.

In this blog, we will explore:

What a steel detailing program is and why it’s essential

The latest trends shaping the steel detailing industry

The top software programs professionals use today

How to choose the best steel detailing program for your needs

Steel Detailing Program

A steel detailing program is specialized software used to create detailed plans, drawings, and reports for steel structures. These programs ensure the precise fabrication and erection of steel components in buildings, bridges, towers, and industrial facilities.

Key Features of Steel Detailing Software:

2D and 3D Modeling – Allows engineers to visualize steel structures before construction.

Automated Material Lists – Generates accurate Bill of Materials (BOM) for fabricators.

Connection Design and Analysis – Ensures structural integrity by optimizing steel joints.

Clash Detection – Prevents costly mistakes by identifying errors before fabrication.

BIM and CAD Integration – Enables seamless collaboration with Building Information Modeling (BIM) platforms.

Cloud-Based Access – Facilitates real-time teamwork and data sharing.

With these capabilities, steel detailing software eliminates human errors, speeds up project timelines, and reduces costs.

Why Steel Detailing Software is Essential in 2025

Steel detailing has become more complex due to the growing demand for sustainable, earthquake-resistant, and high-rise structures. The right software plays a vital role in ensuring these structures are built with precision, durability, and compliance with international standards.

Here’s why modern steel detailing programs are a must-have:

Accuracy and Reduced Errors

Manual detailing is prone to errors, leading to costly rework. Automated steel detailing program ensures high precision, reducing fabrication and erection mistakes.

Faster Project Turnaround

Time is money! With AI-powered automation, steel detailing software can generate shop drawings, reports, and fabrication-ready designs in minutes instead of days.

Seamless Collaboration with BIM

BIM integration allows engineers, architects, and fabricators to work on the same digital model. This reduces miscommunication, prevents design conflicts, and ensures smooth project execution.

Cloud-Based Workflows and Remote Access

With cloud storage, project files can be accessed anytime, anywhere, making remote work and real-time collaboration easy for global teams.

Sustainability and Cost Savings

Optimized steel detailing minimizes material waste, contributing to eco-friendly construction while reducing project costs.

Latest Trends in Steel Detailing Programs

The steel detailing industry is undergoing a tech revolution. Here are the biggest trends reshaping the field:

AI and Automation in Steel Detailing

Modern steel detailing programs now use Artificial Intelligence (AI) to:

Auto-generate shop drawings

Detect design clashes automatically

Optimize steel connections for maximum strength

By automating repetitive tasks, AI reduces human error, boosts productivity, and speeds up project completion.

Augmented Reality (AR) & Virtual Reality (VR) Integration

Steel detailing software now supports AR and VR visualization, allowing engineers to experience a virtual walkthrough of a project before fabrication. This helps identify potential issues before construction begins.

Cloud-Based Steel Detailing for Remote Collaboration

Cloud-based platforms like Tekla Model Sharing allow teams to work on a single model in real-time. This means multiple professionals can update designs without version conflicts or communication gaps.

3D Printing in Steel Fabrication

Some steel detailing programs now support 3D printing compatibility, allowing engineers to create prototypes before full-scale production. This innovation is revolutionizing fabrication processes.

Mobile-Friendly Steel Detailing Applications

With mobile access, steel detailers can view and edit designs on-site, reducing the need for paper drawings and manual revisions.

Top Steel Detailing Programs in 2025

If you’re looking for the best steel detailing program, here are the top software solutions used by professionals worldwide:

Tekla Structures

Best for: Complex steel structures

Advanced 3D modeling and clash detection

Real-time cloud collaboration

Advance Steel (Autodesk)

Best for: BIM-integrated detailing

Parametric steel connections

Automatic shop drawings

SDS/2

Best for: Structural engineering firms

Automated steel connection design

Detailed 3D modeling and fabrication reports

Revit Steel

Best for: Seamless BIM workflow

Design automation and intelligent steel connections

Supports precast and steel detailing

ProSteel (Bentley Systems)

Best for: Industrial steel detailing

Customizable libraries for steel components

Advanced steel modeling features

Each of these programs has unique strengths, so selecting the right one depends on project needs, complexity, and budget.

How to Choose the Right Steel Detailing Program

With so many options, how do you choose the best steel detailing software? Here’s what to consider:

Ease of Use – A user-friendly interface ensures faster adoption by your team.

Integration – Ensure compatibility with BIM, CAD, and fabrication software.

Customization – Look for programs that allow custom steel components and detailing styles.

Cloud and Mobile Access – Essential for remote work and collaboration across multiple locations.

Support & Updates – Regular software updates and customer support availability.

Cost vs. Features – Balance between pricing and software capabilities to get the best value.

Final Thoughts

steel detailing program has revolutionized how we design, fabricate, and construct steel structures. From AI-driven automation to cloud-based collaboration, these tools are making projects faster, smarter, and more cost-effective.

In 2025, BIM integration, VR visualization, and AI-powered automation will continue to reshape the industry. Investing in the right steel detailing program can boost efficiency, reduce errors, and enhance collaboration.