2 minute read

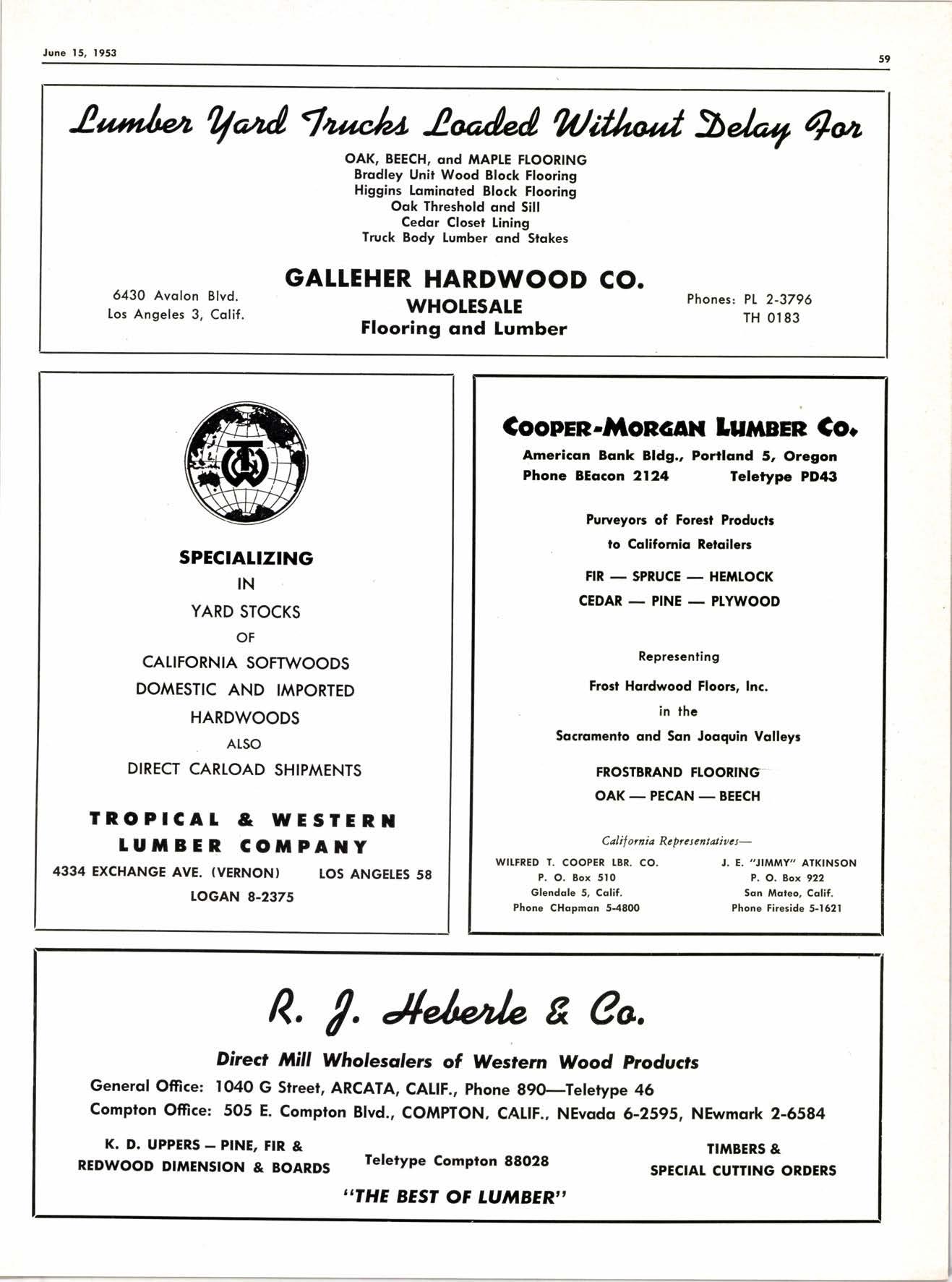

Alrnlt, Ean/ 1ar,tc,/a,t, Aoa/pd Uif/4otf Sdntl 4u,

OAK, BEECH, qnd frlAP[E FIOORING

Brodley Unit Wood Block Flooring

Higgins lqminoted Block Flooring

Oqk Threshold qnd Sill

Cedqr Closei Lining

Truck Body Lumber ond Sfokes

GALTEHER HARDWOOD CO.

6430 Avolon Blvd. los Angeles 3, Cqlif.

WHOtESAtE

Flooring ond Lumber

Phones: PL 2-3796 TH 0183

Cooprn'lttoncatt lflmsEn Co.

Americqn Bonk Bldg., Portlond 5, Orcgon

Phonc BEocon 2124 feletype PDtlil

Purveyorr of Forect Productr . lo Colifomio Reioilerr

SPECIATIZING IN YARD STOCKS OF CATIFORNIA SOFTWOODS

DOMESTIC AND IMPORTED HARDWOODS ALSO DIRECT CARTOAD SHIPMENTS

TROPICAl & WESTERT lUTBER COMPA1|Y

4334 EXCHANGE AVE. (VERNONI tOS ANGETES 58 tocAN 8-2375

FIR-9PRUCE-HEXILOCK

CEDAR-PINE-PLYWOOD

Rcprcscnting

Frost Hqrdwood Floors, lnc. in thc

Sqcrumento qnd Sqn Jooquin Volleyr

FROSTBRAND FTOORING

OAK_PECAN-BEECH

Cal il orn ia Rcprcrcntat iact-

WITFRED I. COOPER I.BR. CO. J. E. "JIMMY" ATKTNSON

P. O. Box 5lO Glendole 5, Colif. Phone CHopmcn 5-480O

R, /. Jlelte/rk & Co,

Direct ld,ill wholesolers oi weslern wood products

Generql ofiice: lo4o G Street, ARCATA, cALlF., phone Sgrretetype 46

P. O. 8ox 922

Sqn Alqleo, Colif.

Phone Fireside 5-1621

Compton Ofiice: 5O5 E. Compton Blvd., COMPTON, CA[|F., NEvodo 6-2595, NEwmork 2-6584

K. D. UPPERS - PINE, FIR & TI,YTBERS & REDWOOD DtftIENStON & BOARDS leletype compton 88028 spEcrAL curilNc oRDERS

''THE BEST OF LUMBER"

Out o[ the Woods

Bv Jim Stevens

Plywood and Hardboard

In its primitive devektPment plyu'ood u'as simplv three veneers l>ound together to make a verv tough board /[-inch thick. Today plyu-ood is tuarketed in sc()res of lte\\' forms. As a specific exanrltle, ()ne conlPanf is producing a tl.rree-plf item that is nrade lrv gluing and pressing'\'eneer flakes to a core of medium-sized chips.

The flakes and chips are resin coated arl<l impregnated. the three lavers are then fused under heat and pressttre of extreme force. The flakes and chips are individuallv sized and shaped on specifications for uniiorm strength and densit.v of core and for characteristics of design on the face veneers.

This product found first ttse in manufactttre of table tops ancl other iurnitttre, garage doors, counter fr()nts. sliding doors and partitions. -\nother recent plvs'rlod item r.rlakes use of economy grade veneers for all plies' lvith kraf t paper glued on for a strong' and clurable llaint surface.

Another cleveloPment utilizes Peeler log cores. 'fhe large ones are put through a small gangsa\\' tltat ctlts thern intcr tu'o by fours. .\ chipper tlses uP the srnaller cores. -\ll residual u'ood is ground into hog iuel for the polver plant.

Peeling the Peeler cream of the Dorrglas fir tirnber crop, is bucked into blocks. usuall-r- eight feet long but at times in lengths up to 16 feet. -\llos-ance is made for the trimmings recluired in n.ranufacture of the finished pl1'l'ood panel. A peeler block goes first through a h1'draulic ora mechanical barker. Then a peeling lathe s'ith a knife that slices around rrith the grou-th rings as the log is turned against it. unrvinds the lavers of n'ood dos'n to a core of coarse rvood and the pith of the tree.

In stanclard modren plvu'ood production. the peeler log.

The unrr'ound sheet of u'ood that streams on fr,,m the lather on conveving rolls u'ill varv in tlrickness frorn l/lOth to 3/l6ths of an inch. The Douglas fir peeling is carried into travs 150 feet long. It is cut into s'idths for panel assemblv. Grading is r-ital in the process. -\t the clipping rnachines. grading is done t() cut out defects and send on panel veneers of highest qualitv.

The drfing of the sheets in 100-foot orens is the next l)r()cess. In irom eight tol5 nrinutes, moisture content is lrrought dos'n to less than fir'e per cent. \ext. the glue s1>reading machines. -'\ slteet rvith glue on each side is sanclu'iched betu'een ts'o drv sheets in standard three-pl1manufacture. Hot presses put the three glued plies-or llanels of fir'e. seven. or nine plies-under pressures of 200 ()r m()re pounds l)er s(ltlare inch in periods of frrlm four t() ten minutes.

Chips into Board .

There is also a cold pressure process that is in common ruse for setting the gltres. There are nlore detailed ()perations. such as gracling. sanding. trimming. patching. pack-