3 minute read

A Healthy Solution

BUNZL HAS HELPED MANY BUSINESSES COMPLY WITH THE PHASING OUT OF SINGLE-USE PLASTICS, INCLUDING ONE OF AUSTRALIA’S LARGEST PRIVATE HOSPITAL OPERATORS.

Plastics are a part of our everyday life; they are convenient and used in many applications. However, there is growing consumer awareness of the issues posed by some plastic and packaging waste. Many singleuse plastics aren’t recyclable so end up in landfill, and, if used outside of the home, can become litter.

To address the issues associated with some single-use plastics, Australian governments are implementing a series of actions to address the plastics problem. Legislation has been introduced that prohibits the sale, supply and distribution of certain single-use plastic products and establishes a framework for adding other products in the future.

For a business such as those on the frontline of healthcare, running private hospitals and day surgery units around Australia, transitioning away from some single-use plastic products is not only an imperative but also a considerable undertaking. So, where do you start?

In early 2020, key stakeholders from one healthcare business – including their ➜

procurement, catering, housekeeping and finance teams – partnered with Bunzl’s business development, product and sustainability experts. The two teams started by considering all the products in the foodservice category, allowing time to proactively transition the healthcare business ahead of legislation. Seven different product types were identified, equating to more than 14 million individual items that would need alternative product solutions.

The Bunzl team, led by Business Development Manager Mark Paterson, worked closely with Vanessa Wee, Category Manager Disposable Food Packaging, to think through all the unique nuances and considerations required to support this healthcare business.

“It wasn’t as simple as replacing product lines,” says Paterson. “We had to meet the specific and exact requirements the customer had as a healthcare provider. This included researching new product lines from local and overseas manufacturers, and ensuring quality standards were adhered to. Where no suitable product existed, we searched for a more sustainable solution to introduce into our business and theirs.”

Another integral person on the Bunzl team was Felicity Kelly, the company’s Sustainable Solutions Lead. Her expertise in sustainable solutions and navigating the complicated government regulations complemented the broader team’s expertise.

“From sourcing to sustainability, we work with manufacturers and our suppliers to ensure our range meets any requirements,” explains Kelly. “First and foremost is to transition from problematic single-use plastics but also to offer products that support a circular economy. These include

products that contain recycled content, are made from renewable materials, are recyclable or compostable.”

Bunzl worked closely with the customer over many months to achieve the full roll-out of suitable quality sustainable products, ahead of the required government timelines, fulfilling the strategic goals and implementation success.

As a global business, Bunzl has experienced single-use plastic phase-outs in other markets that we operate in, such as the UK and Europe. In Australia, we are now drawing upon that experience to work with our customers as they transition towards a more sustainable approach.

We understand that progress takes time, and that the sustainability journey is a complex one to get right. We aim to support our customers at every step of their transition requirements, and will work together to ensure your product range meets your sustainability objectives. Contact one of our sustainability experts today: sustainability@bunzl.com.au.

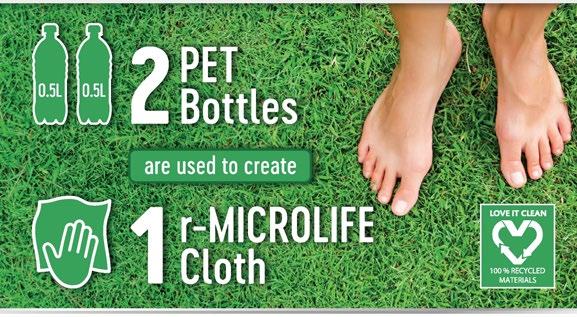

r-MICROLIFE

RECYCLED CLEANING CLOTH

CLOTH IS MADE FROM 100% RECYCLED MATERIALS

r-MicroLife is the first recycled cleaning cloth from Oates® . The cloth is made from 100% recycled post-consumer polyester. It provides the same superior cleaning performance and durability as the virgin fibre product. It removes greasy finger marks and stubborn dirt easily without the use of chemicals.

100% Microfibre cleaning power Up to 99.99% Bovine coronavirus removal from vinyl surfaces as tested at a 3rd party lab 2 PET Bottles are re-used in 1 cloth Very high particle pick-up Absorbent, excellent for spillage