2 minute read

WESTERN LUMBER COMPANY

on famous Coralite permanent pre-finish melamine wall paneling. In full panels, 4' x 5', 4' x 6', 3' x 6'; or borders, 1' x 5'. For details' colors' prices' call: n.

!o t!e_ Long Beach Freeway for fast truck delivery to all Southland retail lumber dealers. Plans have now been completed for the new general offices and specialty warehouse at 48th and Distr-ict Boulevard in tl-re Central Manufacturing District which the pioneer firm will occupy late this ftll. Until the new wirehouse is .99mpleted, pick-up and delivery of Stanton spe- cialty building materials will be made fiom the old warehouse situated at 3850 Ross Street, Vernon, at the former location off 38th street. west on Ross.

Heorings Stoil on Boggs Bill

__Ilearings commenced July 7, at Washington, D.C., orr FR 5, the Boggs bill to implement the expansion of our interna.tional trade, the balance now being with imports exceeding exports.

(Tell them Vou sae it in The Cakfornin Lumber Merchant)

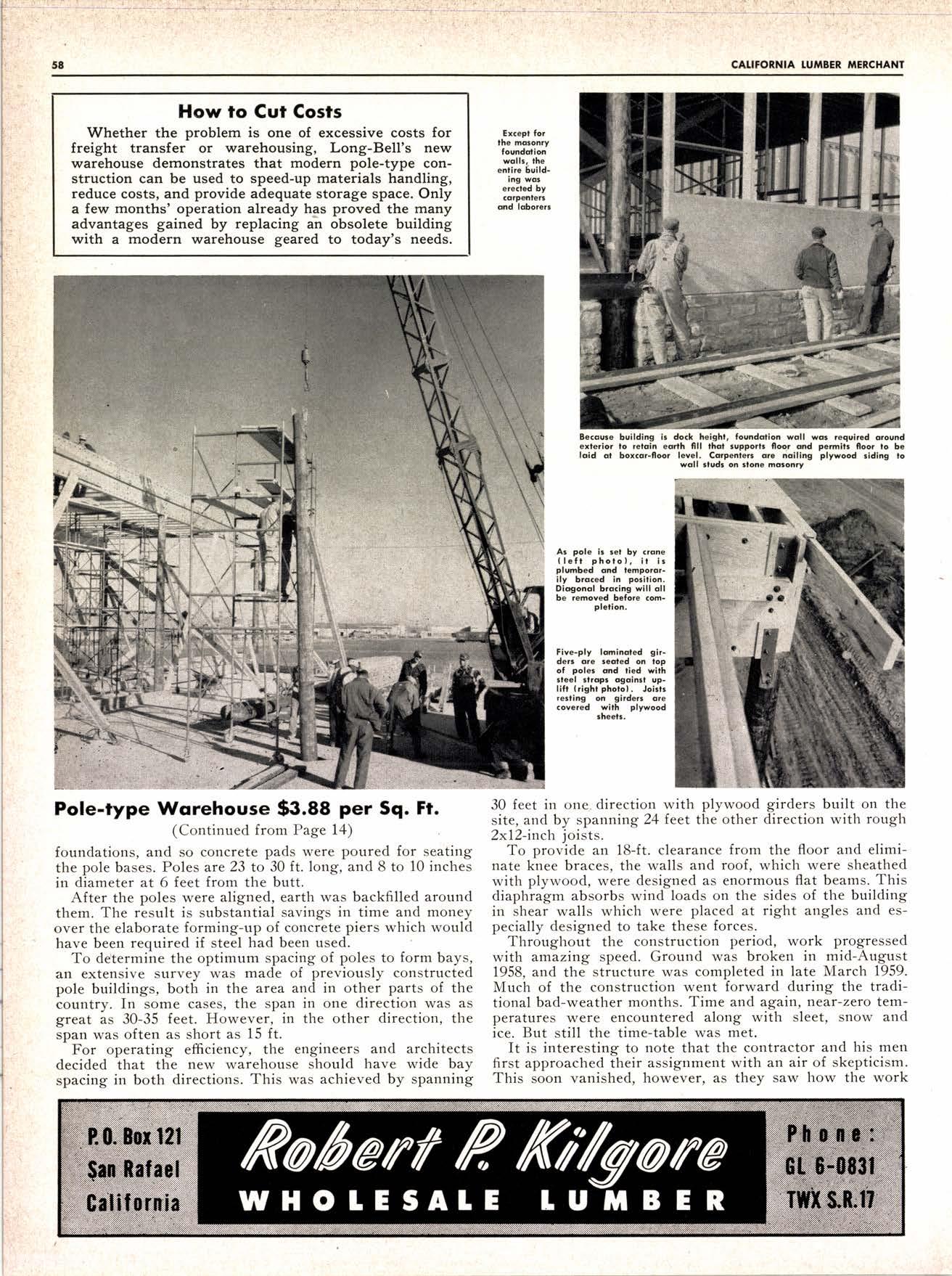

How to Cut Gosts

Whether the problem is one of excessive costs for freight transfer or warehousing, Long-Bell's new warehouse demonstrates that modern pole-type construction can be used to speed-up materials handling, reduce costs, and provide adequate storage space. Only a few months' operation already has proved the many advantages gained by replacing an obsolete building with a modern warehouse geared to today's needs.

Pole-type Wqrehouse t$3.88 per Sq. Ft.

(Continued from Page 14) foundations, and so concrete pads were poured for seating the pole bases. Poles are 23 to 30 ft. long, and 8 to 10 inches in diameter at 6 feet from the butt.

After the poles were aligned, earth was backfilled around them. The result is substantial savings in time and money over the elaborate forming-up of concrete piers which would have been required if steel had been used.

To dCtermine the optimum spacing of poles to form bays, an extensive survey was made oI previously constructed pole buildings, both in the area and in other parts of the country. In some cases, the span in one direction was as great as 30-35 feet. However, in the other direction, the span was often as short as 15 ft.

For operating efficiency, the engineers and architects decided that the new warehouse should have wide bay spacing in both directions. This was achieved by spanning

30 feet in one. direction with plywood girders built on the site, and by spanning 24 feet the other direction with rough Zxl2-inch joists.

To provide an 18-ft. clearance from the floor and eliminate knee braces, the walls and roof, which were sheathed with plywood, were designed as enormous flat beams. This diaphragm absorbs wind loads on the sides of the building in shear walls which were placed at right angles and especially designed to take these forces.

Throughout the construction period, work progressed with amazing speed. Ground was broken in mid-August 1958, and the structure was completed in late March 1959. Much of the construction went forward during the traditional bad-weather months. Time and again, near-zero temperatures were encountered along with sleet, snow and ice. But still the time-table was met.

It is interesting to note that the contractor and his men first approached their assignment with an air of skepticism. This soon vanished. however. as thev saw how the work