5 minute read

Dealers for knowl How to [Jse Hardboard I

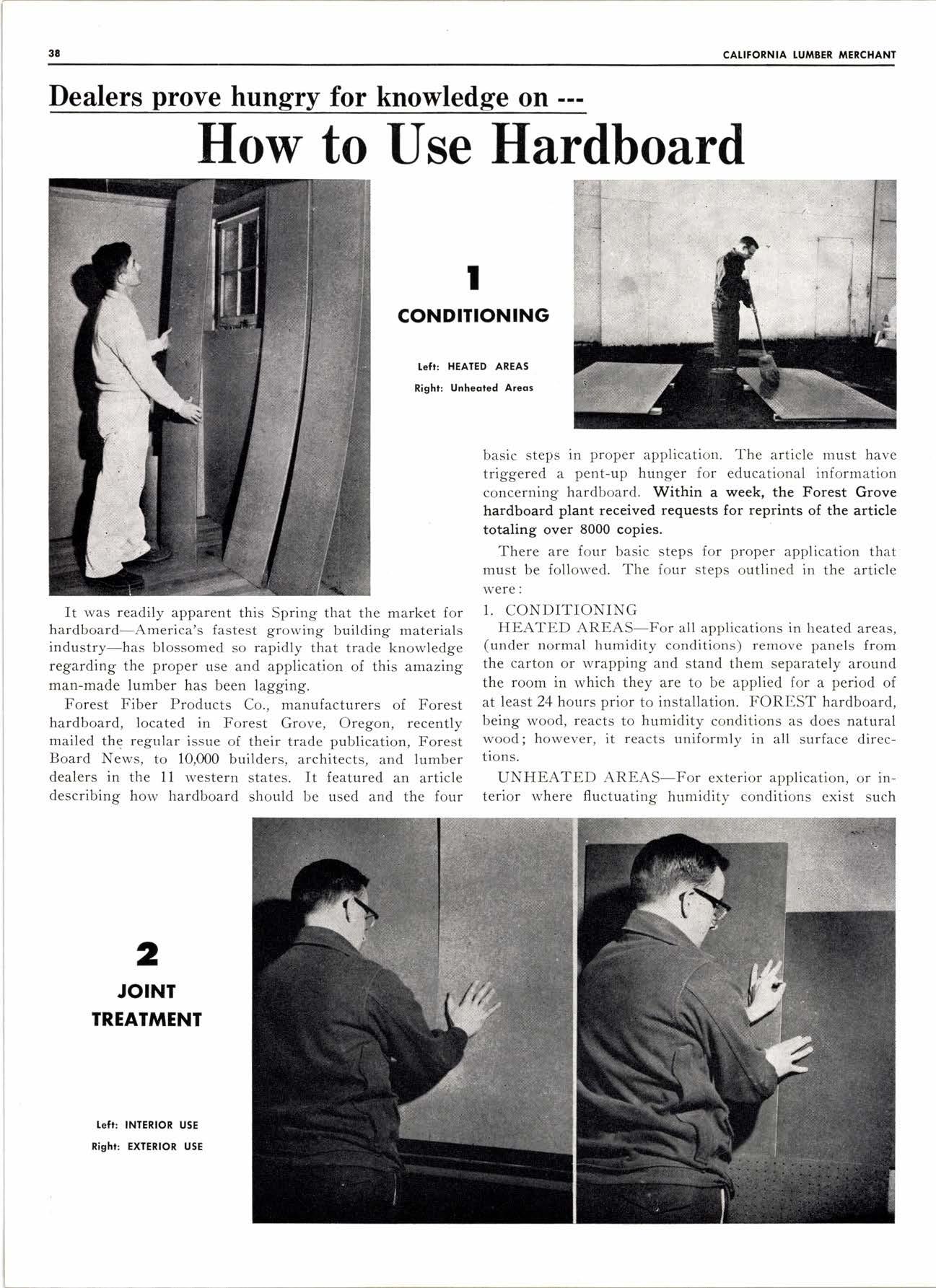

Conditioning

I6f': HEATED AREAS

Righr: Unheoted Areas basic steps in proper application. The article must have triggered a pent-up hunger for educational information concerning hardboard. Within a week, the Forest Grove hardboard plant received requests for reprints of the article totaling over 8000 copies.

There are four basic steps for proper application that must be followed. The four steps outlined in the article were: ft was readily apparent this Spring that the market for hardboard-America's fastest growing building materials industry-has blossomed so rapidly that trade knowledge regarding the proper use and application of this amazing man-made lumber has been lagging.

Forest Fiber Products Co., manufacturers of Forest hardboard, located in Forest Grove, Oregon, recently mailed the regular issue of their trade publication, Forest Board News, to 10,000 builders, architects, and lumber dealers in the 11 western states. It featured an article describing how hardboard should be used and the four

1. CONDITIONING HEATED AREAS-For all applications in heated areas, (under normal humidity conditions) remove panels from the carton or wrapping and stand them separately around the room in which they are to be applied for a period of at least 24hours prior to installation. FOREST hardboard, being wood, reacts to humidity conditions as does natural wood; however, it reacts uniformly in all surface directions.

UNHtrATED AREAS-For exterior application, or interior where fluctuating humidity conditions exist such

3 NAITING ond

Backing

as basements, bathrooms, kitchens, FOREST hardboard panels should be conditioned rvith w:rter. Scrub water with a broom or brush into the textured -qide of the panel and stack back to back. Cover rvith heavy paper or a tarp, for a period of 24 to 48 hours prior to application.

2. JOrNT TREATMENT.

INTERIOR USE-Panels should be brought together in moderate contact (loosely fitted) and never forced into place. Be sure that each panel has been conditioned properly. Forest Tee-N-Gee Panels lvith tongue and groove l\''ere made to make an attractive joint rvith hidden nailing.

EXTERIOR USE-Fit panels together looseiy with a space of about l/16" to Il8" at all joints. You can use a nail that you are using as a guide or spacer at the joint to determine the space to leave.

3. NAILING AND BACKING

NAILING AND FRAMING-NaiI every four inches on all edges and six inches apart on immediate framing. Nail from edge to center to edge (never both edges and then the middle). Nail at least 3/8" from edge. Framing is necessary on all edges and not more than 16" apart throughout the panel.

GLUING-Use a good quality, r'vaterproof tile board adhesive. After the panel has been cut to fit, cover the en- tire panel to the edge with the adhesive. place and press or ro11 the entire surface in place. It should then be braced, or held until the adhesive sets.

1. FINiSHING

'lvith nails,

FIRST COAT MOST IMPORTANTFor all FOREST hardboards except Temper-Treated the most important coat is the first. A good primer, or sealer, preferably heavily pigmented or with body, is necessary. Beautiful finishes are easily achieved provided the first coat is heavy enough to seal the surface. One or two additional coats can then be applied for the desired effect. Finishing is one of hardboard's inherent advantages, and most any application -brush, roller, dip or spray-can be used. Horvever, the performance of the first sealer coat determines the ultimate

Finishing

lefr: FIRST COAT II^OST IMPORTANI

Righr: wtPED-oN PASTEL FINISHES finish. ALL TEMPER-TREAT.ED FOREST HARDBOARDS are presealed and need no prime coat.

WIPtrD-ON PASTEL FINISHES-Bqqau5q of the natural, light Douglas fir color of FOREST hardboard, beautiful light, pastel stains or wiped-on finishes are possible. Use as a base a white enamel undercoat or a white resin sealer. Choose whatever color you want-blue, green, red, etc., any tube color or color in oil, and mix in with the white resin sealer. Mix thoroughly. Brush on, wait approximately two minutes, and wipe off. That is all there is to acquiring a beautiful color. Be sure to test on a small sample first. A coat of clear varnish or lacquer may be applied as a protective covering.

Hardboad is pouring from Pacific Northwest mills in an ever-swelling torrent. Today's booming building rate and growing uses for this amazing man-made wood are reasons why this burgeoning industry is off to another recordbreaking sales year. Homeowners are finding it to be one of the toughest, most durable building materials yet devised. Its smooth surface is so hard that even hammer blows won't dent it. Yet builders find it easy to saw and nail.

Besides going into new homes, hardboard is showing up in a lot of places where it wasn't used a few years back. One rapidly growing use has been for cupboard doors using 314" hardboard. Hardboard is dimensionally stable (stays straight) and, being grainless, does not chip or splinter, and paints beautifully. The list of new hardboard uses includes furniture, tongue-and-groove wall panels, cabinets, straited wall paneling, underlayment for linoleum floors, store display fixtures, and a host of others.

Forest Fiber Products Co. is now working around the clock on a seven-day-a-week basis to keep up with the flood of 1956 orders.

The hardboard industry has already exceeded Stanford research estimates for oroduction in 1955.

Huss Acquires €ontqiner Mill

Huss Ontonagon Pulp and Paper Company, whose ownership is afifiliated with the Huss Lumber Company of Chicago, has purchased National Container Corporation's pulp and paper mill at Ontonagon, Mich., together with its tree farms in Ontonagon and Houghton counties, Michigan, embracing upwards of 30,000 acres, and will immediately start a $3,000,000 expansion program, including the construction of additional plant capacity making pulp and container board out of the high-yield, high-density hardwoods available in the Upper Peninsula of Michigan.

The Ontonagon mill has for many years past been the last northern kraft liner board mill, and with the standing timber su,ch as Spruce, Jack Pine and Hemlock depleted. the dwindling softwood stands threatened its limits for any further industrial development. Yet right at the doorstep of the plant was a residual stand of over 24 million cords of hardwoods that required new pulping techniques which had been proved at the Forest Products Laboratory and were being recognized in the pulp and paper field as the fastest growing new development, namely the neutral sulohite semi-chemical process.

(Tell them you saw it in The California Lumber Merchant)

Son Jooquin Hoo-Hoo Club 3l Activotes Kern County Club; Art Post Elected Presidenl

The new Kern County Hoo-Hoo Club No. 180 was activated June 8 at a meeting conducted by San Joaquin Valley Hoo-Hoo Club No. 31. Club 31 conducted a Concat in which 17 Kittens saw the light of Hoo-Hoo. The members of the degree team were Bob Reid, Les Doddington, Ray Noble, Craig Gaffney, Wally Kennedy, Bert Goebel, Jim Duart, Bob Raymer and Joe Aimar. Harry Merlo was the Visiting Officer.

Hobbs ttall Redwood

The new Kittens and reinstatements \vere as follows:

John H. Meiners, Hayward Lumber Co., Delano

Richard Leon Horton, Hayward Lumber Co., Delano

J.y C. Bruber, Hayward Lumber Co., Delano

John Stace, Taft Lumber Co., Taft

Walter F. Heisey, Bakersfield Sandstone Brick Co., Bakersfield

Sherman C. Martindale, Bakersfield Building Materials, Bakersfield

George W. Johnston, \Minter Lumber Sales, Oakdale

Charles R. Curlee, Curran Corp., Bakersfield

Allen W. Small, Tehachapi Lumber Co., Tehachapi

Philip D. Marx, Tehachapi Supply, Tehachapi

Vernon Giles Mears, Mears Lumber Co., Bakersfield

Virgil E. Mears, Mears Lumber Co., Bakersfield

Robert Sterling lloover, Paul Alley Lumber Co., Porterville

Richard J. Pratt, J. C. Wattenbarger & Sons, Oildale

Edward S. Rouch, Paul Alley Lumber Co., Porterville

Hal E. Aaron, Southern Lumber Sales, Bakersfield

Jim Curran, Bakersfield Sandstone Brick Co., Bakersfield

Robert J. Wright, Delano Bldg. Mats. Co., Delano

George C. Beyer, Delano Bldg. Mats. Co., Delano

Art Post was elected president of the new club. Vicegerent Snark Bob Reid of Fresno conducted the meeting. The Fresno club presented a gong and gavel to the new Kern County Hoo-Hoo. The gong was made out of a circular saw mounted on a maple wood frame, reports Bernard B. Barber, Jr. of Club 31.

Dealers 9331y!y cotnt on Hobbs $Vall for the best in Redwood. 9o years of know-how have made Hobbs lfall a source of satisfaction when it comes to Redwood.

Call, write or wire for prompt service.