5 minute read

House Of The Year

Top honors in the 1950 American Institute of Architect Ilonor Awards Competition have been given A. Quincy Jones, Jr., of Los Angeles, for "distinguished accomplishment in residential design." The Jones' design singled out by the A.I.A. as the number one house of the year is one created for Merchant Builder H. C. Vistendahl of San Diego, Cal.

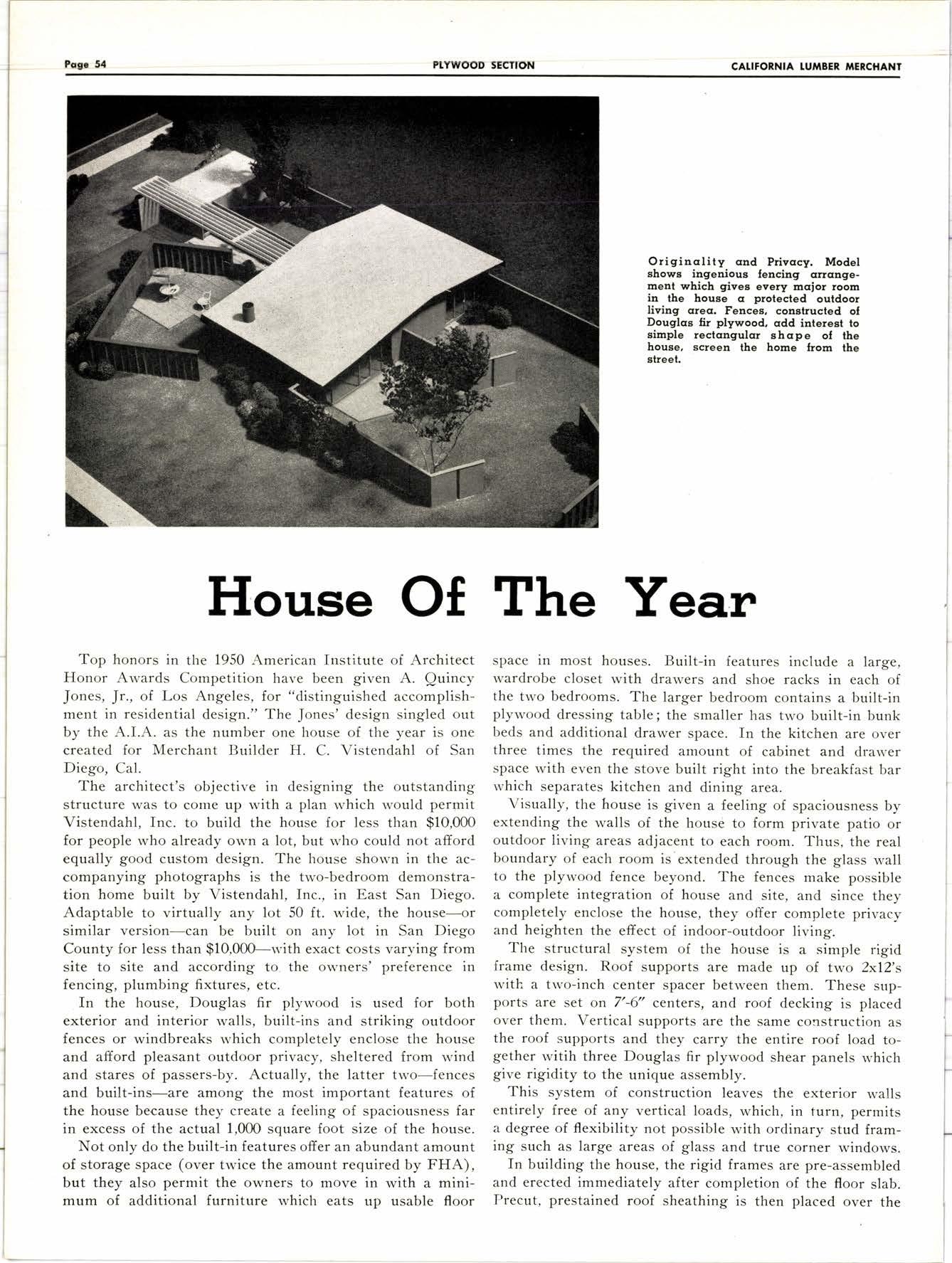

The architect's objective in designing the outstanding structure was to come up with a plan which would permit Vistendahl, Inc. to build the house for less than $10,000 for people who already own a lot, but who could not afford equally good custom design. The house shown in the accompanying photographs is the two-bedroom demonstration home built by Vistendahl, Inc., in East San Diego. Adaptable to virtually any lot 50 ft. wide, the house-e1 similar vs15i61-qan be built on any lot in San Diego County for less than $10,00G-r,vith exact costs varying from site to site and according to the owners' preference in fencing, plumbing fixtures, etc.

In the house, Douglas fir plywood is used for both exterior and interior walls, built-ins and striking outdoor fen,ces or windbreaks which completely enclose the house and afford pleasant outdoor privacy, sheltered from wind and stares of passers-by. Actually, the latter 1ule-fgnqsg and built-ins-are among the most important features of the house because they create a feeling of spaciousness far in excess of the actual 1,000 square foot size of the house.

Not only do the built-in features offer an abundant amount of storage space (over twice the amount required by FHA), but they also permit the owners to move in with a minimum of additional furniture which eats up usable floor space in most houses. Built-in features include a large, wardrobe closet with drawers and shoe racks in each of the two bedrooms. The larger bedroom contains a built-in plywood dressing table; the smaller has two built-in bunk beds and additional drawer space. In the kitchen are over three times the required amount of cabinet and drawer space with even the stove built right into the breakfast bar which separates kitchen and dining area.

Visually, the house is given a feeling of spaciousness by extending the walls of the house to form private patio or outdoor living areas adjacent to each room. Thus, the real boundary of each room is extended through the glass wall to the plywood fence beyond. The fences make possible a complete integration of house and site, and since they cornpletely enclose the house, they offer complete privacy and heighten the effect of indoor-outdoor living.

The structural system of the house is a simple rigid frame design. Roof supports are made up of two 2xl2's with a two-inch center spacer between them. These supports are set on 7'-6" centers, and roof decking is placed over them. Vertical supports are the same construction as the roof supports and they carry the entire roof load together witih three Douglas fir plywood shear panels which give rigidity to the unique assembly.

This system of construction leaves the exterior walls entirely free of any vertical loads, which, in turn, permits a degree of flexibility not possible with ordinary stud framing such as large areas of glass and true corner windows.

In building the house, the rigid frames are pre-assembled and erected immediately after completion of the floor slab. Precut, prestained roof sheathing is then placed over the frame. Once the house is under cover, plyr,vood u'all panels are installed.

Texture Contrqst. Smooth, wcxed plywood pcnreling, brick, glcas cnd bocrd ceiling provide hcndsome texture contrdat in this modern living room. Unique constructiol enploys plywood ehecr pcnels lor rigidity, permits more freedom in design ol wcll portitions.

The interior walls and room partitions of the home are of /s" thick Interior type Douglas fir plywood nailed to 2" x 4" studs, 16" o.c., with casing nails driven flush with the surface of the plywood. The exterior walls are 3/," thick Exterior type Douglas fir plywood and T & G redwood boards; building paper is placed beneath the exterior joints rvhich occur at the framing members. The exterior plywood used for fencing is 3/s" thick where posts are set Z apart; and rf" thick between those posts which are 4' aparl.

Both interior and exterior walls, as well as the numerous plywood built-ins in kitchen and bedrooms are finished with Cabot's stain wax to give a yacht-like natural I'r'ood finish. In kitchen and bath, a waterproof lacquer is put over the lvax finish.

The floor plan of the two-bedroom house is interesting in that one may go from the front entry directly to any room in the house without passing through any other room. Construction economy is achieved in the planning, too, for the bath, laundry and kitchen are all located next to each other, thus eliminating long plumbing runs. Ventilation in the living room and bedrooms is obtained through the use of screen-protected sliding 'ivindows at the top of the rvall panels. Floors of the house are of concrete, lvith a 4" slab being poured over a gravel fill. The sli,b is finished with integral color and polished. Kitchen and bathroom floors are covered rvith imported cork.

Alternate plans of one, tr'r,'o and three bedroom models have been developed from the same basic design. If desired, a radiant heat system can be installed in the concrete floor slab and in hot, dry climates evaporative coolers can be installed.

Plywood Shecthing Plcrnt

The Valley Plyrvood Company, Junction City, Oregon, manufactures Fir plyrvood for sheathing purposes strictly, making about five million feet a month. The product is mostly thick board, used for all sorts of building sheathing such as sub-floors, sub-walls, and sub-roofs. The plant has been operating about seven months.

West coast plywood manufacturers, meeting in Gearhart, Ore., to chart intensive long-range promotion of ne\\' uses for the all purpose panels in industry and defense, have elected B. V. Hancock o{ Irortland, Ore., president of Douglas Fir Ply*'ood Association.

Hancock, execrltive vice president of Cascades Plyrvoocl Corp., assumed leadership of the 67-factory plyu,ood industry with the panel makers currently producing at a record rate of 55 million square feet rveekly to meet g'ro\\'ing militarv requirements and continuing high civilian demand.

Outlining promotion plans for the year ahead, O. Harrv Schrader, association managing director, said the industry will continue its intensive merchandising in all rna jor markets with emphasis on remodeling, maintenance and on industry where the versatile panels are used for everything from highu'ay signs to railroad cars.

Schrader emphasized the growing importance in the plyu'ood picture of neu'and allied products such as hardboards, hardboard overlay on piywood and plastic-faced plywood, declaring that such product development means new sales opportunities all along the distribution chain from manufacturer to retail dealer.

He said the industry's promotional efforts r,vill be directed toward maintaining plywood's preferred position in established markets such as building and concrete form construction r,r'ith aggressive merchandising of new uses for plywood nor,r' being developed in industry and defense.

Schrader pointed out that there are enormous potentials for plywood consumption particularly in the farm market where plywood's large panel size and durability dictate its use for silos, lining for barns and milk houses, grain bins and portable field structures.