3 minute read

advantages

We're neighbors, that's an advantage and it's a good place to start.

We have a clear understanding of your lumber needs.

Personal contact with you stimulates more effort by us.

You deal locally with us, not at long distance. Since we do the scouting, your buying costs are minimized.

You save your time when we work for you.

Should any differences arise, they can be adjusted in person.

We keep our customers advised of local trends.

We keep our mills advised of this area's requirements.

You can eheck on our reputation if you should wish, quickly, aecurately and locally.

You have a pledge for efficient, ethical and reliable service when dealing.with members of this association.

a real "believer" in plywood, and well he should be. Born and raised in the plywood business, he's been working with it since he was 14 years old. Initiated into the wonderworld of Plywood wilh Woodlawn Plywood Co., Hoquiam, Washington, Stolesen is also a machinist by trade, which explains some of the engineering marvels housed in the Redwood Valley plant. Because of the complexity of the business, most of Plywood Fabricators' equipment was custom-made or modified in the company's own machine shop.

That's about the story. Whether it be panel cutting, milling, or panel "stretching," Plywood Fabricators, the Redwood Valley "Cut-IJp," is there to do the job . . . to insure plywood's still bright future, and penetration into new markets . . . through qualified plywood jobbers only.

ftlqsonite ond Koppers Reseorch Component Woll Ponel To Ally Lumber Jobbers, Deolers in Smqll-Troct Sqle

Because Masonite Corporation sees the undeniable need for component walls in the homebuilding industry, it is accelerating its research program to develop a wall system that will be marketed to lumber iobbers and dealers for erection on the job, it has been disilosed by Paul B. Shoemaker, vice-president in charge of sales.

Well under way is Masonitets research with the Koppers Company to create an exterior wall component, and also an interior wall unit, utilizing the Koppers polystyrene, a formed-in-place sandwich-type core, with prefinished siding and a prefinished interior of Masonite hardboard, he said.

As the researchers now see them, the exterior load-bearing wall panels would have insulation, vapor barrier, two factory-finished surfaces and wiring and heating facilities; while the interior partition wall panels would likewise have prefinished surfaces, be narrow to save floor space, moveable and functional.

He described the proposed panels as an evolutionary development in Masonite's research which has developed such component wall systems as Duowall, Panelok and the insulated panels used experimentally in the Knoxville research house of 1958 sponsored by the NAHB Research Institute. Here, the exterior was Masonite Sunline siding, the interior Masonite Misty Walnut.

Discussing the building industry's need for component walls that are ready to install on the job, Shoemaker said:

"New products like the complete wall section have a number of merits that will be iecognized by many in the building and building supply fields. The component panel, made under factory-controlled conditions, is a better prod- uct than can be made on the job site. It is uniform in construction and interchangeable. distributing and dealers, be helping operate ego-

"The trend to component construction, aside from the uniformity of quality and construction standpoints, is an economic necessity. Components made under mass production methods in the factory cost less than conventional construction by costly labor in the field. Completion of construction is quickened, of course.

"Another factor often overlooked is that in our 1960-1965 economy we will not have the labor to build all the homes we need by conventional construction methods." One reason for the rapid increase in use of components for home construction, the sales executive added, is that builders and building supply dealers have felt the competition from the producers of manufactured homes and are therefore turning to similar production techniques.

By following the traditional method of component panels through lumber jobbers he continued, Masonite Corporation will small builders and tract builders alike to nomically.

The new Masonite component panel, which most likely will be erected against steel splines so that functional walls can be achieved as in the Masonite Duowall and Panelok systems, won't be ready for marketing for several months, Shoemaker added.

The company, which has been working several years in the direction of marketing component panels through lumber jobbers and dealers, in 1957 installed its Duowall com(Continued on Page 50) lmported ond Domestic Hordwoods ond Softwoods for Every Purpose

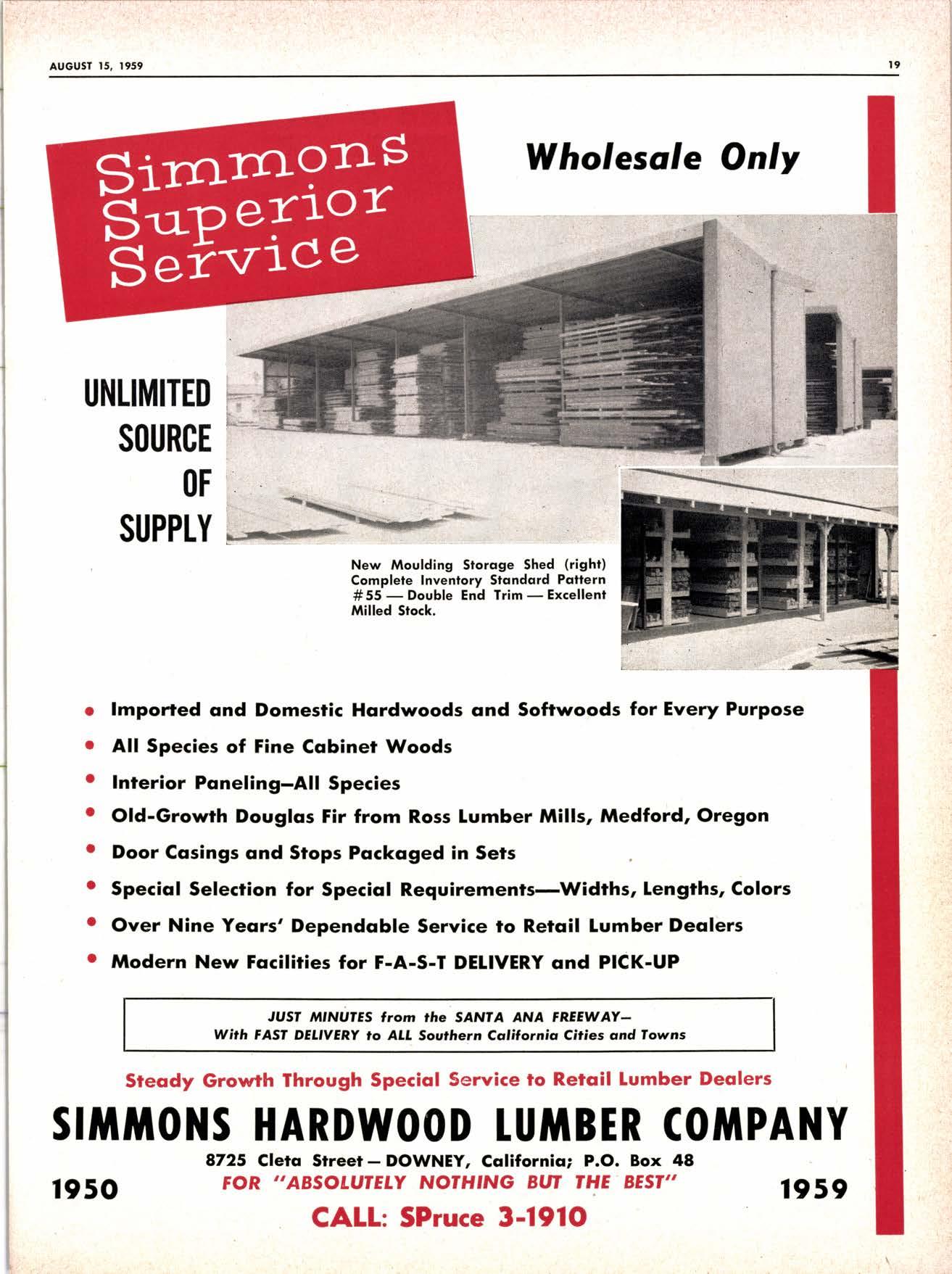

All Species of Fine Gobinet Woods

Interior Poneling-All Species

Old-Growrh Douglos Fir from R.oss Lumber Mills, Medford, Oregon

Door Cosings ond Stops Pockoged in Sets

Speciol Selection for Speciol Requirements-Widrhs, lengfhs, Colors

Over Nine Yeor:s' Dependoble Service to Rerail Lumber Deolers

Modern New Focilities for F-A-S-T DELIVERY ond PICK-UP

JUSI lffNullS from the SANTA ANA FREEWAYWirh FAST DEI|VERY to ALL Southern Colilornia Cifies ond Towns

Steody Growth Through Speciol Service to Retoil lumber Deolers